Complete service repair manual with Electrical Wiring Diagrams for Komatsu 95E Series Diesel Engines, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu 95E Series Diesel Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEN01966-15 – 95E-5 Series Diesel Engine Shop Manual.pdf

SEN04357-00 – 95E-5 Series (KOHAG SPEC.) Diesel Engine Shop Manual.pdf

SEN06060-01 – 95E-6 Series Diesel Engine Shop Manual.pdf

Total Pages: 1,041 pages

File Format: PDF

Language: English

MAIN SECTIONS

01 GENERAL ……. 01-1

11 STRUCTURE AND FUNCTION …. 11-1

12 TESTING AND ADJUSTING ….. 12-1

13 DISASSEMBLY AND ASSEMBLY …. 13-1

14 MAINTENANCE STANDARD ….. 14-1

15 REPAIR AND REPLACEMENT OF PARTS … 15-1

SEN01966-15 – 95E-5 Series Diesel Engine Shop Manual……2

COVER……2

00 Index and foreword……0

Index……4

Composition of shop manual……5

Table of contents……6

Foreword and general information……12

Safety notice……13

How to read the shop manual……18

Explanation of terms for maintenance standard……20

Handling of electric equipment and hydraulic component……22

Handling of connectors newly used for engines……31

How to read electric wire code……34

Precautions when carrying out operation……37

Method of disassembling and connecting push-pull type coupler……40

Standard tightening torque table……43

Conversion table……47

01 Specification……0

Specification and technical data……54

General information……55

Specifications……57

General view……65

Weight table……74

Engine performance curves……75

10 Structure, function and maintenance standard……0

Structure, function and maintenance standard, Part 1……84

General structure……87

Air intake and exhaust unit……89

Air cleaner……91

Turbocharger……93

Muffler……96

Cylinder head……97

Cylinder block……99

Cylinder……102

Main moving parts……103

Crankshaft……105

Camshaft……106

Piston, piston ring and piston pin……107

Connecting rod……108

Flywheel and flywheel housing……111

Timing gear……113

Valve system……117

Valve, valve guide……119

Rocker arm shaft, push rod and tappet……120

Structure, function and maintenance standard, Part 2……122

Lubrication system diagram……124

Oil pump……125

Regulator valve……127

Oil filter……128

Fuel system diagram……130

Supply pump……131

Fuel injection nozzle……133

Fuel filter……134

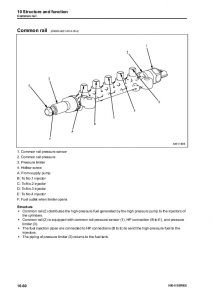

Common rail……135

Various sensor……137

Cooling system diagram……139

Water pump……140

Cooling fan drive and thermostat……143

Starting and charging system electrical circuit diagram……147

Alternator……148

Starting motor……152

Starting aid……154

Engine controller……155

20 Standard value table……0

Standard service value table……158

Standard service value table for testing, adjusting, and troubleshooting……159

Running-in standard and performance test standard……165

30 Testing and adjusting……0

Testing and adjusting……174

Testing and adjusting tools list……176

Sketches of special tools……178

Measuring intake air pressure……179

Testing exhaust temperature……180

Adjusting valve clearance……181

Testing compression pressure……183

Testing blow-by pressure……185

Testing oil pressure……186

Handling fuel system parts……187

Releasing residual pressure in fuel system……187

Testing fuel pressure……188

Reduced cylinder mode operation……189

No-injection cranking……189

Testing leakage from pressure limiter and return rate from injector……190

Bleeding air from fuel circuit……193

Testing fuel system for leakage……195

Testing and adjusting alternator belt tension……196

Handling controller voltage circuit……197

40 Troubleshooting……0

General information on troubleshooting……200

Points on troubleshooting……201

Error code and failure code table……203

Information in troubleshooting table……205

Connection table for connector pin numbers……207

T- branch box and T- branch adapter table……243

Troubleshooting of electrical system (E-mode), Part 1……248

E-1 Code [111/CA111] ECM Critical Internal Failure……251

E-2 Code [115/CA115] Eng. Ne and Bkup Speed Sensor Error……254

E-3 Code [122/CA122] Charge Air Press Sensor High Error……255

E-4 Code [123/CA123] Charge Air Press Sensor Low Error……257

E-5 Code [131/CA131] Throttle Sensor High Error……258

E-6 Code [132/CA132] Throttle Sensor Low Error……261

E-7 Code [144/CA144] Coolant Temp. Sensor High Error……263

E-8 Code [145/CA145] Coolant Temp. Sensor Low Error……265

E-9 Code [153/CA153] Charge Air Temp. Sensor High Error……267

E-10 Code [154/CA154] Charge Air Temp. Sensor Low Error……269

E-11 Code [187/CA187] Sensor Sup. 2 Volt. Low Error……270

E-12 Code [221/CA221] Ambient Air Press. Sensor High Error……271

E-13 Code [222/CA222] Ambient Air Press. Sensor Low Error……273

E-14 Code [227/CA227] Sensor Sup. 2 Volt. High Error……274

E-15 Code [234/CA234] Eng. Overspeed……275

E-16 Code [238/CA238] Ne Speed Sensor Sup. Volt. Error……277

E-17 Code [271/CA271] IMV Short Error……279

E-18 Code [272/CA272] IMV Open Error……281

E-19 Code [322/CA322] Injector #1 System Open/Short Error……283

E-20 Code [324/CA324] Injector #3 System Open/Short Error……285

E-21 Code [331/CA331] Injector #2 System Open/Short Error……287

E-22 Code [332/CA332] Injector #4 System Open/Short Error……289

E-23 Code [351/CA351] INJ. Drive Circuit Error……291

E-24 Code [352/CA352] Sensor Sup. 1 Volt. Low Error……294

E-25 Code [386/CA386] Sensor Sup. 1 Volt. High Error……295

E-26 Code [431/CA431] Idle Validation SW Low error……297

E-27 Code [432/CA432] Idle Validation Process error……297

E-28 Code [435/CA435] Abnormality in engine oil pressure switch……298

E-29 Code [441/CA441] Battery voltage low error……299

E-30 Code [442/CA442] Battery voltage high error……299

Troubleshooting of electrical system (E-mode), Part 2……302

E-31 Code [449/CA449] Rail Press. Very High Error……304

E-32 Code [451/CA451] Rail Press. Sensor High Error……305

E-33 Code [452/CA452] Rail Press. Sensor Low Error……307

E-34 Code [553/CA553] Rail Press. High Error……308

E-35 Code [559/CA559] Rail Press. Low Error……309

E-36 Code [689/CA689] Eng. Ne Speed Sensor Error……313

E-37 Code [731/CA731] Eng. Bkup Speed Sensor Phase Error……315

E-38 Code [757/CA757] All Persistent Data Lost Error……316

E-39 Code [778/CA778] Eng. Bkup Speed Sensor Error……317

E-40 Code [1633/CA1633] KOMNET Dtalink Timeout Error……319

E-41 Code [2185/CA2185] Throttle Sens. Sup. Volt. High Error……320

E-42 Code [2186/CA2186] Throttle Sens. Sup. Volt. Low Error……323

E-43 Code [2249/CA2249] Rail Press. Very Low Error……324

E-44 Code [2311/CA2311] Abnormality in IMV solenoid……325

E-45 Code [2555/CA2555] Grid Heater Relay Volt. Low Error……326

E-46 Code [2556/CA2556] Grid Heater Relay Volt. High Error……327

E-47 Code [(—)/B@BAZG] Eng. Oil press. Low Speed Derate……329

E-48 Code [(—)/B@BAZG] Eng. Oil press. Torque Derate……329

E-49 Code [(—)/B@BCNS] Eng. Overheat……330

Troubleshooting of mechanical system (S-mode)……332

Method of using troubleshooting charts……335

S-1 Starting performance is poor……339

S-2 Engine does not start……340

S-3 Engine does not pick up smoothly……343

S-4 Engine stops during operations……344

S-5 Engine does not rotate smoothly……345

S-6 Engine lacks output (or lacks power)……346

S-7 Exhaust smoke is black (incomplete combustion)……347

S-8 Oil consumption is excessive (or exhaust smoke is blue)……348

S-9 Oil becomes contaminated quickly……349

S-10 Fuel consumption is excessive……350

S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)……351

S-12 Oil pressure drops……352

S-13 Oil level rises (Entry of coolant or fuel)……353

S-14 Coolant temperature becomes too high (overheating)……354

S-15 Abnormal noise is made……355

S-16 Vibration is excessive……356

50 Disassembly and assembly……0

General information on disassembly and assembly……358

How to read this manual……359

Coating materials list……361

Special tools list……364

Sketches of special tools……365

Disassembly and assembly, Part 1……368

General disassembly of engine……369

Disassembly and assembly, Part 2……382

General assembly of engine……383

Disassembly and assembly, Part 3……400

Disassembly and assembly procedure for fuel supply pump unit……401

Disassembly and assembly procedure for oil seal units……403

90 Repair and replacement of parts……0

Information related to repair and replacement……406

Special tool table……407

Sketches of special tools……409

Parts related to cylinder head……412

Part names related to cylinder head……413

Testing and inspection of cylinder head……414

Pressure test of cylinder head……416

Replacement of valve guide……416

Replacement of valve seat insert……418

Repair of cylinder head mounting face by grinding……424

Repair of valve by grinding……425

Parts related to cylinder block……428

Part names related to cylinder block……429

Testing and inspection of cylinder block……430

Part names related to crankshaft……433

Testing and inspection of crankshaft……434

Part names related to connecting rod……435

Testing and inspection of connecting rod……436

Replacement of flywheel ring gear……437

Replacement of crankshaft gear……438

Replacement of camshaft gear……438

Replacement of connecting rod small end bushing……439

Replacement of cam bushing……441

Cylinder liner (Special part for repair)……443

Rework drawing for counter bore……444

Repair of crankshaft by grinding……445

SEN04357-00 – 95E-5 Series (KOHAG SPEC.) Diesel Engine Shop Manual……450

SEN04357-00 WA90-6, WA100M-6……450

00 Index and foreword……452

Index……452

Composition of shop manual……453

Table of contents……454

Foreword and general information……460

Safety notice……461

How to read the shop manual……466

Explanation of terms for maintenance standard……468

Handling of electric equipment and hydraulic component……470

Handling of connectors newly used for engines……479

How to read electric wire code……482

Precautions when carrying out operation……485

Method of disassembling and connecting push-pull type coupler……488

Standard tightening torque table……491

Conversion table……495

01 Specification……502

Specification and technical data……502

Outline……503

Specifications……505

General view……507

Weight table……510

Engine performance curves……511

10 Structure, function and maintenance standard……516

Structure, function and maintenance standard, Part 1……516

General structure……519

Air intake and exhaust system……521

Air intake and exhaust unit……521

Turbocharger……523

Engine unit……527

Cylinder head……527

Cylinder block……529

Cylinder……532

Main moving parts……533

Crankshaft……535

Camshaft……536

Piston, piston ring and piston pin……537

Connecting rod……538

Flywheel and flywheel housing……539

Timing gear……541

Valve system……545

Valve, valve guide……547

Rocker arm shaft, push rod and tappet……548

Structure, function and maintenance standard, Part 2……550

Lubrication system……552

Lubrication system diagram……552

Oil pump……553

Regulator valve……555

Oil filter……556

Fuel system……558

Fuel system diagram……558

Supply pump……559

Fuel injection nozzle……561

Fuel filter……562

Common rail……563

Various sensor……565

Cooling system……567

Cooling system diagram……567

Water pump……568

Cooling fan drive and thermostat……571

Electrical equipment……575

Starting and charging system electrical circuit diagram……575

Alternator……576

Starting motor……578

Starting aid……579

Engine controller……580

20 Standard value table……582

Standard service value table……582

Standard service value table for testing, adjusting, and troubleshooting……583

Running-in standard and performance test standard……584

30 Testing and adjusting……588

Testing and adjusting……588

Testing and adjusting tools list……590

Measuring intake air pressure……591

Testing exhaust temperature……592

Adjusting valve clearance……593

Testing compression pressure……595

Testing blow-by pressure……597

Testing oil pressure……598

Handling fuel system parts……599

Releasing residual pressure in fuel system……599

Testing fuel pressure……600

Reduced cylinder mode operation……601

No-injection cranking……601

Testing leakage from pressure limiter and return rate from injector……602

Bleeding air from fuel circuit……605

Testing fuel system for leakage……607

Testing and adjusting alternator belt tension……608

Handling controller voltage circuit……609

40 Troubleshooting……612

General information on troubleshooting……612

Points on troubleshooting……613

Error code and failure code table……615

Information in troubleshooting table……617

Troubleshooting of electrical system (E-mode), Part 1……620

E-1 Code [111/CA111] ECM Critical Internal Failure……623

E-2 Code [115/CA115] Eng. Ne and Bkup Speed Sensor Error……626

E-3 Code [122/CA122] Charge Air Press Sensor High Error……627

E-4 Code [123/CA123] Charge Air Press Sensor Low Error……629

E-5 Code [131/CA131] Throttle Sensor High Error……630

E-6 Code [132/CA132] Throttle Sensor Low Error……633

E-7 Code [144/CA144] Coolant Temp. Sensor High Error……634

E-8 Code [145/CA145] Coolant Temp. Sensor Low Error……635

E-9 Code [153/CA153] Charge Air Temp. Sensor High Error……637

E-10 Code [154/CA154] Charge Air Temp. Sensor Low Error……639

E-11 Code [187/CA187] Sensor Sup. 2 Volt. Low Error……640

E-12 Code [221/CA221] Ambient Air Press. Sensor High Error……641

E-13 Code [222/CA222] Ambient Air Press. Sensor Low Error……643

E-14 Code [227/CA227] Sensor Sup. 2 Volt. High Error……644

E-15 Code [234/CA234] Eng. Overspeed……646

E-16 Code [238/CA238] Ne Speed Sensor Sup. Volt. Error……647

E-17 Code [271/CA271] IMV Short Error……649

E-18 Code [272/CA272] IMV Open Error……651

E-19 Code [322/CA322] Injector #1 (L/B #1) System Open/Short Error……653

E-20 Code [324/CA324] Injector #3 (L/B #3) System Open/Short Error……655

E-21 Code [331/CA331] Injector #2 (L/B #2) System Open/Short Error……657

E-22 Code [332/CA332] Injector #4 (L/B #4) System Open/Short Error……659

E-23 Code [351/CA351] INJ. Drive Circuit Error……661

E-24 Code [352/CA352] Sensor Sup. 1 Volt. Low Error……664

E-25 Code [386/CA386] Sensor Sup. 1 Volt. High Error……665

E-26 Code [431/CA431] Idle Validation SW Low error……667

E-27 Code [432/CA432] Idle Validation Process error……667

E-28 Code [435/CA435] Abnormality in engine oil pressure switch……668

E-29 Code [441/CA441] Battery voltage low error……669

E-30 Code [442/CA442] Battery voltage high error……669

Troubleshooting of electrical system (E-mode), Part 2……672

E-31 Code [449/CA449] Rail Press. Very High Error……674

E-32 Code [451/CA451] Rail Press. Sensor High Error……675

E-33 Code [452/CA452] Rail Press. Sensor Low Error……677

E-34 Code [553/CA553] Rail Press. High Error……678

E-35 Code [559/CA559] Rail Press. Low Error……679

E-36 Code [689/CA689] Eng. Ne Speed Sensor Error……683

E-37 Code [731/CA731] Eng. Bkup Speed Sensor Phase Error……685

E-38 Code [757/CA757] All Persistent Data Lost Error……686

E-39 Code [778/CA778] Eng. Bkup Speed Sensor Error……687

E-40 Code [1633/CA1633] KOMNET Dtalink Timeout Error……689

E-41 Code [2185/CA2185] Throttle Sens. Sup. Volt. High Error……690

E-42 Code [2186/CA2186] Throttle Sens. Sup. Volt. Low Error……693

E-43 Code [2249/CA2249] Rail Press. Very Low Error……694

E-44 Code [2311/CA2311] Abnormality in IMV solenoid……695

E-45 Code [2555/CA2555] Grid Heater Relay Volt. Low Error……697

E-46 Code [2556/CA2556] Grid Heater Relay Volt. High Error……699

E-47 Code [(- – -)/B@BAZG] Eng. Oil press. Low Speed Derate……701

E-48 Code [(- – -)/B@BAZG] Eng. Oil press. Torque Derate……701

E-49 Code [(- – -)/B@BCNS] Eng. Overheat……702

Troubleshooting of mechanical system (S-mode)……704

Method of using troubleshooting charts……707

S-1 Starting performance is poor……711

S-2 Engine does not start……712

S-3 Engine does not pick up smoothly……715

S-4 Engine stops during operations……716

S-5 Engine does not rotate smoothly……717

S-6 Engine lacks output (or lacks power)……718

S-7 Exhaust smoke is black (incomplete combustion)……719

S-8 Oil consumption is excessive (or exhaust smoke is blue)……720

S-9 Oil becomes contaminated quickly……721

S-10 Fuel consumption is excessive……722

S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)……723

S-12 Oil pressure drops……724

S-13 Oil level rises (Entry of coolant or fuel)……725

S-14 Coolant temperature becomes too high (overheating)……726

S-15 Abnormal noise is made……727

S-16 Vibration is excessive……728

50 Disassembly and assembly……730

General information on disassembly and assembly……730

How to read this manual……731

Coating materials list……732

Special tools list……735

Disassembly and assembly, Part 1……738

General disassembly of engine……739

Disassembly and assembly, Part 2……752

General assembly of engine……753

Disassembly and assembly, Part 3……770

Disassembly and assembly procedure for fuel supply pump unit……771

Disassembly and assembly procedure for oil seal units……773

SEN06060-01 – 95E-6 Series Diesel Engine Shop Manual……776

COVER……776

00 Index and foreword ……778

Index ……779

Foreword, safety and general information ……782

Important safety notice ……782

How to read the shop manual ……789

Explanation of terms for maintenance standard ……791

Handling equipment of fuel system devices ……793

Handling of intake system parts ……794

Handling of hydraulic equipment ……795

Method of disconnecting and connecting of push-pull type coupler ……797

Handling of electrical equipment ……800

How to read electric wire code ……808

Precautions when performing operation ……811

Standard tightening torque table ……816

List of abbreviation ……822

Conversion table ……827

01 Specification ……832

Table of contents ……833

General information ……834

Exhaust gas regulation ……834

Specifications ……837

Applicable machines ……837

Specifications ……838

General view ……841

Weight table ……850

Engine performance curve ……851

10 Structure and function ……854

Table of contents ……855

Components layout ……856

Components layout drawing ……856

Intake and exhaust system parts ……858

Intake and exhaust system layout drawing ……858

Intake and exhaust system circuit diagram ……860

Air cleaner ……862

VFT ……863

EGR system piping drawing ……867

EGR system circuit diagram ……869

EGR valve ……870

EGR cooler ……872

KCCV layout drawing ……874

KCCV ventilator ……876

KDOC muffler ……880

Engine main body parts ……882

General structure ……882

Cylinder head ……886

Cylinder block ……888

Main moving parts ……890

Timing gear ……893

Front cover ……895

Valve system ……896

Flywheel and flywheel housing ……898

Lubrication system ……899

Lubrication system chart ……899

Oil pump ……901

Oil filter ……903

Oil cooler ……905

Oil pan ……906

Fuel system ……907

Fuel system parts layout drawing ……907

Fuel system circuit diagram ……909

Prefilter ……910

Main filter ……911

Supply pump ……912

Common rail ……913

Injector ……914

Cooling system ……918

Cooling system parts layout drawing ……918

Cooling system chart ……919

Drive pulley ……920

Water pump ……922

Thermostat and jiggle valve ……923

Electrical equipment ……927

Alternator ……927

Starting motor ……932

Intake air heater ……936

Engine harness ……937

Engine controller ……939

Sensor ……945

20 Standard value tables ……954

Table of contents ……955

Standard service value table ……956

Standard value table for engine ……956

Running-in standard and performance test standard ……960

50 Disassembly and assembly ……964

Table of contents ……965

Related information on disassembly and assembly ……966

How to read this manual ……966

Coating materials list ……968

Special tools list ……972

Sketches of special tools ……973

Disassembly and assembly ……974

General disassembly of engine ……974

General assembly of engine ……989

Removal and installation procedure of supply pump unit alone ……1012

Engine front oil seal replacement procedure ……1015

Engine rear oil seal replacement procedure ……1016

60 Maintenance standard ……1018

Table of contents ……1019

Intake and exhaust system parts ……1020

VFT ……1020

Engine main body parts ……1021

Cylinder head ……1021

Cylinder block ……1023

Crankshaft ……1025

Piston ……1026

Connecting rod ……1027

Timing gear ……1028

Camshaft ……1029

Valve system ……1030

Valve and valve guide ……1031

Rocker arm shaft, push rod, and tappet ……1032

Flywheel and flywheel housing ……1033

Lubrication system ……1035

Oil pump ……1035

Cooling system ……1037

Water pump ……1037

INDEX……1038

Komatsu 95E Series Diesel Engine Repair Service Manuals