Complete service repair manual for Komatsu/DEMAG Hydraulic Shovels H285S, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

DEMAG Hydraulic Shovels H285S workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

H285S78067OMM – Hydraulic Shovel H285S Operation & Maintenance Manual.pdf

H285S78067SM – Hydraulic Shovel H285S Shop Manual.pdf

H285S78094OMM – Hydraulic Shovel H285S Operation & Maintenance Manual.pdf

H285S78094SM – Hydraulic Shovel H285S Shop Manual.pdf

H285S78115SM – Hydraulic Shovel H285S Operation & Maintenance Manual.pdf

H285S78135SM – Hydraulic Shovel H285S Electrical Diagram.pdf

Total Pages: 2,461 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

DIVISION OF MACHINE

SUPERSTRUCTURE

UNDERCARRIAGE

EQUIPMENT

SPECIAL EQUIPMENT

TOOTH SYSTEMS

LUBRICATION

REFILLING UNIT

HYDRAULIC SYSTEM

CONTROL

CONTROL UNITS

FILTERS OF THE HYDRAULIC OIL

ASSEMBLING THE EXCAVATOR

SHORT INFORMATION

HINTS FOR THE USER

HINTS FOR THE HYDRAULIC CIURCUIT DIAGRAM

ELECTRIC CIRCUIT DIAGRAM

HINTS FOR THE ELECTRIC CIRCUIT DIAGRAMS

HINTS FOR CHECK AND ADJUSTMENTS

PROPULSION

PUMP DISTRIBUTOR GEAR

HYDRAULIC PUMPS

PUMP BEARING LUBRICATION

PUMP REGULATION

HYDRAULIC OIL COOLING

HYDRAULIC OIL TANK

PILOT PRESSURE CIRCUITS

SERVICE LINE CIRCUITS

APPENDIX

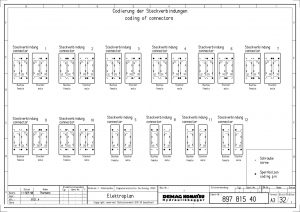

ELECTRICAL DIAGRAMS

H285S78067OMM – Hydraulic Shovel H285S Operation & Maintenance Manual….2

COVER….2

INTRODUCTION….4

GENERAL CONTENT….10

PART 1: OPERATION MANUAL….14

1. FOREWORD….16

2. CONSTRUCTION OF EXCAVATOR….18

2.1 SUPERSTRUCTURE….20

2.2 UNDERCARRIAGE….22

2.3 EQUIPMENT….24

3. SAFETY INSTRUCTIONS….38

4. OPERATOR'S CAB – CONTROL ELEMENTS….46

5. OPERATOR'S CAB – MONITORING ELEMENTS….50

5.1 POWER COMPARTMENT, ENGINE SHUT-OFF SWITCH….54

5.2 MONITORING ELEMENTS OF THE CENTRAL – AND SLEWING RING TOOTHING LUBRICATION SYSTEM….56

6. OPERATING INSTRUCTIONS….58

6.1 BEFORE STARTING THE ENGINE….58

6.2 STARTING….62

6.3 STOPPING….70

6.4 MOVING THE EXCAVATOR….72

6.5 SLEWING AND BRAKING THE SUPERSTRUCTURE….80

6.6 WORKING WITH THE ATTACHMENT….82

6.7 COMBINED OPERATION CYCLES….88

6.8 OPERATING THE HEATER, VENTILATION AND AIR-CONDITIONING….90

6.9 NOT USED….90

6.10 NOT USED….90

6.11 OPERATING THE LUBRICATION SYSTEM….94

6.13 FIRE DETECTION AND SUPPRESSION SYSTEM….100

7. WORKING HINTS….104

8. PARKING THE EXCAVATOR….108

9. REFUELLING THE EXCAVATOR….110

10. CHANGING EQUIPMENT AND/OR COMPONENTS….112

10.1 NOT USED….114

10.2 REMOVING BACKHOE EQUIPMENT….114

10.3 FITTING LOADING EQUIPMENT….118

10.4 NOT USED….118

10.5 NOT USED….118

10.6 NOT USED….118

10.9 REMOVING THE STICK WITH BULLCLAM BUCKET (LOADING EQUIPMENT)….122

10.10 REMOVING THE LOADER OR BULLCLAM BUCKET….124

PART 2: LUBRICATION-AND MAINTENANCE MANUAL….126

1. FOREWORD….128

2. SAFETY INSTRUCTIONS….138

3. FUEL AND LUBRICANTS….142

4. FILLING CAPACITIES….145

5. LUBRICATION AND MAINTENANCE SCHEDULE….147

5.1 INITIAL SERVICING….147

5.2 PERIODIC SERVICING INTERVALS….147

5.3 MAINTENANCE OF ENGINE….161

6. LUBRICATION AND MAINTENANCE WORK….163

6.1 EVERY 10 HOURS OF OPERATION OR DAILY….163

6.2 EVERY 50 HOURS OF OPERATION OR WEEKLY….183

6.3 NOT USED….198

6.4 NOT USED….198

6.5 NOT USED….198

6.6 EVERY 250 HOURS OF OPERATION OR MONTHLY….199

6.7 NOT USED….211

6.8 EVERY 500 HOURS OF OPERATION OR EVERY 3 MONTHS….211

6.9 EVERY 1000 HOURS OF OPERATION OR EVERY 6 MONTHS….241

6.10 EVERY 1500 HOURS OF OPERATION BUT AT LEASE ONCE A YEAR….271

6.11 EVERY 2000 HOURS OF OPERATION OR ANUALLY….279

6.12 WHEN NECESSARY….297

6.13 NOT USED….297

6.14 NOT USED….297

6.15 EXCAVATOR STORAGE….317

6.16 TROUBLESHOOTING….323

H285S78067SM – Hydraulic Shovel H285S Shop Manual….331

COVER….331

FOREWORD….333

LIST OF CONTENTS….337

PART 1….343

DIVISION OF MACHINE….343

SUPERSTRUCTURE….345

UNDERCARRIAGE….347

EQUIPMENT….349

SPECIAL EQUIPMENT….351

TOOTH SYSTEMS….355

LUBRICATION….357

REFILLING UNIT….367

HYDRAULIC SYSTEM….369

CONTROL….373

CONTROL UNITS….375

FILTERS OF THE HYDRAULIC OIL….377

ASSEMBLING THE EXCAVATOR….379

PART 2….407

LIST OF CONTENTS….407

HINTS FOR THE HYDRAULIC CIRCUIT DIAGRAM….415

ELECTRIC CIRCUIT DIAGRAM….431

HINTS FOR THE ELECTRIC CIRCUIT DIAGRAM….437

HINTS FOR CHECK AND ADJUSTMENTS….449

PROPULSION….451

CUMMINS ENGINE….453

SWITCHES, SENSORS AND FILTERS….455

RPM ADJUSTMENTS….459

FAN/FAN DRIVE….465

AIR FILTER….467

COUPLING….469

PUMP DISTRIBUTOR GEAR….471

GEAR LUBRICATION….473

HYDRAULIC PUMPS….477

PUMP BEARING LUBRICATION….479

PUMP REGULATION….481

LOAD LIMIT REGULATION….485

PRESSURE CUT-OFF….495

SETTING OF THE LOAD LIMIT VALVE….497

MEASURING AND SETTING OF THE PRESSURE OF THE PRESSURE CUT-OFF VALVE….499

MEASURING AND SETTING OF THE BEGINNING OF REGULATION WITHOUT A TEST BOLT….501

CHECKING WITH TEST SCREW….503

HYDRAULIC OIL COOLING….505

MEASURING AND SETTING OF THE FAN SPEED….511

COOLING CIRCUIT….515

MEASURING AND SETTING OF THE BACK PRESSURE VALVE….517

CHECKS TO BE PERFORMED IF HYDRAULIC TEMPERATURE IS TOO HIGH….519

HYDRAULIC OIL TANK….521

PILOT PRESSURE CIRCUITS….523

CONTROL OIL SUPPLY….525

CHECKS AND ADJUSTMENTS….529

CONTROL OIL FLOW FROM THE 4 FUNCTIONS PILOT CONTROL UNIT TO THE CONTROL BLOCKS….531

CONTROL OIL FLOW FROM PEDAL TO THE CONTROL BLOCK….537

CONTROL OIL FLOW FROM THE 2 FUNCTION CONTROL UNIT TO CONTROL BLOCK….539

TRAVEL PARKING BRAKE….541

SLEW PARKING BRAKE….543

SERVICE LINE CIRCUITS….545

MEASUREMENTS AND PRESSURE ADJUSTMENTS/SLEW CIRCUIT….555

TRAVEL MOTORS….563

MEASUREMENTS AND PRESSURE ADJUSTMENTS/TRAVEL MOTORS….565

BUCKET CYLINDER….569

MEASUREMENTS AND PRESSURE ADJUSTMENTS/BUCKET CYLINDER….571

CLAM CYLINDER….579

MEASURINGS AND PRESSURE ADJUSTMENTS/CLAM CYLINDER….581

STICK CYLINDER/LOADER ATTACHMENT….591

MEASURINGS AND PRESSURE ADJUSTMENTS/STICK CYLINDER/LOADER ATTACHMENT….593

BOOM CYLINDER/LOADER ATTACHMENT….601

MEASURINGS AND PRESSURE ADJUSTMENTS/BOOM CYLINDERS/LOADER ATTACHMENTS….603

BUCKET CYLINDER (BACK HOE ATTACHMENT)….611

MEASUREMENTS AND PRESSURE ADJUSTMENTS/BUCKET CYLINDER….613

STICK CYLINDER/BACK HOE ATTACHMENT….621

MEASURINGS AND ADJUSTMENTS/STICK CYLINDER/BACK HOE ATTACHMENT….623

BOOM CYLINDER/BACK HOE ATTACHMENT….631

MEASURINGS AND PRESSURE ADJUSTMENTS/BOOM CYLINDERS/BACK HOE ATTACHMENT….633

AIR CONDITION DRIVE….639

MEASUREMENT AND ADJUSTMENT/AIR CONDITION DRIVE….641

LUBRICATION SYSTEM….643

SINGLE CIRCUIT CENTRAL LUBRICATION SYSTEM WITH PROGRESSIVE DISTIBUTORS….645

ELECTRICAL FUNCTION….651

MEASUREMENT AND PRESSURE ADJUSTMENT/COMPRESSED AIR SYSTEM….655

SLEW RING TOOTHING MIST LUBRICATION….661

ELECTRICAL FUNCTION….665

MEASUREMENT AND PRESSURE ADJUSTMENT/COMPRESSED AIR SYSTEM….669

GENERATOR DRIVE….675

MEASUREMENTS AND ADJUSTMENTS/GENERATOR DRIVE….677

PART 3….683

LIST OF CONTENTS….683

PLATFORM….693

DIESEL MOTOR….695

COMPUSAVE ENGINE MOTOR….697

COUPLING….737

UNIVERSAL SHAFT….739

PUMP DISTRIBUTOR GEAR….741

HYDRAULIC PUMPS….747

MAIN PUMPS, A7V HDD….747

GEARED PUMPS….761

HYDRAULIC PUMP A2F….767

HYDRAULIC PUMP A10V 0….771

HYDRAULIC PUMP A7F 0/107….775

DIESEL FUEL TANK….777

ELECTRONIC SET-UP….779

HYDRAULIC OIL TANK….783

HYDRAULIC OIL FILTERS….793

FILTERS IN THE PUMP LINE TO THE CONTROL BLOCKS….793

IN-LINE FILTER….797

RETURN OIL/CASE DRAIN FILTER IN THE HYDRAULIC RESERVOIR….799

BREATHER FILTER ON THE HYDRAULIC OIL RESERVOIR….801

CONTROL BLOCKS AND VALVES….803

4 FOLD CONTROL BLOCK M0 52….803

PRESSURE RELIEF VALVE, PILOT OPERATED….809

SECONDARY VALVE: PRE-CONTROLLED….813

ANTI-CAVITATION VALVE (MAKE-UP VALVE)….815

LOAD HOLDING VALVES INSIDE THE SPOOLS….817

SINGLE CONTROL BLOCK M0 40….819

PRESSURE INCREASING VALVE….825

PRESSURE RELIEF VALVE, PILOT OPERATED….829

CHECK VALVE….833

SHUTTLE VALVE….835

PRESSURE RELIEF VALVE, PRE-CONTROLLED….837

PRESSURE RELIEF VALVE, PILOT OPERATED….839

PRESSURE RELIEF VALVE, PILOT OPERATED….841

PRESSURE RELIEF VALVES TYPE DB/DBW….843

MAGNET VALVE….845

PRESSURE RELIEF VALVE, REMOTE CONTROLLED….847

LOAD LIMIT VALVE….849

NOZZLE BLOCK/PUMP REGULATING….855

PRESSURE SEQUENCE VALVE (PRESSURE CUT OFF VALVE)….857

RESTRICTOR BLOCK….859

PILOT CONTROL UNITS, 4 BOLT UNITS….861

PILOT CONTROL UNITS, 1 BOLT UNITS….865

TRAVEL BRAKE VALVE….867

PRESSURE ACCUMULATOR….871

TESTING THE PRECHARGE PRESSURE AND REFILLING….875

SLEW GEAR….879

REPLACEMENT OF THE DISKS….883

REPLACEMENT OF THE QUAD-RINGS….885

AXIAL PISTON MOTOR….887

SLEW RING….891

UNDERCARRIAGE….893

IDLER WHEEL ASSEMBLY….893

ALTERING THE TRACK TENSION….895

BOTTOM ROLLER….897

TOP ROLLER….899

CRAWLER DRIVE ASS'Y….901

TRAVEL GEAR….905

REPLACEMENT OF THE DISKS….909

REPLACEMENT OF THE QUAD-RINGS….911

DRIVE SPROCKET….913

CRAWLER CHAIN….915

AXIAL PISTON MOTOR….917

ROTARY DISTRIBUTOR….925

HYDRAULIC CYLINDERS….931

AIR CONDITIONING EQUIPMENT….935

MAINTENANCE SCHEDULE….947

PRESSURE MONITORING….965

COMPRESSED AIR SYSTEM….969

COMPRESSOR AT CU ENGINE….969

AIR DRYER….973

AUTOMATIC DRAIN VALVE….979

AIR EQUIPMENT – SERVICE UNIT….981

SOLENOID VALVE….987

VENT VALVE ASSEMBLY….989

LUBE SYSTEM….991

METERING VALVE….991

PROGRESSIVE LUBE DISTRIBUTOR….999

PRESSURE CONTROL UNIT….1003

TROUBLESHOOTING LUBRICATION SYSTEM….1005

SHORT INFORMATION….1021

REVOLUTIONS/PRESSURES….1021

FILLING CAPACITIES….1023

HYDRAULIC OIL….1025

TORQUE CHART….1027

TORQUE CHART – NM….1027

TORQUE CHART – FT LBF….1029

CONVERSION METRIC/INCH….1031

TROUBLESHOOTING H285….1033

GENERAL ….1035

MALFUNCTION WHEN EXTENDING OR RETRACTING CYLINDERS….1037

TROUBLESHOOTING SLEW CIRCUIT….1039

TROUBLESHOOTING SLEW BRAKE CIRCUIT….1041

TROUBLESHOOTING SLEW HOUSE BRAKE CIRCUIT….1043

TROUBLESHOOTING TRAVEL CIRCUIT….1045

TROUBLESHOOTING THE TRAVEL BRAKE CIRCUIT….1047

TROUBLESHOOTING PUMP REGULATION CIRCUIT….1049

TROUBLESHOOTING OIL COOLER CIRCUIT….1051

HYDRAULIC/ELECTRICAL DIAGRAM….1053

CONTENTS….1053

HYDRAULIC DIAGRAM….1054

ELECTRICAL DIAGRAM….1057

H285S78094OMM – Hydraulic Shovel H285S Operation & Maintenance Manual….1083

COVER….1083

INTRODUCTION….1085

GENERAL CONTENTS….1091

PART 1 OPERATION MANUAL….1093

CONTENTS….1093

1 FOREWARD….1095

2 CONSTRUCTION OF THE EXCAVATOR….1097

2.1 SUPERSTRUCTURE….1099

2.2 UNDERCARRIAGE….1101

2.3 EQUIPMENT….1103

3 SAFETY INSTRUCTIONS….1107

4 OPERATOR'S CAB – CONTROLS….1117

5 OPERATOR'S CAB – MONITORS….1121

5.1 POWER HOUSE….1127

5.2 NOT USED….1093

5.3 HEATING SYSTEMS (SPECIAL EQUIPMENT)….1131

6 OPERATION INSTRUCTIONS….1135

6.1 BEFORE STARTING THE ENGINE….1135

6.2 STARTING THE ENGINE….1139

6.3 STOPPING THE ENGINE….1147

6.4 MOVING THE EXCAVATOR….1149

6.5 SLEWING AND BRAKING THE SUPERSTRUCTURE….1157

6.6 WORKING WITH THE ATTACHMENT….1161

6.7 COMBINED OPERATION CYCLES….1167

6.8 OPERATING THE HEATER, VENTILATION AND AIR CONDITIONING….1169

6.11 OPERATION OF THE LUBRICATION SYSTEMS….1173

6.13 FIRE DETECTION AND SUPPRESSION SYSTEM (SPECIAL EQUIPMENT)….1183

7 WORKING INSTRUCTIONS….1187

8 PARKING THE EXCAVATOR….1191

9 REFILLING OF FLUIDS….1193

9.1 SERVICE CRANE FOR GREASE BARRELS (SPECIAL EQUIPMENT)….1195

10 CHANGING EQUIPMENT AND/OR COMPONENTS….1201

10.2 REMOVING THE BACKHOE EQUIPMENT (Z 0065)….1205

10.3 MOUNTING OF THE BULLCLAM BUCKET EQUIPMENT (Z 10353/Z 10355)….1209

10.9 REMOVING STICK WITH BULLCLAM BUCKET (LOADING EQUIPMENT) ILLUS. (Z 19256)….1213

10.10 REMOVING THE LOADER OR BULLCLAM BUCKET….1215

PART 2 LUBRICATION AND MAINTENANCE MANUAL….1217

CONTENTS….1217

1 FOREWARD….1219

1.1 FIRE PREVENTION….1223

1.2 REPAIR WELDINGS….1227

2 SAFETY INSTRUCTIONS….1229

3 FUEL AND LUBRICANTS….1235

4 FILLING CAPACITIES….1239

5 LUBRICATION AND MAINTENANCE SCHEDULE….1241

5.1 INITIAL SERVICING….1241

5.2 PERIODIC SERVICING SCHEDULE….1243

5.3 MAINTENANCE OF ENGINE….1255

6 LUBRICATION AND MAINTENANCE WORK….1259

6.1 EVERY 10 OPERATING HOURS OR DAILY….1259

6.2 EVERY 50 HOURS OF OPERATION OR WEEKLY….1277

6.6 EVERY 250 OPERATING HOURS OR MONTHLY….1287

6.8 EVERY 500 OPERATING HOURS OR EVERY 3 MONTHS….1307

6.9 EVERY 1000 OPERATING HOURS OR EVERY 6 MONTHS….1349

6.11 EVERY 2000 OPERATING HOURS OR YEARLY….1383

6.12 EVERY 3000 OPERATING HOURS HOWEVER AT LEAST ONCE A YEAR….1395

6.15 WHEN NECESSARY….1407

7 EXCAVATOR STORAGE….1423

8 TROUBLE SHOOTING….1429

H285S78094SM – Hydraulic Shovel H285S Shop Manual….1437

COVER….1437

FOREWORD….1439

CONTENTS….1443

PART 1….1445

DIVISION OF MACHINE….1446

SUPERSTRUCTURE….1448

UNDERCARRIAGE….1450

EQUIPMENT….1452

SPECIAL EQUIPMENT….1454

TOOTH SYSTEMS….1456

LUBRICATION….1458

REFILLING UNIT….1468

HYDRAULIC SYSTEM….1470

CONTROL….1474

CONTROL UNITS….1476

FILTERS OF THE HYDRAULIC OIL….1478

ASSEMBLING THE EXCAVATOR….1480

PART 2….1510

LIST OF CONTENTS….1510

SHORT INFORMATION….1518

HINTS FOR THE USER….1520

HINTS FOR THE HYDRAULIC CIRCUIT DIAGRAM….1522

ELECTRIC CIRCUIT DIAGRAM….1541

HINTS FOR THE ELECTRIC CIRCUIT DIAGRAM….1544

HINTS FOR CHECK AND ADJUSTMENTS….1550

PROPULSION….1551

OVERVIEW DIESEL ENGINE….1551

OVERVIEW ELECTRIC MOTOR….1552

ENGINE MOUNTINGS….1553

SWITCHES, SENSORS AND FILTERS….1554

RPM ADJUSTMENTS….1556

FAN DRIVE….1561

AIR FILTER….1562

COUPLING FOR DIESEL ENGINE DRIVEN MACHINES….1563

COUPLING FOR ELECTRIC MOTOR DRIVEN MACHINES….1564

PUMP DISTRIBUTOR GEAR….1566

GEAR LUBRICATION….1567

HYDRAULIC PUMPS….1569

PUMP BEARING LUBRICATION….1570

PUMP REGULATION….1572

FOR MACHINES WITH DIESEL ENGINE ONLY….1572

LOAD LIMIT REGULATION….1573

PRESSURE CUT OFF VALVE….1579

SETTING OF THE LOAD LIMIT VALVE….1580

MEASURING AND SETTING OF THE PRESSURE OF THE PRESSURE CUT OFF VALVES….1582

MEASURING AND SETTING OF THE START OF DESTROKING OF THE MAIN PUMPS….1584

CHECKING WITH TEST BOLT….1585

FOR MACHINES WITH ELECTRONIC MOTOR DRIVE….1586

BRIEF DESCRIPTION OF THE ELECTRONIC PARTS OF THE EGL….1588

HYDRAULIC REGULATION….1589

ADJUSTMENTS….1596

ADJUSTING WORKS FOR THE ELECTRONIC PUMP REGULATION….1604

TROUBLESHOOTING/ELECTRONIC CONTROLLING….1609

MEASURING AND SETTING OF THE PRESSURE CUT OFF VALVES….1612

MEASURING AND SETTING OF THE START OF DESTROKING OF THE MAIN PUMPS….1614

CHECKING WITH TEST BOLT….1615

HYDRAULIC OIL COOLING….1616

FAN DRIVE….1617

MEASURING AND SETTING OF THE FAN SPEED….1619

COOLING CIRCUIT….1622

MEASURING AND SETTING OF THE BACK PRESSURE VALVE….1623

CHECKS TO BE PERFORMED IF HYDRAULIC TEMPERATURE IS TOO HIGH….1624

HYDRAULIC OIL TANK….1625

PILOT PRESSURE CIRCUITS….1626

OVERVIEW….1626

CONTROL OIL SUPPLY….1627

CHECKING AND ADJUSTMENTS….1629

TRAVEL PARKING BRAKE….1630

SLEW BRAKE HOUSE BRAKE….1632

TRAVEL MOTION CONTROL WHEN USING A CABLE REEL….1634

PILOT PRESSURE CUT OFF FOR "BUCKET FILLING" AT TOO HOT HYDRAULIC OIL….1635

PRIORITY FOR STICK OR BOOM IN R.H. CONTROL BLOCK WITH A BHA….1636

SERVICE LINE CIRCUITS….1637

SLEW CIRCUIT….1637

CHECKS AND ADJUSTMENTS….1642

TRAVEL MOTORS….1645

CHECKS AND ADJUSTMENTS….1646

BUCKET CYLINDER….1647

CHECKS AND ADJUSTMENTS….1648

CLAM CYLINDER….1650

CHECKS AND ADJUSTMENTS….1651

STICK CYLINDER/LOADER ATTACHMENT….1655

CHECKS AND ADJUSTMENTS….1656

BOOM CYLINDER/LOADER ATTACHMENT….1659

CHECKS AND ADJUSTMENTS….1660

BUCKET CYLINDER/BACK HOE ATTACHMENT….1663

CHECKS AND ADJUSTMENTS….1664

STICK CYLINDER/BACK HOE ATTACHMNET….1667

CHECKS AND ADJUSTMENTS….1668

BOOM CYLINDER/BACK HOE ATTACHMENT….1671

CHECKS AND ADJUSTMENTS….1672

HYDRAULIC TRACK ADJUSTING SYSTEM….1675

LEGEND….1675

FUNCTION….1676

APPENDIX….1683

HYDRAULIC AIR CONDITION DRIVE….1685

CHECKS AND ADJUSTMENTS….1686

SERVICE MANUAL….1688

GENERATOR DRIVE….1722

CHECKS AND ADJUSTMENTS….1728

LUBRICATION….1736

COMPRESSED AIR SYSTEM….1736

SINGLE LINE CENTRALIZED LUBE SYSTEM….1740

ELECTRICAL FUNCTION….1744

CHECKS AND ADJUSTMENTS….1748

SLEW RING TOOTHING MIST LUBRICATION….1752

ELECTRICAL FUNCTION….1756

CHECKS AND ADJUSTMENTS….1760

SLEW RING TOOTHING DRIP LUBRICATION….1762

ELECTRICAL FUNCTION….1766

CHECKS AND ADJUSTMENTS….1770

CENTRAL LUBRICATION SYSTEM WITH ELECTRIC MOTOR DRIVE PUMPS….1772

DESIGN….1772

SINGLE LINE CENTRALIZED LUBE SYSTEM….1774

ELECTRICAL FUNCTION….1778

CHECKS AND ADJUSTMENTS….1782

SLEW RING DRIP LUBRICATION….1784

ELECTRICAL FUNCTION….1788

CHECKS AND ADJUSTMENTS….1792

SL-1 AND SL-11 INJECTOR….1794

DIFFERENT TIME RELAYS….1798

CABLE REEL/ELECTRIC MACHINE….1804

ELECTRICAL FUNCTION….1806

TRAVEL MOTION CONTROL….1808

SWITCHING MECHANISM WITH SWITCHES 5S4….1810

REQUIRED ADJUSTMENTS/CHECKS….1812

PART 3….1814

CONTENTS….1814

ELECTRICAL DIAGRAM….1815

H285S78115SM – Hydraulic Shovel H285S Operation & Maintenance Manual….1847

Hydraulic Diagram.pdf….0

Electrical Diagram.pdf….0

H285S78135SM – Hydraulic Shovel H285S Electrical Diagram….2391

COVER….2391

CONTENTS….2392

ELECTRICAL DIAGRAM….2393

Komatsu/DEMAG Hydraulic Shovels H285S Repair Service Manuals + Operation & Maintenance Manuals