Complete service repair manual with Electrical Wiring Diagrams for Komatsu Dump Truck HD465-7E0, HD605-7E0, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Dump Truck HD465-7E0, HD605-7E0 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEN01081-18 – Dump Truck HD465-7E0, HD605-7E0 Shop Manual.pdf

GEN00046-04 – Dump Truck HD465-7E0, HD605-7E0 Field Assembly Instruction.pdf

TEN00138-08 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual.pdf

TEN00332-00 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual.pdf

TEN00370-03 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual.pdf

TEN00439-07 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual.pdf

PRODUCT DETAILS:

Total Pages: 3,390 pages

File Format: PDF

Language: English

MAIN SECTIONS

GEN00046-04 – Dump Truck HD465-7E0, HD605-7E0 Field Assembly Instruction…2

COVER…2

CONTENTS…3

1. Major points changed from model 7…5

2. Outline of division…5

3. Dimensions of main components…6

4. Rough schedule of assembly and welding4. Rough schedule of assembly and welding…7

5. List of equipments, tools, and consumables…10

6. Assembly process No…12

List of jigs, tools, and consumables…12

0010 Oil, grease, and coolant…13

0020 Levels of oil, grease, and coolant…14

0030 Positioning rear axle assembly…15

0040 Installing rear suspension…16

0050 Installing of axle rod (upper)…17

0060 Slinging bare machine…18

0070 Installing rear axle assembly (Connecting axle rods)…19

0080 Connecting rear suspension…20

0090 Positioning bare machine…21

0100 Installing right front axle (Connecting A-arm)…22

0110 Installing right front axle (Connecting suspension)…23

0120 Installing right front axle (Connecting steering cylinder and tie rod)…24

0130 Installing right front axle (Connecting brake hose)…25

0140 Installing right front axle (Connecting piping for automatic suspension)…26

0145 Connection and fixing of right front axle wiring harness (ABS specification)…28

0150 Installing tire and wheel assembly…29

0160 Installing body hinge grease tube…30

0165 Installation of rear monitor…31

0170 Installing drive shaft…32

0180 Connecting cooling hose…33

0190 Connecting brake actuating hose…34

0195 Connection and fixing of rear centralized lubrication hoses [4-point greasing…35

0200 Installing right front support…36

0210 Installing R.H platform assembly…37

0215 Fixing of ORBCOMM antenna cable…38

0216 Installation of ORBCOMM antennal pole…39

0220 Installing of fire prevention cover…40

0221 Installation of fire prevention cover (Sand terrain specification)…41

0230 Installing right fender…42

0231 Installation of right fender (Side lamp specification)…43

0240 Installing L.H catwalk assembly…44

0250 Installing L.H handrail…45

0251 Installation of cab side step (Diagonal ladder specification)…46

0252 Installation of diagonal ladder 1 (Diagonal ladder specification)…47

0253 Installation of diagonal ladder 2 (Diagonal ladder specification)…48

0254 Installation of diagonal ladder 3 (Diagonal ladder specification)…49

0255 Assembly of diagonal ladder (Diagonal ladder specification)…50

0256 Installation of under view mirror (Diagonal ladder specification)…51

0260 Installing radio antenna and fixing its cable…52

0270 Installing L.H fender…53

0271 Installation of left fender (Side lamp specification)…54

0280 Installing left side mudguard…55

0290 Installing right side mudguard…56

0295 Installation of R.H exhaust pipe cover (Muffler specification)…57

0296 Installation of R.H exhaust pipe cover (Exhaust selector box specification)…58

0300 Installing transmission underguard…59

0305 Installation of radiator curtain (Radiator curtain specification and sand terrain specification)…60

0310 Removing hoist cylinder bracket…61

0320 Removing hoist piping blind plate…62

0330 Welding body…63

0340 Slinging body…64

0350 Installing hinge pin…65

0360 Connecting hoist cylinder…66

0370 Welding protective cover by actually positioning it on machine…67

0380 Installing body mount…68

0390 Procedure for adjusting body mount shim…69

0395 Welding front body mount bracket…70

0400 Welding exhaust tube by actually positioning it on machine…71

0405 Installation of grease junction tube [4-point greasing specification]…72

0410 Installing poke ejector…73

0420 Installing body lock pin…74

0430 Installing body mudguard…75

0440 Connecting dump sensor…76

0450 Procedure for adjusting dump sensor…77

0460 Calibrating dump control…78

0470 Bleeding air from brake system (Preparation)…79

0480 Bleeding air from brake system (Front)…80

0490 Bleeding air from brake system (Rear)…81

0500 Adjusting suspension…82

0510 Greasing (Right front axle)…83

0520 Greasing (Hoist cylinder)…84

0530 Greasing (Rear suspension and axle rod)…85

0540 Painting…86

0550 Sticking body decal…87

0560 Removing jig…88

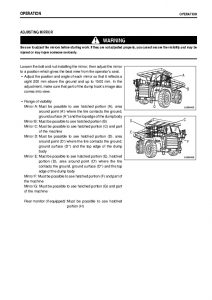

0570 Adjusting angles of mirrors…89

0580 Checking/Adding lubricants…90

C-0010 Preparation of welding body…91

C-0020 Assembly of split body…92

C-0030 Tack welding body…93

C-0040 Welding body…94

C-0050 Welding body instruction (1/2)…95

C-0060 Welding body instruction (2/2)…96

C-0070 Turn over the body…97

C-0080 Welding body protector (1/2)…98

C-0090 Welding body protector (2/2)…99

C-0100 Finishing and painting welded parts of body…100

C-0110 Reworking on body (Exhaust selector box specification)…101

C-0120 Welding of body exhaust pipe (Exhaust selector box specification)…102

Appendix : Field assembly inspection report…103

SEN01081-18 – Dump Truck HD465-7E0, HD605-7E0 Shop Manual…113

TEN00138-08 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual…1759

COVER…1759

FOREWORD…1760

BEFORE READING THIS MANUAL…1761

SAFETY INFORMATION…1764

INTENDED USE…1765

USE OF MACHINE…1765

GENERAL VIEW AND DIRECTIONS OF MACHINE…1765

VISIBILITY FROM OPERATOR'S SEAT…1765

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…1766

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…1766

EPA REGULATIONS, ENGINE NUMBER PLATE…1766

SERVICE METER POSITION…1767

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…1767

CONTENTS…1768

SAFETY…1772

IMPORTANT SAFETY INFORMATION…1773

SAFETY LABELS…1776

POSITION FOR ATTACHING SAFETY LABELS…1777

SAFETY LABELS…1778

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE…1783

PRECAUTIONS BEFORE STARTING OPERATION…1783

PREPARATIONS FOR SAFE OPERATION…1783

FIRE PREVENTION…1785

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE…1786

DO NOT GET CAUGHT IN DUMP BODY…1788

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES…1788

UNAUTHORIZED MODIFICATION…1788

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…1789

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING…1789

PRECAUTIONS FOR OPERATION…1790

PRECAUTIONS FOR JOBSITE…1790

STARTING ENGINE…1792

OPERATION…1794

TRANSPORTATION…1798

TOWING…1799

PRECAUTIONS FOR MAINTENANCE…1800

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE…1800

PRECAUTIONS FOR INSPECTION AND MAINTENANCE…1804

TIRES…1809

OPERATION…1812

GENERAL VIEW…1813

GENERAL VIEW OF MACHINE…1813

GENERAL VIEW OF CONTROLS AND GAUGES…1814

DASHBOARD…1815

EXPLANATION OF COMPONENTS…1816

GENERAL VIEW OF MACHINE…1816

OPERATOR'S CAB…1819

CONTROL LEVERS AND PEDALS…1821

MACHINE MONITOR…1826

DISPLAY OF CHARACTER DISPLAY…1839

OTHER FUNCTIONS OF CHARACTER DISPLAY…1843

SWITCHES…1847

BODY PIVOT PIN…1857

LOCATION OF FIRE EXTINGUISHER…1858

DUST INDICATOR…1858

FUSES…1859

CAR RADIO…1862

CAR STEREO…1864

AIR CONDITIONER…1869

OPERATION…1874

CHECK BEFORE STARTING ENGINE…1874

STARTING ENGINE…1899

OPERATIONS, CHECKS AFTER STARTING ENGINE…1902

STOPPING ENGINE…1902

MOVING MACHINE OFF (FORWARD, REVERSE), STOPPING…1903

SHIFTING GEAR…1909

TRAVELING DOWNHILL…1911

STEERING THE MACHINE…1924

LOADING OPERATIONS…1924

DUMP OPERATIONS…1925

PRECAUTIONS FOR OPERATION…1927

PARKING MACHINE…1928

CHECKS AFTER COMPLETION OF WORK…1928

CHECKS AFTER STOPPING ENGINE…1929

LOCKING…1929

HANDLING TIRES…1930

DETERMINING AND MAINTAINING TRAVEL ROAD…1934

DETERMINING TRAVEL ROAD…1934

MAINTAINING TRAVEL ROAD…1934

WORKSITE…1935

EXAMINATION AN CONFIRMATION OF WORKSITE…1935

WORKING ON LOOSE GROUND…1935

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLE…1936

ENSURE GOOD VISIBILITY…1936

CONFIRMATION OF MARK…1936

TRANSPORTATION…1937

PRECAUTIONS WHEN TRANSPORTING…1937

STEPS FOR TRANSPORTATION…1937

METHOD OF SECURING MACHINE…1938

METHOD OF LIFTING MACHINE…1939

COLD WEATHER OPERATION…1942

PRECAUTIONS FOR LOW TEMPERATURE…1942

PRECAUTIONS AFTER COMPLETION OF WORK…1944

AFTER COLD WEATHER…1944

LONG-TERM STORAGE…1945

BEFORE STORAGE…1945

DURING STORAGE…1945

AFTER STORAGE…1945

PRECAUTIONS BEFORE TRAVELING AFTER LONG-TERM STORAGE…1945

TROUBLESHOOTING…1946

AFTER RUNNING OUT OF FUEL…1946

IF TRANSMISSION HAS TROUBLE…1946

METHOD OF LOWERING DUMP BODY IN EMERGENCY…1947

METHOD OF TOWING MACHINE…1949

IF BATTERY IS DISCHARGED…1953

ACTION IF FIRE OCCURS…1957

OTHER TROUBLE…1958

MAINTENANCE…1964

GUIDES TO MAINTENANCE…1965

SECONDARY MATERIALS FOR OPERATION…1972

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC…1972

OUTLINE OF ELECTRIC SYSTEM…1976

WEAR PARTS…1977

WEAR PARTS LIST…1977

RECOMMENDED FUEL, COOLANT, AND LUBRICANT…1978

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…1979

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…1980

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…1981

TORQUE LIST…1981

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…1982

SAFETY CRITICAL PARTS…1982

MAINTENANCE SCHEDULE CHART…1983

MAINTENANCE SCHEDULE CHART…1983

SERVICE PROCEDURE…1985

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)…1985

WHEN REQUIRED…1986

CHECK BEFORE STARTING…2011

EVERY 250 HOURS SERVICE…2012

EVERY 500 HOURS SERVICE…2026

EVERY 1000 HOURS SERVICE…2036

EVERY 2000 HOURS SERVICE…2046

EVERY 4000 HOURS SERVICE…2049

EVERY 8000 HOURS SERVICE…2053

EVERY 15000 HOURS SERVICE…2054

SPECIFICATIONS…2056

SPECIFICATIONS…2057

ATTACHMENTS, OPTIONS…2058

SELECTING DUMP BODY…2059

HANDLING TACHOGRAPH (TCO20-90W)…2060

EXPLANATION OF COMPONENTS…2060

METHOD OF USE…2063

HANDLING AIR SUSPENSION SEAT…2067

OPERATOR'S SEAT ADJUSTMENT…2067

REMOVAL AND INSTALLATION OF HEADREST…2071

HANDLING AUTOMATIC SPIN REGULATOR (ASR)…2072

EXPLANATION OF COMPONENTS…2072

ACTUATION OF ASR SYSTEM…2073

PRECAUTION WHEN USING ASR SYSTEM…2073

TROUBLESHOOTING…2074

BLEEDING AIR FROM ASR CIRCUIT…2075

HANDLING ANTI SKID BRAKE SYSTEM (ABS)…2076

EXPLANATION OF COMPONENTS…2076

ABS SYSTEM CHECK AFTER STARTING ENGINE…2077

OPERATION OF ABS…2078

PRECAUTION WHEN USING ABS SYSTEM…2078

TROUBLESHOOTING…2079

HANDLING PAYLOAD METER (VHMS BUILT-IN TYPE)…2080

OUTLINE OF SYSTEM…2080

NORMAL OPERATION DISPLAY…2081

EXTERNAL DISPLAY LAMPS…2083

PERFORMING CALIBRATION…2084

DATA STORED IN PAYLOAD METER…2086

PROCEDURE WHEN DOWNLOADING…2087

MACHINE ID, OPEN ID…2091

PAYLOAD (CYCLE DATA ITEM)…2093

SERVICE FUNCTIONS…2093

OTHERS…2093

HANDLING PAYLOAD METER II (CARD TYPE)…2094

METHOD OF USING ACCURATELY…2095

GENERAL LOCATIONS…2096

CONTENT OF DISPLAY (CONTROLLER, EXTERNAL DISPLAY LAMPS)…2101

EXTERNAL DISPLAY LAMPS…2105

DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER…2107

OPERATION OF SWITCHES…2112

PROBLEM AND WARNING DISPLAY (ERROR CODE)…2134

WHEN ERROR CODE F-09 IS DISPLAYED (PROCEDURE FOR REPLACING BATTERY)…2141

OPERATION WHEN ERROR CODE F.CAL IS DISPLAYED OR CONTROLLER HAS BEEN REPLACED…2144

USE OF REAR VIEW MONITOR…2147

NAME AND FUNCTON OF EACH PART OF REAR VIEW MONITOR…2147

SETTING OF REAR VIEW MONITOR…2150

CAUTIONS WHEN USING REAR VIEW MONITOR…2150

HANDLING DUMPING COUNTER…2151

HANDLING BATTERY ISOLATOR…2152

HANDLING MACHINES EQUIPPED WITH VHMS…2154

VHMS INSTALLED, COMMUNICATIONS TERMINAL NOT INSTALLED…2154

VHMS AND COMMUNICATIONS TERMINAL INSTALLED…2154

PROCEDURE WHEN DOWNLOADING…2155

CHECK BEFORE STARTING…2155

INDEX…2158

TEN00332-00 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual…2162

COVER…2162

FOREWORD…2163

BEFORE READING THIS MANUAL…2164

SAFETY INFORMATION…2165

INTENDED USE…2166

USE OF MACHINE…2166

GENERAL VIEW AND DIRECTIONS OF MACHINE…2166

VISIBILITY FROM OPERATOR'S SEAT…2166

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…2167

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…2167

EPA REGULATIONS, ENGINE NUMBER PLATE…2167

SERVICE METER POSITION…2168

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…2168

CONTENTS…2169

SAFETY…2173

IMPORTANT SAFETY INFORMATION…2174

SAFETY LABELS…2177

POSITION FOR ATTACHING SAFETY LABELS…2178

SAFETY LABELS…2179

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE…2184

PRECAUTIONS BEFORE STARTING OPERATION…2184

PREPARATIONS FOR SAFE OPERATION…2184

FIRE PREVENTION…2186

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE…2187

DO NOT GET CAUGHT IN DUMP BODY…2189

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES…2189

UNAUTHORIZED MODIFICATION…2189

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…2190

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING…2190

PRECAUTIONS FOR OPERATION…2191

PRECAUTIONS FOR JOBSITE…2191

STARTING ENGINE…2193

OPERATION…2195

TRANSPORTATION…2199

TOWING…2200

PRECAUTIONS FOR MAINTENANCE…2201

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE…2201

PRECAUTIONS FOR INSPECTION AND MAINTENANCE…2205

TIRES…2210

OPERATION…2213

GENERAL VIEW…2214

GENERAL VIEW OF MACHINE…2214

GENERAL VIEW OF CONTROLS AND GAUGES…2215

DASHBOARD…2216

EXPLANATION OF COMPONENTS…2217

GENERAL VIEW OF MACHINE…2217

OPERATOR'S CAB…2220

CONTROL LEVERS AND PEDALS…2222

MACHINE MONITOR…2227

DISPLAY OF CHARACTER DISPLAY…2240

OTHER FUNCTIONS OF CHARACTER DISPLAY…2244

SWITCHES…2248

BODY PIVOT PIN…2258

LOCATION OF FIRE EXTINGUISHER…2259

DUST INDICATOR…2259

FUSES…2260

CAR RADIO…2263

CAR STEREO…2265

AIR CONDITIONER…2270

OPERATION…2275

CHECK BEFORE STARTING ENGINE…2275

STARTING ENGINE…2300

OPERATIONS, CHECKS AFTER STARTING ENGINE…2303

STOPPING ENGINE…2303

MOVING MACHINE OFF (FORWARD, REVERSE), STOPPING…2304

SHIFTING GEAR…2310

TRAVELING DOWNHILL…2312

STEERING THE MACHINE…2325

LOADING OPERATIONS…2325

DUMP OPERATIONS…2326

PRECAUTIONS FOR OPERATION…2328

PARKING MACHINE…2329

CHECKS AFTER COMPLETION OF WORK…2329

CHECKS AFTER STOPPING ENGINE…2330

LOCKING…2330

HANDLING TIRES…2331

DETERMINING AND MAINTAINING TRAVEL ROAD…2335

DETERMINING TRAVEL ROAD…2335

MAINTAINING TRAVEL ROAD…2335

WORKSITE…2336

EXAMINATION AN CONFIRMATION OF WORKSITE…2336

WORKING ON LOOSE GROUND…2336

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLE…2337

ENSURE GOOD VISIBILITY…2337

CONFIRMATION OF MARK…2337

TRANSPORTATION…2338

PRECAUTIONS WHEN TRANSPORTING…2338

STEPS FOR TRANSPORTATION…2338

METHOD OF SECURING MACHINE…2339

METHOD OF LIFTING MACHINE…2340

COLD WEATHER OPERATION…2343

PRECAUTIONS FOR LOW TEMPERATURE…2343

PRECAUTIONS AFTER COMPLETION OF WORK…2345

AFTER COLD WEATHER…2345

LONG-TERM STORAGE…2346

BEFORE STORAGE…2346

DURING STORAGE…2346

AFTER STORAGE…2346

PRECAUTIONS BEFORE TRAVELING AFTER LONG-TERM STORAGE…2346

TROUBLESHOOTING…2347

AFTER RUNNING OUT OF FUEL…2347

IF TRANSMISSION HAS TROUBLE…2347

METHOD OF LOWERING DUMP BODY IN EMERGENCY…2348

METHOD OF TOWING MACHINE…2349

IF BATTERY IS DISCHARGED…2353

ACTION IF FIRE OCCURS…2357

OTHER TROUBLE…2358

MAINTENANCE…2365

GUIDES TO MAINTENANCE…2366

SECONDARY MATERIALS FOR OPERATION…2374

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC…2374

OUTLINE OF ELECTRIC SYSTEM…2378

WEAR PARTS…2379

WEAR PARTS LIST…2379

RECOMMENDED FUEL, COOLANT, AND LUBRICANT…2380

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…2381

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…2382

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…2383

TORQUE LIST…2383

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…2384

SAFETY CRITICAL PARTS…2384

MAINTENANCE SCHEDULE CHART…2385

MAINTENANCE SCHEDULE CHART…2385

SERVICE PROCEDURE…2387

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)…2387

WHEN REQUIRED…2388

CHECK BEFORE STARTING…2413

EVERY 250 HOURS SERVICE…2414

EVERY 500 HOURS SERVICE…2428

EVERY 1000 HOURS SERVICE…2438

EVERY 2000 HOURS SERVICE…2448

EVERY 4000 HOURS SERVICE…2451

EVERY 8000 HOURS SERVICE…2455

EVERY 15000 HOURS SERVICE…2456

SPECIFICATIONS…2457

SPECIFICATIONS…2458

ATTACHMENTS, OPTIONS…2459

SELECTING DUMP BODY…2460

HANDLING TACHOGRAPH (TCO20-90W)…2461

EXPLANATION OF COMPONENTS…2461

METHOD OF USE…2464

HANDLING AIR SUSPENSION SEAT…2468

OPERATOR'S SEAT ADJUSTMENT…2468

REMOVAL AND INSTALLATION OF HEADREST…2472

HANDLING AUTOMATIC SPIN REGULATOR (ASR)…2473

EXPLANATION OF COMPONENTS…2473

ACTUATION OF ASR SYSTEM…2474

PRECAUTION WHEN USING ASR SYSTEM…2474

TROUBLESHOOTING…2475

BLEEDING AIR FROM ASR CIRCUIT…2476

HANDLING ANTI SKID BRAKE SYSTEM (ABS)…2477

EXPLANATION OF COMPONENTS…2477

ABS SYSTEM CHECK AFTER STARTING ENGINE…2478

OPERATION OF ABS…2479

PRECAUTION WHEN USING ABS SYSTEM…2479

TROUBLESHOOTING…2480

HANDLING PAYLOAD METER (VHMS BUILT-IN TYPE)…2481

OUTLINE OF SYSTEM…2481

NORMAL OPERATION DISPLAY…2482

EXTERNAL DISPLAY LAMPS…2484

PERFORMING CALIBRATION…2485

DATA STORED IN PAYLOAD METER…2487

PROCEDURE WHEN DOWNLOADING…2488

MACHINE ID, OPEN ID…2492

PAYLOAD (CYCLE DATA ITEM)…2494

SERVICE FUNCTIONS…2494

OTHERS…2494

HANDLING PAYLOAD METER II (CARD TYPE)…2495

METHOD OF USING ACCURATELY…2496

GENERAL LOCATIONS…2497

CONTENT OF DISPLAY (CONTROLLER, EXTERNAL DISPLAY LAMPS)…2502

EXTERNAL DISPLAY LAMPS…2506

DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER…2508

OPERATION OF SWITCHES…2513

PROBLEM AND WARNING DISPLAY (ERROR CODE)…2535

WHEN ERROR CODE F-09 IS DISPLAYED (PROCEDURE FOR REPLACING BATTERY)…2542

OPERATION WHEN ERROR CODE F.CAL IS DISPLAYED OR CONTROLLER HAS BEEN REPLACED…2545

USE OF REAR VIEW MONITOR…2548

NAME AND FUNCTON OF EACH PART OF REAR VIEW MONITOR…2548

SETTING OF REAR VIEW MONITOR…2551

CAUTIONS WHEN USING REAR VIEW MONITOR…2551

HANDLING DUMPING COUNTER…2552

HANDLING BATTERY ISOLATOR…2553

HANDLING MACHINES EQUIPPED WITH VHMS…2555

VHMS INSTALLED, COMMUNICATIONS TERMINAL NOT INSTALLED…2555

VHMS AND COMMUNICATIONS TERMINAL INSTALLED…2555

PROCEDURE WHEN DOWNLOADING…2556

CHECK BEFORE STARTING…2556

INDEX…2559

TEN00370-03 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual…2563

COVER…2563

FOREWORD…2564

BEFORE READING THIS MANUAL…2565

SAFETY INFORMATION…2566

INTENDED USE…2567

USE OF MACHINE…2567

GENERAL VIEW AND DIRECTIONS OF MACHINE…2567

VISIBILITY FROM OPERATOR'S SEAT…2567

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…2568

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…2568

EPA REGULATIONS, ENGINE NUMBER PLATE…2568

SERVICE METER POSITION…2569

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…2569

CONTENTS…2570

SAFETY…2574

IMPORTANT SAFETY INFORMATION…2575

SAFETY LABELS…2578

POSITION FOR ATTACHING SAFETY LABELS…2579

SAFETY LABELS…2580

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE…2585

PRECAUTIONS BEFORE STARTING OPERATION…2585

PREPARATIONS FOR SAFE OPERATION…2585

FIRE PREVENTION…2587

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE…2588

DO NOT GET CAUGHT IN DUMP BODY…2590

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES…2590

UNAUTHORIZED MODIFICATION…2590

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…2591

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING…2591

PRECAUTIONS FOR OPERATION…2592

PRECAUTIONS FOR JOBSITE…2592

STARTING ENGINE…2594

OPERATION…2596

TRANSPORTATION…2600

TOWING…2601

PRECAUTIONS FOR MAINTENANCE…2602

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE…2602

PRECAUTIONS FOR INSPECTION AND MAINTENANCE…2606

TIRES…2611

OPERATION…2614

GENERAL VIEW…2615

GENERAL VIEW OF MACHINE…2615

GENERAL VIEW OF CONTROLS AND GAUGES…2616

DASHBOARD…2617

EXPLANATION OF COMPONENTS…2618

GENERAL VIEW OF MACHINE…2618

OPERATOR'S CAB…2621

CONTROL LEVERS AND PEDALS…2623

MACHINE MONITOR…2628

DISPLAY OF CHARACTER DISPLAY…2641

OTHER FUNCTIONS OF CHARACTER DISPLAY…2645

SWITCHES…2649

BODY PIVOT PIN…2659

LOCATION OF FIRE EXTINGUISHER…2660

DUST INDICATOR…2660

FUSES…2661

CAR RADIO…2664

CAR STEREO…2666

AIR CONDITIONER…2671

OPERATION…2676

CHECK BEFORE STARTING ENGINE…2676

STARTING ENGINE…2702

OPERATIONS, CHECKS AFTER STARTING ENGINE…2705

STOPPING ENGINE…2706

MOVING MACHINE OFF (FORWARD, REVERSE), STOPPING…2707

SHIFTING GEAR…2713

TRAVELING DOWNHILL…2715

STEERING THE MACHINE…2728

LOADING OPERATIONS…2728

DUMP OPERATIONS…2729

PRECAUTIONS FOR OPERATION…2731

PARKING MACHINE…2732

CHECKS AFTER COMPLETION OF WORK…2732

CHECKS AFTER STOPPING ENGINE…2733

LOCKING…2733

HANDLING TIRES…2734

DETERMINING AND MAINTAINING TRAVEL ROAD…2738

DETERMINING TRAVEL ROAD…2738

MAINTAINING TRAVEL ROAD…2738

WORKSITE…2739

EXAMINATION AN CONFIRMATION OF WORKSITE…2739

WORKING ON LOOSE GROUND…2739

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLE…2740

ENSURE GOOD VISIBILITY…2740

CONFIRMATION OF MARK…2740

TRANSPORTATION…2741

PRECAUTIONS WHEN TRANSPORTING…2741

STEPS FOR TRANSPORTATION…2741

METHOD OF SECURING MACHINE…2742

METHOD OF LIFTING MACHINE…2743

COLD WEATHER OPERATION…2746

PRECAUTIONS FOR LOW TEMPERATURE…2746

PRECAUTIONS AFTER COMPLETION OF WORK…2748

AFTER COLD WEATHER…2748

LONG-TERM STORAGE…2749

BEFORE STORAGE…2749

DURING STORAGE…2749

AFTER STORAGE…2749

PRECAUTIONS BEFORE TRAVELING AFTER LONG-TERM STORAGE…2749

TROUBLESHOOTING…2750

AFTER RUNNING OUT OF FUEL…2750

IF TRANSMISSION HAS TROUBLE…2750

METHOD OF LOWERING DUMP BODY IN EMERGENCY…2751

METHOD OF TOWING MACHINE…2752

IF BATTERY IS DISCHARGED…2756

ACTION IF FIRE OCCURS…2760

OTHER TROUBLE…2761

MAINTENANCE…2768

GUIDES TO MAINTENANCE…2769

SECONDARY MATERIALS FOR OPERATION…2777

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC…2777

OUTLINE OF ELECTRIC SYSTEM…2781

WEAR PARTS…2782

WEAR PARTS LIST…2782

RECOMMENDED FUEL, COOLANT, AND LUBRICANT…2783

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…2784

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…2785

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…2786

TORQUE LIST…2786

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…2787

SAFETY CRITICAL PARTS…2787

MAINTENANCE SCHEDULE CHART…2788

MAINTENANCE SCHEDULE CHART…2788

SERVICE PROCEDURE…2790

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)…2790

WHEN REQUIRED…2791

CHECK BEFORE STARTING…2816

EVERY 250 HOURS SERVICE…2817

EVERY 500 HOURS SERVICE…2831

EVERY 1000 HOURS SERVICE…2841

EVERY 2000 HOURS SERVICE…2850

EVERY 4000 HOURS SERVICE…2853

EVERY 8000 HOURS SERVICE…2857

EVERY 15000 HOURS SERVICE…2858

SPECIFICATIONS…2860

SPECIFICATIONS…2861

ATTACHMENTS, OPTIONS…2862

SELECTING DUMP BODY…2863

HANDLING TACHOGRAPH (TCO20-90W)…2864

EXPLANATION OF COMPONENTS…2864

METHOD OF USE…2867

HANDLING AIR SUSPENSION SEAT…2871

OPERATOR'S SEAT ADJUSTMENT…2871

REMOVAL AND INSTALLATION OF HEADREST…2875

HANDLING AUTOMATIC SPIN REGULATOR (ASR)…2876

EXPLANATION OF COMPONENTS…2876

ACTUATION OF ASR SYSTEM…2877

PRECAUTION WHEN USING ASR SYSTEM…2877

TROUBLESHOOTING…2878

BLEEDING AIR FROM ASR CIRCUIT…2879

HANDLING ANTI SKID BRAKE SYSTEM (ABS)…2880

EXPLANATION OF COMPONENTS…2880

ABS SYSTEM CHECK AFTER STARTING ENGINE…2881

OPERATION OF ABS…2882

PRECAUTION WHEN USING ABS SYSTEM…2882

TROUBLESHOOTING…2883

HANDLING PAYLOAD METER (VHMS BUILT-IN TYPE)…2884

OUTLINE OF SYSTEM…2884

NORMAL OPERATION DISPLAY…2885

EXTERNAL DISPLAY LAMPS…2887

PERFORMING CALIBRATION…2888

DATA STORED IN PAYLOAD METER…2890

PROCEDURE WHEN DOWNLOADING…2891

MACHINE ID, OPEN ID…2895

PAYLOAD (CYCLE DATA ITEM)…2897

SERVICE FUNCTIONS…2897

OTHERS…2897

HANDLING PAYLOAD METER II (CARD TYPE)…2898

METHOD OF USING ACCURATELY…2899

GENERAL LOCATIONS…2900

CONTENT OF DISPLAY (CONTROLLER, EXTERNAL DISPLAY LAMPS)…2905

EXTERNAL DISPLAY LAMPS…2909

DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER…2911

OPERATION OF SWITCHES…2916

PROBLEM AND WARNING DISPLAY (ERROR CODE)…2938

WHEN ERROR CODE F-09 IS DISPLAYED (PROCEDURE FOR REPLACING BATTERY)…2945

OPERATION WHEN ERROR CODE F.CAL IS DISPLAYED OR CONTROLLER HAS BEEN …2948

USE OF REAR VIEW MONITOR…2951

NAME AND FUNCTON OF EACH PART OF REAR VIEW MONITOR…2951

SETTING OF REAR VIEW MONITOR…2954

CAUTIONS WHEN USING REAR VIEW MONITOR…2954

EXTERNAL POWER SOURCE TYPE ELECTRIC HEATER…2955

SOCKET FOR ENGINE HEATER…2955

CONNECTING EXTERNAL POWER SOURCE…2955

RESTARTING ENGINE…2956

HANDLING EXTERNAL POWER SOURCE TYPE ELECTRIC HEATER…2957

HANDLING DUMPING COUNTER…2963

HANDLING BATTERY ISOLATOR…2964

HANDLING MACHINES EQUIPPED WITH VHMS…2966

VHMS INSTALLED, COMMUNICATIONS TERMINAL NOT INSTALLED…2966

VHMS AND COMMUNICATIONS TERMINAL INSTALLED…2966

PROCEDURE WHEN DOWNLOADING…2967

CHECK BEFORE STARTING…2967

INDEX…2970

TEN00439-07 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual…2974

COVER…2974

FOREWORD…2975

BEFORE READING THIS MANUAL…2976

SAFETY INFORMATION…2977

INTENDED USE…2978

USE OF MACHINE…2978

GENERAL VIEW AND DIRECTIONS OF MACHINE…2978

VISIBILITY FROM OPERATOR'S SEAT…2979

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…2980

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…2980

EPA REGULATIONS, ENGINE NUMBER PLATE…2980

SERVICE METER POSITION…2981

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…2981

CONTENTS…2982

SAFETY…2987

IMPORTANT SAFETY INFORMATION…2988

SAFETY LABELS…2991

POSITION FOR ATTACHING SAFETY LABELS…2992

SAFETY LABELS…2993

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE…2998

PRECAUTIONS BEFORE STARTING OPERATION…2998

PREPARATIONS FOR SAFE OPERATION…2998

FIRE PREVENTION…3000

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE…3001

DO NOT GET CAUGHT IN DUMP BODY…3003

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES…3003

UNAUTHORIZED MODIFICATION…3003

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…3004

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING…3004

PRECAUTIONS FOR OPERATION…3005

PRECAUTIONS FOR JOBSITE…3005

STARTING ENGINE…3007

OPERATION…3009

TRANSPORTATION…3013

TOWING…3014

PRECAUTIONS FOR MAINTENANCE…3015

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE…3015

PRECAUTIONS FOR INSPECTION AND MAINTENANCE…3019

TIRES…3024

OPERATION…3027

GENERAL VIEW…3028

GENERAL VIEW OF MACHINE…3028

GENERAL VIEW OF CONTROLS AND GAUGES…3029

DASHBOARD…3030

EXPLANATION OF COMPONENTS…3031

GENERAL VIEW OF MACHINE…3031

OPERATOR'S CAB…3034

CONTROL LEVERS AND PEDALS…3036

MACHINE MONITOR…3042

DISPLAY OF CHARACTER DISPLAY…3055

OTHER FUNCTIONS OF CHARACTER DISPLAY…3059

SWITCHES…3063

BODY PIVOT PIN…3073

LOCATION OF FIRE EXTINGUISHER…3074

DUST INDICATOR…3074

FUSES…3075

CAR RADIO…3078

CAR STEREO…3080

AIR CONDITIONER…3085

OPERATION…3090

CHECK BEFORE STARTING ENGINE…3090

STARTING ENGINE…3117

OPERATIONS, CHECKS AFTER STARTING ENGINE…3120

STOPPING ENGINE…3121

MOVING MACHINE OFF (FORWARD, REVERSE), STOPPING…3122

SHIFTING GEAR…3128

TRAVELING DOWNHILL…3130

STEERING THE MACHINE…3143

LOADING OPERATIONS…3143

DUMP OPERATIONS…3144

PRECAUTIONS FOR OPERATION…3146

PARKING MACHINE…3147

CHECKS AFTER COMPLETION OF WORK…3147

CHECKS AFTER STOPPING ENGINE…3148

LOCKING…3148

HANDLING TIRES…3149

DETERMINING AND MAINTAINING TRAVEL ROAD…3153

DETERMINING TRAVEL ROAD…3153

MAINTAINING TRAVEL ROAD…3153

WORKSITE…3154

EXAMINATION AN CONFIRMATION OF WORKSITE…3154

WORKING ON LOOSE GROUND…3154

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLE…3155

ENSURE GOOD VISIBILITY…3155

CONFIRMATION OF MARK…3155

TRANSPORTATION…3156

PRECAUTIONS WHEN TRANSPORTING…3156

STEPS FOR TRANSPORTATION…3156

METHOD OF SECURING MACHINE…3157

METHOD OF LIFTING MACHINE…3158

COLD WEATHER OPERATION…3161

PRECAUTIONS FOR LOW TEMPERATURE…3161

PRECAUTIONS AFTER COMPLETION OF WORK…3163

AFTER COLD WEATHER…3163

LONG-TERM STORAGE…3164

BEFORE STORAGE…3164

DURING STORAGE…3164

AFTER STORAGE…3164

PRECAUTIONS BEFORE TRAVELING AFTER LONG-TERM STORAGE…3164

TROUBLESHOOTING…3165

AFTER RUNNING OUT OF FUEL…3165

IF TRANSMISSION HAS TROUBLE…3165

METHOD OF LOWERING DUMP BODY IN EMERGENCY…3166

METHOD OF TOWING MACHINE…3167

IF BATTERY IS DISCHARGED…3171

ACTION IF FIRE OCCURS…3175

OTHER TROUBLE…3176

MAINTENANCE…3183

GUIDES TO MAINTENANCE…3184

SECONDARY MATERIALS FOR OPERATION…3192

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC…3192

OUTLINE OF ELECTRIC SYSTEM…3196

WEAR PARTS…3197

WEAR PARTS LIST…3197

RECOMMENDED FUEL, COOLANT, AND LUBRICANT…3198

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…3199

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…3200

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…3201

TORQUE LIST…3201

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…3202

SAFETY CRITICAL PARTS…3202

MAINTENANCE SCHEDULE CHART…3203

MAINTENANCE SCHEDULE CHART…3203

SERVICE PROCEDURE…3205

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)…3205

WHEN REQUIRED…3206

CHECK BEFORE STARTING…3231

EVERY 250 HOURS SERVICE…3232

EVERY 500 HOURS SERVICE…3245

EVERY 1000 HOURS SERVICE…3255

EVERY 2000 HOURS SERVICE…3264

EVERY 4000 HOURS SERVICE…3268

EVERY 8000 HOURS SERVICE…3272

EVERY 15000 HOURS SERVICE…3273

SPECIFICATIONS…3275

SPECIFICATIONS…3276

ATTACHMENTS, OPTIONS…3279

SELECTING DUMP BODY…3280

HANDLING TACHOGRAPH (TCO20-90W)…3281

EXPLANATION OF COMPONENTS…3281

METHOD OF USE…3283

HANDLING AIR SUSPENSION SEAT…3287

OPERATOR'S SEAT ADJUSTMENT…3287

REMOVAL AND INSTALLATION OF HEADREST…3291

HANDLING AUTOMATIC SPIN REGULATOR (ASR)…3292

EXPLANATION OF COMPONENTS…3292

ACTUATION OF ASR SYSTEM…3293

PRECAUTION WHEN USING ASR SYSTEM…3293

TROUBLESHOOTING…3294

BLEEDING AIR FROM ASR CIRCUIT…3295

HANDLING ANTI SKID BRAKE SYSTEM (ABS)…3296

EXPLANATION OF COMPONENTS…3296

ABS SYSTEM CHECK AFTER STARTING ENGINE…3297

OPERATION OF ABS…3298

PRECAUTION WHEN USING ABS SYSTEM…3298

TROUBLESHOOTING…3299

HANDLING PAYLOAD METER (KOMTRAX Plus BUILT-IN TYPE)…3300

OUTLINE OF SYSTEM…3300

NORMAL OPERATION DISPLAY…3301

EXTERNAL DISPLAY LAMPS…3303

PERFORMING CALIBRATION…3304

DATA STORED IN PAYLOAD METER…3305

PROCEDURE WHEN DOWNLOADING…3307

MACHINE ID, OPEN ID…3311

PAYLOAD (CYCLE DATA ITEM)…3313

SERVICE FUNCTIONS…3313

OTHERS…3313

HANDLING PAYLOAD METER II (CARD TYPE)…3314

METHOD OF USING ACCURATELY…3315

GENERAL LOCATIONS…3316

CONTENT OF DISPLAY (CONTROLLER, EXTERNAL DISPLAY LAMPS)…3321

EXTERNAL DISPLAY LAMPS…3325

DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER…3327

OPERATION OF SWITCHES…3332

PROBLEM AND WARNING DISPLAY (ERROR CODE)…3353

WHEN ERROR CODE F-09 IS DISPLAYED (PROCEDURE FOR REPLACING BATTERY)…3360

OPERATION WHEN ERROR CODE F.CAL IS DISPLAYED OR CONTROLLER HAS BEEN REPLACED…3363

USE OF REAR VIEW MONITOR…3366

NAME AND FUNCTON OF EACH PART OF REAR VIEW MONITOR…3366

SETTING OF REAR VIEW MONITOR…3369

CAUTIONS WHEN USING REAR VIEW MONITOR…3369

EXTERNAL POWER SOURCE TYPE ELECTRIC HEATER…3370

SOCKET FOR ENGINE HEATER…3370

CONNECTING EXTERNAL POWER SOURCE…3370

RESTARTING ENGINE…3371

HANDLING DUMPING COUNTER…3378

HANDLING BATTERY ISOLATOR…3379

HANDLING MACHINES EQUIPPED WITH KOMTRAX Plus…3381

KOMTRAX Plus INSTALLED, COMMUNICATIONS TERMINAL NOT INSTALLED…3381

KOMTRAX Plus AND COMMUNICATIONS TERMINAL INSTALLED…3381

PROCEDURE WHEN DOWNLOADING…3382

CHECK BEFORE STARTING…3383

INDEX…3387

Komatsu Dump Truck HD465-7E0, HD605-7E0 Repair Service Manuals