Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC12R-8, PC15R-8, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC12R-8, PC15R-8 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

WEBM000100 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual.pdf

WEBM000101 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual.pdf

WEBM002800 – Hydraulic Excavator PC15R-8 Shop Manual.pdf

SEBM013103 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual.pdf

SEAM015102T – Hydraulic Excavator PC12R-8, PC15R-8 Operation & Maintenance Manual.pdf

WEAM002702 – Hydraulic Excavator PC12R-8, PC12R-8 HS, PC15R-8, PC15R-8 HS Operation & Maintenance Manual.pdf

WEAM003000 – Hydraulic Excavator PC15R-8 Operation & Maintenance Manual.pdf

WEAM003001 – Hydraulic Excavator PC15R-8 Deluxe Operation & Maintenance Manual.pdf

Total Pages: 2,030 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

SEAM015102T – Hydraulic Excavator PC12R-8, PC15R-8 Operation & Maintenance Manual….2

COVER….2

1. FOREWORD….3

2. SAFETY INFORMATION….6

3. INTRODUCTION….7

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR….8

5. CONTENTS….9

SAFETY….13

6. GENERAL PRECAUTIONS ….14

7. PRECAUTIONS DURING OPERATION….19

7.1 BEFORE STARTING ENGINE….19

7.2 AFTER STARTING ENGINE….21

7.3 TRANSPORTATION….28

7.4 BATTERY….29

7.5 TOWING….31

8. PRECAUTIONS FOR MAINTENANCE….32

8.1 BEFORE CARRYING OUT MAINTENANCE….32

8.2 DURING MAINTENANCE….36

9. POSITION FOR ATTACHING SAFETY LABELS….41

OPERATION….44

10. GENERAL VIEW ….45

10.1 GENERAL VIEW OF MACHINE….45

10.2 GENERAL VIEW OF CONTROLS AND GAUGES….46

11. EXPLANATION OF COMPONENTS….47

11.1 MACHINE MONITOR….47

11.2 SWITCHES ….50

11.3 CONTROL LEVERS AND PEDALS….52

11.4 ENGINE HOOD….56

11.5 OPERATOR'S SEAT….57

11.6 MANUAL STORAGE SPACE・TOOL BOX….57

11.7 BATTERY HOOK….57

11.8 FRONT WINDOW (FOR MACHINE EQUIPPED WITH CAB (OPTION))….58

11.9 DOOR LOCK (FOR MACHINE EQUIPPED WITH CAB (OPTION))….60

11.10 HAMMER FOR EMERGENCY ESCAPE (FOR MACHINE EQUIPPED WITH CAB (OPTION))….61

11.11 CAP, COVER WITH LOCK….61

11.12 FUSE….63

11.13 FUSIBLE LINK….63

12. OPERATION….64

12.1 CHECK BEFORE STARTING ENGINE….64

12.2 STARTING ENGINE….71

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE….74

12.4 MOVING MACHINE OFF….76

12.5 STEERING MACHINE….79

12.6 STOPPING MACHINE….81

12.7 SWINGING….82

12.8 OPERATION OF WORK EQUIPMENT….83

12.9 PROHIBITIONS FOR OPERATION….84

12.10 PRECAUTIONS FOR OPERATION….87

12.11 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS….88

12.12 HOW TO ESCAPE FROM MUD….90

12.13 WORK POSSIBLE USING HYDRAULIC EXCAVATOR….91

12.14 REPLACEMENT OF BUCKET….93

12.15 PARKING MACHINE….94

12.16 CHECK AFTER FINISHING WORK….95

12.17 STOPPING ENGINE….95

12.18 CHECK AFTER STOPPING ENGINE….96

12.19 LOCKING….96

12.20 HANDLING RUBBER SHOES (RUBBER SHOES ONLY)….97

13. TRANSPORTATION….103

13.1 LOADING, UNLOADING WORK….103

13.2 PRECAUTIONS FOR LOADING….105

13.3 PRECAUTIONS FOR TRANSPORTATION….105

13.4 METHOD OF LIFTING MACHINE….106

14. COLD WEATHER OPERATION….107

14.1 PRECAUTIONS FOR LOW TEMPERATURE….107

14.2 PRECAUTIONS AFTER COMPLETION OF WORK….109

14.3 AFTER COLD WEATHER….109

15. LONG-TERM STORAGE….110

15.1 BEFORE STORAGE….110

15.2 DURING STORAGE….111

15.3 AFTER STORAGE….111

16. TROUBLESHOOTING….112

16.1 PHENOMENA THAT ARE NOT FAILURES….112

16.2 METHOD OF TOWING MACHINE….112

16.3 IF BATTERY IS DISCHARGED….113

16.4 OTHER TROUBLE….118

MAINTENANCE….122

17. GUIDES TO MAINTENANCE….123

18. OUTLINES OF SERVICE….125

18.1 OUTLINE OF OIL,FUEL,COOLANT….125

18.2 OUTLINE OF ELECTRIC SYSTEM….128

18.3 OUTLINE OF HYDRAULIC SYSTEM….128

19. WEAR PARTS LIST….129

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE….130

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS….134

21.1 INTRODUCTION OF NECESSARY TOOLS….134

21.2 TORQUE LIST….135

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS….136

23. MAINTENANCE SCHEDULE CHART….138

23.1 MAINTENANCE SCHEDULE CHART….138

23.2 MAINTENANCE INTERVAL WHEN USING HYDRAULIC BREAKER….140

24. SERVICE PROCEDURE….141

24.1 INITIAL 250 HOURS SERVICE….141

24.2 WHEN REQUIRED….142

24.3 CHECK BEFORE STARTING….160

24.4 EVERY 100 HOURS SERVICE….164

24.5 EVERY 250 HOURS SERVICE….165

24.6 EVERY 500 HOURS SERVICE….170

24.7 EVERY 1000 HOURS SERVICE….175

24.8 EVERY 2000 HOURS SERVICE….176

SPECIFICATIONS….179

25. SPECIFICATIONS….180

OPTIONS, ATTACHMENTS….186

26. GENERAL PRECAUTIONS….187

26.1 PRECAUTIONS RELATED TO SAFETY….187

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS….188

27. USING SEAT BELT….189

27.1 SEAT BELT….189

28. HANDLING BUCKET WITH HOOK….191

28.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK….191

28.2 PROHIBITED OPERATIONS….191

28.3 PRECAUTIONS DURING OPERATIONS….191

29. HANDLING 2-WAY PIPING….192

29.1 SWITCHING BETWEEN 1-WAY AND 2-WAY….192

29.2 OPERATING PEDAL….192

30. INTRODUCTION OF OPTIONAL PARTS AND ATTACHMENTS….193

30.1 INTRODUCTION OF OPTIONAL PARTS AND ATTACHMENTS….193

30.2 SELECTION OF TRACK SHOES (STEEL SHOE)….194

30.3 COMBINATIONS TABLE OF ATTACHMENTS….195

30.4 PRECAUTIONS FOR OPERATING WITH HYDRAULIC BREAKER….196

30.5 OPERATION OF QUICK BREAKER ARM….199

SEBM013103 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual….214

COVER….214

CONTENTS….215

SAFETY….218

00 FOREWORD….220

01 GENERAL….238

General assembly drawing….239

Specifications….243

List of lubricant and water….247

10 STRUCTURE AND FUNCTION….248

Power Train….249

Swing circle….250

Track frame and recoil spring….251

Hydraulic piping….252

Hydraulic tank….253

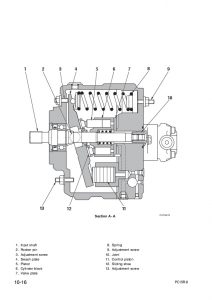

Hydraulic pump….254

Control valve (PC12R-8)….258

CLSS (PC12R-8)….266

Control valve (PC15R-8)….289

CLSS (PC15R-8)….297

Center swivel joint….318

Swing motor….320

Travel motor….322

Valve control….325

PPC valve….326

Work equipment….330

Machine monitor system….331

20 TESTING AND ADJUSTING….334

STANDARD VALUE TABLE….335

Standard value table for engine related parts….335

Standard value table for chassis related parts….337

Standard value table for electrical parts….351

TESTING AND ADJUSTING….353

Tools for testing, adjusting, and troubleshooting….354

Measuring engine speed….355

Measuring exhaust color….356

Adjusting valve clearance….357

Measuring compression pressure….358

Testing and adjusting fuel injection timing….359

Measuring engine oil pressure….360

Testing and adjusting fan belt tension….361

Testing and adjusting fuel control lever….362

Measuring sprocket wear….363

Testing and adjusting track shoe tension….364

Testing and adjusting hydraulic pressure in work equipment, swing, travel circuit ….365

Testing and adjusting LS differential pressure….371

Adjusting PC valve spring….373

Testing and adjusting control circut pressure….374

Measuring output pressure of PPC lock valve and travel boost valve….376

Testing PPC valve output pressure and swing holding brake inlet port pressure….377

Adjusting work equipment, swing PPC valve ….379

Testing and adjusting travel deviation….380

Measuring oil leakage inside work equipment cylinder….381

Releasing remaining pressure from hydraulic circuit….382

Releasing remaining pressure from hydraulic tank ….382

Pressurizing hydraulic tank….382

Bleeding air….383

TROUBLESHOOTING….385

Type of connector and position of installation….386

Connection table for connector pin numbers ….389

Troubleshooting of engine electrical system (E mode)….399

E-Mode related electrical circuit diagram….400

E-1 Engine does not start….401

a) When starting motor does not turn (starting system)….401

b) When starting motor turns (engine stop solenoid system)….403

E-2 Engine does not stop….405

Troubleshooting of hydraulic, mechanical system (H mode)….406

Table of failure modes and causes….407

H- 1 Speeds of all work equipment, swing, travel are slow or lack power….411

H- 2 There is excessive drop in engine speed, or engine stalls….413

H- 3 No work equipment, travel, swing move….414

H- 4 Abnormal noise generated (from around pump)….415

H- 5 Fine control ability is poor or response is poor (PC15R)….415

H- 6 Boom is slow or lacks power….416

H- 7 Arm is slow or lacks power….416

H- 8 Bucket is slow or lacks power….417

H- 9 Boom swing is slow or lacks power….417

H-10 Blade is slow or lacks power….418

H-11 Boom, arm, bucket do not move (boom swing, blade, travel and swing are normal)….418

H-12 Excessive hydraulic drift (boom, arm, bucket, boom swing, blade)….419

a) Boom, bucket, boom swing, blade….419

b) Arm….419

H-13 Excessive time lag (engine at low idling)….419

a) Boom, arm….419

b) Bucket….419

H-14 In compound operations, work equipment with larger load is slow….420

H-15 Travel deviation….421

a) Deviation in normal travel….421

b) Deviation when starting….421

H-16 Travel speed is slow or lacks power….422

H-17 Steering does not turn easily….422

H-18 Travel speed does not switch….423

H-19 Travel does not move (one side only)….423

H-20 Swing speed is slow or lacks power….424

a) Speed is slow or lacks power in both directions….424

b) Speed is slow or lacks power in one direction only (left or right)….424

H-21 Does not swing….425

a) Does not swing in either direction….425

b) Does not swing in one direction (left or right)….425

H-22 Swing acceleration is poor….426

a) Acceleration is poor in both directions….426

b) Acceleration is poor in one direction only (left or right)….426

H-23 Excessive overrun when stopping swing….427

a) Overrun when stopping is excessive in both directions….427

b) Overrun when stopping is excessive in one direction only (left or right)….427

H-24 Excessive shock when stopping swing (in one direction only)….427

H-25 Excessive abnormal noise when stopping swing….428

H-26 Excessive hydraulic drift of swing….428

Troubleshooting of machine monitor system (M mode)….429

Electrical circuit diagram for M Mode related parts….430

M-1 Abnormality in engine oil pressure caution lamp system….431

a) Lamp does not light up when starting switch is turned ON….431

b) Lamp lights up when engine is running (engine oil pressure is normal)….431

M-2 Abnormality in charge caution lamp system….433

a) Lamp does not light up when starting switch is turned ON….433

b) Lamp lights up when engine is running (battery charge is normal)….433

M-3 Abnormality in engine water temperature caution lamp system….435

a) Lamp does not stay lighted up for 3 seconds when starting switch is turned ON….435

b) Lamp does not go out after starting switch has been at ON for 3 seconds….435

c) Lamp lights up when engine is running (engine water temperature is normal)….436

M-4 Abnormality in preheating pilot lamp….437

a) Lamp does not light up when starting switch is turned to HEAT….437

b) Lamp does not go out when starting switch is at HEAT and preheating time (approx. 18 sec.) is completed….437

c) Lamp lights up when starting switch is at position other than HEAT….438

M-5 Abnormality in fuel gauge system….439

a) Gauge does not go up from E when fuel is added to fuel tank….439

b) Gauge does not go down from F even when there is no fuel in fuel tank….439

c) Fuel level does not match gauge display….440

M-6 Abnormality in service meter system….441

a) Service meter does not advance when starting switch is at ON….441

b) Service meter advances when starting switch is at OFF….441

c) Pilot lamp does not flash when service meter is advancing….441

M-7 Abnormality in night lighting system….443

a) Night lighting does not light up when lamp switch is turned ON….443

b) Night lighting lights up when lamp switch is turned OFF ….443

30 DISASSEMBLY AND ASSEMBLY….445

Method of using manual….447

Precautions when carrying out operation….448

Special tool list….450

Starting motor….451

Removal and installation….451

Alternator ….452

Removal and installation….452

Fuel injection pump ….453

Removal and installation….453

Nozzle holder ….454

Removal and installation….454

Water pump ….455

Removal and installation….455

Thermostat ….456

Removal and installation….456

Engine front seal….457

Removal and installation….457

Engine rear seal….458

Removal….458

Installation….459

Cylinder head….460

Removal….460

Installation….461

Radiator….462

Removal….462

Installation….463

Engine, hydraulic pump….464

Removal….445

Installation….466

Fuel tank….467

Removal and installation….467

Damper….468

Removal and installation….468

Center swivel joint….469

Removal and installation….469

Disassembly and assembly….470

Travel motor….471

Removal and installation….471

Sprocket….472

Removal and installation….472

Swing motor….473

Removal and installation….473

Revolving frame….474

Removal….474

Installation….475

Swing circle….476

Removal and installation….476

Idler….477

Removal and installation….477

Disassembly….478

Assembly….479

Idler cushion (rubber shoe)….480

Removal and installation….480

Disassembly and assembly….481

Idler cushion (steel shoe)….482

Disassembly….445

Assembly….483

Track roller….484

Removal and installation….484

Disassembly and assembly….485

Rubber shoe….486

Removal and installation….486

Steel shoe….487

Removal and installation….487

Hydraulic tank….488

Removal….488

Installation….489

Hydraulic oil cooler….490

Removal and installation….490

Hydraulic pump….491

Removal and installation….491

Control valve….492

Removal….492

Installation….493

Disassembly….494

Assembly….499

PPC valve….506

Removal and installation….506

Disassembly….507

Assembly….508

Boom cylinder….509

Removal….509

Installation….510

Arm cylinder….511

Removal….511

Installation….512

Bucket cylinder….513

Removal….513

Installation….514

Swing cylinder….515

Removal….515

Installation….516

Blade cylinder….517

Removal and installation….517

Hydraulic cylinder….518

Disassembly….518

Assembly….521

Work equipment….525

Removal….525

Installation….526

Bucket….527

Removal and installation….527

Arm….528

Removal….528

Installation….529

Bucket, arm….530

Removal….530

Installation….531

Boom….532

Removal ….532

Installation….533

Swing bracket….534

Removal….534

Installation….535

Blade….536

Removal and installation….536

Canopy….537

Removal and installation….537

40 MAINTENANCE STANDARD….538

Swing circle….539

Track frame, recoil spring….540

Idler….541

Track roller….542

Track shoe….543

Hydraulic pump (PC15R-8)….545

Control valve (PC12R-8)….546

Control valve (PC15R-8)….552

Center swivel joint….558

Swing motor….559

PPC valve….560

Hydraulic cylinder….561

Work equipment….563

90 OTHERS….565

Hydraulic circuit diagram PC12R-8….566

Hydraulic circuit diagram PC15R-8….567

Electric circuit diagram PC12R,15R-8….568

WEAM002702 – Hydraulic Excavator PC12R-8, PC12R-8 HS, PC15R-8, PC15R-8 HS Operation & Maintenance Manual….569

1.1 FOREWORD….571

1.2 INFORMATION ON SAFETY….572

1.3 INTRODUCTION….574

1.3.1 INTENDED USES….574

1.3.2 IMPROPER OR UNAUTHORIZED USES….574

1.3.3 MAIN CHARACTERISTICS….575

1.3.4 RUNNING-IN….575

1.4 PRODUCT IDENTIFICATION….576

1.4.1 MACHINE SERIAL NUMBER….576

1.4.2 MACHINE IDENTIFICATION PLATE….576

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE….577

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER….577

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER….578

1.4.6 CAB SERIAL NUMBER….578

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS….579

TABLE OF CONTENTS….581

1.1 FOREWORD 1….581

1.2 INFORMATION ON SAFETY 2….581

1.3 INTRODUCTION 4….581

1.3.1 INTENDED USES 4….581

1.3.2 IMPROPER OR UNAUTHORIZED USES 4….581

1.3.3 MAIN CHARACTERISTICS 5….581

1.3.4 RUNNING-IN 5….581

1.4 PRODUCT IDENTIFICATION 6….581

1.4.1 MACHINE SERIAL NUMBER 6….581

1.4.2 MACHINE IDENTIFICATION PLATE 6….581

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE 7….581

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER 7….581

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER 8….581

1.4.6 CAB SERIAL NUMBER 8….581

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS 9….581

2.1 SAFETY, NOISE AND VIBRATION PLATES 20….581

2.1.1 POSITION OF THE SAFETY PLATES 20….581

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS 22….581

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB 26….581

2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY 27….581

2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED 28….581

2.2 GENERAL PRECAUTIONS 29….581

2.2.1 GENERAL SAFETY RULES 29….581

2.2.2 SAFETY DEVICES AND GUARDS 29….581

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS 29….581

2.2.4 UNAUTHORIZED MODIFICATIONS 30….581

2.2.5 LEAVING THE OPERATOR’S SEAT 30….581

2.2.6 GETTING ON AND OFF THE MACHINE 31….581

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL 31….581

2.2.8 PREVENTING BURNS 32….581

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER 32….581

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT 32….581

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT 33….581

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE 33….581

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT 33….581

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE 34….581

2.3.1 SAFETY ON THE WORK SITE 34….581

2.3.2 FIRE PREVENTION 34….581

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB 34….581

2.3.4 ROOM VENTILATION 35….581

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS 35….581

2.3.6 CLEANING THE WINDOWS – CHECKING THE WINDSHIELD WIPER BLADES 35….581

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING 36….582

2.4.1 STARTING THE ENGINE 36….582

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE 36….582

2.4.3 CHECKS FOR TRAVELLING IN REVERSE 36….582

2.4.4 MOVING THE MACHINE 37….582

2.4.5 MOVING ON SLOPES 38….582

2.4.6 WORKING ON SLOPES 39….582

2.4.7 UNAUTHORIZED OPERATIONS 39….582

2.4.8 PREVENTING ELECTROCUTION 40….582

2.4.9 VISIBILITY 41….582

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES 41….582

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT 41….582

2.4.12 WORKING ON LOOSE GROUND 41….582

2.4.13 PARKING THE MACHINE 42….582

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES 43….582

2.5.1 LOADING AND UNLOADING 43….582

2.5.2 TRANSPORT 43….582

2.6 BATTERY 44….582

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY 44….582

2.6.2 STARTING WITH BOOSTER CABLES 44….582

2.7 PRECAUTIONS FOR THE REMOVAL 45….582

2.8 PRECAUTIONS FOR MAINTENANCE 46….582

2.8.1 WARNING PLATES 46….582

2.8.2 TOOLS 46….582

2.8.3 PERSONNEL 46….582

2.8.4 EQUIPMENT 47….582

2.8.5 WORKING UNDER THE MACHINE 47….582

2.8.6 CLEANING THE MACHINE 47….582

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS 48….582

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY 48….582

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION 48….582

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP 49….582

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR 49….582

2.8.12 USING LAMPS 49….582

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR 50….582

2.8.14 PRECAUTIONS CONCERNING THE STARTER 50….582

2.8.15 HANDLING HIGH-PRESSURE PIPES 51….582

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL 51….582

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE 51….582

2.8.18 COOLING FAN AND BELT 52….582

2.8.19 WASTE MATERIALS 52….582

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES 52….582

3.1 SAFETY LOCKS 54….583

3.1.1 MACHINE LOCKS 54….583

3.2 GENERAL VIEWS 55….583

3.2.1 FRONT GENERAL VIEW 55….583

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY 56….583

3.2.3 GENERAL VIEW OF THE DRIVER’S SEAT 57….583

3.3 INSTRUMENTS AND CONTROLS 58….583

3.3.1 INSTRUMENTS 58….583

3.3.2 WARNING LIGHTS 59….583

3.3.3 SWITCHES AND PUSH BUTTONS 61….583

3.3.4 ELECTRICAL ACCESSORIES 64….583

3.3.5 MACHINE CONTROLS 66….583

3.4 FUSES AND RELAYS 75….583

3.4.1 FUSES 75….583

3.4.2 RELAYS 76….583

3.5 GUARDS AND DRIVER’S SEAT 77….583

3.5.1 ENGINE HOOD 77….583

3.5.2 CANOPY 78….583

3.5.3 CAB 78….583

3.5.3.1 SLIDING DOOR 79….583

3.5.3.2 FRONT OPENING WINDSHIELD 80….583

3.5.3.3 FRONT WINDSHIELD (LOWER PART) 81….583

3.5.3.4 SIDE OPENING WINDOW 82….583

3.5.4 VENTILATION AND HEATING 83….583

3.5.5 SEAT 83….583

3.5.6 SAFETY BELT 84….583

3.5.7 EMERGENCY EXIT 84….583

3.5.8 TECHNICAL DOCUMENTATION CASE 85….583

3.5.9 FIRE EXTINGUISHER 85….583

3.5.10 FIRST AID KIT 85….583

3.6 USE OF THE MACHINE 87….583

3.6.1 CHECKS BEFORE STARTING THE ENGINE 87….583

3.6.1.1 VISUAL CHECKS 87….583

3.6.1.2 DAILY CHECKS 87….583

3.6.1.3 OPERATIONAL CHECKS 88….583

3.6.2 STARTING THE ENGINE 89….583

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES 89….583

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES 90….583

3.6.3 WARMING THE ENGINE 91….583

3.6.4 HEATING THE HYDRAULIC OIL 91….583

3.6.5 HOW TO MOVE THE MACHINE 91….583

3.6.5.1 STEERING (CHANGING DIRECTION) 93….583

3.6.5.2 MOVING ON SLOPES 94….583

3.6.5.3 MAXIMUM IMMERSION DEPTH 95….583

3.7 PARKING THE MACHINE 96….584

3.7.1 PARKING ON LEVEL GROUND 96….584

3.7.2 PARKING ON SLOPES 97….584

3.8 STOPPING THE ENGINE 98….584

3.9 TRANSPORTING THE MACHINE ON MOTOR VEHICLES 99….584

3.9.1 LOADING AND UNLOADING THE MACHINE 99….584

3.9.2 TRANSPORT 100….584

3.10 LIFTING THE MACHINE 101….584

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON 102….584

3.11.1 FUEL AND LUBRICANTS 102….584

3.11.2 COOLANT 102….584

3.11.3 BATTERY 102….584

3.11.4 OTHER PRECAUTIONS 103….584

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK 103….584

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON 104….584

3.13 USING THE WORK EQUIPMENT 105….584

3.13.1 ORGANIZING THE WORK AREA 105….584

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS 106….584

3.13.3 DIGGING METHOD 107….584

3.13.4 CHANGING THE BUCKET 108….584

3.14 USING THE MACHINE WITH VARIABLE TRACK GAUGE 109….584

3.14.1 HOW TO USE THE VARIABLE TRACK GAUGE 109….584

3.14.2 ADJUSTING THE BLADE 110….584

3.15 LONG PERIODS OF INACTIVITY 111….584

3.15.1 BEFORE THE PERIOD OF INACTIVITY 111….584

3.15.2 DURING THE PERIOD OF INACTIVITY 112….584

3.15.3 AFTER THE PERIOD OF INACTIVITY 112….584

3.16 TROUBLESHOOTING 113….584

3.16.1 OCCURRENCES THAT ARE NOT FAILURES 113….584

3.16.2 HOW TO REMOVE THE MACHINE 113….584

3.16.3 AFTER THE FUEL HAS RUN OUT 114….584

3.16.4 IF THE BATTERY IS DOWN 114….584

3.16.4.1 STARTING WITH BOOSTER CABLES 115….584

3.16.5 OTHER TROUBLES 116….584

3.16.5.1 ELECTRICAL CIRCUIT 116….584

3.16.5.2 HYDRAULIC SYSTEM 116….584

3.16.5.3 ENGINE 117….584

4.1 GUIDE TO MAINTENANCE 120….585

4.2 MAINTENANCE NOTES 122….585

4.2.1 NOTES REGARDING THE ENGINE 122….585

4.2.1.1 ENGINE OIL 122….585

4.2.1.2 COOLANT 122….585

4.2.1.3 FUEL 123….585

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM 123….585

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM 124….585

4.2.4 NOTES REGARDING LUBRICATION 124….585

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING 125….585

4.3 FUEL, COOLANT AND LUBRICANTS 126….585

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS 128….585

4.4 DRIVING TORQUES FOR SCREWS AND NUTS 129….585

4.4.1 STANDARD DRIVING TORQUES 129….585

4.4.2 SPECIFIC DRIVING TORQUES 129….585

4.5 LUBRICATION 130….585

4.5.1 LUBRICATION DIAGRAM PC12R 130….585

4.5.2 LUBRICATION DIAGRAM PC12R HS (VARIABLE TRACK GAUGE) 131….585

4.5.3 LUBRICATION DIAGRAM PC15R 132….585

4.5.4 LUBRICATION DIAGRAM PC15R HS (VARIABLE TRACK GAUGE) 133….585

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY 134….585

4.6.1 CRITICAL PARTS FOR SAFETY 135….585

4.7 MAINTENANCE PLAN 138….585

4.7.1 WHEN REQUIRED 141….585

4.7.1.a WASHING THE COOLING CIRCUIT 141….585

4.7.1.b DRAINING THE FUEL TANK 142….585

4.7.1.c CHECKING THE ELECTRICAL SYSTEM 142….585

4.7.1.d CHECKING THE STEEL TRACK TENSION 143….585

4.7.1.e CHECKING THE RUBBER TRACKS 145….585

4.7.1.f CHECKING THE RUBBER TRACK TENSION 147….585

4.7.1.g CHANGING THE RUBBER TRACK 149….585

4.7.1.h LUBRICATING THE ARTICULATIONS 151….585

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER) 152….585

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER 152….585

4.7.2.b CHANGING THE HYDRAULIC OIL 152….585

4.7.3 CHECKS BEFORE STARTING 153….585

4.7.3.a VARIOUS CHECKS 153….585

4.7.3.b CHECKING THE COOLANT LEVEL 153….585

4.7.3.c CHECKING THE FUEL LEVEL 154….585

4.7.3.d CHECKING THE ENGINE OIL LEVEL 154….585

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT 155….585

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic…..585

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION 157….586

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING 157….586

4.7.5.b LUBRICATING THE VARIABLE TRACK GAUGE SLIDING GUIDES (PC12R HS – PC15R HS) 159….586

4.7.5.c CLEANING THE AIR CLEANER CARTRIDGE 160….586

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION 161….586

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION 161….586

4.7.7.a ADJUSTING THE FAN BELT TENSION 161….586

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL 162….586

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS 163….586

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER 164….586

4.7.7.e CHANGING THE ENGINE OIL 165….586

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the syntheti…..586

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION 166….586

4.7.9.a CHANGING THE ENGINE OIL FILTER 166….586

4.7.9.b CHANGING THE FUEL FILTER 167….586

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER 168….586

4.7.9.d CHANGING THE AIR CLEANER CARTRIDGE 169….586

4.7.9.e CLEANING THE OUTSIDE OF THE RADIATORS 169….586

4.7.9.f DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable o…..586

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION 171….586

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS 171….586

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION 172….586

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER 172….586

4.7.11.b CHANGING THE COOLANT 174….586

4.7.11.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE 174….586

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER 174….586

5.1 TECHNICAL DATA 176….586

5.1.1 STANDARD OVERALL DIMENSIONS PC12R 176….586

5.1.2 TECHNICAL CHARACTERISTICS PC12R 177….586

5.1.3 STANDARD OVERALL DIMENSIONS PC12R HS (VARIABLE TRACK GAUGE) 178….586

5.1.4 TECHNICAL CHARACTERISTICS PC12R HS (VARIABLE TRACK GAUGE) 179….586

5.1.5 STANDARD OVERALL DIMENSIONS PC15R 180….586

5.1.6 TECHNICAL CHARACTERISTICS PC15R 181….586

5.1.7 STANDARD OVERALL DIMENSIONS PC15R HS (VARIABLE TRACK GAUGE) 182….586

5.1.8 TECHNICAL CHARACTERISTICS PC15R HS (VARIABLE TRACK GAUGE) 183….586

5.1.9 LIFTING CAPACITY WITH RAISED BLADE PC12R 184….586

5.1.10 LIFTING CAPACITY WITH LOWERED BLADE PC12R 185….586

5.1.11 LIFTING CAPACITY WITH RAISED BLADE PC12R HS (VARIABLE TRACK GAUGE NARROWED) 186….587

5.1.12 LIFTING CAPACITY WITH RAISED BLADE PC12R HS (VARIABLE TRACK GAUGE WIDENED) 187….587

5.1.13 LIFTING CAPACITY WITH LOWERED BLADE PC12R HS (VARIABLE TRACK GAUGE NARROWED) 188….587

5.1.14 LIFTING CAPACITY WITH LOWERED BLADE PC12R HS (VARIABLE TRACK GAUGE WIDENED) 189….587

5.1.15 LIFTING CAPACITY WITH RAISED BLADE PC15R 190….587

5.1.16 LIFTING CAPACITY LOWERED BLADE PC15R 191….587

5.1.17 LIFTING CAPACITY WITH RAISED BLADE PC15R HS (VARIABLE TRACK GAUGE NARROWED) 192….587

5.1.18 LIFTING CAPACITY WITH RAISED BLADE PC15R HS (VARIABLE TRACK GAUGE WIDENED) 193….587

5.1.19 LIFTING CAPACITY WITH LOWERED BLADE PC15R HS (VARIABLE TRACK GAUGE NARROWED) 194….587

5.1.20 LIFTING CAPACITY WITH LOWERED BLADE PC15R HS (VARIABLE TRACK GAUGE WIDENED) 195….587

6.1 AUTHORIZED OPTIONAL EQUIPMENT 198….587

6.1.1 PRECAUTIONS REGARDING SAFETY 198….587

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT 199….587

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT 200….587

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER) 201….587

6.2.1 DESCRIPTION AND CONTROL 201….587

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED 201….587

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER 205….587

6.2.3.1 INSTALLING THE HAMMER 205….587

6.2.3.2 REMOVING THE HAMMER 206….587

6.2.4 MAINTENANCE 206….587

2.1 SAFETY, NOISE AND VIBRATION PLATES….590

2.1.1 POSITION OF THE SAFETY PLATES….590

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS….592

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB….596

2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY….597

2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED….598

2.2 GENERAL PRECAUTIONS….599

2.2.1 GENERAL SAFETY RULES….599

2.2.2 SAFETY DEVICES AND GUARDS….599

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS….599

2.2.4 UNAUTHORIZED MODIFICATIONS….600

2.2.5 LEAVING THE OPERATOR’S SEAT….600

2.2.6 GETTING ON AND OFF THE MACHINE….601

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL….601

2.2.8 PREVENTING BURNS….602

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER….602

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….602

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT….603

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE….603

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT….603

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE….604

2.3.1 SAFETY ON THE WORK SITE….604

2.3.2 FIRE PREVENTION….604

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB….604

2.3.4 ROOM VENTILATION….605

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS….605

2.3.6 CLEANING THE WINDOWS – CHECKING THE WINDSHIELD WIPER BLADES….605

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING….606

2.4.1 STARTING THE ENGINE….606

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE….606

2.4.3 CHECKS FOR TRAVELLING IN REVERSE….606

2.4.4 MOVING THE MACHINE….607

2.4.5 MOVING ON SLOPES….608

2.4.6 WORKING ON SLOPES….609

2.4.7 UNAUTHORIZED OPERATIONS….609

2.4.8 PREVENTING ELECTROCUTION….610

2.4.9 VISIBILITY….611

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES….611

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….611

2.4.12 WORKING ON LOOSE GROUND….611

2.4.13 PARKING THE MACHINE….612

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES….613

2.5.1 LOADING AND UNLOADING….613

2.5.2 TRANSPORT….613

2.6 BATTERY….614

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY….614

2.6.2 STARTING WITH BOOSTER CABLES….614

2.7 PRECAUTIONS FOR THE REMOVAL….615

2.8 PRECAUTIONS FOR MAINTENANCE….616

2.8.1 WARNING PLATES….616

2.8.2 TOOLS….616

2.8.3 PERSONNEL….616

2.8.4 EQUIPMENT….617

2.8.5 WORKING UNDER THE MACHINE….617

2.8.6 CLEANING THE MACHINE….617

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS….618

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY….618

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION….618

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP….619

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR….619

2.8.12 USING LAMPS….619

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR….620

2.8.14 PRECAUTIONS CONCERNING THE STARTER….620

2.8.15 HANDLING HIGH-PRESSURE PIPES….621

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL….621

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE….621

2.8.18 COOLING FAN AND BELT….622

2.8.19 WASTE MATERIALS….622

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES….622

3.1 SAFETY LOCKS….624

3.1.1 MACHINE LOCKS….624

3.2 GENERAL VIEWS….625

3.2.1 FRONT GENERAL VIEW….625

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY….626

3.2.3 GENERAL VIEW OF THE DRIVER’S SEAT….627

3.3 INSTRUMENTS AND CONTROLS….628

3.3.1 INSTRUMENTS….628

3.3.2 WARNING LIGHTS….629

3.3.3 SWITCHES AND PUSH BUTTONS….631

3.3.4 ELECTRICAL ACCESSORIES….634

3.3.5 MACHINE CONTROLS….636

A – (STANDARD PEDAL)….643

B – (OPTIONAL PEDAL)….643

3.4 FUSES AND RELAYS….645

3.4.1 FUSES….645

3.4.2 RELAYS….646

3.5 GUARDS AND DRIVER’S SEAT….647

3.5.1 ENGINE HOOD….647

3.5.2 CANOPY….648

3.5.3 CAB….648

3.5.3.1 SLIDING DOOR….649

3.5.3.2 FRONT OPENING WINDSHIELD….650

3.5.3.3 FRONT WINDSHIELD (LOWER PART)….651

3.5.3.4 SIDE OPENING WINDOW….652

3.5.4 VENTILATION AND HEATING….653

3.5.5 SEAT….653

3.5.6 SAFETY BELT….654

3.5.7 EMERGENCY EXIT….654

3.5.8 TECHNICAL DOCUMENTATION CASE….655

3.5.9 FIRE EXTINGUISHER….655

3.5.10 FIRST AID KIT….655

3.6 USE OF THE MACHINE….657

3.6.1 CHECKS BEFORE STARTING THE ENGINE….657

3.6.1.1 VISUAL CHECKS….657

3.6.1.2 DAILY CHECKS….657

3.6.1.3 OPERATIONAL CHECKS….658

3.6.2 STARTING THE ENGINE….659

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES….659

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES….660

3.6.3 WARMING THE ENGINE….661

3.6.4 HEATING THE HYDRAULIC OIL….661

3.6.5 HOW TO MOVE THE MACHINE….661

3.6.5.1 STEERING (CHANGING DIRECTION)….663

CHANGING DIRECTION WHEN THE MACHINE IS NOT MOVING….663

CHANGING DIRECTION WHEN THE MACHINE IS MOVING (the left and right travel levers are in the same p…..663

HOW TO CARRY OUT A COUNTER-ROTATION (with the machine not moving)….663

3.6.5.2 MOVING ON SLOPES….664

3.6.5.3 MAXIMUM IMMERSION DEPTH….665

3.7 PARKING THE MACHINE….666

3.7.1 PARKING ON LEVEL GROUND….666

3.7.2 PARKING ON SLOPES….667

3.8 STOPPING THE ENGINE….668

3.9 TRANSPORTING THE MACHINE ON MOTOR VEHICLES….669

3.9.1 LOADING AND UNLOADING THE MACHINE….669

3.9.2 TRANSPORT….670

3.10 LIFTING THE MACHINE….671

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON….672

3.11.1 FUEL AND LUBRICANTS….672

3.11.2 COOLANT….672

3.11.3 BATTERY….672

3.11.4 OTHER PRECAUTIONS….673

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK….673

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON….674

3.13 USING THE WORK EQUIPMENT….675

3.13.1 ORGANIZING THE WORK AREA….675

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS….676

3.13.3 DIGGING METHOD….677

3.13.4 CHANGING THE BUCKET….678

3.14 USING THE MACHINE WITH VARIABLE TRACK GAUGE….679

3.14.1 HOW TO USE THE VARIABLE TRACK GAUGE….679

3.14.2 ADJUSTING THE BLADE….680

3.15 LONG PERIODS OF INACTIVITY….681

3.15.1 BEFORE THE PERIOD OF INACTIVITY….681

3.15.2 DURING THE PERIOD OF INACTIVITY….682

3.15.3 AFTER THE PERIOD OF INACTIVITY….682

3.16 TROUBLESHOOTING….683

3.16.1 OCCURRENCES THAT ARE NOT FAILURES….683

3.16.2 HOW TO REMOVE THE MACHINE….683

3.16.3 AFTER THE FUEL HAS RUN OUT….684

3.16.4 IF THE BATTERY IS DOWN….684

3.16.4.1 STARTING WITH BOOSTER CABLES….685

3.16.5 OTHER TROUBLES….686

3.16.5.1 ELECTRICAL CIRCUIT….686

3.16.5.2 HYDRAULIC SYSTEM….686

3.16.5.3 ENGINE….687

4.1 GUIDE TO MAINTENANCE….690

4.2 MAINTENANCE NOTES….692

4.2.1 NOTES REGARDING THE ENGINE….692

4.2.1.1 ENGINE OIL….692

4.2.1.2 COOLANT….692

4.2.1.3 FUEL….693

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM….693

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM….694

4.2.4 NOTES REGARDING LUBRICATION….694

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING….695

4.3 FUEL, COOLANT AND LUBRICANTS….696

LUBRICATION WITH GREASE….696

4.4 DRIVING TORQUES FOR SCREWS AND NUTS….699

4.4.1 STANDARD DRIVING TORQUES….699

4.4.2 SPECIFIC DRIVING TORQUES….699

4.5 LUBRICATION….700

4.5.1 LUBRICATION DIAGRAM PC12R….700

4.5.2 LUBRICATION DIAGRAM PC12R HS (VARIABLE TRACK GAUGE)….701

4.5.3 LUBRICATION DIAGRAM PC15R….702

4.5.4 LUBRICATION DIAGRAM PC15R HS (VARIABLE TRACK GAUGE)….703

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY….704

4.7 MAINTENANCE PLAN….708

4.7.1 WHEN REQUIRED….711

4.7.1.a WASHING THE COOLING CIRCUIT….711

4.7.1.b DRAINING THE FUEL TANK….712

4.7.1.c CHECKING THE ELECTRICAL SYSTEM….712

4.7.1.d CHECKING THE STEEL TRACK TENSION….713

4.7.1.e CHECKING THE RUBBER TRACKS….715

4.7.1.f CHECKING THE RUBBER TRACK TENSION….717

4.7.1.g CHANGING THE RUBBER TRACK….719

4.7.1.h LUBRICATING THE ARTICULATIONS….721

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER)….722

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER….722

4.7.2.b CHANGING THE HYDRAULIC OIL….722

4.7.3 CHECKS BEFORE STARTING….723

4.7.3.a VARIOUS CHECKS….723

4.7.3.b CHECKING THE COOLANT LEVEL….723

4.7.3.c CHECKING THE FUEL LEVEL….724

4.7.3.d CHECKING THE ENGINE OIL LEVEL….724

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT….725

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic…..726

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION….727

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING….727

4.7.5.b LUBRICATING THE VARIABLE TRACK GAUGE SLIDING GUIDES (PC12R HS – PC15R HS)….729

4.7.5.c CLEANING THE AIR CLEANER CARTRIDGE….730

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION….731

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION….731

4.7.7.a ADJUSTING THE FAN BELT TENSION….731

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL….732

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS….733

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER….734

4.7.7.e CHANGING THE ENGINE OIL….735

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the syntheti…..736

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION….736

4.7.9.a CHANGING THE ENGINE OIL FILTER….736

4.7.9.b CHANGING THE FUEL FILTER….737

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER….738

4.7.9.d CHANGING THE AIR CLEANER CARTRIDGE….739

4.7.9.e CLEANING THE OUTSIDE OF THE RADIATORS….739

4.7.9.f DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable o…..740

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION….741

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS….741

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION….742

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER….742

4.7.11.b CHANGING THE COOLANT….744

4.7.11.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE….744

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER….744

5.1 TECHNICAL DATA….746

5.1.1 STANDARD OVERALL DIMENSIONS PC12R….746

WITH CAB….746

WITH CANOPY….746

5.1.2 TECHNICAL CHARACTERISTICS PC12R….747

5.1.3 STANDARD OVERALL DIMENSIONS PC12R HS (VARIABLE TRACK GAUGE)….748

WITH CAB….748

WITH CANOPY….748

5.1.4 TECHNICAL CHARACTERISTICS PC12R HS (VARIABLE TRACK GAUGE)….749

5.1.5 STANDARD OVERALL DIMENSIONS PC15R….750

WITH CAB….750

WITH CANOPY….750

5.1.6 TECHNICAL CHARACTERISTICS PC15R….751

5.1.7 STANDARD OVERALL DIMENSIONS PC15R HS (VARIABLE TRACK GAUGE)….752

WITH CAB….752

WITH CANOPY….752

5.1.8 TECHNICAL CHARACTERISTICS PC15R HS (VARIABLE TRACK GAUGE)….753

5.1.9 LIFTING CAPACITY WITH RAISED BLADE PC12R….754

5.1.10 LIFTING CAPACITY WITH LOWERED BLADE PC12R….755

5.1.11 LIFTING CAPACITY WITH RAISED BLADE PC12R HS (VARIABLE TRACK GAUGE NARROWED)….756

5.1.12 LIFTING CAPACITY WITH RAISED BLADE PC12R HS (VARIABLE TRACK GAUGE WIDENED)….757

5.1.13 LIFTING CAPACITY WITH LOWERED BLADE PC12R HS (VARIABLE TRACK GAUGE NARROWED)….758

5.1.14 LIFTING CAPACITY WITH LOWERED BLADE PC12R HS (VARIABLE TRACK GAUGE WIDENED)….759

5.1.15 LIFTING CAPACITY WITH RAISED BLADE PC15R….760

5.1.16 LIFTING CAPACITY LOWERED BLADE PC15R….761

5.1.17 LIFTING CAPACITY WITH RAISED BLADE PC15R HS (VARIABLE TRACK GAUGE NARROWED)….762

5.1.18 LIFTING CAPACITY WITH RAISED BLADE PC15R HS (VARIABLE TRACK GAUGE WIDENED)….763

5.1.19 LIFTING CAPACITY WITH LOWERED BLADE PC15R HS (VARIABLE TRACK GAUGE NARROWED)….764

5.1.20 LIFTING CAPACITY WITH LOWERED BLADE PC15R HS (VARIABLE TRACK GAUGE WIDENED)….765

6.1 AUTHORIZED OPTIONAL EQUIPMENT….768

6.1.1 PRECAUTIONS REGARDING SAFETY….768

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT….769

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT….770

(PC12R-PC12R HS)….770

(PC15R-PC15R HS)….770

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)….771

6.2.1 DESCRIPTION AND CONTROL….771

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED….771

FOR A CORRECT USE, IT IS NECESSARY TO:….771

ALWAYS AVOID THE FOLLOWING INCORRECT USES:….773

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER….775

6.2.3.1 INSTALLING THE HAMMER….775

6.2.3.2 REMOVING THE HAMMER….776

6.2.4 MAINTENANCE….776

WEAM003000 – Hydraulic Excavator PC15R-8 Operation & Maintenance Manual….777

COVER….777

CONTENTS….787

1.1 FOREW0RD….778

1.2 INFORMATION ON SAFETY….779

1.3 INTRODUCTION….781

1.3.1 INTENDED USES….781

1.3.2 IMPROPER OR UNAUTHORIZED USES….781

1.3.3 MAIN CHARACTERISTICS….782

1.3.4 RUNNING-IN….782

1.4 PRODUCT IDENTIFICATION….783

1.4.1 MACHINE SERIAL NUMBER….783

1.4.2 MACHINE IDENTIFICATION PLATE….783

1.4.3 ENGINE SERIAL NUMBER AND EMISSION LABEL….784

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER….784

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER….784

1.4.6 CAB SERIAL NUMBER….785

1.4.7 SERIAL NUMBERS AND DEALER'S ADDRESS….786

SAFETY AND ACCIDENT PREVENTION….794

2.1 SAFETY PLATES….795

2.1.1 POSITION OF THE SAFETY PLATES….795

2.1.2 POSITION OF THE PICTOGRAMS….810

2.1.3 PICTOGRAMS AND RELEVANT MEANINGS….812

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED….814

2.2 GENERAL PRECAUTIONS….815

2.2.1 GENERAL SAFETY RULES….815

2.2.2 SAFETY DEVICES AND GUARDS….815

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS….815

2.2.4 UNAUTHORIZED MODIFICATIONS….816

2.2.5 LEAVING THE OPERATOR'S SEAT….816

2.2.6 GETTING ON AND OFF THE MACHINE ….817

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL….817

2.2.8 PREVENTING BURNS….818

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWER….818

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….818

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT….819

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE….819

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT….819

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE….820

2.3.1 SAFETY ON THE WORK SITE….820

2.3.2 FIRE PREVENTION….820

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB….820

2.3.4 ROOM VENTILATION….821

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS….821

2.3.6 CLEANING THE WINDOWS – CHECKING THE WINDSHIELD WIPER BLADES….821

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING….822

2.4.1 STARTING THE ENGINE….822

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE….822

2.4.3 CHECKS FOR TRAVELING IN REVERSE….822

2.4.4 MOVING THE MACHINE….823

2.4.5 MOVING THE SLOPES….824

2.4.6 WORKING THE SLOPES….825

2.4.7 UNAUTHORIZED OPERATIONS….825

2.4.8 PREVENTING ELECTROCUTION….826

2.4.9 VISIBILITY….827

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES….827

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….827

2.4.12 WORKING ON LOOSE GROUND….827

2.4.13 PARKING THE MACHINE….828

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES….829

2.5.1 LOADING AND UNLOADING….829

2.5.2 TRANSPORT….829

2.6 BATTERY….830

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY….830

2.6.2 STARTING WITH BOOSTER CABLES….830

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY….831

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE….832

2.8.1 WARNING PLATES….832

2.8.2 TOOLS….832

2.8.3 PERSONNEL….833

2.8.4 EQUIPMENT….833

2.8.5 WORKING UNDER THE MACHINE….833

2.8.6 CLEANING THE MACHINE….833

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS….834

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY….834

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION….834

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP….835

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR….835

2.8.12 USING LAMPS….835

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR….836

2.8.14 PRECAUTIONS CONCERNING THE STARTER….836

2.8.15 HANDLING HIGH-PRESSURE PIPES….837

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH PRESSURE OIL….837

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE….837

2.8.18 COOLING FAN AND BELT….838

2.8.19 WASTE MATERIALS….838

THE MACHINE AND ITS OPERATIONS….840

3.1 SAFETY LOCKS….841

3.1.1 MACHINE LOCKS….841

3.2 GENERAL VIEWS….842

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB (OPTIONAL)….842

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY….843

3.2.3 GENERAL VIEW OF THE DRIVER'S SEAT….844

3.3. INSTRUMENTS AND CONTROLS….845

3.3.1 INSTRUMENTS….845

3.3.2 WARNINGS LIGHTS….846

3.3.3 SWITCHES AND PUSH BUTTONS….848

3.3.4 ELECTRICAL ACCESSORIES….851

3.3.5 MACHINE CONTROLS….853

3.4 FUSES AND RELAYS….862

3.4.1 FUSES….862

3.4.2 RELAYS….863

3.5 GUARDS AND DRIVER'S SEAT….864

3.5.1 ENGINE HOOD….864

3.5.2 CANOPY….865

3.5.3 CAB (OPTIONAL)….865

3.5.3.1 SLIDING DOOR….866

3.5.3.2 FRONT OPENING WINDSHEILD….867

3.5.3.3 FRONT WINDSHEILD (LOWER PART)….868

3.5.3.4 SIDE OPENING WINDOW….869

3.5.4 VENTILATION AND HEATING (ONLY ON MACHINES WITH CAB)….870

3.5.5 SEAT….870

3.5.6 SAFETY BELT….871

3.5.7 EMERGENCY EXIT (ONLY ON MACHINES WITH CAB)….871

3.5.8 TECHNICAL DOCUMENTATION CASE….872

3.5.9 FIRE EXTINGUISHER….872

3.5.10 FIRST AID KIT….872

3.6 USE OF THE MACHINE….874

3.6.1 CHECKS BEFORE STARTING THE ENGINE….874

3.6.1.1 VISUAL CHECKS….874

3.6.1.2 DAILY CHECKS….874

3.6.1.3 OPERATIONAL CHECKS….875

3.6.2 STARTING THE ENGINE….876

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES….876

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES….877

3.6.3 WARMING THE ENGINE….878

3.6.4 HEATING THE HYDRAULIC OIL….878

3.6.5 HOW TO MOVE THE MACHINE….878

3.6.5.1 STEERING (CHANGING DIRECTION)….880

3.6.5.2 MOVING ON SLOPES….881

3.6.5.3 MAXIMUM IMMERSION DEPTH….882

3.7 PARKING THE MACHINE….883

3.7.1 PARKING ON LEVEL GROUND….883

3.7.2 PARKING ON SLOPES….884

3.8 STOPPING THE ENGINE….885

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES….886

3.9.1 LOADING AND UNLOADING THE MACHINE….886

3.9.2 TRANSPORT….887

3.10 LIFTING THE MACHINE….888

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON….889

3.11.1 FUEL AND LUBRICANTS….889

3.11.2 COOLANT….889

3.11.3 BATTERY….889

3.11.4 OTHER PRECAUTIONS….890

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF THE END OF WORK….890

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON….891

3.13 USING THE WORK EQUIPMENT….892

3.13.1 ORGANIZING THE WORK AREA….892

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS….893

3.13.3 DIGGING METHOD….894

3.13.4 CHANING THE BUCKET….895

3.14 USING THE MACHINE WITH VARIABLE TRACK GAUGE….896

3.14.1 HOW TO SEE THE VARIABLE TRACK GAUGE….896

3.14.2 ADJUSTING THE BLADE….897

3.15 LONG PERIODS OF INACTIVITY….898

3.15.1 BEFORE THE PERIOD OF INACTIVITY….898

3.15.2 DURING THE PERIOD OF INACTIVITY….899

3.15.3 AFTER THE PERIOD OF INACTIVITY….899

3.16 TROUBLESHOOTING….900

3.16.1 OCCURRENCES THAT ARE NOT FAILURES….900

3.16.2 HOW TO REMOVE THE MACHINE….900

3.16.3 AFTER THE FUEL HAS RUN OUT….901

3.16.4 IF THE BATTERY IS DOWN….901

3.16.4.1 STARTING WITH BOOSTER CABLES….902

3.16.5 OTHER TROUBLES….903

3.16.5.1 ELECTRICAL CIRCUT….903

3.16.5.2 HYDRAULIC SYSTEM….903

3.16.5.3 ENGINE….904

MAINTENANCE….906

4.1 GUIDE TO MAINTENANCE….907

4.2 MAINTENANCE NOTES….909

4.2.1 NOTES REGARDING THE ENGINE….909

4.2.1.1 ENGINE OIL….909

4.2.1.2 COOLANT….909

4.2.1.3 FUEL….910

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM….910

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM….911

4.2.4 NOTES REGARDING LUBRICATION….911

4.2.5 PARTS SUJECT TO WEAR THAT PERIODICALLY NEED CHANGING….912

4.3 FUEL, COOLANT AND LUBRICANTS….913

4.4 NUT AND BOLT TIGHTEN TOU….917

4.4.1 STANDARD TIGHTENING TORQUES….917

4.4.2 SPECIFIC TIGHTENING TORQUES….917

4.5 LUBRICATION….918

4.5.1 LUBRICATION DIAGRAM….918

4.5.2 LUBRICATION DIAGRAM (VARIABLE TRACK GAUGE)….919

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY….920

4.6.1 CRITICAL PARTS FOR SAFETY….921

4.7 MAINTENANCE PLAN….923

4.7.1 WHEN REQUIRED….926

4.7.1.A WASHING THE COOLING CIRCUIT….926

4.7.1.B DRAINING THE FUEL TANK….927

4.7.1.C CHECKING THE ELECTRICAL SYSTEM….927

4.7.1.D CHECKING THE STEEL TRACK TENSION….928

4.7.1.E CHECKING THE RUBBER TRACKS….930

4.7.1.F CHECKING THE RUBBER TRACK TENSION….932

4.7.1.G CHANGING THE RUBBER TRACK….934

4.7.2 MAINTENANCE INTERVALS IN CASE OF THE DEMOLITION HAMMER (BREAKER)….936

4.7.2 A CHANGING THE HYDRAULIC OIL FILTER….936

4.7.2.B CHANGING THE HYDRAULIC OIL….936

4.7.3 CHECKS BEFORE STARTING….937

4.7.3.A VARIOUS CHECKS….937

4.7.3.B CHECKING THE COOLANT LEVEL….937

4.7.3 C CHECKING THE FUEL LEVEL….938

4.7.3.D CHECKING THE ENGINE OIL LEVEL….938

4.7.3.E CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT….939

4.7.4 MAINTENANCE EVERY 100 HOURS OF OPERATION….940

4.7.4.A LUBRICATING THE JOINTS AND THE BALL – BEARING RING….940

4.7.4.B LUBRICATING THE VARIABLE TRACK GAUGE SLIDING GUIDES (ONLY <<HS>> VERSION)….941

4.7.4.C. CLEANING THE AIR CLEANER CARTRIDGE….942

4.7.5 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION….943

4.7.6 MAINTENANCE EVERY N250 HOURS OF OPERATION….943

4.7.6.A ADJUSTING THE FAN BELT TENSION….943

4.7.6.B CHECKING THE BATTERY ELECTROLYTE LEVEL….944

4.7.6.C CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS….945

4.7.6.D CHANGING THE HYDRAULIC SYSTEM OIL FILTER….946

4.7.6.E CHANGING THE ENGINE OIL….947

4.7.7 MAINTENANCE EVERY 500 HOURS OF OPERATION….948

4.7.7.A CHANGING THE ENGINE OIL FILTER….948

4.7.7.B CHANGING THE FUEL FILTER….949

4.7.7.C CHANGING THE FUEL PUMP PRECLEANER….950

4.7.7.D CHANGING THE AIR CLEANER CARTRIDGE….951

4.7.7.E CLEANING THE OUTSIDE OF THE RADIATORS….951

4.7.8 MAINTENANCE EVERY 1000 HOURS OF OPERATION….952

4.7.8.A CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS….952

4.7.9 MAINTENANCE EVERY 2000 HOURS OF OPERATION….953

4.7.9.A CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER….953

4.7.9.B CHANGING THE COOLANT….955

4.7.9.C CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE….955

4.7.9.D CHECKING THE ALTERNATOR AND THE STARTER….955

TECHNICAL SPECIFICATIONS….956

5.1 TECHNICAL DATA….957

5.1.1 STANDARD OVERALL DIMENSIONS….957

5.1.2 TECHNICAL CHARACTERISTICS….958

5.1.3 OVERALL DIMENSIONS (ONLY <<HS>> VERSION)….959

5.1.4 TECHNICAL CHARACTERISTICS (ONLY <<HS>> VERSION)….960

5.1.5 LIFTING CAPACITY….961

5.1.6 LIFTING CAPACITY (ONLY <<HS>> VERSION)….962

AUTHORIZED OPTIONAL EQUIPMENT….964

6.1 AUTHORIZED OPTIONAL EQUIPMENT….965

6.1.1 PRECAUTIONS REGARDING SAFETY….965

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT….966

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT….967

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)….968

6.2.1 DESCRIPTION AND CONTROL….968

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED….968

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER….972

6.2.3.1 INSTALLING THE HAMMER….972

6.2.3.2 REMOVING THE HAMMER….973

6.2.4 MAINTENANCE….973

WEAM003001 – Hydraulic Excavator PC15R-8 Deluxe Operation & Maintenance Manual….974

COVER….974

1.1 FOREWARD….975

1.2 INFORMATION ON SAFETY….976

1.3 INTRODUCTION….978

1.3.1 INTENDED USES….978

1.3.2 IMPROPER OR UNAUTHORIZED USES….978

1.3.3 MAIN CHARACTERISTICS….979

1.3.4 RUNNING-IN….979

1.4 PRODUCT IDENTIFICATION….980

1.4.1 MACHINE SERIAL NUMBER….980

1.4.2 MACHINE IDENTIFICATION PLATE….980

1.4.3 ENGINE SERIAL NUMBER AND EMISSION LABEL….981

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER….981

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER….981

1.4.6 CAB SERIAL NUMBER….982

1.4.7 SERIAL NUMBERS AND DEALER'S ADDRESS….983

CONTENTS….984

SAFETY AND ACCIDENT PREVENTION….991

2.1 SAFETY PLATES….992

2.1.1 POSITION OF THE SAFETY PLATES….992

2.1.2 POSITION OF THE PICTOGRAMS….1007

2.1.3 PICTOGRAMS AND RELEVANT MEANINGS….1009

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED….1011

2.2 GENERAL PRECAUTIONS….1012

2.2.1 GENERAL SAFETY RULES….1012

2.2.2 SAFETY DEVICES AND GUARDS….1012

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS….1012

2.2.4 UNAUTHORIZED MODIFICATIONS….1013

2.2.5 LEAVING THE OPERATOR'S SEAT….1013

2.2.6 GETTING ON AND OFF THE MACHINE….1014

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL….1014

2.2.8 PREVENTING BURNS….1015

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER….1015

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….1015

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT….1016

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE….1016

2.2.12 PRECAUTIONS CONCERNING THE EQUIPMENT….1016

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE….1017

2.3.1 SAFETY ON THE WORK SITE….1017

2.3.2 FIRE PREVENTION….1017

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB….1017

2.3.4 ROOM VENTILATION….1018

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS….1018

2.3.6 CLEANING THE WINDOWS – CHECKING THE WINDSHIELD WIPER BLADES….1018

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING….1019

2.4.1 STARTING THE ENGINE….1019

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE….1019

2.4.3 CHECKS FOR TRAVELLING IN REVERSE….1019

2.4.4 MOVING THE MACHINE….1020

2.4.5 MOVING ON SLOPES….1021

2.4.6 WORKING ON SLOPES….1022

2.4.7 UNAUTHORIZED OPERATIONS….1022

2.4.8 PREVENTING ELECTROCUTION….1023

2.4.9 VISIBILITY….1024

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES….1024

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….1024

2.4.12 WORKING ON LOOSE GROUND….1024

2.4.13 PARKING THE MACHINE….1025

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES….1026

2.5.1 LOADING AND UNLOADING….1026

2.5.2 TRANSPORT….1026

2.6 BATTERY….1027

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY….1027

2.6.2 STARTING WITH THE BOOSTER CABLES….1027

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY….1028

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE….1029

2.8.1 WARNING PLATES….1029

2.8.2 TOOLS….1029

2.8.3 PERSONNEL….1030

2.8.4 EQUIPMENT….1030

2.8.5 WORKING UNDER THE MACHINE….1030

2.8.6 CLEANING THE MACHINE….1030

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS….1031

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY….1031

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION….1031

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP….1032

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR….1032

2.8.12 USING LAMPS….1032

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR….1033

2.8.14 PRECAUTIONS CONCERNING THE STARTER….1033

2.8.15 HANDLING HIGH-PRESSURE PIPES….1034

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL….1034

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE….1034

2.8.18 COOLING FAN AND BELT….1035

2.8.19 WASTE MATERIALS….1035

2.8.20 PRECAUTIONS FOR THE USE OF THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES….1035

THE MACHINE AND ITS OPERATIONS….1037

3.1 SAFETY LOCKS….1038

3.1.1 MACHINE LOCKS….1038

3.2 GENERAL VIEWS….1039

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB (OPTIONAL)….1039

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY….1040

3.2.3 GENERAL VIEW OF THE DRIVER'S SEAT….1041

3.3 INSTRUMENTS AND CONTROLS….1042

3.3.1 INSTRUMENTS….1042

3.3.2 WARNING LIGHTS….1043

3.3.3 SWITCHES AND PUSH BUTTONS….1045

3.3.4 ELECTRICAL ACCESSORIES….1048

3.3.5 MACHINE CONTROLS….1050

3.4 FUSES AND RELAYS….1059

3.4.1 FUSES….1059

3.4.2 RELAYS….1060

3.5 GUARDS AND DRIVER'S SEAT….1061

3.5.1 ENGINE HOOD….1061

3.5.2 CANOPY….1062

3.5.3 CAB (OPTIONAL)….1062

3.5.3.1 SLIDING DOOR….1063

3.5.3.2 FRONT OPENING WINDSHIELD….1064

3.5.3.3 FRONT WINDSHIELD (LOWER PART)….1065

3.5.3.4 SIDE OPENING WINDOW….1066

3.5.4 VENTILATION AND HEATING (ONLY ON MACHINES WITH CAB)….1067

3.5.5 SEAT….1067

3.5.6 SAFETY BELT….1068

3.5.7 EMERGENCY EXIT (ONLY ON MACHINES WITH CAB)….1068

3.5.8 TECHNICAL DOCUMENTATION CASE….1069

3.5.9 FIRE EXTINGUISHER….1069

3.5.10 FIRST AID KIT….1069

3.6 USE OF THE MACHINE….1071

3.6.1 CHECKS BEFORE STARTING MACHINE….1071

3.6.1.1 VISUAL CHECKS….1071

3.6.12 DAILY CHECKS….1071

3.6.1.3 OPERATIONAL CHECKS….1072

3.6.2 STARTING THE ENGINE….1073

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES….1073

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES….1074

3.6.3 WARMING THE ENGINE….1075

3.6.4 HEATING THE HYDRAULIC OIL….1075

3.6.5 HOW TO MOVE THE MACHINE….1075

3.6.5.1 STEERING (CHANGING DIRECTION)….1077

3.6.5.2 MOVING ON SLOPES….1078

3.6.5.3 MAXIMUM IMMERSION DEPTH….1079

3.7 PARKING THE MACHINE….1080

3.7.1 PARKING ON LEVEL GROUND….1080

3.7.2 PARKING ON SLOPES….1081

3.8 STOPPING THE ENGINE….1082

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES….1083

3.9.1 LOADING AND UNLOADING THE MACHINE….1083

3.9.2 TRANSPORT….1084

3.10 LIFTING THE MACHINE….1085

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON….1086

3.11.1 FUEL AND LUBRICANTS….1086

3.11.2 COOLANT….1086

3.11.3 BATTERY….1086

3.11.4 OTHER PRECAUTIONS….1087

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK….1087

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON….1088

3.13 USING THE WORK EQUIPMENT….1089

3.13.1 ORGANIZING THE WORK AREA….1089

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS….1090

3.13.3 DIGGING METHOD….1091

3.13.4 CHANGING THE BUCKET….1092

3.14 USING THE MACHINE WITH VARIABLE TRACK GUAGE….1093

3.14.1 HOW TO USE THE VARIABLE TRACK GUAGE….1093

3.14.2 ADJUSTING THE BLADE….1094

3.15 LONG PERIODS OF INACTIVITY….1095

3.15.1 BEFORE THE PERIOD OF INACTIVITY….1095

3.15.2 DURING THE PERIOD OF INACTIVITY….1096

3.15.3 AFTER THE PERIOD OF INACTIVITY….1096

3.16 TROUBLESHOOTING….1097

3.16.1 OCCURENCES THAT ARE NOT FAILURES….1097

3.16.2 HOW TO REMOVE THE MACHINE….1097

3.13.3 AFTER THE FUEL HAS RUN OUT….1098

3.16.4 IF THE BATTERY IS DOWN….1098

3.16.4.1 STARTING WITH BOOSTER CABLES….1099

3.16.5 OTHER TROUBLES….1100

3.16.5.1 ELECTRICAL CIRCUIT….1100

3.16.5.2 HYDRAULIC SYSTEM….1100

3.16.5.3 ENGINE….1101

MAINTENANCE….1103

4.1 GUIDE TO MAINTENANCE….1104

4.2 MAINTENANCE NOTES….1106

4.2.1 NOTES REGARDING THE ENGINE….1106

4.2.1.1 ENGINE OIL….1106

4.2.1.2 COOLANT….1106

4.2.1.3 FUEL….1107

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM….1107

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM….1108

4.2.4 NOTES REGARDING LUBRICATION….1108

4.2.5 PARTS SUBJEST TO WEAR THAT PERIODICALLY NEED CHANGING….1109

4.3 FUEL, COOLANT AND LUBRICANTS….1110

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS….1114

4.4 NUT AND BOLT TIGHTENING TORQUES….1115

4.4.1 STANDARD TIGHTENING TORQUES….1115

4.4.2 SPECIFIC TIGHTENING TORQUES….1115

4.5 LUBRICATION….1116

4.5.1 LUBRICATION DIAGRAM….1116

4.5.2 LUBRICATION DIAGRAM (VARIABLE TRACK GUAGE)….1117

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY….1118

4.6.1 CRITICAL PARTS FOR SAFETY….1119

4.7 MAINTENANCE PLAN….1121

4.7.1 WHEN REQUIRED….1124

4.7.1.a WASHING THE COOLING CIRCUIT….1124

4.7.1.b DRAINING THE FUEL TANK….1125

4.7.1.c CHECKING THE ELECTRICAL SYSTEM….1125

4.7.1.d CHECKING THE STEEL TRACK TENSION….1126

4.7.1.e CHECKING THE RUBBER TRACKS….1128

4.7.1.f CHECKING THE RUBBER TRACKS TENSION….1130

4.7.1.g CHANGING THE RUBBER TRACK….1132

4.7.1.h LUBRICATING THE ARTICULATIONS….1134

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER)….1135

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER….1135

4.7.2.b CHANGING THE HYDRAULIC OIL….1135

4.7.3 CHECKS BEFORE STARTING….1136

4.7.3.a VARIOUS CHECKS….1136

4.7.3.b CHECKING THE COOLANT LEVEL….1136

4.7.3.c CHECKING THE FUEL LEVEL….1137

4.7.3.d CHECKING THE ENGINE OIL LEVEL….1137

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT….1138

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (ONLY FOR MACHINES IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES….1139

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION….1140

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING….1140

4.7.5.b LUBRICATING THE VARIABLE TRACK GUAGE SLIDING GUIDES (ONLY IN <HS> VERSION)….1141

4.7.5.c CLEANING THE AIR CLEANER CARTRIDGE….1142

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION….1143

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION….1143

4.7.7.a ADJUSTING THE FAN BELT TENSION….1143

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL….1144

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS….1145

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER….1146

4.7.7.e CHANGING THE ENGINE OIL….1147

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (ONLY FOR MACHINE IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES….1148

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION….1148

4.7.9.a CHAINGING THE ENGINE OIL FILTER….1148

4.7.9.b CHANGING THE FUEL FILTER….1149

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER….1150

4.7.9.d CHANGING THE AIR CLEANER CARTRIDGE….1151

4.7.9.e CLEANING THE OUTSIDE OF THE RADIATORS….1151

4.7.9.f DRAINING THE HYDRAULIC OIL TANK (ONLY FOR MACHINES IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES IS USED)….1152

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION….1153

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS….1153

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION….1154

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER….1154

4.7.11.b CHANGING THE COOLANT….1156

4.7.11.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE….1156

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER….1156

TECHNICAL SPECIFICATIONS….1157

5.1 TECHNICAL DATA….1158

5.1.1 STANDARD OVERALL DIMENSIONS….1158

5.1.2 TECHNICAL CHARACTERISTICS….1159

5.1.3 OVERALL DIMENSIONS (ONLY <HS> VERSION)….1160

5.1.4 TECHNICAL CHARACTERISTICS (ONLY <HS> VERSION)….1161

5.1.5 LIFTING CAPACITY….1162

5.1.6 LIFTING CAPACITY (ONLY <HS> VERISON)….1163

AUTHORIZED OPTIONAL EQUIPMENT….1165

6.1 AUTHORIZED OPTIONAL EQUIPMENT….1166

6.1.1 PRECAUTIONS REGARDING SAFETY….1166

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT….1167

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT….1168

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)….1169

6.2.1 DESCRIPTION AND CONTROL….1169

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED….1169

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER….1173

6.2.3.1 INSTALLING THE HAMMER….1173

6.2.3.2 REMOVING THE HAMMER….1174

6.2.4 MAINTENANCE….1174

WEBM000100 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual….1175

CONTENTS….1177

LIST OF REVISED PAGES….1179

SAFETY….1181

FOREWORD….1183

HOW TO READ THE SHOP MANUAL….1184

HOISTING INSTRUCTIONS….1185

STANDARD TIGHTENING TORQUE….1186

COATING MATERIALS….1187

ELECTRIC WIRE CODE….1188

WEIGHT TABLE….1189

TABLE OF OIL AND COOLANT QUANTITIES….1190

10. STRUCTURE AND FUNCTION….1191

POWER TRAIN….1192

SWING CIRCLE….1194

SWING MOTOR….1195

FINAL DRIVE….1196

TRACK FRAME AND RECOIL SPRING….1197

CARRIER ROLLER….1199

STEEL SHOE….1200

HYDRAULIC SYSTEM….1201

HYDRAULIC CIRCUIT DIAGRAM….1205

HYDRAULIC PUMP….1209

CONTROL VALVE….1214

CLSS….1222

SWIVEL JOINT….1265

TRAVEL MOTOR….1267

CYLINDERS….1270

VALVE CONTROL….1274

ACCUMULATOR….1275

PPC VALVE….1276

SOLENOID VALVE….1281

CUTTING SHOVEL CONTROL VALVE….1283

ELECTRICAL CIRCUIT DIAGRAM….1285

20. TESTING AND ADJUSTMENTS….1287

NORMAL OR STANDARD TECHNICAL DATA….1288

SPECIAL TOOLS….1309

CHECKING THE ENGINE SPEED….1311

ADJUSTMENT OF VALVE CLEARANCE….1312

MEASUREMENT OF THE COMPRESSION PRESSURE….1313

CONTROL AND ADJUSTMENT OF THE TENSION OF THE FAN BELT….1314

CONTROL AND ADJUSTMENT OF THE INJECTION TIMING….1315

CONTROL AND ADJUSTMENT OF THE ACCELERATOR STROKE….1317

ADJUSTMENT OF THE STROKE OF THE BLADE COMMAND LEVER….1318

CONTROL AND ADJUSTMENT OF THE STROKE OF THE TRAVEL LEVER….1319

CENTERING ADJUSTMENT OF THE BOOM SWING COMMAND PEDAL….1320

ADJUSTMENT OF THE PPC VALVE CLEARANCES….1321

ADJUSTMENT OF THE RUBBER PAD AND SAFETY MICROSWITCH FOR SERVO-CONTROL ENGAGEMENT….1322

CONTROL AND ADJUSTMENT OF THE TRACK-SHOE TENSION….1323

CONTROL AND REGULATION OF PRESSURE IN THE HYDRAULIC CIRCUIT….1324

CONTROL AND REGULATION OF THE LS DIFFERENTIAL PRESSURE AND ADJUSTMENT OF THE LS VALVE….1330

REGULATION OF THE PC VALVE….1332

CONTROL AND REGULATION OF THE SERVOCONTROL POWER SUPPLY….1333

ELIMINATION OF RESIDUAL PRESSURES – PRESSURISATION OF THE TANK….1335

BLEEDING AIR FROM THE HYDRAULIC CIRCUITS….1336

CONTROL OF HYDRAULIC DRIFTS – ANALYSIS OF THE CAUSES OF A DRIFT….1338

CHECKING FOR ANY LEAKAGES INSIDE THE WORKING EQUIPMENT CYLINDERS….1344

CHECKING FOR ANY LEAKAGES INSIDE THE SWING MOTOR….1345

METHODS FOR TESTING FOR LEAKAGES INSIDE THE SWIVEL JOINT….1346

30. REMOVAL AND INSTALLATION….1349

HOW TO READ THE MANUAL….1351

PRECAUTIONS TO BE TAKEN WHILE WORKING….1352

SPECIAL TOOLS….1353

STARTER MOTOR….1355

ALTERNATOR….1356

PUMP GROUP….1357

INJECTION NOZZLES….1358

CYLINDER HEAD….1359

OIL COOLER….1363

RADIATOR….1364

ENGINE HOOD….1365

CAB AND CANOPY….1366

HEATING FAN….1368

REAR COUNTERWEIGHT….1369

TOP COVER AND SIDE PANELS….1370

HYDRAULIC OIL TANK….1372

FUEL TANK….1375

ENGINE PUMP GROUP….1376

PUMP….1379

ENGINE PUMP COUPLING….1380

CONTROL VALVE….1381

RIGHT-HAND PPC VALVE (BOOM-BUCKET)….1383

LEFT-HAND PPC VALVE (ARM-BUCKET)….1384

SERVOCONTROL SOLENOID GROUP….1385

SWIVEL JOINT….1387

SWING MOTOR….1388

REVOLVING FRAME….1389

SWING CIRCLE….1391

TRAVEL MOTOR….1392

RUBBER TRACK SHOES….1393

TRACK SHOES….1394

SPROCKET WHEEL….1395

FINAL DRIVE….1396

IDLER AND RECOIL SPRING ASSEMBLY….1407

TRACK ROLLERS….1410

BOOM CYLINDER….1411

ARM CYLINDER….1412

BUCKET CYLINDER….1413

BOOM SWING CYLINDER….1414

BLADE CYLINDER….1415

WORKING EQUIPMENT CYLINDER….1416

UPPER WORKING EQUIPMENT….1422

BUCKET….1424

ARM….1425

BOOM….1427

BOOM SWING SUPPORT….1429

BLADE….1430

40. STANDARD MAINTENANCE….1431

SWING CIRCLE….1432

TRACK FRAME AND RECOIL SPRING….1433

IDLER….1434

FINAL DRIVE….1435

SPROCKET….1436

TRACK ROLLER….1437

TRACK SHOE….1438

HYDRAULIC PUMP….1440

CONTROL VALVE….1442

SWIVEL JOINT….1454

SWING MOTOR….1455

TRAVEL MOTOR….1456

PPC VALVE….1460

CYLINDERS….1464

WORK EQUIPMENT….1466

WEBM000101 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual….1471

COVER….1471

CONTENTS….1473

LIST OF REVISED PAGES….1475

SAFETY….1477

FOREWORD….1479

HOW TO READ THE SHOP MANUAL….1480

HOISTING INSTRUCTIONS….1481

STANDARD TIGHTENING TORQUE….1482

COATING MATERIALS….1483

ELECTRIC WIRE CODE….1484

WEIGHT TABLE….1485

TABLE OF OIL AND COOLANT QUANTITIES….1486

10.STRUCTURE AND FUNCTION….1489

POWER TRAIN….1490

SWING CIRCLE….1492

SWING MOTOR….1493

FINAL DRIVE….1494

TRACK FRAME AND RECOIL SPRING….1495

VARIABLE GAUGE TRACK FRAME AND RECOIL SPRING….1497

CARRIER ROLLER….1498

STEEL SHOE….1499

HYDRAULIC SYSTEM PC12R-8….1501

HYDRAULIC SYSTEM PC15R-8….1503

HYDRAULIC CIRCUIT DIAGRAM PC12R-8….1505

HYDRAULIC CIRCUIT DIAGRAM PC12R-8 MISTRAL….1507

HYDRAULIC CIRCUIT DIAGRAM PC12R-8 HS….1509

HYDRAULIC CIRCUIT DIAGRAM PC12R-8 MISTRAL HS….1511

HYDRAULIC CIRCUIT DIAGRAM PC15R-8….1513

HYDRAULIC CIRCUIT DIAGRAM PC15R-8 HS….1515

HYDRAULIC CIRCUIT DIAGRAM….1516

HYDRAULIC PUMP….1517

CONTROL VALVE PC12R-8 PC12R-8 MISTRAL….1522

CONTROL VALVE PC12R-8 HS PC12R-8 MISTRAL HS….1524

CLSS….1532

CONTROL VALVE PC15R-8….1550

CLSS….1560

SWIVEL JOINT….1577

TRAVEL MOTOR….1580

CYLINDERS….1583

VALVE CONTROL….1587

ACCUMULATOR….1588

PPC VALVE….1589

PPC VALVE….1591

SOLENOID VALVE….1594

VARIABLE GAUGE UNDERCARRIAGE SERVOCONTROL….1597

SAFETY VALVE….1598

CUTTING SHOVEL CONTROL VALVE….1599

ELECTRICAL CIRCUIT DIAGRAM….1601

20.TESTING AND ADJUSTMENTS….1605

NORMAL OR STANDARD TECHNICAL DATA….1606

SPECIAL TOOLS….1627

CHECKING THE ENGINE SPEED….1629

ADJUSTMENT OF VALVE CLEARANCE….1630

MEASUREMENT OF THE COMPRESSION PRESSURE….1631

CONTROL AND ADJUSTMENT OF THE TENSION OF THE FAN BELT….1632

CONTROL AND ADJUSTMENT OF THE INJECTION TIMING….1633

CONTROL AND ADJUSTMENT OF THE ACCELERATOR STROKE….1635

ADJUSTMENT OF THE STROKE OF THE BLADE COMMAND LEVER….1636

CONTROL AND ADJUSTMENT OF THE STROKE OF THE TRAVEL LEVER….1637

CENTERING ADJUSTMENT OF THE BOOM SWING COMMAND PEDAL….1638

ADJUSTMENT OF THE RUBBER PAD AND SAFETY MICROSWITCH FOR SERVO-CONTROL ENGAGEMENT….1639

CONTROL AND ADJUSTMENT OF THE TRACK-SHOE TENSION….1640

CONTROL AND REGULATION OF THE PRESSURE IN THE HYDRAULIC CIRCUITS (PC12R)….1641

CONTROL AND REGULATION OF THE PRESSURES IN THE HYDRAULIC CIRCUITS (PC15R)….1644

CONTROL AND REGULATION OF THE LS DIFFERENTIAL PRESSURE AND ADJUSTMENT OF THE LS VALVE….1647

REGULATION OF THE PC VALVE….1649

CONTROL AND REGULATION OF THE SERVO-CONTROL POWER SUPPLY (PC12R)….1650

CONTROL AND REGULATION OF THE SERVO-CONTROL POWER SUPPLY (PC15R)….1651

ELIMINATION OF RESIDUAL PRESSURES – PRESSURISATION OF THE TANK….1652

BLEEDING AIR FROM THE HYDRAULIC CIRCUITS….1653

CONTROL OF HYDRAULIC DRIFTS – ANALYSIS OF THE CAUSES OF A DRIFT….1655

CHECKING FOR ANY LEAKAGES INSIDE THE WORKING EQUIPMENT CYLINDERS….1661

CHECKING FOR ANY LEAKAGES INSIDE THE SWING MOTOR….1662

METHODS FOR TESTING FOR LEAKAGES INSIDE THE SWIVEL JOINT….1663

30.REMOVAL AND INSTALLATION….1671

HOW TO READ THE MANUAL….1673

PRECAUTIONS TO BE TAKEN WHILE WORKING….1674

SPECIAL TOOLS….1675

STARTER MOTOR….1677

ALTERNATOR….1678

PUMP GROUP….1679

INJECTION NOZZLES….1680

CYLINDER HEAD….1681

OIL COOLER….1685

RADIATOR….1686

ENGINE HOOD….1687

CAB AND CANOPY….1688

HEATING FAN….1690

REAR COUNTERWEIGHT….1691

TOP COVER AND SIDE PANELS….1692

HYDRAULIC OIL TANK….1694

FUEL TANK….1697

ENGINE-PUMP GROUP….1698

PUMP….1701

ENGINE-PUMP COUPLING….1702

CONTROL VALVE….1703

RIGHT-HAND PPC VALVE (BOOM-BUCKET)….1705

LEFT-HAND PPC VALVE (ARM-BUCKET)….1706

SERVOCONTROL SOLENOID GROUP (PC12 WITHOUT TRAVEL INCREMENT)….1707

SERVOCONTROL SOLENOID GROUP (PC12 WITH TRAVEL INCREMENT – PC15R)….1708

SWIVEL JOINT….1709

SWING MOTOR….1710

REVOLVING FRAME….1711

SWING CIRCLE….1713

TRAVEL MOTOR….1714

RUBBER TRACK SHOES….1715

TRACK-SHOES….1716

SPROCKET WHEEL….1717

COMPLETE FINAL DRIVE….1718

FINAL DRIVE….1719

IDLER AND RECOIL SPRING ASSEMBLY….1729

IDLER….1730

SPRING RECOIL AND THRUST CYLINDER GROUPS….1731

TRACK ROLLERS….1732

BOOM CYLINDER….1733

ARM CYLINDER….1734

BUCKET CYLINDER….1735

BOOM SWING CYLINDER….1736

BLADE CYLINDER….1737

WORKING EQUIPMENT CYLINDER….1738

UPPER WORKING EQUIPMENT….1744

BUCKET….1746

ARM….1747

BOOM….1749

BOOM SWING SUPPORT….1751

BLADE….1752

40.STANDARD MAINTENANCE….1755

SWING CIRCLE….1756

TRACK FRAME AND RECOIL SPRING….1757

VARIABLE GAUGE TRACK FRAME AND RECOIL SPRING….1758

IDLER….1759

FINAL DRIVE….1760

SPROCKET….1761

TRACK ROLLER….1762

TRACK SHOE….1763

HYDRAULIC PUMP….1765

CONTROL VALVE….1767

SWIVEL JOINT….1779

SWING MOTOR….1781

TRAVEL MOTOR….1782

CYLINDERS PC12R-8….1788

CYLINDERS PC15R-8….1789

WORK EQUIPMENT PC12R-8….1790

WORK EQUIPMENT PC15R-8….1792

WEBM002800 – Hydraulic Excavator PC15R-8 Shop Manual….1795

COVER….1795

FOREWARD….1800

HOW TO READ THE SHOP MANUAL….1803

HOISTING INSTRUCTIONS….1804