Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC150, PC150LC, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC150-3, PC150LC-3, PC150-5, PC150LC-5 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM021K0304 – Hydraulic Excavator PC150-3, PC150LC-3 Shop Manual.pdf

SEBM021K0502 – Hydraulic Excavator PC150-5 Shop Manual.pdf

SEBMA021KD500 – Hydraulic Excavator PC150LC-5 Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,575 pages

File Format: PDF

Language: English

SEBM021K0304 – Hydraulic Excavator PC150-3, PC150LC-3 Shop Manual…2

SEBM021K0502 – Hydraulic Excavator PC150-5 Shop Manual…561

COVER…561

CONTENTS…562

10 STRUCTURE AND FUNCTION…577

POWER TRAIN…578

FINAL DRIVE…579

SWING CIRCLE…580

SWING MACHINERY…581

TRACK FRAME…582

IDLER…583

IDLER CUSHION…583

CARRIER ROLLER…584

TRACK ROLLER…584

TRACK SHOE…585

HYDRAULIC PIPING…587

HYDRAULIC CIRCUIT DIAGRAM…588

HYDRAULIC TANK…589

OLSS (OPEN CENTER LOAD SENSING SYSTEM)…590

HYDRAULIC PUMP…592

L.H. 6-SPOOL CONTROL VALVE…611

R.H. 5-SPOOL CONTROL VALVE…614

SWING MOTOR…617

CENTER SWIVEL JOINT…620

TRAVEL MOTOR…621

VALVE CONTROL…628

PPC VALVE…629

ACCUMULATOR…633

SAFETY LOCK VALVE…633

SOLENOID VALVE…634

SHUTTLE VALVE…638

BOOM HOLDING VALVE…639

HYDRAULIC CYLINDER…642

ELECTRICAL WIRING DIAGRAM…644

ELECTRICAL CIRCUIT DIAGRAM…646

ENGINE CONTROL SYSTEM…648

PEMC SYSTEM…659

EMACC (ELECTRONIC MONITOR AND CONTROL CONSOLE)…686

20 TESTING AND ADJUSTING…693

TABLE OF JUDGEMENT STANDARD VALUE…694

STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM…706

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING…717

ADJUSTING VALVE CLEARANCE…718

MEASURING COMPRESSION PRESSURE…719

TESTING AND ADJUSTING FUEL INJECTION TIMING…720

ADJUSTING TRAVEL OF GOVERNOR MOTOR LEVER…721

ADJUSTING ENGINE SPEED SENSOR…722

ADJUSTING TRAVEL LIMIT SWITCH…722

INSPECTION OF SWING CIRCLE BEARING CLEARANCE…723

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT…724

TESTING AND ADJUSTING CHARGING PUMP PRESSURE…726

TESTING AND ADJUSTING MAIN PUMP CONTROL PRESSURE…728

MEASURING STROKE OF SERVO PISTON…735

TESTING AND ADJUSTING TRAVEL DEVIATION…736

MEASURING OUTPUT PRESSURE OF PPC VALVE…738

ADJUSTING PPC VALVE…739

TESTING PPC SHUTTLE VALVE…740

MEASURING SOLENOID VALVE OUTLET PORT PRESSURE…741

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT…742

BLEEDING AIR…744

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT…746

TROUBLESHOOTING…747

POINTS TO REMEMBER WHEN TROUBLESHOOTING…748

SEQUENCE OF EVENTS IN TROUBLESHOOTING…749

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE…750

CHECKS BEFORE TROUBLESHOOTING…757

ELECTRICAL CIRCUIT DIAGRAM…758

POSITION OF CONNECTORS FOR TROUBLESHOOTING…761

CONNECTION TABLE FOR CONNECTOR…763

HANDLING CONNECTORS…771

EXPLANATION OF FUNCTIONS OF CONTROL MECHANISM OF ELECTRICAL SYSTEM…772

DISPLAY METHOD FOR MONITOR PANEL, PUMP CONTROLLER AND ENGINE THROTTLE CONTROLLER…775

ACTION OF SELF-DIAGNOSTIC FUNCTION AND SYMPTOMS ON MACHINE…779

METHOD OF USING JUDGEMENT TABLE…782

METHOD OF USING TROUBLESHOOTING CHARTS…784

TROUBLESHOOTING OF ENGINE THROTTLE CONTROLLER SYSTEM (E MODE)…786

ENGINE THROTTLE CONTROLLER OR IN ENGINE RELATED PARTS…787

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING ON ENGINE THROTTLE CONTROLLER SYSTEM…788

E-1 [ABNORMALITY IN POWER SOURCE SYSTEM OR CONTROLLER] IS DISPLAYED (ALL LAMPS OFF)…789

E-2 [SHORT CIRCUIT IN GOVERNOR MOTOR] IS DISPLAYED…791

E-3 [ABNORMALITY IN BATTERY RELAY] IS DISPLAYED…792

E-4 [DISCONNECTION IN WIRING HARNESS OF GOVERNOR MOTOR] IS DISPLAYED…793

E-5 [ABNORMALITY IN GOVERNOR POTENTIOMETER] IS DISPLAYED…794

E-6 [ABNORMALITY IN FUEL CONTROL DIAL] IS DISPLAYED…796

E-7 [ABNORMALITY IN NO.2 THROTTLE SIGNAL] IS DISPLAYED…797

E-8 ENGINE DOES NOT START…799

E-9 ENGINE ROTATION IS IRREGULAR…801

a) IDLING ROTATION IS IRREGULAR…801

b) THERE IS HUNTING…803

E-10 LACK OF OUTPUT POWER (MAX. ENGINE SPEED IS TOO LOW)…805

E-11 ENGINE DOES NOT STOP…807

E-12 AUTOMATIC WARMING-UP OPERATION IS DEFECTIVE…809

TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM (C MODE)…810

CHART FOR DISTINGUISHING IF FAILURE IS IN PUMP CONTROLLER OR IN HYDRAULIC RELATED PARTS…811

C-1 [OFF] SELF-DIAGNOSTIC DISPLAY OF CONTROLLER DOES NOT LIGHT UP…812

C-2 [01] [SHORT CIRCUIT IN STRAIGHT-TRAVEL SOLENOID SYSTEM] IS DISPLAYED…813

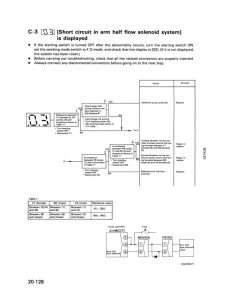

C-3 [03] [SHORT CIRCUIT IN ARM HALF FLOW SOLENOID SYSTEM] IS DISPLAYED…814

C-4 [04] [SHORT CIRCUIT IN SWING BRAKE SOLENOID SYSTEM] IS DISPLAYED…815

C-5 [05] [SHORT CIRCUIT IN TRAVEL SPEED SOLENOID SYSTEM] IS DISPLAYED…816

C-6 [07] [SHORT CIRCUIT IN CO CANCEL SOLENOID SYSTEM] IS DISPLAYED…817

C-7 [08] [SHORT CIRCUIT IN TVC SOLENOID SYSTEM (1) ] IS DISPLAYED…818

C-8 [09] [SHORT CIRCUIT IN TVC SOLENOID SYSTEM (2) ] IS DISPLAYED…819

C-9 [11] [DISCONNECTION IN STRAIGHT-TRAVEL SOLENOID SYSTEM] IS DISPLAYED…820

C-10 [13] [DISCONNECTION IN ARM HALF FLOW SOLENOID SYSTEM] IS DISPLAYED…821

C-11 [14] [DISCONNECTION IN SWING BRAKE SOLENOID SYSTEM] IS DISPLAYED…822

C-12 [15] [DISCONNECTION IN TRAVEL SPEED SOLENOID SYSTEM] IS DISPLAYED…823

C-13 [17] [DISCONNECTION IN CO CANCEL SOLENOID SYSTEM] IS DISPLAYED…824

C-14 [18] [DISCONNECTION IN TVC SOLENOID SYSTEM] IS DISPLAYED…825

C-15 [21] [ABNORMALITY IN NO.2 THROTTLE SIGNAL SYSTEM] IS DISPLAYED…826

C-16 [22] [ABNORMALITY IN THROTTLE SIGNAL SYSTEM] IS DISPLAYED…827

C-17 [23] [ABNORMALITY IN PUMP PRESSURE SENSOR SIGNAL SYSTEM] IS DISPLAYED…828

C-18 [25] [ABNORMALITY IN PUMP PRESSURE SENSOR POWER SOURCE SYSTEM] IS DISPLAYED…830

C-19 [26] [ABNORMALITY DISCONNECTION IN WIRING IN ENGINE SPEED SENSOR SYSTEM] IS DISPLAYED…831

C-20 [28] [ABNORMALITY IN AUTO-DECELERATION SIGNAL OUTPUT SYSTEM] IS DISPLAYED…832

C-21 [29] [ABNORMALITY IN OVERHEAT SIGNAL SYSTEM] IS DISPLAYED…833

C-22 [88] [CONTROLLER ABNORMAL SYSTEM] IS DISPLAYED…834

TROUBLESHOOTING OF PUMP CONTROLLER INPUT SIGNAL SYSTEM (F MODE)…835

F-1 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [P1] [WORK EQUIPMENT OIL PRESSURE SWITCH]…836

F-2 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [P2] [SWING OIL PRESSURE SWITCH]…837

F-3 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [P6] [TRAVEL LIMIT SWITCH]…838

F-4 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [b5] [SWING LOCK SWITCH]…839

F-5 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [Hi] OR [Lo] [TRAVEL SPEED SWITCH]…840

F-6 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [Ad] [AUTO-DECELERATION SWITCH]…841

F-7 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [88] [DECIMAL POINT OF ENGINE SPEED SENSOR]…842

F-8 PUMP CONTROLLER WORKING MODE DISPLAY DOES NOT SWITCH…843

F-9 PUMP CONTROLLER POWER SET DISPLAY DOES NOT SWITCH…844

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)…845

H-1 SPEEDS OF WORK EQUIPMENT, TRAVEL SWING ARE ALL SLOW…846

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS…848

H-3 WORK EQUIPMENT, TRAVEL, SWING DO NOT MOVE, OR SPEED IS EXTREMELY SLOW…850

H-4 ALL WORK EQUIPMENT, TRAVEL, SWING LACK POWER…852

H-5 POWER SET SELECTION SYSTEM DOES NOT SWITCH…852

H-6 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)…853

H-7 AUTO-DECELERATION DOES NOT ACTUATED…853

H-8 BOOM, ARM SPEED IS EXTREMELY SLOW…854

H-9 WORK EQUIPMENT (BOOM, ARM, BUCKET) SPEED IS SLOW…855

H-10 WORK EQUIPMENT (BOOM, ARM, BUCKET) LACKS POWER…857

H-11 EXCESSIVE HYDRAULIC DRIFT…857

H-12 EXCESSIVE TIME LAG…859

H-13 DOES NOT ENTER FINISHING OPERATION (F.O) MODE…859

H-14 WHEN MACHINE IS TRAVELING, IT DEVIATES NATURALLY TO ONE SIDE…860

a) DEVIATES IN SAME DIRECTION BOTH IN FORWARD AND REVERSE…860

b) DEVIATES IN DIFFERENT DIRECTION IN FORWARD AND REVERSE…862

H-15 EXCESSIVE DEVIATION DURING COMPOUND OPERATIONS…863

H-16 EXCESSIVE DEVIATION WHEN STARTING…864

H-17 TRAVEL LACKS POWER (OR SPEED IS SLOW)…866

H-18 TRAVEL SPEED DOES NOT SWITCH…866

H-19 MACHINE DOES NOT MOVE (ONE SIDE ONLY)…867

H-20 TRAVEL LEVER IS HEAVY…867

H-21 DOES NOT SWING…868

H-22 SWING SPEED IS SLOW OR ACCELERATION IS POOR…870

H-23 EXCESSIVE OVERRUN WHEN STOPPING SWING…871

H-24 EXCESSIVE SHOCK WHEN STOPPING SWING…871

H-25 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING…872

H-26 EXCESSIVE HYDRAULIC DRIFT OF SWING…872

H-27 WHEN OPERATED SIMULTANEOUSLY WITH ARM, SWING SPEED IS SLOW…872

TABLE OF FAILURE MODES AND CAUSES…873

TROUBLESHOOTING OF MONITOR SYSTEM (P MODE)…874

P-1 MONITOR PANEL LAMPS DO NOT LIGHT UP FOR 3 SECONDS WHEN STARTING SWITCH IS TURNED ON…875

a) NO MONITOR PANEL LAMPS LIGHT UP…875

b) SOME MONITOR PANEL LAMPS DO NOT LIGHT UP…875

P-2 MONITOR PANEL LAMPS ALL LIGHT UP WHEN STARTING SWITCH IS TURNED ON, BUT DO NOT GO OUT…876

P-3 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CHECK ITEMS FLASH (LEVELS FOR CHECK ITEMS ARE AS SPECIFIED)…877

a) COOLANT LEVEL FLASHES…877

b) ENGINE OIL LEVEL FLASHES…878

P-4 PREHEATING IS NOT BEING USED, BUT PREHEATING DISPLAY LIGHTS UP…879

P-5 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED, CHECK ITEMS FLASH…880

a) ALTERNATOR SYSTEM…880

b) ENGINE OIL PRESSURE SYSTEM…880

P-6 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CAUTION ITEMS FLASH…881

P-7 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED, CAUTION ITEMS FLASH (WHEN THERE IS NO ABNORMALITY IN CHECK ITEMS OR ENGINE)…882

a) ENGINE OIL PRESSURE FLASHES…882

b) COOLANT LEVEL FLASHES…882

c) COOLANT TEMPERATURE FLASHES…883

d) CHARGE FLASHES…883

e) FUEL LEVEL FLASHES…884

P-8…885

(a) WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), BUZZER DOES NOT SOUND FOR 1 SECOND CAUTION ITEM IS FLASHING BUT BUZZER DOES NOT SOUND…885

(b) THERE IS NO ABNORMALITY DISPLAY ON THE MONITOR, BUT THE BUZZER SOUNDS…885

P-9 PANEL LIGHTING OF MONITOR PANEL DOES NOT LIGHT UP (LIQUID CRYSTAL DISPLAY IS NORMAL)…886

P-10 COOLANT TEMPERATURE SHOWS ABNORMALLY LOW TEMPERATURE…887

P-11 COOLANT TEMPERATURE GAUGE GIVES NO DISPLAY (DURING OPERATION,ON LEVEL OF GAUGE IS DISPLAYED)…887

P-12 FUEL LEVEL GAUGE ALWAYS DISPLAYS FULL…888

P-13 FUEL GAUGE GIVES NO DISPLAY…888

P-14…889

(a) LAMPS DO NOT LIGHT UP…889

(b) LAMPS LIGHT UP EVEN WHEN LAMP SWITCH IS NO OPERATED…889

P-15 …891

(a) WIPERS DO NOT WORK…891

(b) WIPERS WORK EVEN WHEN WIPER SWITCH IS NOT OPERATED…891

P-16…893

(a) FAN DOES NOT WORK…893

(b) FAN WORKS EVEN WHEN FAN SWITCH IS NOT OPERATED…893

P-17 WORKING MODE DOES NOT SWITCH…895

P-18 POWER SET DOES NOT SWITCH…896

P-19 AUTO-DECELERATION DOES NOT SWITCH (DOES NOT ENTER AUTO-DECELERATION; AUTO-DECELERATION IS NOT CANCELED)…897

P-20 TRAVEL SPEED DOES NOT SWITCH BETWEEN HI AND LO…898

P-21 WARMING-UP OPERATION IS NOT CARRIED OUT BELOW 30℃, OR WARMING-UP OPERATION IS NOT CANCELED EVEN WHEN TEMPERATURE GOES ABOVE 30℃…899

P-22 EVEN WHEN SWING LOCK SWITCH IS TURNED ON (LOCK), SWING LOCK LAMP ON MONITOR PANEL DOES NOT LIGHT UP…900

P-23 FUEL LEVEL SENSOR SYSTEM DEFECTIVE…901

P-24 COOLANT TEMPERATURE SENSOR SYSTEM DEFECTIVE…902

P-25 ENGINE OIL LEVEL SENSOR SYSTEM DEFECTIVE…903

P-26 COOLANT LEVEL SENSOR SYSTEM DEFECTIVE…904

30 DISASSEMBLY AND ASSEMBLY…905

METHOD OF USING MANUAL…907

PRECAUTIONS WHEN CARRYING OUT OPERATION…908

SPECIAL TOOL LIST…910

WEIGHT TABLE…913

TIGHTENING TORQUES AND STANDARD VALUES TABLE…914

LUBRICANT AND COOLANT TABLE…920

STARTING MOTOR…921

REMOVAL…921

INSTALLATION…921

ALTERNATOR…921

REMOVAL…921

INSTALLATION…921

ENGINE OIL COOLER…923

REMOVAL…923

INSTALLATION…923

FUEL INJECTION PUMP…923

REMOVAL…923

INSTALLATION…923

WATER PUMP…925

REMOVAL…925

INSTALLATION…925

NOZZLE HOLDER…925

REMOVAL…925

INSTALLATION…925

TURBOCHARGER…927

REMOVAL…927

INSTALLATION…927

THERMOSTAT…927

REMOVAL…927

INSTALLATION…927

ENGINE FRONT SEAL…929

REMOVAL…929

INSTALLATION…929

ENGINE REAR SEAL…929

REMOVAL…929

INSTALLATION…929

GOVERNOR MOTOR…931

REMOVAL…931

INSTALLATION…931

CYLINDER HEAD…933

REMOVAL…933

INSTALLATION…933

HYDRAULIC COOLER…935

REMOVAL…935

INSTALLATION…935

RADIATOR, HYDRAULIC COOLER…935

REMOVAL…935

INSTALLATION…935

ENGINE, HYDRAULIC PUMP…937

REMOVAL…937

INSTALLATION…937

PTO…939

REMOVAL…939

INSTALLATION…939

DISASSEMBLY…939

ASSEMBLY…939

CENTER SWIVEL JOINT…941

REMOVAL…941

INSTALLATION…941

DISASSEMBLY…941

ASSEMBLY…941

FINAL DRIVE…943

REMOVAL…943

INSTALLATION…943

DISASSEMBLY…945

ASSEMBLY…947

TRAVEL MOTOR (HMV110ADT)…953

DISASSEMBLY…953

ASSEMBLY…958

SPROCKET…968

REMOVAL…968

INSTALLATION…968

SWING MOTOR…970

REMOVAL…970

INSTALLATION…970

SWING MACHINERY…970

REMOVAL…970

INSTALLATION…970

SWING MOTOR (KMF90-2 (AB))…972

DISASSEMBLY…972

ASSEMBLY…975

SWING MACHINERY…980

DISASSEMBLY…980

ASSEMBLY…982

REVOLVING FRAME…986

REMOVAL…986

INSTALLATION…986

SWING CIRCLE…986

REMOVAL…986

INSTALLATION…986

IDLER, RECOIL SPRING…988

REMOVAL…988

INSTALLATION…988

RECOIL SPRING…990

DISASSEMBLY…990

ASSEMBLY…990

TRACK ROLLER…992

REMOVAL…992

INSTALLATION…992

CARRIER ROLLER…992

REMOVAL…992

INSTALLATION…992

TRACK SHOE…994

REMOVAL…994

INSTALLATION…994

CHARGING PUMP…994

REMOVAL…994

INSTALLATION…994

MAIN PUMP INPUT SHAFT…996

REMOVAL…996

INSTALLATION…996

HYDRAULIC PUMP…996

REMOVAL…996

INSTALLATION…996

DISASSEMBLY…998

ASSEMBLY…1003

CONTROL VALVE…1015

REMOVAL…1015

INSTALLATION…1015

DISASSEMBLY…1017

ASSEMBLY…1017

MAIN RELIEF VALVE…1019

REMOVAL…1019

INSTALLATION…1019

DISASSEMBLY…1019

ASSEMBLY…1019

TVC VALVE…1021

REMOVAL…1021

INSTALLATION…1021

CO,NC VALVE…1021

REMOVAL…1021

INSTALLATION…1021

SERVO VALVE…1021

REMOVAL…1021

INSTALLATION…1021

WORK EQUIPMENT PPC VALVE…1023

REMOVAL…1023

INSTALLATION…1023

DISASSEMBLY…1023

ASSEMBLY…1023

PPC SHUTTLE VALVE…1025

REMOVAL…1025

INSTALLATION…1025

BOOM HOLDING VALVE…1027

REMOVAL…1027

INSTALLATION…1027

DISASSEMBLY…1027

ASSEMBLY…1027

BOOM CYLINDER…1029

REMOVAL…1029

INSTALLATION…1029

ARM CYLINDER…1031

REMOVAL…1031

INSTALLATION…1031

BUCKET CYLINDER…1033

REMOVAL…1033

INSTALLATION…1033

HYDRAULIC CYLINDER…1035

DISASSEMBLY…1035

ASSEMBLY…1037

WORK EQUIPMENT…1039

REMOVAL…1039

INSTALLATION…1039

BUCKET…1041

REMOVAL…1041

INSTALLATION…1041

ARM…1041

REMOVAL…1041

INSTALLATION…1041

ARM, BUCKET…1043

REMOVAL…1043

INSTALLATION…1043

BOOM…1045

REMOVAL…1045

INSTALLATION…1045

OPERATOR'S CAB…1047

REMOVAL…1047

INSTALLATION…1047

COUNTERWEIGHT…1047

REMOVAL…1047

INSTALLATION…1047

ENGINE THROTTLE CONTROLLER…1049

REMOVAL…1049

INSTALLATION…1049

PUMP CONTROLLER…1049

REMOVAL…1049

INSTALLATION…1049

MONITOR PANEL…1051

REMOVAL…1051

INSTALLATION…1051

40 MAINTENANCE STANDARD…1053

FINAL DRIVE…1054

SWING CIRCLE…1056

SWING MACHINERY…1057

TRACK FRAME…1058

IDLER…1059

TRACK ROLLER…1061

CARRIER ROLLER…1062

TRACK SHOE…1063

HYDRAULIC PUMP…1065

CHARGING PUMP AND RELIEF VALVE…1066

L.H. 6-SPOOL CONTROL VALVE…1067

R.H. 5-SPOOL CONTROL VALVE…1070

SWING MOTOR…1073

CENTER SWIVEL JOINT…1074

TRAVEL MOTOR…1075

PPC VALVE…1076

BOOM HOLDING VALVE…1077

HYDRAULIC CYLINDER…1078

WORK EQUIPMENT…1079

SEBMA021KD500 – Hydraulic Excavator PC150LC-5 Shop Manual…1081

Komatsu Hydraulic Excavator PC150, PC150LC Repair Service Manuals