Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC170LC-10, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC170LC-10 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEN06367-02 – Hydraulic Excavator PC170LC-10 Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,450 pages

File Format: PDF

Language: English

COVER..1

00 Index and foreword ..3

Index ..4

Foreword, safety and general information ..15

Important safety notice ..15

How to read the shop manual ..22

Explanation of terms for maintenance standard ..24

Handling equipment of fuel system devices ..26

Handling of intake system parts ..27

Handling of hydraulic equipment ..28

Method of disconnecting and connecting of push-pull type coupler ..30

Handling of electrical equipment ..33

How to read electric wire code ..41

Precautions when performing operation ..44

Practical use of KOMTRAX ..49

Standard tightening torque table ..50

List of abbreviation ..56

Conversion table ..61

01 Specification ..67

Table of contents ..68

Specifications ..69

Specification drawing ..69

Working range drawings ..70

Specifications ..71

Weight table ..74

Table of fuel, coolant, and lubricants ..75

10 Structure and function ..77

Table of contents ..78

Engine and cooling system ..79

Engine related parts ..79

VFT ..81

EGR system piping drawing ..85

EGR system circuit diagram ..87

EGR valve ..88

EGR cooler ..90

KCCV layout drawing ..92

KCCV ventilator ..95

KDOC muffler ..97

Cooling system ..99

Power train ..101

Power train system ..101

Swing circle ..103

Swing machinery ..104

Final drive ..106

Undercarriage and frame ..108

Track frame and idler cushion ..108

Hydraulic system ..110

Hydraulic component layout ..110

Valve control ..113

Hydraulic tank ..115

CLSS ..117

Main pump ..121

Control valve ..147

Swing motor ..195

Travel motor ..197

PPC valve ..212

Solenoid valve ..234

Attachment circuit selector valve (for high pressure circuit) ..238

Attachment circuit selector valve (for low pressure circuit) ..240

Center swivel joint ..243

Accumulator ..245

Work equipment ..246

Work equipment ..246

Work equipment shim ..247

Bucket play adjustment shim ..248

Cab and its attachments ..249

Cab mount and cab tipping stopper ..249

ROPS cab ..250

Electrical system ..251

Electrical control system ..251

Machine monitor system ..296

KOMTRAX system ..318

Sensor ..321

20 Standard value tables ..339

Table of contents ..340

Standard service value table ..341

Standard value table for engine ..341

Standard value table for machine ..343

Standard value table for electrical system ..357

30 Testing and adjusting ..365

Table of contents ..366

Related information on testing and adjusting ..367

Tools for testing and adjusting ..367

Sketch of tools for testing and adjusting ..370

Engine and cooling system ..371

Testing engine speed ..371

Testing boost pressure ..372

Testing exhaust gas color ..374

Testing and adjusting valve clearance ..375

Testing compression pressure ..378

Testing blowby pressure ..382

Testing engine oil pressure ..383

Testing fuel pressure ..384

Testing fuel discharge, return and leakage ..389

Bleeding air from fuel system ..394

Testing fuel circuit for leakage ..396

Handling cylinder cutout mode operation ..397

Handling no-injection cranking operation ..398

Checking and adjusting air conditioner compressor belt tension ..399

Replacing fan belt ..400

Power train ..401

Testing swing circle bearing clearance ..401

Undercarriage and frame ..402

Testing and adjusting track tension ..402

Hydraulic system ..403

Releasing remaining pressure from hydraulic circuit ..403

Testing oil pressure of control circuit ..404

Testing and adjusting oil pressure in work equipment, swing, and travel circuits ..405

Testing and adjusting oil pressure in pump PC control circuit ..409

Testing and adjusting oil pressure in pump LS control circuit ..412

Testing outlet pressure of solenoid valve ..416

Testing PPC valve outlet pressure ..419

Adjusting play of work equipment and swing PPC valves ..421

Testing pump swash plate sensor ..422

Isolating the parts causing hydraulic drift in work equipment ..423

Testing and adjusting travel deviation ..425

Testing oil leakage ..427

Bleeding air from hydraulic circuit ..430

Cab and its attachments ..432

Checking cab tipping stopper ..432

Adjusting mirrors ..433

Electrical system ..435

Special functions of machine monitor ..435

KOMTRAX terminal start-up procedure ..493

Adjusting rearview camera angle ..496

Handling voltage circuit of engine controller ..498

Handling battery disconnect switch ..499

Testing diodes ..500

Pm clinic ..501

Pm Clinic service ..501

40 Troubleshooting ..511

Table of contents ..512

Related information on troubleshooting ..518

Troubleshooting points ..518

Sequence of events in troubleshooting ..520

Checks before troubleshooting ..522

Inspection procedure before troubleshooting ..524

Preparation work for troubleshooting of electrical system ..542

Classification and procedure for troubleshooting ..547

Symptom and troubleshooting numbers ..550

Information in troubleshooting table ..553

Procedure for troubleshooting wiring harness of pressure sensor system for open circuit ..555

Connector list and layout ..558

Connector contact identification ..568

T-branch box and T-branch adapter table ..606

Fuse location table ..611

Failure codes table ..613

Troubleshooting by failure code (Display of code) ..620

Failure code [879AKA] A/C Inner Sensor Open Circuit ..620

Failure code [879AKB] A/C Inner Sensor Short Circuit ..621

Failure code [879BKA] A/C Outer Sensor Open Circuit ..622

Failure code [879BKB] A/C Outer Sensor Short Circuit ..623

Failure code [879CKA] Ventilating Sensor Open Circuit ..624

Failure code [879CKB] Ventilating Sensor Short Circuit ..625

Failure code [879DKZ] Sunlight Sensor Open Or Short Circuit ..626

Failure code [879EMC] Ventilation Damper Abnormality ..627

Failure code [879FMC] Air Mix Damper Abnormality ..628

Failure code [879GKX] Refrigerant Abnormality ..629

Failure code [989L00] Engine Controller Lock Caution 1 ..630

Failure code [989M00] Engine Controller Lock Caution 2 ..631

Failure code [989N00] Engine Controller Lock Caution 3 ..632

Failure code [AA10NX] Air Cleaner Clogging ..633

Failure code [AB00KE] Charge Voltage Low ..635

Failure code [B@BAZG] Eng Oil Press Low ..637

Failure code [B@BAZK] Eng Oil Level Low ..638

Failure code [B@BCNS] Eng Water Overheat ..639

Failure code [B@BCZK] Eng Water Level Low ..640

Failure code [B@HANS] Hyd Oil Overheat ..642

Failure code [CA115] Eng Ne and Bkup Speed Sens Error ..643

Failure code [CA122] Chg Air Press Sensor High Error ..644

Failure code [CA123] Chg Air Press Sensor Low Error ..646

Failure code [CA131] Throttle Sensor High Error ..648

Failure code [CA132] Throttle Sensor Low Error ..650

Failure code [CA144] Coolant Temp Sens High Error ..652

Failure code [CA145] Coolant Temp Sens Low Error ..654

Failure code [CA153] Chg Air Temp Sensor High Error ..656

Failure code [CA154] Chg Air Temp Sensor Low Error ..658

Failure code [CA187] Sensor 2 Supply Volt Low Error ..660

Failure code [CA221] Ambient Press Sensor High Error ..662

Failure code [CA222] Ambient Press Sens Low Error ..664

Failure code [CA227] Sensor 2 Supply Volt High Error ..666

Failure code [CA234] Eng Overspeed ..667

Failure code [CA238] Ne Speed Sensor Supply Volt Error ..668

Failure code [CA239] Ne Speed Sens Supply Volt High Error ..669

Failure code [CA271] IMV/PCV1 Short Error ..670

Failure code [CA272] IMV/PCV1 Open Error ..672

Failure code [CA295] Ambient Press Sens In Range Error ..674

Failure code [CA322] Inj #1(L#1) Open/Short Error ..675

Failure code [CA324] Inj #3(L#3) Open/Short Error ..677

Failure code [CA331] Inj #2(L#2) Open/Short Error ..679

Failure code [CA332] Inj #4(L#4) Open/Short Error ..681

Failure code [CA343] ECM Critical Internal Failure ..683

Failure code [CA351] Injectors Drive Circuit Error ..684

Failure code [CA352] Sensor 1 Supply Volt Low Error ..685

Failure code [CA356] Mass Air Flow Sensor High Error ..687

Failure code [CA357] Mass Air Flow Sensor Low Error ..689

Failure code [CA386] Sensor 1 Supply Volt High Error ..691

Failure code [CA428] Water in Fuel Sensor High Error ..692

Failure code [CA429] Water in Fuel Sensor Low Error ..694

Failure code [CA435] Eng Oil Press Sw Error ..696

Failure code [CA441] Battery Voltage Low Error ..697

Failure code [CA442] Battery Voltage High Error ..699

Failure code [CA449] Rail Press Very High Error ..700

Failure code [CA451] Rail Press Sensor High Error ..701

Failure code [CA452] Rail Press Sensor Low Error ..703

Failure code [CA466] KVGT Motor Driver Position Error ..705

Failure code [CA488] Chg Air Temp High Torque Derate ..707

Failure code [CA515] Rail Press Sens Sup Volt High Error ..708

Failure code [CA516] Rail Press Sens Sup Volt Low Error ..710

Failure code [CA553] Rail Press High Error ..712

Failure code [CA555] Crankcase Press High Error 1 ..713

Failure code [CA556] Crankcase Press High Error 2 ..714

Failure code [CA559] Rail Press Low Error ..715

Failure code [CA689] Eng Ne Speed Sensor Error ..719

Failure code [CA691] Intake Air Temp Sens High Error ..721

Failure code [CA692] Intake Air Temp Sens Low Error ..723

Failure code [CA697] ECM Internal Temp Sensor High Error ..725

Failure code [CA698] ECM Int Temp Sensor Low Error ..726

Failure code [CA731] Eng Bkup Speed Sens Phase Error ..727

Failure code [CA778] Eng Bkup Speed Sensor Error ..728

Failure code [CA1117] Persistent Data Lost Error ..731

Failure code [CA1695] Sensor 5 Supply Volt High Error ..732

Failure code [CA1696] Sensor 5 Supply Volt Low Error ..733

Failure code [CA1843] Crankcase Press Sens High Error ..734

Failure code [CA1844] Crankcase Press Sens Low Error ..736

Failure code [CA1896] EGR Valve Stuck Error ..738

Failure code [CA1942] Crankcase Press Sens In Range Error ..739

Failure code [CA1961] EGR_Motor Driver IC Over Temp Error ..740

Failure code [CA2185] Throt Sensor Sup Volt High Error ..741

Failure code [CA2186] Throt Sensor Sup Volt Low Error ..743

Failure code [CA2249] Rail Press Very Low Error ..745

Failure code [CA2272] EGR Valve Pos Sens Low Error ..746

Failure code [CA2311] IMV Solenoid Error ..748

Failure code [CA2349] EGR Valve Solenoid Open Error ..749

Failure code [CA2353] EGR Valve Solenoid Short Error ..751

Failure code [CA2357] EGR Valve Servo Error ..753

Failure code [CA2373] Exhaust Manifold Press Sens High Error ..754

Failure code [CA2374] Exhaust Manifold Press Sens Low Error ..756

Failure code [CA2375] EGR Orifice Temp Sens High Error ..758

Failure code [CA2376] EGR Orifice Temp Sens Low Error ..760

Failure code [CA2554] Exh Manifold Press Sens In Range Error ..762

Failure code [CA2555] Grid Htr Relay Volt Low Error ..763

Failure code [CA2556] Grid Htr Relay Volt High Error ..765

Failure code [CA2961] EGR Orifice Temp High Error 1 ..767

Failure code [CA2973] Chg Air Press Sensor In Range Error ..768

Failure code [CA3419] Mass Air Flow Sensor Sup Volt High Error ..769

Failure code [CA3421] Mass Air Flow Sensor Sup Volt Low Error ..771

Failure code [CA3724] EGR/KVGT Motor Driver Power Low Error ..773

Failure code [CA3741] Rail Press Valve Trip Error ..775

Failure code [CA3918] KVGT Stuck Error ..776

Failure code [CA3919] KVGT Motor Driver IC Over Temp Error ..777

Failure code [CA3921] KVGT Servo Error 2 ..778

Failure code [CA3922] KVGT Motor Driver Open Error ..779

Failure code [CA3923] KVGT Motor Driver Short Error ..781

Failure code [D110KB] Battery Relay Drive Short Circuit ..783

Failure code [D19JKZ] Personal Code Relay Abnormality ..785

Failure code [D811MC] KOMTRAX Error ..788

Failure code [D862KA] GPS Antenna Open Circuit ..789

Failure code [D8ALKA] System Operating Lamp Disconnection (KOMTRAX) ..790

Failure code [D8ALKB] System Operating Lamp Short Circuit (KOMTRAX) ..792

Failure code [D8AQKR] CAN2 Discon (KOMTRAX) ..793

Failure code [DA20MC] Pump Controller Malfunction ..795

Failure code [DA22KK] Pump Solenoid Power Low Error ..796

Failure code [DA25KP] 5V Sensor 1 Power Abnormality ..798

Failure code [DA29KQ] Model Selection Abnormality ..800

Failure code [DA2LKA] System Operating Lamp Disconnection (Pump Con) ..802

Failure code [DA2LKB] System Operating Lamp Short Circuit (Pump Con) ..804

Failure code [DA2QKR] CAN2 Discon (Pump Con) ..805

Failure code [DA2RKR] CAN1 Discon (Pump Con) ..807

Failure code [DAF0MB] Monitor ROM Abnormality ..808

Failure code [DAF0MC] Monitor Error ..809

Failure code [DAF8KB] Camera Power Supply Short Circuit ..810

Failure code [DAF9KQ] Model Selection Abnormality ..812

Failure code [DAFGMC] GPS Module Error ..813

Failure code [DAFLKA] Operating Lamp Open Circuit(Monitor) ..814

Failure code [DAFLKB] System Operating Lamp Short Circuit (Monitor) ..816

Failure code [DAFQKR] CAN2 Discon (Monitor) ..817

Failure code [DAZ9KQ] A/C Model Selection Abnormality ..818

Failure code [DAZQKR] CAN2 Discon (Aircon ECU) ..819

Failure code [DB2QKR] CAN2 Discon (Engine Con) ..823

Failure code [DB2RKR] CAN1 Discon (Engine Con) ..827

Failure code [DGH2KB] Hyd Oil Sensor Short Circuit ..832

Failure code [DHA4KA] Air Cleaner Clogging Sensor Open Circuit ..834

Failure code [DHPAMA] F Pump Press Sensor Abnormality ..836

Failure code [DHPBMA] R Pump Press Sensor Abnormality ..838

Failure code [DHS3MA] Arm Curl PPC Press Sensor Abnormality ..840

Failure code [DHS4MA] Bucket Curl PPC Press Sensor Abnormality ..842

Failure code [DHS8MA] Boom Raise PPC Press Sensor Abnormality ..844

Failure code [DHS9MA] Boom Lower PPC Press Sensor Abnormality ..846

Failure code [DHSAMA] Swing RH PPC Press Sensor Abnormality ..848

Failure code [DHSBMA] Swing LH PPC Press Sensor Abnormality ..850

Failure code [DHSCMA] Arm Dump PPC Press Sensor Abnormality ..852

Failure code [DHSDMA] Bucket Dump PPC Press Sensor Abnormality ..854

Failure code [DKR0MA] Pump Swash Plate Sensor Abnormality ..856

Failure code [DR21KX] Camera 2 Picture Rev. Drive Abnormality ..858

Failure code [DR31KX] Camera 3 Picture Rev. Drive Abnormality ..860

Failure code [DV20KB] Travel Alarm Short Circuit ..861

Failure code [DW43KA] Travel Speed Sol Open Circuit ..863

Failure code [DW43KB] Travel Speed Sol Short Circuit ..865

Failure code [DW45KA] Swing Brake Sol Open Circuit ..867

Failure code [DW45KB] Swing Brake Sol Short Circuit ..870

Failure code [DW91KA] Travel Junction Sol Open Circuit ..872

Failure code [DW91KB] Travel Junction Sol Short Circuit ..874

Failure code [DWA2KA] Attachment Sol Open Circuit ..876

Failure code [DWA2KB] Attachment Sol Short Circuit ..878

Failure code [DWJ0KA] Merge-divider Sol Open Circuit ..879

Failure code [DWJ0KB] Merge-divider Sol Short Circuit ..880

Failure code [DWK0KA] 2-Stage Relief Sol Open Circuit ..881

Failure code [DWK0KB] 2-Stage Relief Sol Short Circuit ..883

Failure code [DXA8KA] PC-EPC Sol Open Circuit ..884

Failure code [DXA8KB] PC-EPC Sol Short Circuit ..886

Failure code [DXE4KA] Attachment Flow EPC Open Circuit ..888

Failure code [DXE4KB] Attachment Flow EPC Short Circuit ..890

Failure code [DY20KA] Wiper Working Abnormality ..891

Failure code [DY20MA] Wiper Parking Abnormality ..893

Failure code [DY2CKB] Washer Drive Short Circuit ..895

Failure code [DY2DKB] Wiper Drive (Fwd) Short Circuit ..897

Failure code [DY2EKB] Wiper Drive (Rev) Short Circuit ..899

Troubleshooting of electrical system (E-mode) ..901

E-1 Engine does not start (Engine does not crank) ..901

E-2 Manual preheating system does not work ..907

E-3 Automatic preheating system does not work ..910

E-4 While preheating is working, preheating monitor does not light up ..912

E-5 When starting switch is turned to ON position, machine monitor displays nothing ..914

E-6 While starting switch is turned to ON position (with engine stopped), engine oil level monitor lights up in yellow ..917

E-7 While starting switch is turned to ON position (with engine stopped), radiator coolant level monitor lights up in yellow ..918

E-8 Engine coolant temperature monitor lights up in red while engine is running ..919

E-9 Hydraulic oil temperature monitor lights up in red while engine is running ..920

E-10 Charge level monitor lights up in red while engine is running ..921

E-11 Fuel level monitor lights up in red while engine is running ..922

E-12 Air cleaner clogging monitor lights up in yellow while engine is running ..923

E-13 Water separator monitor lights up in red while engine is running ..924

E-14 Engine coolant temperature monitor lights up in red while engine is running ..925

E-15 Hydraulic oil temperature monitor lights up in red while engine is running ..926

E-16 Engine oil pressure monitor lights up in red while engine is running ..927

E-17 Fuel gauge display does not move from minimum or maximum ..928

E-18 Fuel gauge indicates incorrect amount (indicates neither full nor empty) ..929

E-19 Engine coolant temperature gauge display does not move from minimum or maximum ..930

E-20 Engine coolant temperature gauge indicates incorrect temperature (indicates neither full nor empty) ..931

E-21 Hydraulic oil temperature gauge does not move from minimum or maximum ..932

E-22 Hydraulic oil temperature gauge indicates incorrect temperature (indicates neither full nor empty) ..934

E-23 Contents of display on machine monitor is different from actual machine condition ..935

E-24 Some areas of machine monitor screen are not displayed ..936

E-25 Function switch does not work ..937

E-26 Automatic warm-up system does not operate (in cold season) ..938

E-27 Auto-deceleration monitor does not light up, or does not go out, while auto-deceleration switch is operated ..939

E-28 Auto-deceleration function does not operate or is not canceled while lever is operated ..940

E-29 Working mode selection screen is not displayed while working mode selector switch is operated ..941

E-30 Setting of engine and hydraulic pump is not changed while working mode is changed ..942

E-31 Travel speed monitor does not change when travel speed switch is operated ..943

E-32 Travel speed does not change while travel speed selection is changed ..944

E-33 Alarm buzzer does not stop sounding ..945

E-34 Service meter is not displayed, while starting switch is in OFF position ..946

E-35 Service mode cannot be selected ..947

E-36 Any of work equipment, swing and travel does not work ..948

E-37 Any of work equipment, swing and travel cannot be locked ..950

E-38 Upper structure does not swing while swing parking brake cancel switch is set to CANCEL position ..952

E-39 Swing brake does not operate while swing parking brake cancel switch is set to NORMAL position ..954

E-40 One-touch power maximizing function does not operate, or indicator is not displayed on monitor ..956

E-41 One-touch power maximizing function cannot be canceled ..958

E-42 Alarm does not sound during travel ..959

E-43 Alarm does not stop sounding while machine is stopped ..960

E-44 Horn does not sound ..961

E-45 Horn does not stop sounding ..963

E-46 Wiper monitor does not light up, or does not go out, while wiper switch is operated ..964

E-47 Wiper does not operate while wiper switch is operated ..965

E-48 Window washer does not operate while window washer switch is operated ..967

E-49 Boom LOWER is not displayed correctly with monitoring function ..968

E-50 Arm OUT is not displayed correctly with monitoring function ..969

E-51 Arm IN is not displayed correctly with monitoring function ..970

E-52 Boom RAISE is not displayed correctly with monitoring function ..971

E-53 Bucket CURL is not displayed correctly with monitoring function ..972

E-54 Bucket DUMP is not displayed correctly with monitoring function ..973

E-55 Swing is not displayed correctly with monitoring function ..974

E-56 Travel is not displayed correctly with monitoring function ..975

E-57 Service is not displayed correctly with monitoring function ..977

E-58 Attachment hydraulic circuit cannot be changed ..979

E-59 KOMTRAX system does not operate normally ..980

Troubleshooting of hydraulic and mechanical system (H-mode) ..981

Information described in troubleshooting table (H-mode) ..981

System chart of hydraulic and mechanical systems ..982

Failure mode and cause table ..984

H-1 All of work equipments, swing and travel operations lack speed or power ..992

H-2 Engine speed drops significantly or engine stalls ..994

H-3 All work equipment, swing and travel does not work ..995

H-4 Unusual sound is heard from around hydraulic pump ..996

H-5 Fine control performance or response is poor ..997

H-6 Boom speed or power is low ..998

H-7 Arm speed or power is low ..1001

H-8 Bucket speed or power is low ..1004

H-9 Work equipment does not move in single operation ..1006

H-10 Hydraulic drift of boom is large ..1007

H-11 Hydraulic drift of arm is large ..1008

H-12 Hydraulic drift of bucket is large ..1009

H-13 Time lag of work equipment is large ..1010

H-14 When part of work equipment is relieved singly, other parts of work equipment move ..1012

H-15 One-touch power maximizing function does not operate ..1013

H-16 In combined operation of work equipment, equipment having heavier load moves slower ..1014

H-17 In combined operations of swing and boom RAISE, boom rising speed is low ..1015

H-18 In combined operation of swing and travel, travel speed drops largely ..1016

H-19 Machine does not travel straight ..1017

H-20 Travel speed is slow ..1019

H-21 Machine is hard to steer or travel power is low ..1021

H-22 Travel speed does not change, or travel speed is too slow or fast ..1024

H-23 One of tracks does not run ..1025

H-24 Upper structure does not swing to the right or left ..1027

H-25 Upper structure swing only to the right or left ..1028

H-26 Swing acceleration or swing speed is low in both directions (right and left) ..1029

H-27 Swing acceleration performance is poor or swing speed is slow in only one direction ..1030

H-28 Upper structure overruns excessively when it stops swinging (both right and left) ..1031

H-29 Upper structure overruns excessively when it stops swinging (either right or left) ..1032

H-30 Shock is large when upper structure stops swinging ..1033

H-31 Large unusual noise is heard when upper structure stops swinging ..1034

H-32 Swing drift on a slope is large while swing parking brake is applied ..1035

H-33 Swing drift on a slope is large while swing parking brake is released ..1036

H-34 Attachment hydraulic circuit cannot be changed while attachment is installed ..1037

H-35 Oil flow in attachment circuit cannot be controlled ..1038

Troubleshooting of engine (S-mode) ..1039

Information mentioned in troubleshooting table (S mode) ..1039

S-1 Engine does not crank when starting switch is turned to START position ..1040

S-2 Engine cranks but no exhaust smoke comes out ..1041

S-3 Fuel is being injected but engine does not start (misfiring: engine cranks but does not start) ..1042

S-4 Engine startability is poor ..1043

S-5 Engine does not pick up smoothly ..1045

S-6 Engine stops during operation ..1047

S-7 Engine runs rough or is unstable ..1049

S-8 Engine lacks power ..1050

S-9 Exhaust smoke is black ..1052

S-10 Engine oil consumption is excessive ..1054

S-11 Oil becomes contaminated quickly ..1055

S-12 Fuel consumption is excessive ..1056

S-13 Oil is in coolant (or coolant spurts or coolant level goes down) ..1057

S-14 Oil pressure drops ..1058

S-15 Fuel mixes into engine oil ..1059

S-16 Water mixes into engine oil (milky) ..1060

S-17 Coolant temperature rises too high (overheating) ..1061

S-18 Unusual noise is heard ..1062

S-19 Vibration is excessive ..1063

S-20 Air cannot be bled from fuel circuit ..1064

50 Disassembly and assembly ..1065

Table of contents ..1066

Related information on disassembly and assembly ..1068

How to read this manual ..1068

Coating materials list ..1070

Special tools list ..1074

Sketches of special tools ..1079

Engine and cooling system ..1083

Removal and installation of supply pump assembly ..1083

Removal and installation of injector assembly ..1087

Removal and installation of cylinder head assembly ..1093

Removal and installation of radiator assembly ..1110

Removal and installation of hydraulic oil cooler assembly ..1112

Removal and installation of aftercooler assembly ..1115

Removal and installation of engine and main pump assembly ..1117

Removal and installation of engine front oil seal ..1124

Removal and installation of engine rear oil seal ..1128

Removal and installation of fuel cooler assembly ..1131

Removal and installation of fuel tank assembly ..1133

Removal and installation of engine hood assembly ..1135

Removal and installation of KDOC assembly ..1137

Removal and installation of KCCV assembly ..1139

Removal and installation of air cleaner assembly ..1144

Power train ..1146

Removal and installation of travel motor and final drive assembly ..1146

Disassembly and assembly of final drive assembly ..1147

Removal and installation of swing motor and swing machinery assembly ..1156

Disassembly and assembly of swing machinery assembly ..1158

Removal and installation of swing circle assembly ..1165

Undercarriage and frame ..1166

Separation and connection of track shoe assembly ..1166

Removal and installation of sprocket ..1168

Removal and installation of idler and idler cushion assembly ..1169

Disassembly and assembly of idler assembly ..1170

Disassembly and assembly of idler cushion assembly ..1173

Disassembly and assembly of track roller assembly ..1175

Disassembly and assembly of carrier roller assembly ..1177

Removal and installation of revolving frame assembly ..1180

Removal and installation of counterweight assembly ..1182

Hydraulic system ..1184

Removal and installation of center swivel joint assembly ..1184

Disassembly and assembly of center swivel joint assembly ..1187

Removal and installation of hydraulic tank assembly ..1188

Removal and installation of main pump assembly ..1192

Removal and installation of main pump input shaft oil seal ..1195

Removal and installation of control valve assembly ..1196

Disassembly and assembly of control valve assembly ..1200

Disassembly and assembly of work equipment PPC valve assembly ..1202

Disassembly and assembly of travel PPC valve assembly ..1204

Work equipment ..1206

Removal and installation of work equipment assembly ..1206

Disassembly and assembly of work equipment cylinder assembly ..1209

Cab and its attachments ..1215

Removal and installation of operator's cab assembly ..1215

Removal and installation of operator cab glass (adhered glass) ..1220

Removal and installation of front window assembly ..1230

Removal and installation of floor frame assembly ..1236

Removal and installation of air conditioner unit assembly ..1241

Removal and installation of operator's seat ..1245

Removal and installation of seat belt ..1247

Removal and installation of front wiper assembly ..1249

Electrical system ..1256

Removal and installation of air conditioner compressor assembly ..1256

Removal and installation of air conditioner condenser assembly ..1258

Removal and installation of engine controller assembly ..1260

Removal and installation of pump controller assembly ..1262

Removal and installation of machine monitor assembly ..1265

Removal and installation of pump swash plate sensor ..1267

Removal and installation of mass air flow and temperature sensor ..1268

Removal and installation of KOMTRAX terminal assembly ..1269

60 Maintenance standard ..1271

Table of contents ..1272

Engine and cooling system ..1273

Engine mount ..1273

Cooling system ..1274

Power train ..1275

Swing circle ..1275

Swing machinery ..1276

Final drive ..1277

Sprocket ..1279

Undercarriage and frame ..1281

Track frame and idler cushion ..1281

Idler ..1283

Track roller ..1285

Carrier roller ..1286

Track shoe ..1287

Hydraulic system ..1291

Hydraulic tank ..1291

Main pump ..1292

Control valve ..1295

Travel motor ..1306

Work equipment and swing PPC valve ..1309

Travel PPC valve ..1312

1st-line attachment PPC valve (with EPC valve) ..1315

2nd-line attachment PPC valve ..1318

Solenoid valve ..1320

Attachment circuit selector valve (for high-pressure circuit) ..1321

Attachment circuit selector valve (for low-pressure circuit) ..1322

Center swivel joint ..1323

Work equipment ..1324

Work equipment ..1324

Boom cylinder ..1333

Arm cylinder ..1334

Bucket cylinder ..1335

80 Appendix ..1337

Table of contents ..1338

Air conditioner components ..1339

Precautions for refrigerant ..1339

Air conditioner component ..1340

Configuration and function of refrigeration cycle ..1343

Outline of refrigeration cycle ..1344

Air conditioner unit ..1346

Dual pressure switch ..1353

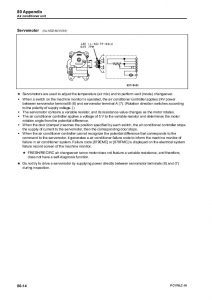

Air conditioner controller ..1354

Compressor ..1355

Air conditioner condenser ..1356

Sunlight sensor ..1358

Outer temperature sensor (outside air temperature sensor) ..1359

Procedure for testing and troubleshooting ..1360

Circuit diagram and arrangement of connector pins ..1362

System diagram ..1364

Input and output signals of the air conditioner controller ..1365

Parts and connectors layout ..1367

Testing air leakage (duct) ..1371

Testing with self-diagnosis function ..1374

Testing vent (mode) changeover ..1377

Testing FRESH/RECIRC air changeover ..1379

Testing sunlight sensor ..1380

Testing (dual) pressure switch for refrigerant ..1381

Testing relays ..1382

Troubleshooting chart 1 ..1383

Troubleshooting chart 2 ..1384

Information in troubleshooting table ..1387

Failure code list related to air conditioner ..1388

Failure code [879AKA] A/C Inner Sensor Open Circuit ..1389

Failure code [879AKB] A/C Inner Sensor Short Circuit ..1390

Failure code [879BKA] A/C Outer sensor Open Circuit ..1391

Failure code [879BKB] A/C Outer sensor Short Circuit ..1393

Failure code [879CKA] Ventilating Sensor Open Circuit ..1395

Failure code [879CKB] Ventilating Sensor Short Circuit ..1396

Failure code [879DKZ] Sunlight sensor Open or Short Circuit ..1397

Failure code [879EMC] Ventilation Damper Abnormality ..1399

Failure code [879FMC] Air Mix Damper Abnormality ..1400

Failure code [879GKX] Refrigerant Abnormality ..1401

A-1 Troubleshooting for power supply system (Air conditioner does not operate) ..1402

A-2 Troubleshooting for compressor and refrigerant system (Air is not cooled) ..1404

A-3 Troubleshooting for blower motor system (No air comes out or air flow is abnormal) ..1407

A-4 Troubleshooting for FRESH/RECIRC air changeover ..1409

Troubleshooting with gauge pressure ..1411

Connection of service tool ..1414

Precautions for disconnecting and connecting air conditioner piping ..1416

Handling of compressor oil ..1418

Desiccant replacement ..1420

90 Diagrams and drawings ..1423

Table of contents ..1424

Hydraulic circuit diagram ..1425

Symbols in hydraulic circuit diagram ..1425

Hydraulic circuit diagram ..1428

Electric circuit diagram ..1430

Symbols in electric circuit diagram ..1430

Electrical circuit diagram ..1434

Electric circuit diagram for air conditioner unit ..1440

INDEX..1441

Komatsu Hydraulic Excavator PC170LC Repair Service Manuals