Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC20, PC25, PC30, PC40, PC45, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC20-3, PC20-6, PC25-1, PC30-3, PC30-6, PC30-7, PC40-6, PC40-7, PC45-1 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM020R0604 – Hydraulic Excavator PC20-6, PC30-6, PC40-6 Shop Manual.pdf

SEBM020S0707 – Hydraulic Excavator PC25-1, PC30-7, PC40-7, PC45-1 Shop Manual.pdf

SEBM0225C01 – Hydraulic Excavator PC20-3, PC30-3 Shop Manual.pdf

SEAM020P0700 – Hydraulic Excavator PC20-7 Operation & Maintenance Manual.pdf

SEAM006600 – Hydraulic Excavator PC25-1, PC30-7, PC40-7, PC45-1 Operation & Maintenance Manual.pdf

SEAM009502T – Hydraulic Excavator PC40-7 Operation & Maintenance Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,522 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

SEAM006600 – Hydraulic Excavator PC25-1, PC30-7, PC40-7, PC45-1 Operation & Maintenance Manual…2

COVER…2

1. FOREWORD…3

2. SAFETY INFORMATION…4

3. INTRODUCTION…5

3.1 INTENDED USE…5

3.2 FEATURES…5

3.3 BREAKING IN THE MACHINE…5

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…6

4.1 MACHINE SERIAL NO. PLATE POSITION…6

4.2 ENGINE SERIAL NO. PLATE POSITION…6

4.3 TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…6

CONTENTS…7

SAFETY…11

6. GENERAL PRECAUTIONS…12

7. PRECAUTIONS DURING OPERATION…17

7.1 BEFORE STARTING ENGINE…17

7.2 OPERATING MACHINE…19

7.3 TRANSPORTATION…24

7.4 BATTERY…25

7.5 TOWING…26

7.6 BUCKET WITH HOOK…27

8. PRECAUTIONS FOR MAINTENANCE…30

8.1 BEFORE CARRYING OUT MAINTENANCE…30

8.2 DURING MAINTENANCE…33

9. POSITION FOR ATTACHING SAFETY LABELS…37

OPERATION…41

10. GENERAL VIEW…42

10.1 GENERAL VIEW OF MACHINE…42

10.2 GENERAL VIEW OF CONTROLS AND GAUGES…43

11. EXPLANATION OF COMPONENTS…44

11.1 MACHINE MONITOR…44

11.2 SWITCHES…49

11.3 CONTROL LEVERS AND PEDALS…52

11.4 ENGINE HOOD…56

11.5 FRONT WINDOW (MACHINES EQUIPPED WITH CAB)…57

11.6 DOOR LOCK…59

11.7 FUSE…60

11.8 FUSIBLE LINK…60

11.9 CAP, COVER WITH LOCK…61

11.10 CANOPY (MACHINES EQUIPPED WITH CANOPY)…62

12. OPERATION…63

12.1 CHECK BEFORE STARTING ENGINE…63

12.2 STARTING ENGINE…71

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE…73

12.4 MOVING MACHINE OFF…75

12.5 STEERING MACHINE…78

12.6 STOPPING MACHINE…80

12.7 SWINGING…81

12.8 OPERATION OF WORK EQUIPMENT…82

12.9 PROHIBITIONS FOR OPERATION…83

12.10 PRECAUTIONS FOR OPERATION…86

12.11 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS…87

12.12 HOW TO ESCAPE MUD…89

12.13 WORK POSSIBLE USING HYDRAULIC EXCAVATOR…90

12.14 REPLACEMENT OF BUCKET…92

12.15 PARKING MACHINE…95

12.16 CHECK AFTER FINISHING WORK…96

12.17 STOPPING ENGINE…96

12.18 CHECK AFTER STOPPING ENGINE…97

12.19 LOCKING…97

12.20 HANDLING RUBBER SHOES (RUBBER SHOES ONLY)…98

13. TRANSPORTATION…103

13.1 LOADING, UNLOADING WORK…103

13.2 METHOD OF LIFTING MACHINE…105

13.3 PRECAUTIONS FOR LOADING…107

13.4 PRECAUTIONS FOR TRANSPORTATION…108

14. COLD WEATHER OPERATION…109

14.1 PRECAUTIONS FOR LOW TEMPERATURE…109

14.2 PRECAUTIONS AFTER COMPLETION OF WORK…111

14.3 PREPARING THE CAB HEATER (MACHINES EQUIPPED WITH CAB)…111

14.4 AFTER COLD WEATHER…111

15. LONG-TERM STORAGE…112

15.1 BEFORE STORAGE…112

15.2 DURING STORAGE…113

15.3 AFTER STORAGE…113

16. TROUBLESHOOTING…114

16.1 PHENOMENA THAT ARE NOT FAILURES…114

16.2 METHOD OF TOWING MACHINE…114

16.3 PRECAUTIONS ON PARTICULAR JOBSITES…114

16.4 IF BATTERY IS DISCHARGED…115

16.5 OTHER TROUBLE…120

MAINTENANCE…125

17. GUIDES TO MAINTENANCE…126

18. OUTLINES OF SERVICE…128

18.1 OUTLINE OF OIL, FUEL, COOLANT…128

18.2 OUTLINE OF ELECTRIC SYSTEM…131

18.3 OUTLINE OF HYDRAULIC SYSTEM…132

19. WEAR PARTS LIST…133

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…134

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…138

21.1 INTRODUCTION OF NECESSARY TOOLS…138

21.2 TORQUE LIST…139

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…140

23. MAINTENANCE SCHEDULE CHART…142

23.1 MAINTENANCE SCHEDULE CHART…142

23.2 MAINTENANCE INTERVAL WHEN USING HYDRAULIC BREAKER…144

24. SERVICE PROCEDURE…145

24.1 INITIAL 250 HOURS SERVICE…145

CHECK ENGINE VALVE CLEARANCE, ADJUST…192

24.2 WHEN REQUIRED…146

24.2.1 CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT…146

24.2.2 CLEAN INSIDE OF COOLING SYSTEM…149

24.2.3 DRAIN WATER, SEDIMENT FROM FUEL TANK…153

24.2.4 CLEAN WATER SEPARATOR ELEMENT…153

24.2.5 CHECK ELECTRIC WIRINGS…154

24.2.6 CHECK RUBBER SHOES (MACHINE EQUIPPED WITH RUBBER SHOES)…155

24.2.7 CHECK AND ADJUST TRACK TENSION (MACHINE EQUIPPED WITH RUBBER SHOES)…157

24.2.8 REPLACE RUBBER SHOES (MACHINE EQUIPPED WITH RUBBER SHOES)…159

24.2.9 CHECK AND ADJUST TRACK TENSION (MACHINE EQUIPPED WITH STEEL SHOES)…162

24.2.10 REPLACE BUCKET TEETH (VERTICAL PIN TYPE)…165

24.2.11 INSPECTION OF BUCKET PLAY ADJUSTMENT MECHANISM…168

24.3 CHECK BEFORE STARTING…169

24.3.1 CHECK COOLANT LEVEL, ADD WATER…169

24.3.2 CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL…169

24.3.3 CHECK FUEL LEVEL, ADD FUEL…170

24.3.4 CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL…171

24.3.5 CHECK DUST INDICATOR…172

24.3.6 CHECK WATER SEPARATOR…172

24.4 EVERY 100 HOURS SERVICE…173

24.4.1 LUBRICATING…173

1. SWING PINION (1POINT)…173

2. SWING CIRCLE (1POINT)…173

3. BOOM SWING CYLINDER FOOT PIN (1POINT)…173

4. BOOM SWING CYLINDER ROD END (1POINT)…173

5. BOOM CYLINDER FOOT PIN (1POINT)…173

6. BLADE CYLINDER FOOT PIN (1POINT)…173

7. BLADE FOOT PIN (2 POINTS)…173

8. BLADE CYLINDER ROD END (1POINT)…173

9. BOOM FOOT PIN (2 POINTS)…173

10. BOOM SWING BRACKET PIN (2 POINTS)…173

11. ARM CYLINDER FOOT PIN (1POINT)…174

12. BOOM CYLINDER ROD END (1POINT)…174

13. BOOM-ARM COUPLING PIN (1POINT)…174

14. ARM CYLINDER ROD END PIN (1POINT)…174

15. BUCKET CYLINDER FOOT PIN (1POINT)…174

16. BUCKET CYLINDER ROD END PIN (1POINT)…174

17. LINK COUPLING PIN (1POINT)…174

18. BUCKET-LINK COUPLING PIN (2 POINTS)…174

19. ARM-BUCKET COUPLING PIN (1POINT)…174

20. ARM-LINK COUPLING PIN (1POINT)…174

24.5 EVERY 250 HOURS SERVICE…175

24.5.1 CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE…175

24.5.2 CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL…177

24.5.3 CHECK LEVEL OF BATTERY ELECTROLYTE…179

24.5.4 REPLACE HYDRAULIC FILTER ELEMENT…180

24.5.5 CHECK FAN BELT TENSION, ADJUST…181

24.6 EVERY 500 HOURS SERVICE…182

24.6.1 REPLACE FUEL FILTER CARTRIDGE…182

24.6.2 CLEAN, CHECK RADIATOR FINS…184

24.7 EVERY 1000 HOURS SERVICE…185

24.7.1 CHANGE OIL IN SWING MACHINERY CASE…185

24.7.2 CHANGE OIL IN FINAL DRIVE CASE…186

24.8 EVERY 2000 HOURS SERVICE…188

24.8.1 CHANGE OIL IN HYDRAULIC TANK CLEAN STRAINER…188

24.8.2 CHECK ALTERNATOR, STARTING MOTOR…192

24.8.3 CHECK ENGINE VALVE CLEARANCE, ADJUST…192

SPECIFICATIONS…193

25. SPECIFICATIONS…194

OPTIONS, ATTACHMENTS…211

26. GENERAL PRECAUTIONS…212

26.1 PRECAUTIONS RELATED TO SAFETY…212

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS…213

27. HANDLING BUCKET WITH HOOK…214

27.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK…214

27.2 PROHIBITED OPERATIONS…214

27.3 PRECAUTIONS DURING OPERATIONS…214

SEAM009502T – Hydraulic Excavator PC40-7 Operation & Maintenance Manual…215

COVER…215

1. FOREWORD…216

2. SAFETY INFORMATION…219

3. INTRODUCTION…220

4. LOCATION OF PLATES,TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…221

5. CONTENTS…222

SAFETY…225

6. GENERAL PRECAUTIONS…226

7. PRECAUTIONS DURING OPERATION…231

7.1 BEFORE STARTING ENGINE…231

7.2 OPERATING MACHINE…233

7.3 TRANSPORTATION…238

7.4 BATTERY…239

7.5 TOWING…240

7.6 BUCKET WITH HOOK…241

8. PRECAUTIONS FOR MAINTENANCE…244

8.1 BEFORE CARRYING OUT MAINTENANCE…244

8.2 DURING MAINTENANCE…247

9. POSITION FOR ATTACHING SAFETY LABELS…251

OPERATION…255

10. GENERAL VIEW…256

10.1 GENERAL VIEW OF MACHINE…256

10.2 GENERAL VIEW OF CONTROLS AND GAUGES…257

11. EXPLANATION OF COMPONENTS…258

11.1 MACHINE MONITOR…258

11.2 SWITCHES…263

11.3 CONTROL LEVERS AND PEDALS…265

11.4 ENGINE HOOD…269

11.5 FUSE…270

11.6 FUSIBLE LINK…270

11.7 CAP, COVER WITH LOCK…271

11.8 USING SEAT BELT…272

11.9 STORAGE PLACE FOR OPERATION AND MAINTENANCE MANUAL…273

11.10 HANDLING ACCUMULATOR…273

12. OPERATION…275

12.1 CHECK BEFORE STARTING ENGINE…275

12.2 STARTING ENGINE…283

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE…285

12.4 MOVING MACHINE OFF…287

12.5 STEERING MACHINE…290

12.6 STOPPING MACHINE…292

12.7 SWINGING…293

12.8 OPERATION OF WORK EQUIPMENT…294

12.9 PROHIBITIONS FOR OPERATION…295

12.10 PRECAUTIONS FOR OPERATION…298

12.11 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS…299

12.12 HOW TO ESCAPE FROM MUD…301

12.13 WORK POSSIBLE USING HYDRAULIC EXCAVATOR…302

12.14 REPLACEMENT OF BUCKET…304

12.15 PARKING MACHINE…307

12.16 CHECK AFTER FINISHING WORK…308

12.17 STOPPING ENGINE…308

12.18 CHECK AFTER STOPPING ENGINE…309

12.19 LOCKING…309

12.20 HANDLING RUBBER SHOES (RUBBER SHOES ONLY)…310

13. TRANSPORTATION…315

13.1 LOADING, UNLOADING WORK…315

13.2 METHOD OF LIFTING MACHINE…317

13.3 PRECAUTIONS FOR LOADING…319

13.4 PRECAUTIONS FOR TRANSPORTATION…320

14. COLD WEATHER OPERATION…321

14.1 PRECAUTIONS FOR LOW TEMPERATURE…321

14.2 PRECAUTIONS AFTER COMPLETION OF WORK…323

14.3 PREPARING THE CAB HEATER (MACHINES EQUIPPED WITH CAB)…323

14.4 AFTER COLD WEATHER…323

15. LONG-TERM STORAGE…324

15.1 BEFORE STORAGE…324

15.2 DURING STORAGE…325

15.3 AFTER STORAGE…325

16. TROUBLESHOOTING…326

16.1 PHENOMENA THAT ARE NOT FAILURES…326

16.2 METHOD OF TOWING MACHINE…326

16.3 PRECAUTIONS ON PARTICULAR JOBSITES…326

16.4 IF BATTERY IS DISCHARGED…327

16.5 OTHER TROUBLE…332

MAINTENANCE…336

17. GUIDES TO MAINTENANCE…337

18. OUTLINES OF SERVICE…339

18.1 OUTLINE OF OIL,FUEL,COOLANT…339

18.2 OUTLINE OF ELECTRIC SYSTEM…342

18.3 OUTLINE OF HYDRAULIC SYSTEM…343

19. WEAR PARTS LIST…344

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…345

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…349

21.1 INTRODUCTION OF NECESSARY TOOLS…349

21.2 TORQUE LIST…350

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…351

23. MAINTENANCE SCHEDULE CHART…353

23.1 MAINTENANCE SCHEDULE CHART…353

23.2 MAINTENANCE INTERVAL WHEN USING HYDRAULIC BREAKER…355

24. SERVICE PROCEDURE…356

24.1 INITIAL 250 HOURS SERVICE…356

24.2 WHEN REQUIRED…357

24.3 CHECK BEFORE STARTING…380

24.4 EVERY 100 HOURS SERVICE…384

24.5 EVERY 250 HOURS SERVICE…386

24.6 EVERY 500 HOURS SERVICE…392

24.7 EVERY 1000 HOURS SERVICE…395

24.8 EVERY 2000 HOURS SERVICE…397

SPECIFICATIONS…402

25. SPECIFICATIONS…403

SEAM020P0700 – Hydraulic Excavator PC20-7 Operation & Maintenance Manual…407

COVER…407

FOREWORD…408

BREAKING IN YOUR NEW MACHINE…409

CONTENTS…410

GENERAL LOCATIONS AND SPECIFICATIONS…411

INSTRUMENTS AND CONTROLS…413

CHECK BEFORE STARTING…439

OPERATING YOUR MACHINE…445

REPLACEMENT OF BUCKET…465

SELECTION OF TRACK SHOES (STEEL SHOES ONLY)…467

HANDLING RUBBER SHOES (RUBBER SHOES ONLY)…468

COLD WEATHER OPERATION…475

PERIODIC MAINTENANCE…480

PERIODICAL REPLACEMENT OF SAFETY PARTS…481

MAINTENANCE TABLE…484

OIL FILLER AND LEVEL GAUGE POSITIONS…487

CHECK BEFORE STARTING…489

EVERY 100 HOURS SERVICE…489

EVERY 250 HOURS SERVICE…491

EVERY 500 HOURS SERVICE…497

EVERY 1000 HOURS SERVICE…499

EVERY 2000 HOURS SERVICE…501

WHEN REQUIRED…503

SERVICE METER…521

MACHINE AND ENGINE SERIAL NUMBERS…523

FUEL,COOLANT AND LUBRICANTS…525

SAFETY AND OPERATION…527

CONTENTS…528

SAFETY HINTS…529

OPERATING RADIO…545

LOCKING CAP…549

HANDLING OF BATTERY…551

METHOD OF RAISING THE MACHINE…554

TRANSPORTATION…556

PRECAUTIONS FOR MAINTENANCE…557

STORAGE…563

COOLANT AND LUBRICANTS…564

SEBM020R0604 – Hydraulic Excavator PC20-6, PC30-6, PC40-6 Shop Manual…565

COVER…565

CONTENTS…566

10 STRUCTURE AND FUNCTION…581

POWER TRAIN…582

SWING CIRCLE…583

SWING MACHINERY…584

SPROCKET…586

TRACK FRAME AND RECOIL SPRING…587

IDLER…588

TRACK ROLLER…588

TRACK SHOE…589

HYDRAULIC PIPING…591

HYDRAULIC CIRCUIT SCHEMATICS…593

HYDRAULIC CIRCUIT DIAGRAM…596

HYDRAULIC TANK…603

HYDRAULIC TRIPLE GEAR PUMP…605

6-SPOOL CONTROL VALVE…607

2-SPOOL CONTROL VALVE…609

3-SPOOL CONTROL VALVE…610

CENTER SWIVEL JOINT…613

SWING MOTOR…615

TRAVEL MOTOR (WITH REDUCTION GEAR)…616

VALVE CONTROL…621

WORK EQUIPMENT…622

ELECTRICAL CIRCUIT DIAGRAM…623

20 TESTING AND ADJUSTING…627

TABLE OF JUDGEMENT STANDARD VALVE…628

TESTING AND ADJUSTING TOOL LIST…638

ADJUSTING VALVE CLEARANCE (PC20,30-6)…639

ADJUSTING VALVE CLEARANCE (PC40-6)…640

MEASURING COMPRESSION PRESSURE…641

TESTING AND ADJUSTING FUEL INJECTION TIMING (PC20,30-6)…642

TESTING AND ADJUSTING FUEL INJECTION TIMING (PC40-6)…643

BLEEDING AIR FROM HYDRAULIC CYLINDERS…644

MEASURING AND ADJUSTING HYDRAULIC PRESSURE…645

MEASURING HYDRAULIC PRESSURE OF ACCELERATION CIRCUIT (PC30,40-6)…648

MEASURING DISCHARGE AMOUNT OF PUMP…649

MEASURING OIL LEAKAGE FROM SWING, TRAVEL MOTORS…650

TESTING FOR LEAKAGE OF OIL FROM CENTER SWIVEL JOINT (PC20-6)…651

TESTING FOR LEAKAGE OF OIL FROM CENTER SWIVEL JOINT (PC30-6)…652

TESTING FOR LEAKAGE OF OIL FROM CENTER SWIVEL JOINT (PC40-6)…653

MEASURING LEAKAGE FROM HYDRAULIC CYLINDERS…654

TROUBLESHOOTING…655

PREPARATION OF TROUBLESHOOTING…656

HOW TO USE DIAGNOSTIC TABLE…658

PREVENTING RECURRENCE OF THE SAME TROUBLE…660

1.WORK EQUIPMENT, SWING, AND TRAVEL DO NOT MOVE, OR SPEED IS EXTREMELY SLOW…661

2.ARM IN (OUT) LACKS POWER (INCLUDING LACK OF SPEED)…662

3.BUCKET CURL (DUMP), BOOM RAISE (PUSHING UP CHASSIS), AND BOOM SWING LACK POWER (INCLUDING LACK OF SPEED)…663

4.ARM IN (OUT) OPERATION IS IMPOSSIBLE…664

5.BUCKET CURL (DUMP), BOOM RAISE (LOWER), BOOM SWING OPERATION IS IMPOSSIBLE…665

6.EXCESSIVE HYDRAULIC DRIFT OF WORK EQUIPMENT (BOOM, ARM, BUCKET, BLADE, BOOM SWING)…666

7.BLADE LACKS POWER (INCLUDING LACK OF SPEED)…667

8.BLADE OPERATION IS IMPOSSIBLE…668

9.LEFT (RIGHT) BOOM SWING LACKS POWER (INCLUDING LACK OF SPEED)…669

10.SWING OPERATION IS IMPOSSIBLE TO LEFT (OR RIGHT)…670

11.EXCESSIVE OVERRUN OF SWING ON SLOPES (HYDRAULIC DRIFT OF SWING)…671

12.EXCESSIVE OVERRUN WHEN SWING IS STOPPED…672

13.MACHINE NATURALLY DEVIATES TO ONE SIDE WHEN TRAVELING…673

14.MACHINE DOES NOT TRAVEL FORWARD (IN REVERSE)…674

15.TRAVEL SPEED DOES NOT CHANGE (PC30.40-6)…675

30 DISASSEMBLY AND ASSEMBLY…676

METHOD OF READING MANUAL…678

TABLE OF SPECIAL TOOLS…680

STARTING MOTOR…682

REMOVAL…682

INSTALLATION…682

ALTERNATOR…682

REMOVAL…682

INSTALLATION…682

WATER PUMP…684

REMOVAL…684

INSTALLATION…684

FUEL INJECTION PUMP…686

REMOVAL…686

INSTALLATION…686

NOZZLE HOLDER…688

REMOVAL…688

INSTALLATION…688

CYLINDER HEAD…690

REMOVAL (PC20.30-6)…690

INSTALLATION (PC20.30-6)…690

REMOVAL (PC40-6)…692

INSTALLATION (PC40-6)…692

HYDRAULIC OIL COOLER …694

REMOVAL…694

INSTALLATION…694

RADIATOR…694

REMOVAL …694

INSTALLATION…694

ENGINE…696

REMOVAL (PC20,30-6)…696

INSTALLATION (PC20,30-6)…696

REMOVAL (PC40-6)…698

INSTALLATION (PC40-6)…698

SWING CIRCLE…700

REMOVAL…700

INSTALLATION…700

SWING MACHINERY…702

REMOVAL…702

INSTALLATION …702

DISASSEMBLY (PC20.30-6)…704

ASSEMBLY (PC20.30-6)…706

DISASSEMBLY (PC40-6)…708

ASSEMBLY (PC40-6)…710

REVOLVING FRAME…712

REMOVAL…712

INSTALLATION…712

TRACK SHOE…714

REMOVAL…714

INSTALLATION…714

TRACK ROLLER…716

REMOVAL…716

INSTALLATION…716

IDLER, RECOIL SPRING…716

REMOVAL…716

INSTALLATION…716

RECOIL SPRING…718

DISASSEMBLY…718

ASSEMBLY…718

SPROCKET…720

REMOVAL…720

INSTALLATION…720

HYDRAULIC PUMP…720

REMOVAL…720

INSTALLATION…720

6-SPOOL CONTROL VALVE…722

REMOVAL…722

INSTALLATION…722

3-SPOOL CONTROL VALVE…722

REMOVAL…722

INSTALLATION…722

2-SPOOL CONTROL VALVE…722

REMOVAL…722

INSTALLATION…722

6-SPOOL CONTROL VALVE…724

DISASSEMBLY…724

ASSEMBLY…724

3-SPOOL CONTROL VALVE…726

DISASSEMBLY…726

ASSEMBLY…726

SWING MOTOR…728

REMOVAL…728

INSTALLATION…728

DISASSEMBLY…730

ASSEMBLY…732

CENTER SWIVEL JOINT…734

REMOVAL…734

INSTALLATION…734

DISASSEMBLY (PC20,30-6)…736

ASSEMBLY (PC20,30-6)…736

DISASSEMBLY (PC40-6)…738

ASSEMBLY (PC40-6)…738

TRAVEL MOTOR…740

REMOVAL…740

INSTALLATION…740

DISASSEMBLY (PC20-6)…742

ASSEMBLY (PC20-6)…754

DISASSEMBLY (PC30,40-6)…772

ASSEMBLY (PC30,40-6)…786

DISASSEMBLY (PC20-6)…804

ASSEMBLY (PC20-6)…812

DISASSEMBLY (PC30-6)…822

ASSEMBLY (PC30-6)…830

DISASSEMBLY (PC40-6)…842

ASSEMBLY (PC40-6)…850

BOOM CYLINDER …860

REMOVAL…860

INSTALLATION…860

ARM CYLINDER …862

REMOVAL…862

INSTALLATION…862

BUCKET CYLINDER…862

REMOVAL…862

INSTALLATION…862

BLADE CYLINDER…864

REMOVAL…864

INSTALLATION…864

BOOM SWING CYLINDER…864

REMOVAL…864

INSTALLATION…864

HYDRAULIC CYLINDER…866

DISASSEMBLY…866

ASSEMBLY…868

REPLACING HYDRAULIC CYLINDER PISTON RING…870

WORK EQUIPMENT…872

REMOVAL…872

INSTALLATION…872

BLADE …872

REMOVAL…872

INSTALLATION…872

BUCKET…874

REMOVAL…874

INSTALLATION…874

ARM …874

REMOVAL…874

INSTALLATION…874

ARM, BUCKET…876

REMOVAL…876

INSTALLATION…876

BOOM…876

REMOVL…876

INSTALLATION…876

FLOOR FRAME…878

REMOVAL…878

INSTALLATION…878

40 MAINTENANCE STANDARD…880

SWING CIRCLE…881

SWING MACHINERY…882

SPROCKET…884

TRACK FRAME AND RECOIL SPRING…885

IDLER…886

TRACK ROLLER…887

TRACK SHOE…888

TRIPLE GEAR PUMP…890

CENTER SWIVEL JOINT…892

SWING MOTOR…894

TRAVEL MOTOR BRAKE VALVE…895

6-SPOOL CONTROL VALVE…897

2-SPOOL CONTROL VALVE…898

3-SPOOL CONTROL VALVE…899

HYDRAULIC CYLINDER…900

WORK EQUIPMENT…906

SEBM020S0707 – Hydraulic Excavator PC25-1, PC30-7, PC40-7, PC45-1 Shop Manual…910

COVER…910

CONTENTS…911

SAFETY…914

SAFETY NOTICE…914

FOREWARD…916

GENERAL…916

HOW TO READ THE SHOP MANUAL…917

HOISTING INSTRUCTIONS…918

COATING MATERIALS…919

STANDARD TIGHTENING TORQUE…920

ELECTRIC WIRE CODE…922

CONVERSION TABLE…923

WEIGHT TABLE…930

WEIGHT TABLE…931

LIST OF LUBRICANT AND WATER…934

10 STRUCTURE AND FUNCTION…937

POWER TRAIN…938

SWING CIRCLE…939

SWING MACHINERY…940

TRACK FRAME AND RECOIL SPRING…942

HYDRAULIC PIPING…945

HYDRAULIC CIRCUIT DIAGRAM…946

HYDRAULIC TANK AND FUEL TANK…950

HYDRAULIC PUMP…951

CONTROL PUMP…959

7 – SPOOL CONTROL VALVE…960

2 – SPOOL CONTROL VALVE…964

SWING MOTOR…968

CENTER SWIVEL JOINT…971

TRAVEL MOTOR…972

HYDRAULIC CYLINDER…977

VALVE CONTROL…981

PPC VALVE…982

SOLENOID VALVE…988

WORK EQUIPMENT…990

HYDRAULIC BREAKER…991

ELECTRICAL CIRCUIT DIAGRAM…994

MONITOR SYSTEM…997

20 TESTING AND ADJUSTING…1006

TABLE OF JUDGEMENT STANDARD VALUE…1007

STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM…1025

TOOL FOR TESTING, ADJUSTING, AND TROUBLESHOOTING…1027

ADJUSTING VALVE CLEARANCE…1028

MEASURING COMPRESSION PRESSURE…1030

ADJUSTING FUEL INJECTION TIMING…1031

MEASURING ENGINE OIL PRESSURE…1032

ADJUSTING FUEL CONTROL LEVER…1034

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT…1035

TESTING CONTROL CIRCUIT PRESSURE…1038

MEASURING OUTPUT PRESSURE OF PPC VALVE…1039

ADJUSTING PPC VALVE…1040

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE…1041

MEASURING SOLENOID VALVE OUTLET PORT PRESSURE…1043

ADJUSTING BLADE CONTROL LEVER…1044

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT…1045

BLEEDING AIR FROM HYDRAULIC CIRCUIT…1046

RELEASING REMAINING FROM HYDRAULIC CIRCUIT…1048

TESTING HYDRAULIC BREAKER GAS PRESSURE…1049

TROUBLESHOOTING…1051

SEQUENCE OF EVENTS IN TROUBLESHOOTING…1052

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE…1053

CHECKS BEFORE TROUBLESHOOTING…1060

ELECTRICAL CIRCUIT DIAGRAM…1061

POSITION OF CONNECTORS FOR TROUBLESHOOTING…1064

CONNECTION TABLE FOR CONNECTOR…1068

METHOD OF USING TROUBLESHOOTING CHARTS…1075

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)…1077

E-1 THE ENGINE DOES NOT STOP WHEN THE STARTING SWITCH IS TURNED OFF…1078

E-2 WORK EQUIPMENT DOES NOT MOVE EVEN WHEN WORK EQUIPMENT LOCK LEVER IS RELEASED…1081

E-3 WORK EQUIPMENT MOVES EVEN WHEN WORK EQUIPMENT LOCK LEVER IS LOCKED…1082

E-4 TRAVEL SPEED DOES NOT INCREASE EVEN WHEN TRAVEL SPEED ACCELERATION PEDAL IS DEPRESSED…1083

E-5 TRAVEL SPEED INCREASES EVEN WHEN TRAVEL SPEED ACCELERATION PEDAL IS NOT DEPRESSED…1084

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)…1085

H-1 SPEEDS OF WORK EQUIPMENT, TRAVEL, SWING ARE ALL SLOW…1086

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS…1087

H-3 WORK EQUIPMENT, TRAVEL, SWING DO NOT MOVE, OR SPEED IS EXTREMELY SLOW…1088

a) NONE OF WORK EQUIPMENT, TRAVEL, SWING DO NOT MOVE, OR SPEED IS SLOW…1088

b) ONLY TRAVEL IS NORMAL, OR DROP IN SPEED IS COMPARATIVELY SMALL…1089

H-4 ALL WORK EQUIPMENT, TRAVEL, SWING LACK POWER…1089

H-5 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)…1089

H-6 WORK EQUIPMENT (BOOM, ARM, BUCKET) SPEED IS SLOW…1090

H-7 WORK EQUIPMENT (BOOM, ARM, BUCKET) LACKS POWER…1091

H-8 EXCESSIVE HYDRAULIC DRIFT…1091

H-9 EXCESSIVE TIME LAG…1091

H-10 WHEN MACHINE IS TRAVELING, IT DEVIATES NATURALLY TO ONE SIDE…1092

a) DEVIATES IN THE SAME DIRECTION BOTH IN FORWARD AND REVERSE…1092

b) DEVIATES IN DIFFERENT DIRECTION IN FORWARD AND REVERSE…1096

H-11 EXCESSIVE DEVIATION WHEN STARTING (PC30, 40)…1097

H-12 TRAVEL LACKS POWER (OR SPEED IS SLOW)…1098

H-13 TRAVEL SPEED DOES NOT SWITCH…1099

H-14 MACHINE DOES NOT MOVE (ONE SIDE ONLY)…1099

H-15 TRAVEL LEVER IS HEAVY…1100

H-16 DOES NOT SWING…1100

H-17 SWING SPEED IS SLOW OR ACCELERATION IS POOR…1102

H-18 EXCESSIVE OVERRUN WHEN STOPPING SWING…1102

H-19 EXCESSIVE SHOCK WHEN STOPPING SWING…1103

H-20 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING…1103

H-21 EXCESSIVE HYDRAULIC DRIFT OF SWING…1104

H-22 EXCESSIVE HYDRAULIC DRIFT OF BOOM SWING…1105

TABLE OF FAILURE MODES AND CAUSES…1106

TROUBLESHOOTING OF MONITOR SYSTEM (M MODE)…1107

M-1 MONITOR PANEL DOES NOT WORK…1108

M-2 MONITOR PANEL CAUTION AND GAUGE LAMPS DO NOT LIGHT UP FOR 3 SECONDS AFTER STARTING SWITCH IS TURNED ON, OR ALL LAMPS STAY…1109

M-3 (OIL PRESSURE CAUTION LAMP) DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED)…1110

M-4 (CHARGE CAUTION LAMP) DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED)…1110

M-5 (PREHEATING PILOT LAMP) DOES NOT LIGHT UP WHEN PREHEATING…1111

M-6 (ENGINE OIL LEVEL CAUTION LAMP) LIGHTS UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED) (ENGINE OIL LEVEL IS NORMAL)…1111

M-7 (ENGINE OIL PRESSURE CAUTION LAMP) LIGHTS UP WHEN ENGINE IS RUNNING (ENGINE OIL PRESSURE IS NORMAL)…1112

M-8 (CHARGE CAUTION LAMP) LIGHTS UP WHEN ENGINE IS RUNNING…1112

M-9 ABNORMALITY IN COOLANT TEMPERATURE GAUGE DISPLAY…1113

a) AFTER ENGINE IS STARTED, GAUGE STAYS AT LOWEST LEVEL AND DOES NOT MOVE…1113

b) AFTER ENGINE IS STARTED, LEVEL RISES IMMEDIATELY. ENTERS RED RANGE EVEN WHEN ENGINE IS NOT OVERHEATING…1113

M-10 ABNORMALITY IN FUEL GAUGE DISPLAY…1114

a) ALL SEGMENTS OF FUEL GAUGE GO OUT…1114

b) FUEL LEVEL HAS GONE DOWN, BUT FUEL GAUGE STILL GIVES FULL DISPLAY, AND DOES NOT GO DOWN…1114

c) FUEL GAUGE DOES NOT GIVE FULL DISPLAY EVEN WHEN FUEL TANK IS FILLED…1115

M-11 WHEN STARTING SWITCH IS TURNED ON, BUZZER DOES NOT SOUND FOR 1 SECOND…1115

M-12 ABNORMALITY IN SERVICE METER DISPLAY…1116

a) SERVICE METER DOES NOT MOVE WHEN ENGINE IS RUNNING…1116

b) SERVICE METER PILOT LAMP DOES NOT FLASH…1116

M-13 NIGHT LIGHTING DOES NOT LIGHT UP…1117

a) WHEN LAMP SWITCH IS AT POSITION 1 OR POSITION 2, INTERNAL LIGHTING OF MONITOR (GAUGE PORTION) DOES NOT LIGHT UP…1117

b) WHEN LAMP SWITCH IS AT POSITION 2, WORKING LAMP IS NOT BLOWN BEFORE STARTING TROUBLESHOOTING…1117

M-14 HEATER DOES NOT WORK WHEN HEATER SWITCH IS OPERATED (MACHINES WITH CAB SPECIFICATION)…1118

TROUBLESHOOTING OF HYDRAULIC BREAKER…1119

30 DISASSEMBLY AND ASSEMBLY…1122

METHOD OF USING MANUAL…1123

PRECAUTIONS WHEN CARRYING OUT OPERATION…1124

SPECIAL TOOL LIST…1126

WEIGHT TABLE…1131

TIGHTENING TORQUES AND STANDARD VALUES TABLE…1132

LUBRICANT AND COOLANT TABLE…1133

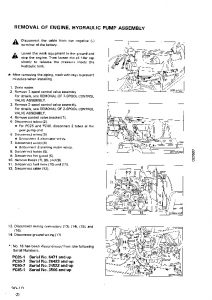

ENGINE, HYDRAULIC PUMP ASSEMBLY…1135

REMOVAL…1135

INSTALLATION…1138

HYDRAULIC PUMP ASSEMBLY…1139

HYDRAULIC PUMP ASSEMBLY (PC30-7)…1139

DISASSEMBLY…1139

ASSEMBLY…1141

HYDRAULIC PUMP ASSEMBLY (PC45-1)…1147

DISASSEMBLY…1147

ASSEMBLY…1151

GEAR PUMP ASSEMBLY…1158

DISASSEMBLY AND ASSEMBLY…1158

CENTER SWIVEL JOINT ASSEMBLY…1159

REMOVAL AND INSTALLATION…1159

DISASSEMBLY AND ASSEMBLY…1160

TRAVEL MOTOR ASSEMBLY …1161

TRAVEL MOTOR ASSEMBLY (PC25-1, PC30-7, PC40-7)…1161

DISASSEMBLY…1161

ASSEMBLY…1167

TRAVEL MOTOR ASSEMBLY (PC45-1)…1173

DISASSEMBLY…1173

ASSEMBLY…1182

SWING MOTOR ASSEMBLY…1193

DISASSEMBLY…1193

ASSEMBLY…1195

SWING MACHINERY ASSEMBLY…1199

DISASSEMBLY…1199

ASSEMBLY…1201

REVOLVING FRAME ASSEMBLY…1203

REMOVAL AND INSTALLATION…1203

RECOIL SPRING ASSEMBLY…1204

DISASSEMBLY…1204

ASSEMBLY…1206

2 SPOOL CONTROL VALVE ASSEMBLY…1209

DISASSEMBLY…1209

ASSEMBLY…1210

7 SPOOL CONTROL VALVE ASSEMBLY…1211

DISASSEMBLY…1211

ASSEMBLY…1213

PPC VALVE ASSEMBLY…1215

DISASSEMBLY…1215

ASSEMBLY…1216

HYDRAULIC CYLINDER ASSEMBLY…1217

DISASSEMBLY…1217

ASSEMBLY…1219

WORK EQUIPMENT ASSEMBLY…1221

REMOVAL AND INSTALLATION…1221

BUCKET ASSEMBLY…1222

REMOVAL AND INSTALLATION…1222

HYDRAULIC BREAKER ASSEMBLY…1223

REMOVAL AND INSTALLATION…1223

DISASSEMBLY…1224

ASSEMBLY…1227

HYDRAULIC BREAKER BUSHING…1231

REMOVAL…1231

CHISEL…1232

REMOVAL AND INSTALLATION…1232

40 MAINTENANCE STANDARD…1235

SWING CIRCLE…1236

SWING MACHINERY…1237

SPROCKET…1239

TRACK FRAME AND RECOIL FRAME…1242

IDLER…1246

TRACK ROLLER…1252

CARRIER ROLLER…1258

TRACK SHOE…1260

HYDRAULIC PUMP…1264

7 SPOOL CONTROL VALVE…1266

2 SPOOL CONTROL VALVE…1268

SWING MOTOR…1269

CENTER SWIVEL JOINT…1270

PPC VALVE…1271

HYDRAULIC CYLINDER…1274

WORK EQUIPMENT…1278

HYDRAULIC BREAKER…1282

PISTON, CHISEL…1284

SEBM0225C01 – Hydraulic Excavator PC20-3, PC30-3 Shop Manual…1297

Komatsu Hydraulic Excavator PC20, PC25, PC30, PC40, PC45 Repair Service Manuals