Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC20R, PC25R, PC27R, PC27R Deluxe, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8, PC27R-8 Deluxe workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

WEBM000200 – Hydraulic Excavator PC20R-8, PC27R-8 Shop Manual.pdf

WEBM000201 – Hydraulic Excavator PC20R-8, PC27R-8 Shop Manual.pdf

WEBM002900 – Hydraulic Excavator PC27R-8 Shop Manual.pdf

WEBM003800 – Hydraulic Excavator PC27R-8 Deluxe Shop Manual.pdf

SEBM010801 – Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8 Shop Manual.pdf

SEAM015203T – Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8 Operation & Maintenance Manual.pdf

WEAM000101 – Hydraulic Excavator PC20R-8, PC27R-8 Operation & Maintenance Manual.pdf

WEAM003100 – Hydraulic Excavator PC27R-8 Operation & Maintenance Manual.pdf

WEAM003102 – Hydraulic Excavator PC27R-8 Deluxe Operation & Maintenance Manual.pdf

Total Pages: 2,419 pages

File Format: PDF

Language: English

SEAM015203T – Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8 Operation & Maintenance Manual…2

COVER…2

1.FOREWORD…3

2.SAFETY INFORMATION…6

3.INTRODUCTION…7

4.LOCATION OF PLATES,TABLE TO ENTER SERIAL NO.AND DISTRIBUTOR…8

5.CONTENTS…9

SAFETY…13

6.GENERAL PRECAUTIONS…14

7.PRECAUTIONS DURING OPERATION…19

7.1 BEFORE STARTING ENGINE…19

7.2 OPERATING MACHINE…21

7.3 TRANSPORTATION…28

7.4 BATTERY…29

7.5 TOWING…31

7.6 LIFTING OPERATIONS…31

7.7 WINDOW WASHER FLUID…31

8.PRECAUTIONS FOR MAINTENANCE…32

8.1 BEFORE CARRYING OUT MAINTENANCE…32

8.2 DURING MAINTENANCE…36

9.POSITION FOR ATTACHING SAFETY LABELS…41

OPERATION…45

10.GENERAL VIEW…46

10.1 GENERAL VIEW OF MACHINE…46

10.2 GENERAL VIEW OF CONTROLS AND GAUGES…47

11.EXPLANATION OF COMPONENTS…48

11.1 MACHINE MONITOR…48

11.2 SWITCHES…53

11.3 CONTROL LEVERS AND PEDALS…56

11.4 ENGINE HOOD …60

11.5 FRONT WINDOW(MACHINE EQUIPPED WITH CAB)…61

11.6 SLIDING DOOR(MACHINE EQUIPPED WITH CAB)…63

11.7 HAMMER FOR EMERGENCY ESCAPE(MACHINE EQUIPPED WITH CAB)…64

11.8 FUSES…64

11.9 FUSIBLE LINK…65

11.10 CAP,COVER WITH LOCK…65

11.11 MANUAL STORING SPACE…66

11.12 TOOL BOX…66

11.13 DUST INDICATOR…66

12.OPERATION…67

12.1 CHECK BEFORE STARTING ENGINE…67

12.2 STARTING ENGINE…75

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE…77

12.4 MOVING MACHINE OFF…79

12.5 STEERING MACHINE…82

12.6 STOPPING MACHINE…84

12.7 SWINGING…85

12.8 OPERATION OF WORK EQUIPMENT…86

12.9 PRECAUTIONS FOR OPERATION…87

12.10 PRECAUTIONS FOR OPERATION…89

12.11 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS…90

12.12 HOW TO ESCAPE FROM MUD…92

12.13 WORK POSSIBLE USING HYDRAULIC EXCAVATOR…93

12.14 REPLACEMENT OF BUCKET…95

12.15 PARKING MACHINE…96

12.16 CHECK AFTER FINISHING WORK…97

12.17 STOPPING ENGINE…97

12.18 CHECK AFTER STOPPING ENGINE…98

12.19 LOCKING…98

12.20 HANDLING RUBBER SHOES (RUBBER SHOES ONLY)…99

13.TRANSPORTATION…104

13.1 LOADING,UNLOADING WORK…104

13.2 METHOD OF LIFTING MACHINE…106

13.3 PRECAUTIONS FOR LOADING AND SECURING MACHINE…108

13.4 PRECAUTIONS FOR TRANSPORTATION…109

14.COLD WEATHER OPERATION…110

14.1 PRECAUTIONS FOR LOW TEMPERATURE…110

14.2 PRECAUTIONS AFTER COMPLETION OF WORK…112

14.3 PREPARING THE CAB HEATER(MACHINE EQUIPPED WITH CAB)…112

14.4 AFTER COLD WEATHER…112

15.LONG-TERM STORAGE…113

15.1 BEFORE STORAGE…113

15.2 DURING STORAGE…114

15.3 AFTER STORAGE…114

16.TROUBLESHOOTING…115

16.1 PHENOMENA THAT ARE NOT FAILURES…115

16.2 METHOD OF TOWING MACHINE…115

16.3 PRECAUTIONS ON PARTICULAR JOBSITES…115

16.4 IF BATTERY IS DISCHARGED…116

16.5 OTHER TROUBLE…121

MAINTENANCE …125

17.GUIDES TO MAINTENANCE…126

18.OUTLINES OF SERVICE…128

18.1 OUTLINE OF OIL,FUEL,COOLANT…128

18.2 OUTLINE OF ELECTRIC SYSTEM…131

18.3 OUTLINE OF HYDRAULIC SYSTEM…132

19.WEAR PARTS LIST…133

20.USE OF FUEL,COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…134

21.STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…138

21.1 INTRODUCTION OF NECESSARY TOOLS…138

21.2 TORQUE LIST…139

22.PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…140

23.MAINTENANCE SCHEDULE CHART…142

23.1 MAINTENANCE SCHEDULE CHART…142

23.2 MAINTENANCE INTERVAL WHEN USING HYDRAULIC BREAKER…144

24.SERVICE PROCEDURE…145

24.1 INITIAL 250 HOURS SERVICE…145

24.2 WHEN REQUIRED…146

24.3 CHECK BEFORE STARTING…165

24.4 EVERY 100 HOURS SERVICE…169

24.5 EVERY 250 HOURS SERVICE…170

24.6 EVERY 500 HOURS SERVICE…175

24.7 EVERY 1000 HOURS SERVICE…181

24.8 EVERY 2000 HOURS SERVICE…182

SPECIFICATIONS…186

25.SPECIFICATIONS…187

OPTIONS,ATTACHMENTS…202

26.GENERAL PRECAUTIONS…203

26.1 PRECAUTIONS RELATED TO SAFETY…203

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS…204

27.HANDLING BUCKET WITH HOOK…205

27.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK…205

27.2 PROHIBITED OPERATIONS…205

27.3 PRECAUTIONS DURING OPERATIONS…205

28.USING SEAT BELT…206

28.1 SEAT BELT…206

29.OPERATION OF CAR RADIO(MACHINE EQUIPPED WITH CAB)…208

29.1 EXPLANATION OF CONTROLS…208

29.2 OPERATION METHOD…210

29.3 PRECAUTIONS FOR USE…212

29.4 SPECIFICATIONS…213

30.OPERATION OF WINDOW WASHER(MACHINE EQUIPPED WITH CAB)…214

30.1 OPERATION OF WINDOW WASHER…214

30.2 CHECK AND REFILLING OF WINDOW WASHER FLUID…214

31.HANDLING OF 1-WAY AND 2-WAY …215

31.1 SELECTION OF 1-WAY AND 2-WAY…215

31.2 OPERATION OF PEDAL…215

32.INTRODUCTION OF ATTACHMENTS…216

32.1 SPECIFICATIONS AND USES…216

32.2 COMBINATIONS TABLE OF ATTACHMENTS…217

32.3 PRECAUTIONS FOR OPERATING WITH HYDRAULIC BREAKER…218

32.4 OPERATION OF QUICK BREAKER ARM…221

32.5 HANDLING POWER TILT,MECHANICAL ANGLE BLADE…238

SEBM010801 – Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8 Shop Manual…241

COVER…241

CONTENTS…242

01 GENERAL…265

GENERAL ASSEMBLY DRAWING…266

SPECIFICATIONS…272

WEIGHT TABLE…278

LIST OF LUBRICANT AND WATER…280

10 STRUCTURE AND FUNCTION…282

POWER TRAIN…283

SWING CIRCLE…285

SWING MACHINERY…287

TRACK FRAME…288

RECOIL SPRING…291

HYDRAULIC PIPING …292

HYDRAULIC CIRCUIT DIAGRAM…294

HYDRAULIC TANK…297

HYDRAULIC PUMP…299

CONTROL VALVE…322

CLSS…330

CENTER SWIVEL JOINT…353

SWING MOTOR…354

TRAVEL MOTOR…362

VALVE CONTROL…367

PPC VALVE…368

WORK EQUIPMENT…372

ELECTRICAL CIRCUIT DIAGRAM…373

MACHINE MONITOR SYSTEM…374

20 TESTING AND ADJUSTING…379

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS…380

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS…382

STANDARD VALUE TABLE FOR ELECTRICAL PARTS…397

TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING…399

MEASURING ENGINE SPEED…400

MEASURING EXHAUST COLOR…401

ADJUSTING VALVE CLEARANCE…402

MEASURING COMPRESSION PRESSURE…403

TESTING AND ADJUSTING FUEL INJECTION TIMING…404

MEASURING ENGINE OIL PRESSURE…406

TESTING AND ADJUSTING ALTERNATOR FAN BELT TENSION…407

MEASURING SPROCKET WEAR…408

TESTING AND ADJUSTING TRACK SHOE TENSION…409

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT,SWING,TRAVEL CIRCUIT…410

TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE…414

ADJUSTING PC VALVE…418

TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE…419

MEASURING OUTPUT PRESSURE OF PPC LOCK VALVE AND TRAVEL BOOST VALVE…421

TESTING PPC VALVE OUTPUT PRESSURE AND SWING HOLDING BRAKE INLET PORT PRESSURE…422

ADJUSTING WORK EQUIPMENT,SWING PPC VALVE…426

TESTING AND ADJUSTING TRAVEL DEVIATION…427

MEASURING OIL LEAKAGE INSIDE CYLINDER…428

RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT…429

RELEASING REMAINING PRESSURE FROM HYDRAULIC TANK…429

PRESSURIZING HYDRAULIC TANK…429

BLEEDING AIR…430

TROUBLESHOOTING…432

POINTS TO REMEMBER WHEN TROUBLESHOOTING…433

SEQUENCE OF EVENTS IN TROUBLESHOOTING…434

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE…435

CHECKS BEFORE TROUBLESHOOTING…443

TYPE OF CONNECTOR AND POSITION OF INSTALLATION…444

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS…447

METHOD OF USING TROUBLESHOOTING CHARTS…457

TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)…460

E-MODE RELATED ELECTRICAL CIRCUIT DIAGRAM…461

E-1 ENGINE DOES NOT START…462

a) WHEN STARTING MOTOR DOES NOT TURN(STARTING SYSTEM)…462

b) WHEN STARTING MOTOR TURNS(ENGINE STOP SOLENOID SYSTEM)…464

E-2 ENGINE DOES NOT STOP…466

TROUBLESHOOTING OF HYDRAULIC,MECHANICAL SYSTEM(H MODE)…467

TABLE OF FAILURE MODES AND CAUSES…468

H-1 SPEEDS OF ALL WORK EQUIPMENT,SWING,TRAVEL ARE SLOW OR LACK POWER…470

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED,OR ENGINE STALLS…471

H-3 NO WORK EQUIPMENT,TRAVEL,SWING MOVE…471

H-4 ABNORMAL NOISE GENERATED(FROM AROUND PUMP)…472

H-5 FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR…472

H-6 BOOM IS SLOW OR LACKS POWER…473

H-7 ARM IS SLOW OR LACKS POWER…473

H-8 BUCKET IS SLOW OR LACKS POWER…474

H-9 BOOM SWING IS SLOW OR LACKS POWER…474

H-10 BLADE IS SLOW OR LACKS POWER…475

H-11 BOOM,ARM,BUCKET DO NOT MOVE(BOOM SWING,BLADE,TRAVEL AND SWING ARE NORMAL)…475

H-12 EXCESSIVE HYDRAULIC DRIFT(BOOM,ARM,BUCKET,BOOM SWING,BLADE)…476

a) BOOM…476

b) ARM,BUCKET…476

c) BOOM SWING…476

d) BLADE…477

H-13 EXCESSIVE TIME LAG(ENGINE AT LOW IDLING)…477

H-14 IN COMPOUND OPERATIONS,WORK EQUIPMENT WITH LARGER LOAD IS SLOW…477

H-15 TRAVEL DEVIATION…478

a) DEVIATION IN NORMAL TRAVEL…478

b) DEVIATION WHEN STARTING…478

H-16 TRAVEL SPEED IS SLOW OR LACKS POWER…479

H-17 STEERING DOES NOT TURN EASILY…479

H-18 TRAVEL SPEED DOES NOT SWITCH…480

H-19 TRAVEL DOES NOT MOVE(ONE SIDE ONLY)…480

H-20 SWING SPEED IS SLOW OR LACKS POWER…481

a) SPEED IS SLOW OR LACKS POWER IN BOTH DIRECTIONS…481

b) SPEED IS SLOW OR LACKS POWER IN ONE DIRECTION ONLY(LEFT OR RIGHT)…481

H-21 DOES NOT SWING…482

a) DOES NOT SWING IN EITHER DIRECTION…482

b) DOES NOT SWING IN ONE DIRECTION(LEFT OR RIGHT)…482

H-22 SWING ACCELERATION IS POOR…483

a) ACCELERATION IS POOR IN BOTH DIRECTIONS…483

b) ACCELERATION IS POOR IN ONE DIRECTION ONLY(LEFT OR RIGHT)…483

H-23 EXCESSIVE OVERRUN WHEN STOPPING SWING…484

a) OVERRUN WHEN STOPPING IS EXCESSIVE IN BOTH DIRECTIONS…484

b) OVERRUN WHEN STOPPING IS EXCESSIVE IN ONE DIRECTION ONLY(LEFT OR RIGHT)…484

H-24 EXCESSIVE SHOCK WHEN STOPPING SWING(IN ONE DIRECTION ONLY)…485

H-25 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING…485

H-26 EXCESSIVE HYDRAULIC DRIFT OF SWING…485

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM(M MODE)…486

ELECTRICAL CIRCUIT DIAGRAM FOR M MODE RELATED PARTS…487

M-1 WHEN THE STARTING SWITCH IS TURNED ON,NO DISPLAY IS GIVEN…488

M-2 WHEN STARTING SWITCH IS TURNED ON,EVEN WHEN SELF CHECK IS COMPLETED(ALL LAMPS LIGHT UP FOR 3 SECONDS),LAMPS DO NOT GO OUT…488

M-3 WHEN STARTING SWITCH IS TURNED ON,SOME SELF CHECK LAMPS DO NOT LIGHT UP FOR 3 SECONDS…489

a) NO GAUGE LAMPS LIGHT UP(FUEL,COOLANT TEMPERATURE)…489

b) CAUTION LAMPS(ENGINE OIL PRESSURE,BATTERY CHARGE),PILOT LAMP(PREHEATING) DO NOT LIGHT UP…489

M-4 DURING SELF CHECK(ALL LAMPS LIGHT UP FOR 3 SECONDS),EVEN IF STARTING SWITCH IS TURNED TO START,SELF CHECK IS NOT COMPLETED IN 3 SECONDS…489

M-5 WHEN STARTING SWITCH IS ON(ENGINE STOPPED),ENGINE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP…490

M-6 WHEN STARTING SWITCH IS ON(ENGINE STOPPED),CHARGE CAUTION LAMP DOES NOT LIGHT UP…491

M-7 WHEN STARTING SWITCH IS TURNED TO HEAT,PREHEATING PILOT LAMP DOES NOT LIGHT UP…492

M-8 WHEN ENGINE IS RUNNING,ENGINE OIL PRESSURE CAUTION LAMP LIGHTS UP…492

M-9 WHEN ENGINE IS RUNNING,CHARGE CAUTION LAMP LIGHTS UP…493

M-10 ABNORMALITY IN COOLANT TEMPERATURE GAUGE…495

a) LEVEL DOES NOT RISE FROM SEGMENT C…495

b) LEVEL DOES NOT GO DOWN FROM SEGMENT H,OR ALL SEGMENTS GO OUT…495

c) COOLANT TEMPERATURE DOES NOT MATCH GAUGE DISPLAY…496

M-11 ABNORMALITY IN FUEL GAUGE…497

a) LEVEL DOES NOT RISE FROM SEGMENT E OR ALL SEGMENTS GO OUT…497

b) LEVEL DOES NOT GO DOWN FROM SEGMENT F…497

c) FUEL LEVEL DOES NOT MATCH GAUGE DISPLAY…498

M-12 DEFECTIVE OPERATION OF ALARM BUZZER…499

a) BUZZER DOES NOT SOUND…499

b) BUZZER CONTINUES TO SOUND AND DOES NOT STOP…499

M-13 WHEN ENGINE IS RUNNING,SERVICE METER DOES NOT ADVANCE…500

a) WHEN CHARGE CAUTION LAMP DOES NOT LIGHT UP…500

b) WHEN CHARGE CAUTION LAMP LIGHTS UP…500

c) PILOT LAMP DOES NOT FLASH(SERVICE METER IS ACTUATED)…500

M-14 NIGHT LIGHTING DOES NOT LIGHT UP…501

a) GAUGE LIGHTING DOES NOT LIGHT UP…501

b) SERVICE METER LIGHTING DOES NOT LIGHT UP…501

30 DISASSEMBLY AND ASSEMBLY…502

METHOD OF USING MANUAL…504

PRECAUTIONS WHEN CARRYING OUT OPERATION…505

SPECIAL TOOL LIST…507

SKETCHES OF SPECIAL TOOLS…511

STARTING MOTOR…516

REMOVAL AND INSTALLATION…516

ALTERNATOR…517

REMOVAL AND INSTALLATION…517

FUEL INJECTION PUMP…518

REMOVAL…518

INSTALLATION…519

NOZZLE HOLDER…520

REMOVAL AND INSTALLATION…520

WATER PUMP…521

REMOVAL…521

INSTALLATION…522

THERMOSTAT…523

REMOVAL AND INSTALLATION…523

ENGINE FRONT SEAL…524

REMOVAL AND INSTALLATION…524

ENGINE REAR SEAL…525

REMOVAL…525

INSTALLATION…526

CYLINDER HEAD…527

REMOVAL…527

INSTALLATION…528

RADIATOR…529

REMOVAL AND INSTALLATION…529

ENGINE,HYDRAULIC PUMP…530

REMOVAL…530

INSTALLATION…533

FUEL TANK…534

REMOVAL AND INSTALLATION…534

DAMPER…535

REMOVAL AND INSTALLATION…535

CENTER SWIVEL JOINT…536

REMOVAL AND INSTALLATION…536

DISASSEMBLY AND ASSEMBLY…537

TRAVEL MOTOR…538

REMOVAL AND INSTALLATION…538

DISASSEMBLY AND ASSEMBLY(PHV-190(FOR PC20R-8))…539

DISASSEMBLY AND ASSEMBLY(PHV-200(FOR PC25R-8),PHV-250(FOR PC27R-8))…550

SPROCKET…565

REMOVAL AND INSTALLATION…565

SWING MOTOR,SWING MACHINERY…566

REMOVAL…566

INSTALLATION…567

DISASSEMBLY…568

ASSEMBLY…571

SWING MOTOR(LMF16AB(FOR PC25R-8 AND PC27R-8)…574

DISASSEMBLY…574

ASSEMBLY…579

REVOLVING FRAME…587

REMOVAL…587

INSTALLATION…588

SWING CIRCLE…589

REMOVAL AND INSTALLATION…589

IDLER…590

REMOVAL AND INSTALLATION…590

DISASSEMBLY…591

ASSEMBLY…592

RECOIL SPRING…594

REMOVAL AND INSTALLATION…594

DISASSEMBLY AND ASSEMBLY…595

TRACK ROLLER…596

REMOVAL AND INSTALLATION…596

DISASSEMBLY…597

ASSEMBLY…598

CARRIER ROLLER…599

REMOVAL AND INSTALLATION…599

DISASSEMBLY AND ASSEMBLY…600

RUBBER SHOE…601

REMOVAL AND INSTALLATION…601

STEEL SHOE…602

REMOVAL AND INSTALLATION…602

HYDRAULIC TANK…603

REMOVAL AND INSTALLATION…603

HYDRAULIC COOLER…604

REMOVAL AND INSTALLATION…604

HYDRAULIC PUMP…605

REMOVAL AND INSTALLATION…605

MAIN PUMP(LPV-30(FOR PC25R-8 AND PC27R-8)…606

DISASSEMBLY…606

ASSEMBLY…614

CONTROL VALVE…625

REMOVAL…625

INSTALLATION…626

DISASSEMBLY…627

ASSEMBLY…632

PPC VALVE…639

REMOVAL AND INSTALLATION…639

DISASSEMBLY…640

ASSEMBLY…641

BOOM CYLINDER…642

REMOVAL…642

INSTALLATION…643

ARM CYLINDER…644

REMOVAL…644

INSTALLATION…645

BUCKET CYLINDER…646

REMOVAL…646

INSTALLATION…647

BOOM SWING CYLINDER…648

REMOVAL…648

INSTALLATION…649

BLADE CYLINDER…650

REMOVAL AND INSTALLATION…650

HYDRAULIC CYLNDER…651

DISASSEMBLY…651

ASSEMBLY…654

WORK EQUIPMENT…657

REMOVAL…657

INSTALLATION…658

BUCKET…659

REMOVAL AND INSTALLATION…659

ARM…660

REMOVAL…660

INSTALLATION…661

BUCKET,ARM…662

REMOVAL…662

INSTALLATION…663

BOOM…664

REMOVAL…664

INSTALLATION…665

BOOM SWING BRACKET…666

REMOVAL…666

INSTALLATION…667

BLADE…668

REMOVAL AND INSTALLATION…668

OPERATOR'S CAB…669

REMOVAL AND INSTALLATION…669

CANOPY…669

REMOVAL AND INSTALLATION…669

FLOOR FRAME…670

REMOVAL…670

INSTALLATION…671

40 MAINTENANCE STANDARD…672

SWING CIRCLE…673

SWING MACHINERY…675

TRACK FRAME,RECOIL SPRING…677

IDLER…678

CARRIER ROLLER…679

TRACK ROLLER…680

TRACK SHOE…681

HYDRAULIC PUMP…683

HYDRAULIC PUMP(LPV30)…684

CONTROL VALVE…685

CENTER SWIVEL JOINT…691

SWING MOTOR…692

TRAVEL MOTOR…694

PPC VALVE…695

HYDRAULIC CYLINDER…696

WORK EQUIPMENT…699

90 OTHERS…705

HYDRAULIC PIPING PC20R-8…706

HYDRAULIC PIPING PC25R,27R-8…707

HYDRAULIC CIRCUIT DIAGRAM PC20R-8…708

HYDRAULIC CIRCUIT DIAGRAM PC25R-8…709

HYDRAULIC CIRCUIT DIAGRAM PC27R-8…710

CLSS 10A. OPERATION OF THE SYSTEM AS A WHOLE PC20R-8…711

CLSS 10B. OPERATION OF THE SYSTEM AS A WHOLE PC25R,PC27R-8…712

ELECTRICAL CIRCUIT DIAGRAM PC20R,25R,27R-8…713

WEAM000101 – Hydraulic Excavator PC20R-8, PC27R-8 Operation & Maintenance Manual…714

1.1 FOREWORD…716

1.2 INFORMATION ON SAFETY…717

1.3 INTRODUCTION…719

1.3.1 INTENDED USES…719

1.3.2 IMPROPER OR UNAUTHORIZED USES…719

1.3.3 MAIN CHARACTERISTICS…720

1.3.4 RUNNING-IN…720

1.4 PRODUCT IDENTIFICATION…721

1.4.1 MACHINE SERIAL NUMBER…721

1.4.2 MACHINE IDENTIFICATION PLATE…721

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE…722

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER…722

1.4.5 SWING MOTOR SERIAL NUMBER (for PC20R only)…723

1.4.6 SWING REDUCTION GEAR SERIAL NUMBER (for PC27R only)…723

1.4.7 CAB SERIAL NUMBER…723

1.4.8 SERIAL NUMBERS AND DEALER’S ADDRESS…724

TABLE OF CONTENTS…726

1.1 FOREWORD 1…726

1.2 INFORMATION ON SAFETY 2…726

1.3 INTRODUCTION 4…726

1.3.1 INTENDED USES 4…726

1.3.2 IMPROPER OR UNAUTHORIZED USES 4…726

1.3.3 MAIN CHARACTERISTICS 5…726

1.3.4 RUNNING-IN 5…726

1.4 PRODUCT IDENTIFICATION 6…726

1.4.1 MACHINE SERIAL NUMBER 6…726

1.4.2 MACHINE IDENTIFICATION PLATE 6…726

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE 7…726

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER 7…726

1.4.5 SWING MOTOR SERIAL NUMBER (for PC20R only) 8…726

1.4.6 SWING REDUCTION GEAR SERIAL NUMBER (for PC27R only) 8…726

1.4.7 CAB SERIAL NUMBER 8…726

1.4.8 SERIAL NUMBERS AND DEALER’S ADDRESS 9…726

2.1 SAFETY, NOISE AND VIBRATION PLATES 20…726

2.1.1 POSITION OF THE SAFETY PLATES 20…726

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS 22…726

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB 26…726

2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY 27…726

2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED 27…726

2.2 GENERAL PRECAUTIONS 28…726

2.2.1 GENERAL SAFETY RULES 28…726

2.2.2 SAFETY DEVICES AND GUARDS 28…726

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS 28…726

2.2.4 UNAUTHORIZED MODIFICATIONS 29…726

2.2.5 LEAVING THE OPERATOR’S SEAT 29…726

2.2.6 GETTING ON AND OFF THE MACHINE 30…726

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL 30…726

2.2.8 PREVENTING BURNS 31…726

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER 31…726

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT 32…726

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT 32…726

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE 32…726

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT 32…726

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE 33…726

2.3.1 SAFETY ON THE WORK SITE 33…726

2.3.2 FIRE PREVENTION 33…726

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB 33…726

2.3.4 ROOM VENTILATION 34…726

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS 34…726

2.3.6 CLEANING THE WINDOWS – CHECKING THE WINDSHIELD WIPER BLADES 34…726

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING 35…727

2.4.1 STARTING THE ENGINE 35…727

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE 35…727

2.4.3 CHECKS FOR TRAVELLING IN REVERSE 35…727

2.4.4 MOVING THE MACHINE 36…727

2.4.5 MOVING ON SLOPES 37…727

2.4.6 WORKING ON SLOPES 38…727

2.4.7 UNAUTHORIZED OPERATIONS 38…727

2.4.8 PREVENTING ELECTROCUTION 39…727

2.4.9 VISIBILITY 40…727

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES 40…727

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT 40…727

2.4.12 WORKING ON LOOSE GROUND 40…727

2.4.13 PARKING THE MACHINE 41…727

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES 42…727

2.5.1 LOADING AND UNLOADING 42…727

2.5.2 TRANSPORT 42…727

2.6 BATTERY 43…727

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY 43…727

2.6.2 STARTING WITH BOOSTER CABLES 43…727

2.7 PRECAUTIONS FOR THE REMOVAL 44…727

2.8 PRECAUTIONS FOR MAINTENANCE 45…727

2.8.1 WARNING PLATES 45…727

2.8.2 TOOLS 45…727

2.8.3 PERSONNEL 45…727

2.8.4 EQUIPMENT 46…727

2.8.5 WORKING UNDER THE MACHINE 46…727

2.8.6 CLEANING THE MACHINE 46…727

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS 47…727

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY 47…727

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION 47…727

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP 48…727

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR 48…727

2.8.12 USING LAMPS 48…727

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR 49…727

2.8.14 PRECAUTIONS CONCERNING THE STARTER 49…727

2.8.15 HANDLING HIGH-PRESSURE PIPES 50…727

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL 50…727

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE 50…727

2.8.18 COOLING FAN AND BELT 51…727

2.8.19 WASTE MATERIALS 51…727

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES 51…727

3.1 SAFETY LOCKS 54…728

3.1.1 MACHINE LOCKS 54…728

3.2 GENERAL VIEWS 55…728

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB 55…728

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY 56…728

3.2.3 GENERAL VIEW OF THE DRIVER’S SEAT 57…728

3.3 INSTRUMENTS AND CONTROLS 58…728

3.3.1 INSTRUMENTS 58…728

3.3.2 WARNING LIGHTS 60…728

3.3.3 SWITCHES AND PUSH BUTTONS 62…728

3.3.4 ELECTRICAL ACCESSORIES 65…728

3.3.5 MACHINE CONTROLS 67…728

3.4 FUSES AND RELAYS 75…728

3.4.1 FUSES 75…728

3.4.1.1 EQUIPMENT FUSES 75…728

3.4.1.2 MAIN FUSE 76…728

3.4.2 RELAYS 77…728

3.5 GUARDS AND DRIVER’S SEAT 78…728

3.5.1 ENGINE HOOD 78…728

3.5.2 RIGHT COUNTERWEIGHT 79…728

3.5.3 CANOPY 79…728

3.5.4 CAB 80…728

3.5.5 VENTILATION AND HEATING 83…728

3.5.6 SEAT 84…728

3.5.7 SAFETY BELT 84…728

3.5.8 EMERGENCY EXIT 85…728

3.5.9 TECHNICAL DOCUMENTATION CASE 85…728

3.5.10 FIRE EXTINGUISHER 86…728

3.5.11 FIRST AID KIT 86…728

3.6 USE OF THE MACHINE 87…728

3.6.1 CHECKS BEFORE STARTING THE ENGINE 87…728

3.6.1.1 VISUAL CHECKS 87…728

3.6.1.2 DAILY CHECKS 87…728

3.6.1.3 OPERATIONAL CHECKS 88…728

3.6.2 STARTING THE ENGINE 89…728

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES 89…728

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES 90…728

3.6.3 WARMING THE ENGINE 91…728

3.6.4 HEATING THE HYDRAULIC OIL 91…728

3.6.5 HOW TO MOVE THE MACHINE 91…728

3.6.5.1 STEERING (CHANGING DIRECTION) 93…728

3.6.5.2 MOVING ON SLOPES 94…728

3.6.5.3 MAXIMUM IMMERSION DEPTH 95…728

3.7 PARKING THE MACHINE 96…729

3.7.1 PARKING ON LEVEL GROUND 96…729

3.7.2 PARKING ON SLOPES 97…729

3.8 STOPPING THE ENGINE 98…729

3.9 TRANSPORTING THE MACHINE ON MOTOR VEHICLES 99…729

3.9.1 LOADING AND UNLOADING THE MACHINE 99…729

3.9.2 TRANSPORT 100…729

3.10 LIFTING THE MACHINE 101…729

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON 102…729

3.11.1 FUEL AND LUBRICANTS 102…729

3.11.2 COOLANT 102…729

3.11.3 BATTERY 102…729

3.11.4 OTHER PRECAUTIONS 103…729

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK 103…729

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON 104…729

3.13 USING THE WORK EQUIPMENT 105…729

3.13.1 ORGANIZING THE WORK AREA 105…729

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS 106…729

3.13.3 DIGGING METHOD 107…729

3.13.4 CHANGING THE BUCKET 108…729

3.14 LONG PERIODS OF INACTIVITY 109…729

3.14.1 BEFORE THE PERIOD OF INACTIVITY 109…729

3.14.2 DURING THE PERIOD OF INACTIVITY 110…729

3.14.3 AFTER THE PERIOD OF INACTIVITY 110…729

3.15 TROUBLESHOOTING 111…729

3.15.1 OCCURRENCES THAT ARE NOT FAILURES 111…729

3.15.2 HOW TO REMOVE THE MACHINE 111…729

3.15.3 AFTER THE FUEL HAS RUN OUT 112…729

3.15.4 IF THE BATTERY IS DOWN 112…729

3.15.4.1 STARTING WITH BOOSTER CABLES 113…729

3.15.5 OTHER TROUBLES 114…729

3.15.5.1 ELECTRICAL CIRCUIT 114…729

3.15.5.2 HYDRAULIC SYSTEM 114…729

3.15.5.3 ENGINE 115…729

4.1 GUIDE TO MAINTENANCE 118…730

4.2 MAINTENANCE NOTES 120…730

4.2.1 NOTES REGARDING THE ENGINE 120…730

4.2.1.1 ENGINE OIL 120…730

4.2.1.2 COOLANT 120…730

4.2.1.3 FUEL 121…730

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM 121…730

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM 122…730

4.2.4 NOTES REGARDING LUBRICATION 122…730

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING 123…730

4.3 FUEL, COOLANT AND LUBRICANTS 124…730

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS 126…730

4.4 DRIVING TORQUES FOR SCREWS AND NUTS 127…730

4.4.1 STANDARD DRIVING TORQUES 127…730

4.4.2 SPECIFIC DRIVING TORQUES 127…730

4.5 LUBRICATION 128…730

4.5.1 LUBRICATION DIAGRAM 128…730

4.6 PERIODICAL CHANGE OF THE COMPONENTS THAT ARE CONNECTED WITH SAFETY 129…730

4.6.1 CRITICAL PARTS FOR SAFETY 130…730

4.7 MAINTENANCE PLAN 133…730

4.7.1 WHEN REQUIRED 136…730

4.7.1.a WASHING THE COOLING CIRCUIT 136…730

4.7.1.b DRAINING THE FUEL TANK 137…730

4.7.1.c CHECKING THE ELECTRICAL SYSTEM 138…730

4.7.1.d CHECKING THE STEEL TRACK TENSION 138…730

4.7.1.e CHECKING THE RUBBER TRACKS 140…730

4.7.1.f CHECKING THE RUBBER TRACK TENSION 142…730

4.7.1.g CHANGING THE RUBBER TRACK 144…730

4.7.1.h CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE 146…730

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER) 147…730

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER 147…730

4.7.2.b CHANGING THE HYDRAULIC OIL 147…730

4.7.3 CHECKS BEFORE STARTING 148…730

4.7.3.a VARIOUS CHECKS 148…730

4.7.3.b CHECKING THE COOLANT LEVEL 148…730

4.7.3.c CHECKING THE FUEL LEVEL 149…730

4.7.3.d CHECKING THE ENGINE OIL LEVEL 149…730

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT 150…730

4.7.3.f CHECKING THE AIR CLEANER CLOGGING INDICATOR 151…730

4.7.3.g CHECKING THE FUEL FILTER FOR SEDIMENT AND WATER 151…730

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic…730

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION 153…730

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING 153…730

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION 155…731

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION 155…731

4.7.7.a ADJUSTING THE FAN BELT TENSION 155…731

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL 156…731

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS 156…731

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER 157…731

4.7.7.e CHANGING THE ENGINE OIL 158…731

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the syntheti…731

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION 159…731

4.7.9.a CHANGING THE ENGINE OIL FILTER 159…731

4.7.9.b CHANGING THE FUEL FILTER 160…731

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER 161…731

4.7.9.d CLEANING THE OUTSIDE OF THE RADIATORS 162…731

4.7.9.e DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable o…731

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION 164…731

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS 164…731

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION 165…731

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER 165…731

4.7.11.b CHANGING THE COOLANT 168…731

4.7.11.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE 169…731

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER 169…731

5.1 TECHNICAL DATA 172…731

5.1.1 STANDARD OVERALL DIMENSIONS (for model PC20R only) 172…731

5.1.2 TECHNICAL CHARACTERISTICS PC20R 173…731

5.1.3 STANDARD OVERALL DIMENSIONS (for model PC27R only) 174…731

5.1.4 TECHNICAL CHARACTERISTICS PC27R 175…731

5.1.5 LIFTING CAPACITY WITH CAB (for model PC20R only) 176…731

5.1.6 LIFTING CAPACITY WITH CANOPY (for model PC20R only) 177…731

5.1.7 LIFTING CAPACITY WITH CAB (for model PC27R only) 178…731

5.1.8 LIFTING CAPACITY WITH CANOPY (for model PC27R only) 179…731

6.1 AUTHORIZED OPTIONAL EQUIPMENT 182…732

6.1.1 PRECAUTIONS REGARDING SAFETY 182…732

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT 183…732

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT 184…732

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER) 185…732

6.2.1 DESCRIPTION AND CONTROL 185…732

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED 185…732

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER 189…732

6.2.3.1 INSTALLING THE HAMMER 189…732

6.2.3.2 REMOVING THE HAMMER 190…732

6.2.4 MAINTENANCE 190…732

6.3 ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT 191…732

6.3.1 SELECTION VALVE (1) 191…732

6.3.2 CONTROL PEDAL (2) 192…732

6.3.3 ASSEMBLYING AND CONNECTING THE EQUIPMENT 193…732

6.3.4 MAINTENANCE 194…732

2.1 SAFETY, NOISE AND VIBRATION PLATES…735

2.1.1 POSITION OF THE SAFETY PLATES…735

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS…737

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB…741

2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY…742

2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED…742

2.2 GENERAL PRECAUTIONS…743

2.2.1 GENERAL SAFETY RULES…743

2.2.2 SAFETY DEVICES AND GUARDS…743

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS…743

2.2.4 UNAUTHORIZED MODIFICATIONS…744

2.2.5 LEAVING THE OPERATOR’S SEAT…744

2.2.6 GETTING ON AND OFF THE MACHINE…745

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL…745

2.2.8 PREVENTING BURNS…746

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER…746

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…747

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT…747

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE…747

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT…747

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE…748

2.3.1 SAFETY ON THE WORK SITE…748

2.3.2 FIRE PREVENTION…748

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB…748

2.3.4 ROOM VENTILATION…749

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS…749

2.3.6 CLEANING THE WINDOWS – CHECKING THE WINDSHIELD WIPER BLADES…749

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING…750

2.4.1 STARTING THE ENGINE…750

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE…750

2.4.3 CHECKS FOR TRAVELLING IN REVERSE…750

2.4.4 MOVING THE MACHINE…751

2.4.5 MOVING ON SLOPES…752

2.4.6 WORKING ON SLOPES…753

2.4.7 UNAUTHORIZED OPERATIONS…753

2.4.8 PREVENTING ELECTROCUTION…754

2.4.9 VISIBILITY…755

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES…755

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…755

2.4.12 WORKING ON LOOSE GROUND…755

2.4.13 PARKING THE MACHINE…756

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES…757

2.5.1 LOADING AND UNLOADING…757

2.5.2 TRANSPORT…757

2.6 BATTERY…758

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY…758

2.6.2 STARTING WITH BOOSTER CABLES…758

2.7 PRECAUTIONS FOR THE REMOVAL…759

2.8 PRECAUTIONS FOR MAINTENANCE…760

2.8.1 WARNING PLATES…760

2.8.2 TOOLS…760

2.8.3 PERSONNEL…760

2.8.4 EQUIPMENT…761

2.8.5 WORKING UNDER THE MACHINE…761

2.8.6 CLEANING THE MACHINE…761

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS…762

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY…762

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION…762

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP…763

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR…763

2.8.12 USING LAMPS…763

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR…764

2.8.14 PRECAUTIONS CONCERNING THE STARTER…764

2.8.15 HANDLING HIGH-PRESSURE PIPES…765

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL…765

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE…765

2.8.18 COOLING FAN AND BELT…766

2.8.19 WASTE MATERIALS…766

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES…766

3.1 SAFETY LOCKS…769

3.1.1 MACHINE LOCKS…769

3.2 GENERAL VIEWS…770

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB…770

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY…771

3.2.3 GENERAL VIEW OF THE DRIVER’S SEAT…772

3.3 INSTRUMENTS AND CONTROLS…773

3.3.1 INSTRUMENTS…773

3.3.2 WARNING LIGHTS…775

3.3.3 SWITCHES AND PUSH BUTTONS…777

3.3.4 ELECTRICAL ACCESSORIES…780

3.3.5 MACHINE CONTROLS…782

LEVER 1 (BASIC MANOEUVRES)…783

LEVER 2 (BASIC MANOEUVRES)…783

LEVER 1 (COMBINED MANOEUVRES)…784

LEVER 2 (COMBINED MANOEUVRES)…784

3.4 FUSES AND RELAYS…790

3.4.1 FUSES…790

3.4.1.1 EQUIPMENT FUSES…790

3.4.1.2 MAIN FUSE…791

3.4.2 RELAYS…792

3.5 GUARDS AND DRIVER’S SEAT…793

3.5.1 ENGINE HOOD…793

3.5.2 RIGHT COUNTERWEIGHT…794

3.5.3 CANOPY…794

3.5.4 CAB…795

3.5.5 VENTILATION AND HEATING…798

3.5.6 SEAT…799

3.5.7 SAFETY BELT…799

3.5.8 EMERGENCY EXIT…800

3.5.9 TECHNICAL DOCUMENTATION CASE…800

3.5.10 FIRE EXTINGUISHER…801

3.5.11 FIRST AID KIT…801

3.6 USE OF THE MACHINE…802

3.6.1 CHECKS BEFORE STARTING THE ENGINE…802

3.6.1.1 VISUAL CHECKS…802

3.6.1.2 DAILY CHECKS…802

3.6.1.3 OPERATIONAL CHECKS…803

3.6.2 STARTING THE ENGINE…804

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES…804

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES…805

3.6.3 WARMING THE ENGINE…806

3.6.4 HEATING THE HYDRAULIC OIL…806

3.6.5 HOW TO MOVE THE MACHINE…806

3.6.5.1 STEERING (CHANGING DIRECTION)…808

3.6.5.2 MOVING ON SLOPES…809

3.6.5.3 MAXIMUM IMMERSION DEPTH…810

3.7 PARKING THE MACHINE…811

3.7.1 PARKING ON LEVEL GROUND…811

3.7.2 PARKING ON SLOPES…812

3.8 STOPPING THE ENGINE…813

3.9 TRANSPORTING THE MACHINE ON MOTOR VEHICLES…814

3.9.1 LOADING AND UNLOADING THE MACHINE…814

3.9.2 TRANSPORT…815

3.10 LIFTING THE MACHINE…816

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON…817

3.11.1 FUEL AND LUBRICANTS…817

3.11.2 COOLANT…817

3.11.3 BATTERY…817

3.11.4 OTHER PRECAUTIONS…818

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK…818

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON…819

3.13 USING THE WORK EQUIPMENT…820

3.13.1 ORGANIZING THE WORK AREA…820

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS…821

3.13.3 DIGGING METHOD…822

3.13.4 CHANGING THE BUCKET…823

3.14 LONG PERIODS OF INACTIVITY…824

3.14.1 BEFORE THE PERIOD OF INACTIVITY…824

3.14.2 DURING THE PERIOD OF INACTIVITY…825

3.14.3 AFTER THE PERIOD OF INACTIVITY…825

3.15 TROUBLESHOOTING…826

3.15.1 OCCURRENCES THAT ARE NOT FAILURES…826

3.15.2 HOW TO REMOVE THE MACHINE…826

3.15.3 AFTER THE FUEL HAS RUN OUT…827

3.15.4 IF THE BATTERY IS DOWN…827

3.15.4.1 STARTING WITH BOOSTER CABLES…828

3.15.5 OTHER TROUBLES…829

3.15.5.1 ELECTRICAL CIRCUIT…829

3.15.5.2 HYDRAULIC SYSTEM…829

3.15.5.3 ENGINE…830

4.1 GUIDE TO MAINTENANCE…833

4.2 MAINTENANCE NOTES…835

4.2.1 NOTES REGARDING THE ENGINE…835

4.2.1.1 ENGINE OIL…835

4.2.1.2 COOLANT…835

4.2.1.3 FUEL…836

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM…836

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM…837

4.2.4 NOTES REGARDING LUBRICATION…837

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING…838

4.3 FUEL, COOLANT AND LUBRICANTS…839

LUBRICATION WITH GREASE…839

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS…841

4.4 DRIVING TORQUES FOR SCREWS AND NUTS…842

4.4.1 STANDARD DRIVING TORQUES…842

4.4.2 SPECIFIC DRIVING TORQUES…842

4.5 LUBRICATION…843

4.5.1 LUBRICATION DIAGRAM…843

4.6 PERIODICAL CHANGE OF THE COMPONENTS THAT ARE CONNECTED WITH SAFETY…844

4.6.1 CRITICAL PARTS FOR SAFETY…845

FUEL SUPPLY SYSTEM…845

HYDRAULIC SYSTEM…846

4.7 MAINTENANCE PLAN…848

4.7.1 WHEN REQUIRED…851

4.7.1.a WASHING THE COOLING CIRCUIT…851

4.7.1.b DRAINING THE FUEL TANK…852

4.7.1.c CHECKING THE ELECTRICAL SYSTEM…853

4.7.1.d CHECKING THE STEEL TRACK TENSION…853

4.7.1.e CHECKING THE RUBBER TRACKS…855

4.7.1.f CHECKING THE RUBBER TRACK TENSION…857

4.7.1.g CHANGING THE RUBBER TRACK…859

4.7.1.h CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE…861

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER)…862

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER…862

4.7.2.b CHANGING THE HYDRAULIC OIL…862

4.7.3 CHECKS BEFORE STARTING…863

4.7.3.a VARIOUS CHECKS…863

4.7.3.b CHECKING THE COOLANT LEVEL…863

4.7.3.c CHECKING THE FUEL LEVEL…864

4.7.3.d CHECKING THE ENGINE OIL LEVEL…864

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT…865

4.7.3.f CHECKING THE AIR CLEANER CLOGGING INDICATOR…866

4.7.3.g CHECKING THE FUEL FILTER FOR SEDIMENT AND WATER…866

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic…867

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION…868

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING…868

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION…870

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION…870

4.7.7.a ADJUSTING THE FAN BELT TENSION…870

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL…871

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS…871

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER…872

4.7.7.e CHANGING THE ENGINE OIL…873

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the syntheti…874

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION…874

4.7.9.a CHANGING THE ENGINE OIL FILTER…874

4.7.9.b CHANGING THE FUEL FILTER…875

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER…876

4.7.9.d CLEANING THE OUTSIDE OF THE RADIATORS…877

4.7.9.e DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable o…878

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION…879

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS…879

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION…880

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER…880

4.7.11.b CHANGING THE COOLANT…883

4.7.11.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE…884

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER…884

5.1 TECHNICAL DATA…887

5.1.1 STANDARD OVERALL DIMENSIONS (for model PC20R only)…887

MACHINE WITH CAB…887

MACHINE WITH CANOPY…887

5.1.2 TECHNICAL CHARACTERISTICS PC20R…888

5.1.3 STANDARD OVERALL DIMENSIONS (for model PC27R only)…889

MACHINE WITH CAB…889

MACHINE WITH CANOPY…889

5.1.4 TECHNICAL CHARACTERISTICS PC27R…890

5.1.5 LIFTING CAPACITY WITH CAB (for model PC20R only)…891

5.1.6 LIFTING CAPACITY WITH CANOPY (for model PC20R only)…892

5.1.7 LIFTING CAPACITY WITH CAB (for model PC27R only)…893

5.1.8 LIFTING CAPACITY WITH CANOPY (for model PC27R only)…894

6.1 AUTHORIZED OPTIONAL EQUIPMENT…897

6.1.1 PRECAUTIONS REGARDING SAFETY…897

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT…898

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT…899

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)…900

6.2.1 DESCRIPTION AND CONTROL…900

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED…900

FOR A CORRECT USE, IT IS NECESSARY TO:…900

ALWAYS AVOID THE FOLLOWING INCORRECT USES:…902

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER…904

6.2.3.1 INSTALLING THE HAMMER…904

6.2.3.2 REMOVING THE HAMMER…905

6.2.4 MAINTENANCE…905

6.3 ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT…906

6.3.1 SELECTION VALVE (1)…906

6.3.2 CONTROL PEDAL (2)…907

6.3.3 ASSEMBLYING AND CONNECTING THE EQUIPMENT…908

6.3.4 MAINTENANCE…909

WEAM003100 – Hydraulic Excavator PC27R-8 Operation & Maintenance Manual…910

COVER…910

1.1 FORWARD…911

1.2 INFORMATION ON SAFETY…912

1.3 INTRODUCTION…914

1.3.1 INTENDED USES…914

1.3.2 IMPROPER OR UNAUTHORIZED USES…914

1.3.3 MAIN CHARACTERISTICS…915

1.3.4 RUNNING-IN…915

1.4 PRODUCT IDENTIFICATION…916

1.4.1 MACHINE SERIAL NUMBER …916

1.4.2 MACHINE IDENTIFICATION PLATE…916

1.4.3 ENGINE SERIAL NUMBER AND EMISSION LABEL…917

1.4.4TRAVEL REDUCTION GEAR SERIAL NUMBER…917

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER…918

1.4.6 CAB SERIAL NUMBER…918

1.4.7 SERIAL NUMBERS AND DEALER'S ADDRESS…919

TABLE OF CONTENTS…920

SAFETY AND ACCIDENT PREVENTION…927

2.1 SAFETY PLATES…928

2.1.1 POSITION OF THE SAFETY PLATES…928

2.1.2 POSITION OF THE PICTOGRAMS…944

2.1.3 PICTOGRAMS AND REVELANT MEANINGS…946

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED…947

2.2 GENERAL PRECAUTIONS…948

2.2.1 GENERAL SAFETY RULES…948

2.2.2 SAFETY DEVICES AND GUARDS…948

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS…948

2.2.4 UNAUTHORIZED MODIFICATIONS…949

2.2.5 LEAVING THE OPERATORS SEAT…949

2.2.6 GETTING ON AND OFF THE MACHINE…950

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL…950

2.2.8 PREVENTING BURNS…951

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWER …951

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…952

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT…952

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE…952

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT…952

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE…953

2.3.1 SAFETY ON THE WORK SITE…953

2.3.2 FIRE PREVENTION…953

2.3.3 PRECAUTIONS TO BE TAKEN FROM THE OPERATOR'S CAB…953

2.3.4 ROOM VENTILATION…954

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS…954

2.3.6 CLEANING THE WINDOWS – CHECKING THE WINDSHEILD WIPER BLADES…954

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING…955

2.4.1 STARTING THE ENGINE…955

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE …955

2.4.3 CHECKS FOR TRAVELLING IN REVERSE…955

2.4.4 MOVING THE MACHINE…956

2.4.5 MOVING ON SLOPES…957

2.4.6 WORKING ON THE SLOPES…958

2.4.7 UNAUTHORIZED OPERATIONS…958

2.4.8 PREVENTING ELECTROCUTION…959

2.4.9 VISIBILITY…960

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES …960

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…960

2.4.12 WORKING ON THE LOOSE GROUND …960

2.4.13 PARKING THE MACHINE…961

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES…962

2.5.1 LOADING AND UNLOADING…962

2.5.2 TRANSPORT…962

2.6 BATTERY…963

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY…963

2.6.2 STARTING WITH BOOSTER CABLES…963

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY…964

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE…965

2.8.1 WARNINGS PLATES…965

2.8.2 TOOLS…965

2.8.3 PERSONNEL…966

2.8.4 EQUIPMENT…966

2.8.5 WORKING THE MACHINE…966

2.8.6 CLEANING THE MACHINE…966

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS…967

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY…967

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION…967

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP…968

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR…968

2.8.12 USING LAMPS…968

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR…969

2.8.14 PRECAUTIONS CONCERNING THE STARTER…969

2.8.15 HANDLING HIGH-PRESSURE PIPES…970

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESURE OIL…970

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE…970

2.8.18 COOLING FAN AND BELT…971

2.8.19 WASTE MATERIALS…971

DESCRIPTION AND USE OF THE MACHINE…973

3.1 SAFETY LOCKS…974

3.1.1 MACHINE LOCKS…974

3.2 GENERAL VIEWS…975

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB…975

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY…976

3.2.3 GENERAL VIEW OF THE DRIVER'S SEAT…977

3.3 INSTRUMENTS AND CONTROLS…978

3.3.1 INSTRUMENTS, WARNING LIGHTS AND PUSH BUTTONS…978

3.3.2 MACHINE CONTROLS…984

3.4 FUSES AND RELAYS…993

3.4.1 FUSES…993

3.4.1.1 EQUIPMENT FUSES…993

3.4.1.2 MAIN FUSE…994

3.4.2 RELAYS…995

3.5 GUARDS AND DRIVER'S SEAT…996

3.5.1 ENGINE HOOD…996

3.5.2 CANOPY CAB …997

3.5.3 CAB…997

3.5.4 VENTILATION AND HEATING…1000

3.5.5 SEAT…1000

3.5.6 SAFETY BELT…1001

3.5.7 EMERGENCY EXIT…1001

3.5.8 TECHNICAL DOCUMENTATION CASE…1002

3.5.9 FIRE EXTINGUISHER…1002

3.5.10 FIRST AID KIT…1002

3.6 USE OF THE MACHINE…1003

3.6.1 CHECKS BEFORE STARTING THE ENGINE…1003

3.6.1.1 VISUAL CHECKS…1003

3.6.1.2 DAILY CHECKS…1003

3.6.1.3 OPERATIONAL CHECKS…1004

3.6.2 STARTING THE ENGINE…1005

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES…1005

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES…1006

3.6.3 WARMING THE ENGINE…1007

3.6.4 HEATING THE HYDRAULIC OIL…1007

3.6.5 HOW TO MOVE THE MACHINE…1007

3.6.5.1 STEERING (CHANGING DIRECTION)…1009

3.6.5.2 MOVING ON SLOPES…1010

3.6.5.3 MAXIMUM IMMERSION DEPTH…1011

3.7 PARKING THE MACHINE…1012

3.7.1 PARKING ON LEVEL GROUND…1012

3.7.2 PARKING ON SLOPES…1013

3.8 STOPPING THE ENGINE…1014

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES…1015

3.9.1 LOADING AND UNLOADING THE MACHINE…1015

3.9.2 TRANSPORT…1016

3.10 LIFTING THE MACHINE…1017

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON…1018

3.11.1 FUEL AND LUBRICANTS…1018

3.11.2 COOLANT…1018

3.11.3 BATTERY…1018

3.11.4 OTHER PRECAUTIONS…1019

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK…1019

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON…1020

3.13 USING THE WORK EQUIPMENT…1021

3.13.1 ORGANIZING THE WORK AREA…1021

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS…1022

3.13.3 DIGGING METHOD…1023

3.13.4 CHAGING THE BUCKETT…1024

3.14 LONG PERIODS OF INACTIVITY…1025

3.14.1 BEFORE THE PERIOD OF INACTIVITY…1025

3.14.2 DURING THE PERIOD OF INACTIVITY…1026

3.14.3 AFTER THE PERIOD OF INACTIVITY…1026

3.15 TROUBLESHOOTING…1027

3.15.1 OCCURRENCES THAT ARE NOT FAILURES…1027

3.15.2 HOW TO REMOVE THE MACHINE…1027

3.15.3 AFTER THE FUEL HAS RUN OUT…1028

3.15.4 IF THE BATTERY IS DOWN…1028

3.15.4.1 STARTING WITH BOOSTER CABLES…1029

3.15.5 OTHER BOOSTER CABLES…1030

3.15.5.1 ELECTRIC CIRCUIT…1030

3.15.5.2 HYDRAULIC SYSTEM…1030

3.15.5.3 ENGINE…1031

MAINTENANCE…1033

4.1 GUIDE TO MAINTENANCE…1034

4.2 MAINTENANCE NOTES…1036

4.2.1 NOTES REGARDING THE ENGINE…1036

4.2.1.1 ENGINE OIL…1036

4.2.1.2 COOLANT…1036

4.2.1.3 FUEL…1037

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM…1037

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM…1038

4.2.4 NOTES REGARDING LUBRICATION…1038

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING…1039

4.3 FUEL, COOLANT AND LUBRICANTS…1040

4.4 NUT AND BOLT TIGHTENING TORQUES…1044

4.4.2 SPECIFIC TIGHTENING TORQUES…1044

4.5 LUBRICATION…1045

4.5.1 LUBRICATION DIAGRAM…1045

4.6 PERIODICAL CHANGE OF THE COMPONENTS THAT ARE CONNECTED WITH SAFETY…1046

4.7 MAINTENANCE PLAN…1050

4.7.1 WHEN REQUIRED…1050

4.7.1.A WASHING THE COOLANT CIRCUIT…1052

4.7.1.B DRAINING THE FUEL TANK…1053

4.7.1.C CHECKING THE ELECTRICAL SYSTEM…1053

4.7.1.D CHECKING THE STEEL TRACK TENSION…1054

4.7.1.E CHECKING THE RUBBER TRACKS…1056

4.7.1 F CHECKING THE RUBBER TRACK TENSION…1058

4.7.1.G CHANGING THE RUBBER TRACK…1060

4.7.1.H CHECKIJNG,CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE…1062

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER(BREAKER)…1063

4.7.2.A CHANGING THE HYDRAULIC OIL FILTER…1063

4.7.2.B CHANGING THE HYDRAULIC OIL…1063

4.7.3 CHECKS BEFORE STARTING…1064

4.7.3.A VARIOUS CHECKS…1064

4.7.3.B CHECKING THE COOLANT LEVEL…1064

4.7.3.C CHECKING THE FUEL LEVEL…1065

4.7.3.D CHECKING THE ENGINE OIL LEVEL…1065

4.7.3.E CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT…1066

4.7.3.F CHECKING THE AIR CLEANER CLOGGING INDICATOR…1067

4.7.3.G CHECKING THE FUEL FILTER FOR SEDIMENT AND WATER…1067

4.7.4 MAINTENANCE EVERY 100 HOURS OF OPERATION…1068

4.7.4.A LUBRICATING THE JOINTS AND THE BALL-BEARING RING…1068

4.7.5 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION…1070

4.7.6 MAINTENANCE EVEY 250 HOURS OF OPERATION…1070

4.7.6.A ADJUSTING THE FAN BELT TENSION…1070

4.7.6.B CHECKING THE BATTERY ELECTROLYTE LEVEL…1071

4.7.6 C CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS…1071

4.7.6.D CHANGING THE HYDRAULIC SYSTEM OIL FILTER…1072

4.7.6 E CHANGING THE ENGINE OIL…1073

4.7.7 MAINTENANCE EVERY 500 HOURS OF OPERATION…1074

4.7.7.A CHANGING THE ENGINE OIL FILTER…1074

4.7.7.B CHANGING THE FUEL FILTER …1075

4.7.7.C CHANGING THE FUEL PUMP PRECLEANER…1076

4.7.7.D CLEANING THE OUTSIDE OF THE RADIATORS…1077

4.7.8 MAINTENANCE EVERY 1000 HOURS OF OPERATION…1078

4.7.8. A CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS…1078

4.7.9 MAINTENANCE EVERY 2000 HOURS OF OPERATION…1079

4.7.9.A CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER…1079

4.7.9.B CHANGING THE COOLANT…1081

4.7.9.C CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE…1081

4.7.9.D CHECKING THE ALTERNATOR AND THE STARTER…1081

TECHNICAL SPECIFICATIONS…1083

5.1 TECHNICAL DATA…1084

5.1.1 STANDARD OVERALL DIMENSIONS…1084

5.1.2 TECHNICAL CHARACTERISTICS…1086

5.1.3 LIFTING CAPACITY WITH CAB…1087

5.1.4 LIFTING CAPACITY WITH CANOPY…1088

AUTHORIZED OPTIONAL EQUIPMENT…1089

6.1 AUTHORIZED OPTIONAL EQUIPMENT…1090

6.1.1 PRECAUTIONS REGARDING SAFETY…1090

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT…1091

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT…1092

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEOLITION HAMMER (BREAKER)…1093

6.2.1 DESCRIPTION AND CONTROL…1093

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBESERVED…1093

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER…1097

6.2.3.1 INSTALLING THE HAMMER…1097

6.2.3.2 REMOVING THE HAMMER…1098

6.2.4 MAINTENANCE…1098

6.3 ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT…1099

6.3.1 SELECTION VALVE (1)…1099

6.3.2 CONTROL PEDAL (2)…1100

6.3.3 ASSEMBLYING AND CONNECTING THE EQUIPMENT…1101

6.3.4 MAINTENANCE…1102

WEAM003102 – Hydraulic Excavator PC27R-8 Deluxe Operation & Maintenance Manual…1103

COVER…1103

1.1 FOREWORD…1104

1.2 INFORMATION ON SAFETY…1105

1.3 INTRODUCTION…1107

1.3.1 INTENDED USES…1107

1.3.2 IMPROPER OR UNAUTHORIZED USES…1107

1.3.3 MAIN CHARACTERISTICS…1108

1.3.4 RUNNING-IN…1108

1.4 PRODUCT IDENTIFICATION…1109

1.4.1 MACHINE SERIAL NUMBER…1109

1.4.2 MACHINE IDENTIFICATION PLATE…1109

1.4.3 ENGINE SERIAL NUMBER AND EMISSION LABEL…1110

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER…1110

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER…1111

1.4.6 CAB SERIAL NUMBER…1111

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS…1112

TABLE OF CONTENTS…1113

SAFETY AND ACCIDENT PREVENTION…1120

2.1 SAFETY PLATES…1121

2.1.1 POSITION OF THE SAFETY PLATES…1121

2.1.2 POSITION OF THE PICTOGRAMS…1137

2.1.3 PICTOGRAMS AND RELEVANT MEANINGS…1139

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED…1140

2.2 GENERAL PRECAUTIONS…1141

2.2.1 GENERAL SAFETY RULES…1141

2.2.2 SAFETY DEVICES AND GUARDS…1141

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS…1141

2.2.4 UNAUTHORIZED MODIFICATIONS…1142

2.2.5 LEAVING THE OPERATOR’S SEAT…1142

2.2.6 GETTING ON AND OFF THE MACHINE…1143

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL…1143

2.2.8 PREVENTING BURNS…1144

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER…1144

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…1145

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT…1145

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE…1145

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT…1145

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE…1146

2.3.1 SAFETY ON THE WORK SITE…1146

2.3.2 FIRE PREVENTION…1146

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB…1146

2.3.4 ROOM VENTILATION…1147

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS…1147

2.3.6 CLEANING THE WINDOWS – CHECKING THE WINDSHIELD WIPER BLADES…1147

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING…1148

2.4.1 STARTING THE ENGINE…1148

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE…1148

2.4.3 CHECKS FOR TRAVELLING IN REVERSE…1148

2.4.4 MOVING THE MACHINE…1149

2.4.5 MOVING ON SLOPES…1150

2.4.6 WORKING ON SLOPES…1151

2.4.7 UNAUTHORIZED OPERATIONS…1151

2.4.8 PREVENTING ELECTROCUTION…1152

2.4.9 VISIBILITY…1153

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES…1153

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…1153

2.4.12 WORKING ON LOOSE GROUND…1153

2.4.13 PARKING THE MACHINE…1154

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES…1155

2.5.1 LOADING AND UNLOADING…1155

2.5.2 TRANSPORT…1155

2.6 BATTERY…1156

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY…1156

2.6.2 STARTING WITH BOOSTER CABLES…1156

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY…1157

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE…1158

2.8.1 WARNING PLATES…1158

2.8.2 TOOLS…1158

2.8.3 PERSONNEL…1159

2.8.4 EQUIPMENT…1159

2.8.5 WORKING UNDER THE MACHINE…1159

2.8.6 CLEANING THE MACHINE…1159

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS…1160

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY…1160

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION…1160

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP…1161

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR…1161

2.8.12 USING LAMPS…1161

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR…1162

2.8.14 PRECAUTIONS CONCERNING THE STARTER…1162

2.8.15 HANDLING HIGH-PRESSURE PIPES…1163

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL…1163

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE…1163

2.8.18 COOLING FAN AND BELT…1164

2.8.19 WASTE MATERIALS…1164

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES…1164

THE MACHINE AND ITS OPERATIONS…1166

3.1 SAFETY LOCKS…1167

3.1.1 MACHINE LOCKS…1167

3.2 GENERAL VIEWS…1168

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB…1168

3.2.2 GENERAL VIEW OF MACHINE WITH CANOPY…1169

3.2.3 GENERAL VIEW OF THE DRIVER'S SEAT…1170

3.3 INSTRUMENTS AND CONTROLS…1171

3.3.1 INSTRUMENTS…1171

3.3.2 WARNING LIGHTS…1173

3.3.3 SWITCHES AND PUSH BUTTONS…1175

3.3.4 ELECTRICAL ACCESSORIES…1178

3.3.5 MACHINE CONTROLS…1180

3.4 FUSES AND RELAYS…1193

3.4.1 FUSES…1193

3.4.1.1 EQUIPMENT FUSES…1193

3.4.1.2 MAIN FUSE…1194

3.4.2 RELAYS…1195

3.5 GUARDS AND DRIVER'S SEAT…1196

3.5.1 ENGINE HOOD…1196

3.5.2 RIGHT COUNTERWEIGHT…1197

3.5.3 CANOPY…1197

3.5.4 CAB…1198

3.5.5 VENTILATION AND HEATING…1201

3.5.6 SEAT…1202

3.5.7 SAFETY BELT…1202

3.5.8 EMERGENCY EXIT…1203

3.5.9 TECHNICAL DOCUMENTATION CASE…1203

3.5.10 FIRE EXTINGUISHER…1204

3.5.11 FIRST AID KIT…1204

3.6 USE OF THE MACHINE…1206

3.6.1 CHECKS BEFORE STARTING THE ENGINE…1206

3.6.1.1 VISUAL CHECKS…1206

3.6.1.2 DAILY CHECKS…1206

3.6.1.3 OPERATIONAL CHECKS…1207

3.6.2 STARTING THE ENGINE…1208

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES…1208

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES…1209

3.6.3 WARMING THE ENGINE…1210

3.6.4 HEATING THE HYDRAULIC OIL…1210

3.6.5 HOW TO MOVE THE MACHINE…1210

3.6.5.1 STEERING (CHANGING DIRECTION)…1212

3.6.5.2 MOVING ON SLOPES…1213

3.6.5.3 MAXIMUM IMMERSION DEPTH…1214

3.7 PARKING THE MACHINE…1215

3.7.1 PARKING ON LEVEL GROUND…1215

3.7.2 PARKING ON SLOPES…1216

3.8 STOPPING THE ENGINE…1217

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES…1218

3.9.1 LOADING AND UNLOADING THE MACHINE…1218

3.9.2 TRANSPORT…1219

3.10 LIFTING THE MACHINE…1220

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON…1221

3.11.1 FUEL AND LUBRICANTS…1221

3.11.2 COOLANT…1221

3.11.3 BATTERY…1221

3.11.4 OTHER PRECAUTIONS…1222

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK…1222

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON…1223

3.13 USING THE WORK EQUIPMENT…1224

3.13.1 ORGANIZING THE WORK AREA…1224

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS…1225

3.13.3 DIGGING METHOD…1226

3.13.4 CHANGING THE BUCKET…1227

3.14 LONG PERIODS OF INACTIVITY…1228

3.14.1 BEFORE THE PERIOD OF INACTIVITY…1228

3.14.2 DURING THE PERIOD OF INACTIVITY…1229

3.14.3 AFTER THE PERIOD OF INACTIVITY…1229

3.15 TROUBLESHOOTING…1230

3.15.1 OCCURENCES THAT ARE NOT FAILURES…1230

3.15.2 HOW TO REMOVE THE MACHINE…1230

3.15.3 AFTER THE FUEL HAS RUN OUT…1231

3.15.4 IF THE BATTERY IS DOWN…1231

3.15.4.1 STARTING WITH BOOSTER CABLES…1232

3.15.5 OTHER TROUBLES…1233

3.15.5.1 ELECTRICAL CIRCUIT…1233

3.15.5.2 HYDRAULIC SYSTEM…1233

3.15.5.3 ENGINE…1234

MAINTENANCE…1236

4.1 GUIDE TO MAINTENANCE…1237

4.2 MAINTENANCE NOTES…1239

4.2.1 NOTES REGARDING THE ENGINE…1239

4.2.1.1 ENGINE OIL…1239

4.2.1.2 COOLANT…1239

4.2.1.3 FUEL…1240

4.2.2 NOTES REGUARDING THE HYDRAULIC SYSTEM…1240

4.2.3 NOTES REGUARDING THE ELECRICAL SYSTEM…1241

4.2.4 NOTES REGUARDING LUBRICATION…1241

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING…1242

4.3 FUEL, COOLANT AND LUBRICANTS…1243

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS…1247

4.4 NUT AND BOLT TIGHTENING TORQUES…1248

4.4.1 STANDARD TIGHTENING TORQUES…1248

4.4.2 SPECIFIC TIGHTENING TORQUES…1248

4.5 LUBRICATION…1249

4.5.1 LUBRICATION DIAGRAM…1249

4.6 PERIODICAL CHANGE OF THE COMPONENTS THAT ARE CONNECTED WITH SAFETY…1250

4.6.1 CRITICAL PARTS FOR SAFETY…1251

4.7 MAINTENANCE PLAN…1254

4.7.1 WHEN REQUIRED…1257

4.7.1.a WASHING THE COOLING CIRCUIT…1257

4.7.1.b DRAINING THE FUEL TANK…1258

4.7.1.c CHECKING THE ELECTRICAL SYSTEM…1259

4.7.1.d CHECKING THE STEEL TRACK TENSION…1259

4.7.1.e CHECKING THE RUBBER TRACKS…1261

4.7.1.f CHECKING THE RUBBER TRACK TENSION…1263

4.7.1.g CHANGING THE RUBBER TRACK…1265

4.7.1.h CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE…1267

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER)…1268

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER…1268

4.7.2.b CHANGING THE HYDRAULIC OIL…1268

4.7.3 CHECKS BEFORE STARTING…1269

4.7.3.a VARIOUS CHECKS…1269

4.7.3.b CHECKING THE COOLANT LEVEL…1269

4.7.3.c CHECKING THE FUEL LEVEL…1270

4.7.3.d CHECKING THE ENGINE OIL LEVEL…1270

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT…1271

4.7.3.f CHECKING THE AIR CLEANER CLOGGING INDICATOR…1272

4.7.3.g CHECKING THE FUEL FILTER FOR SEDIMENT AND WATER…1272

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (ONLY FOR MACHINES IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES…1273

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION…1274

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING…1274

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION…1276

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION…1276

4.7.7.a ADJUSTING THE FAN BELT TENSION…1276

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL…1277

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS…1277

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER…1278

4.7.7.e CHANGING THE ENGINE OIL…1279

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (ONLY FOR MACHINES IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEE…1280

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION…1280

4.7.9.a CHANGING THE OIL FILTER…1280

4.7.9.b CHANGING THE FUEL FILTER…1281

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER…1282

4.7.9.d CLEANING THE OUTSIDE OF THE RADIATORS…1283

4.7.9.e DRAINING THE HYDRAULIC OIL TANK (ONLY FOR MACHINES IN WHICH THE SYNTHETOC BIODEGRADABLE OIL TYPE HEES IS USED)…1284

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION…1285

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS…1285

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION…1286

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER…1286

4.7.11.b CHANGING THE COOLANT…1289

4.7.11.C CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE…1290

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER…1290

TECHNICAL SPECIFICATIONS…1292

5.1 TECHNICAL DATA…1293

5.1.1 STANDARD OVERALL DIMENSIONS…1293

5.1.2 TECHNICAL CHARACTERISTICS…1295

5.1.3 LIFTING CAPACITY WITH CAB…1296

5.1.4 LIFTING CAPACITY WITH CANOPY…1297

AUTHORIZED OPTIONAL EQUIPMENT…1298

6.1 AUTHORIZED OPTIONAL EQUIPMENT…1299

6.1.1 PRECAUTIONS REGARDING SAFETY…1299

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT…1300

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT…1301

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)…1302

6.2.1 DESCRIPTION AND CONTROL…1302

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED…1302

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER…1306

6.2.3.1 INSTALLING THE HAMMER…1306

6.2.3.2 REMOVING THE HAMMER…1307

6.2.4 MAINTENANCE…1307

6.3 ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT…1308

6.3.1 SELECTION VALVE (1)…1308

6.3.2 CONTROL PEDAL (2)…1309

6.3.3 ASSEMBLYING AND CONNECTING THE EQUIPMENT…1310

6.3.4 MAINTENANCE…1311

WEBM000200 – Hydraulic Excavator PC20R-8, PC27R-8 Shop Manual…1312

WEBM000201 – Hydraulic Excavator PC20R-8, PC27R-8 Shop Manual…1608

COVER…1608

CONTENTS…1610

LIST OF REVISED PAGES…1612

SAFETY…1614

FOREWORD…1616

HOW TO READ THE SHOP MANUAL…1617

HOISTING INSTRUCTIONS…1618

STANDARD TIGHTENING TORQUE…1619

COATING MATERIALS…1620

ELECTRIC WIRE CODE…1621

WEIGHT TABLE…1622

TABLE OF OIL AND COOLANT QUANTITIES…1623

10.STRUCTURE AND FUNCTION…1626

POWER TRAIN…1627

SWING CIRCLE…1629

SWING MACHINERY PC27R-8…1631

FINAL DRIVE…1632

TRACK FRAME…1633

RECOIL SPRING…1635

CARRIER ROLLER PC27R-8…1636

TRACK ROLLER…1636

STEEL SHOE…1637

HYDRAULIC SYSTEM PC20R-8…1638

HYDRAULIC SYSTEM PC27R-8…1640

HYDRAULIC CIRCUIT DIAGRAM PC20R-8…1642

HYDRAULIC CIRCUIT DIAGRAM PC27R-8…1644

HYDRAULIC PUMP PC20R-8…1645

HYDRAULIC PUMP PC27R-8…1649

TCC VALVE, LS VALVE, SERVO PISTON…1655

CONTROL VALVE…1669

CLSS…1677

SWIVEL JOINT…1694

SWING MOTOR…1695

TRAVEL MOTOR…1699

CYLINDER…1702

ACCUMULATOR…1706

PPC VALVE…1707

PPC VALVE…1711

SOLENOID VALVE…1714

ELECTRICAL DIAGRAM (1/3)…1716

ELECTRICAL DIAGRAM (2/3)…1718

ELECTRICAL DIAGRAM (3/3)…1720

20.TESTING AND ADJUSTMENT…1724

NORMAL OR STANDARD TECHNICAL DATA…1725

SPECIAL TOOLS…1747

CHECKING THE ENGINE SPEED…1748

ADJUSTMENT OF VALVE CLEARANCE…1749

MEASUREMENT OF THE COMPRESSION PRESSURE…1750

CONTROL AND ADJUSTMENT OF THE TENSION OF THE FAN BELT…1751

CONTROL AND ADJUSTMENT OF THE INJECTION TIMING…1752

CONTROL AND ADJUSTMENT OF THE ACCELERATOR STROKE…1754

ADJUSTMENT OF THE STROKE OF THE BLADE COMMAND LEVER…1755

ADJUSTING THE FLEXIBLE CABLES…1756

CONTROL AND ADJUSTMENT OF THE STROKE OF THE TRAVEL LEVER…1757

ADJUSTMENT OF THE STROKE OF THE BOOM SWING COMMAND PEDAL…1758

ADJUSTMENT OF THE PPC VALVE CLEARANCES…1759

ADJUSTMENT OF THE RUBBER PAD AND SAFETY MICROSWITCH FOR SERVO-CONTROL ENGAGEMENT…1760

CONTROL AND ADJUSTMENT OF THE TRACK-SHOE TENSION…1761

CONTROL AND REGULATION OF THE PRESSURES IN THE HYDRAULIC CIRCUITS…1762

CONTROL AND REGULATION OF THE LS DIFFERENTIAL PRESSURE AND ADJUSTMENT OF THE LS VALVE (PC20R-8)…1767

REGULATION OF THE PC VALVE (PC20R-8)…1769

CONTROL AND REGULATION OF THE LS DIFFERENTIAL PRESSURE AND ADJUSTMENT OF THE LS VALVE (PC27R-8)…1770

REGULATION OF THE PC VALVE (PC27R-8)…1772

CONTROL AND REGULATION OF THE SERVO-CONTROL POWER SUPPLY…1773

ELIMINATION OF RESIDUAL PRESSURES – PRESSURISATION OF THE TANK…1774

BLEEDING AIR FROM THE HYDRAULIC CIRCUITS…1775

CONTROL OF HYDRAULIC DRIFTS – ANALYSIS OF THE CAUSES OF A DRIFT…1777

CHECKING FOR ANY LEAKAGES INSIDE THE WORKING EQUIPMENT CYLINDERS…1783

CHECKING FOR ANY LEAKAGES INSIDE THE SWING MOTOR…1784

METHODS FOR TESTING FOR LEAKAGES INSIDE THE SWIVEL JOINT…1785

30.REMOVAL AND INSTALLATION…1790

HOW TO READ THE MANUAL…1792

PRECAUTIONS TO BE TAKEN WHILE WORKING…1793

SPECIAL TOOLS…1794

STARTER MOTOR…1796

ALTERNATOR…1797

INJECTION PUMP…1798

NOZZLE HOLDER…1800

WATER COOLANT PUMP…1801

CYLINDER HEAD…1803

ENGINE HOOD…1805

CANOPY…1806

CAB…1807

HEATING FAN…1808

COUNTERWEIGHT…1810

FUEL TANK…1811

HYDRAULIC TANK…1812

OIL-COOLER – RADIATOR GROUP…1814

ENGINE-PUMP GROUP…1816

PUMP…1819

ENGINE-PUMP COUPLING…1820

LATERAL LOWER COVER…1821

INNER CONTROL VALVE BOX COVER…1822

CONTROL VALVE…1823

LEFT-HAND PPC VALVE (ARM-BUCKET)…1825

RIGHT-HAND PPC VALVE (BOOM-BUCKET)…1826

SERVOCONTROL SOLENOID GROUP…1827

PLATFORM…1828

SWIVEL JOINT…1831

SWING MACHINERY…1832

REVOLVING FRAME…1835

SWING CIRCLE…1837

RUBBER TRACK SHOES…1838

STEEL TRACK-SHOES…1839

SPROCKET WHEEL…1840

FINAL DRIVE…1841

IDLER AND RECOIL SPRING…1842

SPRING RECOIL AND THRUST CYLINDER GROUPS…1843

IDLER…1844

TRACK ROLLERS…1845

BOOM CYLINDER…1846

ARM CYLINDER…1848

BUCKET CYLINDER…1849

BOOM SWING CYLINDER…1850

BLADE CYLINDER…1852

WORK EQUIPMENT CYLINDERS…1853

UPPER WORK EQUIPMENT…1859

BUCKET…1861

ARM…1862

ARM ASSEMBLY…1864

BOOM…1865

BOOM SWING SUPPORT…1867

BLADE…1868

40.STANDARD MAINTENANCE…1872

SWING CIRCLE…1873

SWING MACHINERY PC27R-8…1874

FINAL DRIVE…1875

SPROCKET…1876

TRACK FRAME AND RECOIL SPRING…1877

IDLER…1878

CARRIER ROLLER PC27R-8…1879

TRACK ROLLER…1880

TRACK SHOE…1881

HYDRAULIC PUMP…1883

CONTROL VALVE…1885

SWIVEL JOINT…1891

SWING MOTOR…1892

TRAVEL MOTOR…1895

PPC VALVE…1897

CYLINDER…1899

WORK EQUIPMENT PC20R-8…1901

WORK EQUIPMENT PC27R-8…1903

WEBM002900 – Hydraulic Excavator PC27R-8 Shop Manual…1906

COVER…1906

CONTENTS…1907

FOREWARD…1910

FOREWARD…1912

HOW TO READ THE SHOP MANUAL…1913

HOISTING INSTRUCTIONS…1914

STANDARD TIGHTENING TORQUE…1915

COATING MATERIALS…1917

ELECTRIC WIRE CODE…1918

WEIGHT TABLE…1919

TABLE OF OIL AND COOLANT QUANTIES…1920

10 STRUCTURE AND FUNCTION…1922

POWER TRAIN…1923

SWING CIRCLE…1924

SWING MACHINERY…1925

FINAL DRIVE…1926

TRACK FRAME…1927

RECOIL SPRING…1928

CARRIER ROLLER…1929

TRACK ROLLER…1929

STEEL SHOE…1930

HYDRAULIC SYSTEM…1931

HYDRAULIC CIRCUIT DIAGRAM…1932

HYDRAULIC PUMP…1934

CONTROL VALVE…1952

CLSS…1960

SWIVEL JOINT…1977

SWING MOTOR…1978

TRAVEL MOTOR…1980

CYLINDER…1982

ACCUMULATOR…1985

PPC VALVE…1990

SOLENOID VALVE…1993

ELECTRICAL DIAGRAM (1/3)…1995

ELECTRICAL DIAGRAM (2/3)…1996

ELECTRICAL DIAGRAM (3/3)…1997

20 TESTING AND ADJUSTING…1999

NORMAL OR STANDARD TECHNICAL DATA…2000

SPECIAL TOOLS…2011

CHECKING THE ENGINE SPEED…2012

ADJUSTMENT OF VALVE CLEARANCE…2013

MEASUREMENT OF THE COMPRESSOR PRESSURE…2014

CONTROL AND ADJUSTMENT OF THE TENSION OF THE FAN BELT…2015

CONTROL AND ADJUSTMENT OF THE INJECTION TIMING…2016

CONTROL AND ADJUSTMENT OF THE ACCELERATOR STROKE …2018

ADJUSTMENTOF THE STROKE OF THE BLADE COMMAND LEVER…2019

ADJUSTING THE FLEXIBLE CABLES…2020

CONTROL AND ADJUSTMENT OF THE STROKE OF THE TRAVEL LEVER…2021

ADJUSTMENT OF THE STROKE OF THE BOOM SWING COMMAND PEDAL…2022

ADJUSTMENT OF THE PPC VALVE CLEARANCES…2023

ADJUSTMENT OF THE RUBBER PAD AND SAFETY MICROSWITCH FOR SERVO-CONTROL ENGAGEMENT…2024

CONTROL AND ADJUSTMENTOF THE STROKE OF THE TRACK-SHOE TENSION…2025

CONTROL AND REGULATION OF THE PREEURES IN THE HYDRAULIC CIRCUTIS…2026

CONTROL AND REGULATION OF THE LS DIFFERENTIAL PRESSURE AND ADJUSTMENT OF THE LS VALVE…2029

REGULATION OF THE PC VALVE…2031

CONTROL AND REGULATION O THE SERVO-CONTROL POWER SUPPLY…2032

ELIMINATION OF RESIDUAL PRESSURES – PRESSURISATION OF THE TANK…2033

BLEEDING AIR FROM THE HYDRAULIC CIRCUITS…2034

CONTROL OF HYDRAULIC DRIFTS – ANALYSIS OF THE CAUSES OF A DRIFT…2036

CHECKING FOR ANY LEAKAGES INSIDE THE WORKING EQUIPMENT CYLINDERS…2042

CHECKING FOR ANY LEAKAGES INSIDE THE SWING MOTOR…2043

METHODS FOR TESTING FOR LEAKAGES INSIDE THE SWIVEL JOINT…2044

30 REMOVAL AND INSTALLATION…2047

HOW TO READ THE MANUAL…2049

PRECAUTIONS TO BE TAKEN WHILE WORKING…2050

SPECIAL TOOLS…2051

STARTER MOTOR…2053

REMOVAL…2053

INSTALLATION…2053

ALTERNATOR…2054

REMOVAL…2054

INSTALLATION…2054

INJECTION PUMP…2055

REMOVAL…2055

INSTALLATION…2056

NOZZLE HOLDER…2057

REMOVAL…2057

INSTALLATION…2057

WATER COOLANT PUMP…2058

REMOVAL…2058

INSTALLATION…2059

CYLINDER HEAD…2060

REMOVAL…2060

INSTALLATION…2061

OIL COOLER…2062

REMOVAL…2062

INSTALLATION…2062

RADIATOR…2063

REMOVAL…2063

INSTALLATION…2063

ENGINE HOOD…2064

REMOVAL…1907

INSTALLATION…1907

CANOPY…2065

REMOVAL…2065

INSTALLATION…2065

CAB…2066

REMOVAL…2066

INSTALLATION…2066

HEATING FAN…2067

REMOVAL…2067

INSTALLATION…2068

COUNTERWEIGHT…2069

REMOVAL…2069

INSTALLATION…2069

DIESEL FUEL TANK…2070

REMOVAL…2070

INSTALLATION…2070

HYDRAULIC OIL TANK…2071

REMOVAL…2071

INSTALLATION…2072

OIL-COOLER-RADIATOR GROUP…2073

REMOVAL…2073

INSTALLATION…2074

ENGINE-PUMP GROUP…2075

REMOVAL…2075

INSTALLATION…2077

PUMP…2078

REMOVAL…2078

INSTALLATION…2078

ENGINE-PUMP COUPLING…2079

REMOVAL…2079

INSTALLATION…2079

SIDE LOWER PANELS…2080

REMOVAL…2080

INSTALLATION…2080

INNER CONTROL VALVE BOX COVER…2081

REMOVAL…2081

INSTALLATION…2081

CONTROL VALVE…2082

REMOVAL…2082

INSTALLATION…2083

LEFT-HAND PPC VALVE (ARM-BUCKET)…2084

REMOVAL…2084

INSTALLATION…2084

RIGHT-HAND PPC VALVE (BOOM-BUCKET)…2085

REMOVAL…2085

INSTALLATION…2085

SERVOCONTROL SOLENOID GROUP…2086

REMOVAL…2086

INSTALLATION…2086

PLATFORM…2087

REMOVAL…2087

INSTALLATION…2089

SWIVEL JOINT…2090

REMOVAL…2090

INSTALLATION…2090

SWING MACHINERY…2091

REMOVAL…2090

INSTALLATION…2092

REVOLVING FRAME…2093

REMOVAL…2093

INSTALLATION…2094

SWING CIRCLE…2095

REMOVAL…2095

INSTALLATION…2095

RUBBER TRACK SHOES…2096

REMOVAL…2096

INSTALLATION…2096

STEEL TRACK-SHOES…2097

REMOVAL…2097

INSTALLATION…2097

SPROCKET WHEEL…2098

REMOVAL…2098

INSTALLATION…2098

FINAL DRIVE…2099

REMOVAL…2099

INSTALLATION…2099

IDLER AND RECOIL SPRING ASSEMBLY…2100

REMOVAL…2100

INSTALLATION…2100

SPRING RECOIL AND THRUST CYLINDER GROUPS…2101

DISASSEMBLY…2101

ASSEMBLY…2101

IDLER…2102

DISASSEMBLY…2102

ASSEMBLY…2102

TRACK ROLLERS…2103

REMOVAL…2103

INSTALLATION…2103

BOOM CYLINDER…2104

REMOVAL…2104

INSTALLATION…2105

ARM CYLINDER…2106

REMOVAL…2106

INSTALLATION…2106

BUCKET CYLINDER…2107

REMOVAL…2107

INSTALLATION…2107

BOOM SWING CYLINDER…2108

REMOVAL…2108

INSTALLATION…2109

BLADE CYLINDER…2110

REMOVAL…2110

INSTALLATION…2110

WORKING EQUIPMENT CYLINDERS…2111

DISASSEMBLY…2111

ASSEMBLY…2113

UPPER WORKING EQUIPMENT…2117

REMOVAL…2117

INSTALLATION…2118

ARM…2119

REMOVAL…2119

INSTALLATION…2120

ARM ASSEMBLY…2121

REMOVAL…2121

INSTALLATION…2121

BOOM…2122

REMOVAL…2122

INSTALLATION…2123

BOOM SWING SUPPORT…2124

REMOVAL…2124

INSTALLATION…2124

BLADE…2125

REMOVAL…2125

INSTALLATION…2125

40 MAINTENANCE STANDARD…2127

SWING CIRCLE…2128

SWING MACHINERY…2129

FINAL DRIVE…2130

SPROCKET…2131

TRACK FRAME AND RECOIL SPRING…2132

IDLER…2133

CARRIER ROLLER…2134

TRACK ROLLER…2135

TRACK SHOE…2136

HYDRAULIC PUMP…2138

CONTROL VALVE…2139

SWIVEL JOINT…2145

SWING MOTOR…2146

TRAVEL MOTOR…2147

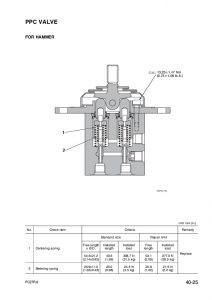

PPC VALVE (FOR BOOM, ARM, BUCKET, SWING)…2149

PPC VALVE (FOR HAMMER)…2150

CYLINDER…2151

WORK EQUIPMENT…2153

WEBM003800 – Hydraulic Excavator PC27R-8 Deluxe Shop Manual…2156

COVER…2156

CONTENTS…2158

SAFETY…2162

FOREWORD…2164

HOW TO READ THE SHOP MANUAL…2165

HOISTING INSTRUCTIONS…2166

STANDARD TIGHTENING TORQUE…2167

COATING MATERIALS…2169

ELECTRIC WIRE CODE…2170

WEIGHT TABLE…2171

TABLE OF OIL COOLANT QUANTITIES…2172

10. STRUCTURE AND FUNCTION…2176

POWER TRAIN…2177

SWING CIRCLE…2178

SWING MACHINERY…2179

FINAL DRIVE…2180

TRACK FRAME…2181

RECOIL SPRING…2182

CARRIER ROLLER…2183

TRACK ROLLER…2183

STEEL SHOE…2184