Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC50UU, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC50UU-1, PC50UU-2 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM020U0104 – Hydraulic Excavator PC50UU-1 Shop Manual.pdf

SEBM000906 – Hydraulic Excavator PC50UU-2 Shop Manual.pdf

SEAM020U0100 – Hydraulic Excavator PC50UU-1 Operation & Maintenance Manual.pdf

SEAM020U0101 – Hydraulic Excavator PC50UU-1 Operation & Maintenance Manual.pdf

SEAM005500 – Hydraulic Excavator PC50UU-2 Operation & Maintenance Manual.pdf

SEAM005503T – Hydraulic Excavator PC50UU-2 Operation & Maintenance Manual.pdf

SEAM034800 – Hydraulic Excavator PC28UU-2 Operation & Maintenance Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,895 pages

File Format: PDF

Language: English

SEAM005500 – Hydraulic Excavator PC50UU-2 Operation & Maintenance Manual…2

COVER…2

1. FOREWORD…3

2. SAFETY INFORMATION…4

3. INTRODUCTION…5

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…6

CONTENTS…7

SAFETY…12

6. General Precautions…13

7. Precautions During Operation…18

7.1 Before Starting Engine…18

7.2 Operating Machine…20

7.3 Transportation…25

7.4 Battery…26

7.5 Towing…27

8. Precautions for Maintenance…28

8.1 Before Carrying Out Maintenance…28

8.2 During Maintenance…31

9. Position for Attaching Safety Labels…35

OPERATION…40

10. General View…41

10.1 General View of Machine…41

10.2 General View of Controls and Gauges…42

11. Explanation of Components…43

11.1 Machine Monitor…44

11.2 Switches…50

11.3 Control Levers and Pedals…53

11.4 Engine Hood…57

11.5 Front Window…58

11.6 Sliding Door…60

11.7 Fuse Box…61

11.8 Fusible Link…61

11.9 Cap with Lock, Cover…62

11.10 Tool Box…63

11.11 Grease Gun Holder…63

12. Operation…64

12.1 Check Before Starting Engine…64

12.2 Starting Engine…72

12.3 Operations and Checks After Starting Engine…74

12.4 Moving Machine Off…77

12.5 Steering Machine…79

12.6 Stopping Machine…81

12.7 Swinging…82

12.8 Prohibitions for Operation…83

12.9 Precautions for Operation…85

12.10 Precautions when Traveling Up or Down Hills…86

12.11 Work Possible Using Hydraulic Excavator…88

12.12 Parking Machine…90

12.13 Check After Finishing Work…91

12.14 Stopping Engine…91

12.15 Check After Stopping Engine…92

12.16 Locking…92

12.17 How to Excape From Mud…93

12.18 Replacement of Bucket…94

12.19 Handling 4-System…96

12.20 Handling Rubber Shoes (Rubber Shoes Only)…106

13. Transportation…111

13.1 Loading, Unloading Work…111

13.2 Method for Lifting Chassis…113

13.3 Precautions for Loading…115

13.4 Precautions for Transportation…116

14. Cold Weather Operation…117

14.1 Precautions for Low Temperature…117

14.2 Cautions After Completion of Work…119

14.3 Preparing the Cab Heater…120

14.4 After Cold Weather…120

15. Long-term Storage…121

15.1 Before Storage…121

15.2 During Storage…122

15.3 After Storage…122

16. Troubleshooting…123

16.1 Phenomena That Are Not Failures…123

16.2 Method of Towing Machine…125

16.3 Precautions on Particular Jobsites…125

16.4 If Battery is Discharged…126

16.5 Other Trouble…130

MAINTENANCE…136

17. Guides to Maintenance…137

18. Outlines of Service…140

18.1 Outline of Oil, Fuel, Coolant…140

18.2 Relating to Electric System…143

19. Wear Parts List…144

20. Use of Fuel, Coolant and Lubricants According to Ambient Temperature…145

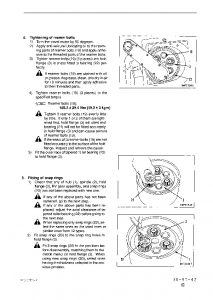

21. Standard Tightening Torbues for Bolts and Nuts…149

21.1 Introduction of Necessary Tools…149

21.2 Torque List…150

22. Periodic Replacement of Safety Critical Parts…151

23. Maintenance Schedule Chart…153

23.1 Maintenance Schedule Chart…153

24. Service Procedure…156

24.1 Initial 250 Hours Service (only after the first 250 hours)…156

Engine Valve Clearance, Check and Adjust…156

24.2 When Required…157

Check, Clean and Replace Air Cleaner Element…157

Clean Inside of Cooling System…160

Drain Water, Sediment from Fuel Tank…164

Check Level of Battery Electrolyte…165

Clean Water Separator Element…166

Check Electric Wirings…167

Check Rubber Shoes (machine equipped with rubber shoes)…168

Check and Adjust Track Tension (machine equipped with rubber shoes)…170

Replace Rubber Shoes (machine equipped with rubber shoes)…173

Check and Adjust Track Tension (machine equipped with steel shoes)…176

Replace Bucket Teeth…179

Adjust Bucket Clearance…180

24.3 Check Before Starting…181

Check and Refill Coolant…181

Check Oil Level in Engine Oil Pan, Add Oil…181

Check Fuel Level…182

Check Oil Level in Hydraulic Tank, Add Oil…183

Check Dust Indicator…184

Check Water Separator…184

24.4 Every 100 Hours Service…185

Lubricating…185

Swing Circle (1 point)…185

Swing Pinion (1 point)…185

Blade Cylinder Foot Pin ( 1 point)…185

Blade Cylinder Rod End ( 1 point)…185

Blade Foot Pin ( 2 points)…185

First Boom Foot Pin ( 2 points)…185

Boom Cylinder Foot Pin ( 1 point)…185

Boom Cylinder Rod End ( 1 point)…185

First Boom – Second Boom Coupling Pin ( 2 points)…185

Offset Cylinder Foot Pin ( 1 point)…186

Offset Cylinder Rod End Pin ( 1 point)…186

Sub-link Coupling Pin ( 2 points)…186

Second Boom – Third Bracket Coupling Pin ( 2 points )…186

Arm Cylinder Foot Pin ( 2 points )…186

Arm Cylinder Rod End Pin ( 1 point)…186

Third Bracket – Arm Coupling Pin ( 2 points )…186

Bucket Cylinder Foot Pin ( 1 point )…186

Bucket Cylinder Rod End Pin ( 1 point )…186

Arm-Link Coupling Pin ( 1 point )…186

Link Coupling Pin ( 1 point )…186

Bucket-Link Coupling Pin ( 1 point )…186

Arm-Bucket Coupling Pin ( 1 point )…186

24.5 Every 250 Hours Service…187

Change Oil in Engine Oil Pan, Replace Engine Oil Filter Cartridge…187

Check Oil Level in Final Drive Case, Add Oil…189

Replace Hydraulic Filter Element…190

Check Fan Belt Tension, Adjust…192

24.6 Every 500 Hours Serv ice…193

Replace Fuel Filter Cartridge…193

Clean, Check Radiator Fins…195

24.7 Every 1000 Hours Service…196

Change Oil in Swing Machinery Case…196

Change Oil in Final Drive Case…197

24.8 Every 2000 Hours Service…198

Change Oil in Hydraulic Tank, Clean Strainer…198

Check Alternator, Starting Motor…200

Check Engine Valve Clearance, Adjust…200

SPECIFICATIONS…202

25. Specifications…203

OPTION, ATTACHMENT…206

26. Using Car Radio…207

26.1 Explanation of Parts…207

26.2 Method of Use…209

26.3 Precautions for Use…210

26.4 Specifications…211

27. Using Car Cooler…212

27.1 Control Panel…212

27.2 Precautions When Using…212

27.3 Inspection and Maintenance of Car Cooler…213

28. Handling Window Washer…215

28.1 Operation of Window Washer…215

28.2 Check Window Washer Fluid, Add Fluid…215

29. General Precautions…216

29.1 Precautions Related to Safety…216

30. Introduction of Attachments…217

30.1 Specification, Use…217

30.2 Precautions When installing Attachments…218

30.3 Replacing Bucket Teeth ( bucket with vertical pin type tooth )…219

30.4 Precautions When Using Hydraulic Breaker…222

31. Machines Able to Install Attachments…225

31.1 Explanation of Equipment…225

31.2 Hydraulic Circuit…227

31.3 Operation…228

31.4 Long-term Storage…229

31.5 Specifications…229

SEAM005503T – Hydraulic Excavator PC50UU-2 Operation & Maintenance Manual…230

COVER…230

1. FOREWORD…231

2. SAFETY INFORMATION…234

3. INTRODUCTION…235

4. LOCATION OF PLATES,TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…236

5. CONTENTS…237

SAFETY…241

6. GENERAL PRECAUTIONS…242

7. PRECAUTIONS DURING OPERATION…247

7.1 BEFORE STARTING ENGINE…247

7.2 OPERATING MACHINE…249

7.3 TRANSPORTATION…254

7.4 BATTERY…255

7.5 TOWING…256

8. PRECAUTIONS FOR MAINTENANCE…257

8.1 BEFORE CARRYING OUT MAINTENANCE…257

8.2 DURING MAINTENANCE…260

9. POSITION FOR ATTACHING SAFETY LABELS…264

OPERATION…268

10. GENERAL VIEW…269

10.1 GENERAL VIEW OF MACHINE…269

10.2 GENERAL VIEW OF CONTROLS AND GAUGES…270

11. EXPLANATION OF COMPONENTS…271

11.1 MACHINE MONITOR…272

11.2 SWITCHES…278

11.3 CONTROL LEVERS AND PEDALS…281

11.4 ENGINE HOOD…285

11.5 FRONT WINDOW…286

11.6 SLIDING DOOR…288

11.7 FUSE BOX…289

11.8 FUSIBLE LINK…289

11.9 CAP WITH LOCK,COVER…290

11.10 TOOL BOX…291

11.11 GREASE GUN HOLDER…291

12. OPERATION…292

12.1 CHECK BEFORE STARTING ENGINE…292

12.2 STARTING ENGINE…300

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE…302

12.4 MOVING MACHINE OFF…305

12.5 STEERING MACHINE…307

12.6 STOPPING MACHINE…309

12.7 SWINGING…310

12.8 PROHIBITIONS FOR OPERATION…311

12.9 PRECAUTIONS FOR OPERATION…313

12.10 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS…314

12.11 WORK POSSIBLE USING HYDRAULIC EXCAVATOR…316

12.12 PARKING MACHINE…318

12.13 CHECK AFTER FINISHING WORK…319

12.14 STOPPING ENGINE…319

12.15 CHECK AFTER STOPPING ENGINE…320

12.16 LOCKING…320

12.17 HOW TO ESCAPE FROM MUD…321

12.18 REPLACEMENT OF BUCKET…322

12.19 HANDLING 4-SYSTEM…324

12.20 HANDLING RUBBER SHOES (RUBBER SHOES ONLY)…334

13. TRANSPORTATION…339

13.1 LOADING, UNLOADING WORK…339

13.2 METHOD OF LIFTING CHASSIS…341

13.3 PRECAUTIONS FOR LOADING…343

13.4 PRECAUTIONS FOR TRANSPORTATION…344

14. COLD WEATHER OPERATION…345

14.1 PRECAUTIONS FOR LOW TEMPERATURE…345

14.2 COUTIONS AFTER COMPLETION OF WORK…347

14.3 PREPARING THE CAB HEATER…348

14.4 AFTER COLD WEATHER…348

15. LONG-TERM STORAGE…349

15.1 BEFORE STORAGE…349

15.2 DURING STORAGE…350

15.3 AFTER STORAGE…350

16. TROUBLESHOOTING…351

16.1 PHENOMENA THAT ARE NOT FAILURES…351

16.2 METHOD OF TOWING MACHINE…353

16.3 PRECAUTIONS ON PARTICULAR JOBSITES…353

16.4 IF BATTERY IS DISCHARGED…354

16.5 OTHER TROUBLE…358

MAINTENANCE…363

17. GUIDES TO MAINTENANCE…364

18. OUTLINES OF SERVICE…367

18.1 OUTLINE OF OIL,FUEL,COOLANT…367

18.2 RELATING TO ELECTRIC SYSTEM…370

19. WEAR PARTS LIST…371

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…372

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…376

21.1 INTRODUCTION OF NECESSARY TOOLS…376

21.2 TORQUE LIST…377

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…378

23. MAINTENANCE SCHEDULE CHART…380

24. SERVICE PROCEDURE…383

24.1 INITIAL 250 HOURS SERVICE…383

24.2 WHEN REQUIRED…384

24.3 CHECK BEFORE STARTING…408

24.4 EVERY 100 HOURS SERVICE…412

24.5 EVERY 250 HOURS SERVICE…413

24.6 EVERY 500 HOURS SERVICE…419

24.7 EVERY 1000 HOURS SERVICE…424

24.8 EVERY 2000 HOURS SERVICE…425

24.9 EVERY 4000 HOURS SERVICE…426

SPECIFICATIONS…429

25. SPECIFICATIONS…430

OPTIONS,ATTACHMENTS…433

26. USING CAR RADIO…434

26.1 EXPLANATION OF PARTS…434

26.2 METHOD OF USE…436

26.3 PRECAUTIONS FOR USE…437

26.4 SPECIFICATIONS…438

27. USING CAR COOLER…439

27.1 CONTROL PANEL…439

27.2 PRECAUTIONS WHEN USING…439

27.3 INSPECTION AND MAINTENANCE OF CAR COOLER…440

28. HANDLING WINDOW WASHER…442

28.1 OPERATION OF WINDOW WASHER…442

28.2 CHECK WINDOW WASHER FLUID,ADD FLUID…442

29. GENERAL PRECAUTIONS…443

29.1 PRECAUTIONS RELATED TO SAFETY…443

30. INTRODUCTION OF ATTACHMENTS…444

30.1 SPECIFICATION,USE…444

30.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS…445

30.3 REPLACING BUCKET TEETH (BUCKET WITH VERTICAL PIN TYPE TOOTH)…446

30.4 PRECAUTIONS WHEN USING HYDRAULIC BREAKER…449

31. MACHINES ABLE TO INSTALL ATTACHMENTS…452

31.1 EXPLANATION OF EQUIPMENT…452

31.2 HYDRAULIC CIRCUIT…454

31.3 OPERATION…455

31.4 LONG-TERM STORAGE…456

31.5 SPECIFICATIONS…456

SEAM020U0100 – Hydraulic Excavator PC50UU-1 Operation & Maintenance Manual…458

COVER…458

FOREWORD…459

BREAKING IN YOUR NEW MACHINE…460

CONTENTS…461

GENERAL LOCATIONS AND SPECIFICATIONS…462

INSTRUMENTS AND CONTROLS…463

CHECK BEFORE STARTING…475

OPERATING YOUR MACHINE…479

REPLACEMENT OF BUCKET…493

COLD WEATHER OPERATION…494

PERIODIC MAINTENANCE…498

MAINTENANCE TABLE…499

OIL FILLER AND LEVEL GAUGE POSITIONS…502

EVERY 50 HOURS SERVICE…503

EVERY 100 HOURS SERVICE…504

INITIAL 250 HOURS SERVICE…507

EVERY 250 HOURS SERVICE…507

EVERY 500 HOURS SERVICE…512

EVERY 1000 HOURS SERVICE…515

EVERY 2000 HOURS SERVICE…517

WHEN REQUIRED…519

TROUBLE SHOOTING GUIDE…525

SERVICE METER…528

MACHINE AND ENGINE SERIAL NUMBERS…529

FUEL,COOLANT AND LUBRICANTS…530

SAFETY AND OPERATION…532

CONTENTS…533

SAFETY HINTS…534

EXCAVATOR'S WORK…543

HANDLING OF BATTERY…544

TRANSPORTATION…547

PRECAUTIONS FOR MAINTENANCE…549

STORAGE…554

COOLANT AND LUBRICANTS…556

SEAM020U0101 – Hydraulic Excavator PC50UU-1 Operation & Maintenance Manual…558

COVER…558

FOREWORD…559

BREAKING IN YOUR NEW MACHINE…560

CONTENTS…561

GENERAL LOCATIONS AND SPECIFICATIONS…562

INSTRUMENTS AND CONTROLS…563

CHECK BEFORE STARTING…576

OPERATING YOUR MACHINE…581

REPLACEMENT OF BUCKET…596

COLD WEATHER OPERATION…597

PERIODIC MAINTENANCE…601

PERIODICAL REPLACEMENT OF SAFETY PARTS…602

MAINTENANCE TABLE…604

OIL FILLER AND LEVEL GAUGE POSITIONS…607

EVERY 50 HOURS SERVICE…608

EVERY 100 HOURS SERVICE…609

INITIAL 250 HOURS SERVICE…612

EVERY 250 HOURS SERVICE…612

EVERY 500 HOURS SERVICE…617

EVERY 1000 HOURS SERVICE…620

EVERY 2000 HOURS SERVICE…622

WHEN REQUIRED…624

HANDLING RUBBER SHOES…630

TROUBLE SHOOTING GUIDE…635

SERVICE METER…638

MACHINE AND ENGINE SERIAL NUMBERS…639

FUEL,COOLANT AND LUBRICANTS…640

SAFETY AND OPERATION…642

CONTENTS…643

SAFETY HINTS…644

EXCAVATOR'S WORK…653

HANDLING OF BATTERY…654

TRANSPORTATION…657

METHOD OF RAISING THE MACHINE…659

PRECAUTIONS FOR MAINTENANCE…660

STORAGE…665

COOLANT AND LUBRICANTS…667

SEAM034800 – Hydraulic Excavator PC28UU-2 Operation & Maintenance Manual…669

COVER…669

1. FOREWORD…670

2. SAFETY INFORMATION…671

3. INTRODUCTION…672

4. LOCATION OF PLATES,TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…673

5. CONTENTS…674

SAFETY…678

6. GENERAL PRECAUTIONS…679

7. PRECAUTION DURING OPERATION…684

7.1 BEFORE STARTING ENGINE…684

7.2 OPERATING MACHINE…686

7.3 TRANSPORTATION…691

7.4 BATTERY…692

7.5 TOWING…693

8. PRECAUTIONS FOR MAINTENANCE…694

8.1 BEFORE CARRYING OUT MAINTENANCE…694

8.2 DURING MAINTENANCE…697

9. POSITION FOR ATTACHING SAFETY LABELS…701

9.1 POSITION FOR ATTACHING SAFETY LABELS…701

OPERATION…704

10. GENERAL VIEW…705

10.1 GENERAL VIEW OF MACHINE…705

10.2 GENERAL VIEW OF CONTROLS AND GAUGES…706

11. EXPLANATION OF COMPONENTS…707

11.1 MACHINE MONITOR…708

11.2 SWITCHES…714

11.3 CONTROL LEVERS AND PEDALS…716

11.4 ENGINE HOOD…720

11.5 FUSE BOX…721

11.6 FUSIBLE LINK…721

11.7 COVER WITH LOCK…722

11.8 TOOL BOX…723

11.9 GREASE GUN HOLDER…723

12. OPERATION…724

12.1 CHECK BEFORE STARTING ENGINE…724

12.2 STARTING ENGINE…731

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE…733

12.4 MOVING MACHINE OFF…736

12.5 STEERING MACHINE…738

12.6 STOPPING MACHINE…740

12.7 SWINGING…741

12.8 PROHIBITIONS FOR OPERATION…742

12.9 PRECAUTIONS FOR OPERATION…744

12.10 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS…745

12.11 WORK POSSIBLE USING HYDRAULIC EXCAVATOR…747

12.12 PARKING MACHINE…749

12.13 CHECK AFTER FINISHING WORK…750

12.14 STOPPING ENGINE…750

12.15 CHECK AFTER STOPPING ENGINE…751

12.16 LOCKING…751

12.17 HOW TO ESCAPE FROM MUD…752

12.18 REPLACEMENT OF BUCKET…753

12.19 HANDLING 4-SYSTEM…755

12.20 HANDLING RUBBER SHOES (RUBBER SHOES ONLY)…765

13. TRANSPORTATION…770

13.1 LOADING,UNLOADING WORK…770

13.2 METHOD FOR LIFTING CHASSIS…772

13.3 PRECAUTIONS FOR LOADING…774

13.4 PRECAUTIONS FOR TRANSPORTATION…775

14. COLD WEATHER OPERATION…776

14.1 PRECAUTIONS FOR LOW TEMPERATURE…776

14.2 CAUTIONS AFTER COMPLETION OF WORK…778

14.3 PREPARING THE CAB HEATER (IF EQUIPPED)…779

14.4 AFTER COLD WEATHER…779

15. LONG-TERM STORAGE…780

15.1 BEFORE STORAGE…780

15.2 DURING STORAGE…781

15.3 AFTER STORAGE…781

16. TROUBLESHOOTING…782

16.1 PHENOMENA THAT ARE NOT FAILURES…782

16.2 METHOD OF TOWING MACHINE…784

16.3 PRECAUTIONS ON PARTICULAR JOBSITES…784

16.4 IF BATTERY IS DISCHARGED…785

16.5 OTHER TROUBLE…789

MAINTENANCE…794

17. GUIDES TO MAINTENANCE…795

18. OUTLINES OF SERVICE…798

18.1 OUTLINE OF OIL,FUEL,COOLANT…798

18.2 RELATING TO ELECTRIC SYSTEM…801

19. WEAR PARTS LIST…802

20. USE OF FUEL,COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…803

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…807

21.1 INTRODUCTION OF NECESSARY TOOLS…807

21.2 TORQUE LIST…808

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…809

23. MAINTENANCE SCHEDULE CHART…811

23.1 MAINTENANCE SCHEDULE CHART…811

24. SERVICE PROCEDURE…814

24.1 INITIAL 250 HOURS SERVICE…814

24.2 WHEN REQUIRED…815

24.3 CHECK BEFORE STARTING…838

24.4 EVERY 100 HOURS SERVICE…842

24.5 EVERY 250 HOURS SERVICE…844

24.6 EVERY 500 HOURS SERVICE…849

24.7 EVERY 1000 HOURS SERVICE…852

24.8 EVERY 2000 HOURS SERVICE…854

SPECIFICATIONS…857

25. SPECIFICATIONS…858

OPTIONS,ATTACHMENTS…861

26. GENERAL PRECAUTIONS…862

26.1 PRECAUTIONS RELATED TO SAFETY…862

27. HANDLING BUCKET WITH HOOK…863

27.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK…863

27.2 PROHIBITED OPERATIONS…863

27.3 PRECAUTIONS DURING OPERATIONS…863

28. INTRODUCTION OF ATTACHMENTS…864

28.1 SPECIFICATION,USE…864

28.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS…865

28.3 HANDLING POWER TILT,MECHANICAL ANGLE BLADE…866

SEBM020U0104 – Hydraulic Excavator PC50UU-1 Shop Manual…1710

COVER…1710

CONTENTS…1711

10 STRUCTURE AND FUNCTION…1724

POWER TRAIN…1725

SWING MACHINERY…1726

SWING CIRCLE…1727

TRACK FRAME AND RECOIL SPRING…1728

IDLER…1730

TRACK ROLLER…1731

TRACK SHOE…1732

HYDRAULIC PIPING…1733

HYDRAULIC CIRCUIT SCHEMATICS…1734

HYDRAULIC CIRCUIT DIAGRAM…1736

HYDRAULIC TANK AND FUEL TANK…1738

HYDRAULIC PUMP…1739

6-SPOOL CONTROL VALVE…1740

3-SPOOL CONTROL VALVE…1744

SUCTION VALVE…1747

SWING MOTOR…1749

CENTER SWIVEL JOINT…1750

TRAVEL MOTOR WITH REDUCTION GEAR…1751

1. TRAVEL MOTOR AND FINAL DRIVE…1752

2. BRAKE VALVE…1755

HYDRAULIC CYLINDER…1757

WORK EQUIPMENT CONTROL…1760

WORK EQUIPMENT…1761

ELECTRICAL CIRCUIT…1762

20 TESTING AND ADJUSTING…1764

TABLE OF JUDGEMENT STANDARD VALUE…1765

TESTING AND ADJUSTING TOOL LIST…1780

ADJUSTING VALVE CLEARANCE…1781

MEASURING COMPRESSION PRESSURE…1782

ADJUSTING FUEL INJECTION TIMING…1783

TESTING AND ADJUSTING HYDRAULIC PRESSURE…1784

MEASURING OIL LEAKAGE FROM SWING AND TRAVEL MOTOR…1786

MEASURING OIL LEAKAGE FROM CYLINDER…1787

CHECKING FOR OIL LEAKAGE FROM SWIVEL JOINT…1788

TROUBLESHOOTING…1789

PREPARATION OF TROUBLESHOOTING…1790

HOW TO USE DIAGNOSTIC TABLE…1792

PREVENTING RECURRENCE OF THE SAME TROUBLE…1794

DIAGNOSTIC TABLE…1795

1.BUCKET CURL(DUMP)LACKS POWER OR SPEED…1795

2.ARM(BOOM)LACKS POWER OR SPEED…1796

3.IMPOSSIBLE TO CURL OR DUMP BUCKET…1797

4.IMPOSSIBLE TO MOVE WORK EQUPIMENT(BOOM,ARM)…1798

5.HYDRAULIC DRIFT OF WORK EQUIPMENT IS EXCESSIVE(BOOM,ARM,BUCKET,BLADE)…1799

6.BLADE,BOOM,OFFSET SPEED TOO LOW…1800

7.BLADE,BOOM,OFFSET DO NOT MOVE…1801

8.LEFT(OR RIGHT)SWING LACKS POWER OR SPEED…1802

9.IMPOSSIBLE TO SWING TO LEFT(OR RIGHT)…1803

10.HYDRAULIC DRIFT OF SWING ON SLOPES IS EXCESSIVE…1804

11.SWING BRAKE ANGLE IS EXCESSIVE…1805

12.MACHINE DEVIATES TO ONE SIDE WHEN TRAVELING…1806

13.IMPOSSIBLE TO TRAVEL FORWARD(OR REVERSE)…1807

30 DISASSEMBLY AND ASSEMBLY…1808

METHOD OF READING MANUAL…1810

SPECIAL TOOL LIST…1812

WEIGHT TABLE…1814

TIGHTENING TORQUE TABLE…1815

LIST OF LUBRICANT AND WATER…1817

STARTING MOTOR…1818

REMOVAL…1818

INSTALLATION…1818

ALTERNATOR…1818

REMOVAL…1818

INSTALLATION…1818

NOZZLE HOLDER…1820

REMOVAL…1820

INSTALLATION…1820

RADIATOR…1820

REMOVAL…1820

INSTALLATION…1820

FUEL INJECTION PUMP…1822

REMOVAL…1822

INSTALLATION…1822

CYLINDER HEAD…1824

REMOVAL…1824

INSTALLAION…1824

FAN PULLEY…1826

REMOVAL…1826

INSTALLATION…1826

WATER PUMP…1826

REMOVAL…1826

INSTALLATION…1826

THERMOSTAT…1826

REMOVAL…1826

INSTALLATION…1826

ENGINE…1828

REMOVAL…1828

INSTALLATION…1828

SWING CIRCLE…1830

REMOVAL…1830

INSTALLATION…1830

SWING MACHINERY…1830

REMOVAL…1830

INSTALLATION…1830

DISASSEMBLY…1832

ASSEMBLY…1834

CENTER SWIVEL JOINT…1836

REMOVAL…1836

INSTALLATION…1836

DISASSEMBLY…1836

ASSEMBLY…1836

SWING MOTOR…1838

REMOVAL…1838

INSTALLATION…1838

TRAVEL MOTOR…1838

REMOVAL…1838

INSTALLATION…1838

REVOLVING FRAME…1840

REMOVAL…1840

INSTALLATION…1840

IDLER…1842

REMOVAL…1842

INSTALLATION…1842

RECOIL SPRING…1842

REMOVAL…1842

INSTALLAION…1842

DISASSEMBLY…1842

ASSEMBLY…1842

TRACK ROLLER…1844

REMOVAL…1844

INSTALLATION…1844

TRACK SHOE…1846

REMOVAL…1846

INSTALLAION…1846

HYDRAULIC PUMP…1848

REMOVAL…1848

INSTALLATION…1848

6-SPOOL CONTROL VALVE…1850

REMOVAL…1850

INSTALLATION…1850

3-SPOOL CONTROL VALVE…1850

REMOVAL…1850

INSTALLATION…1850

6-SPOOL CONTROL VALVE…1852

DISASSEMBLY…1852

ASSEMBLY…1852

3-SPOOL CONTROL VALVE…1854

DISASSEMBLY…1854

ASSEMBLY…1854

MAIN RELIEF VALVE…1856

REMOVAL…1856

INSTALLATION…1856

DISASSEMBLY…1856

ASSEMBLY…1856

BOOM CYLINDER…1858

REMOVAL…1858

INSTALLATION…1858

ARM CYLINDER…1858

REMOVAL…1858

INSTALLATION…1858

BUCKET CYLINDER …1860

REMOVAL…1860

INSTALLATION…1860

BLADE CYLINDER…1860

REMOVAL…1860

INSTALLATION…1860

OFFSET CYLINDER…1862

REMOVAL…1862

INSTALLATION…1862

HYDRAULIC CYLINDER…1864

DISASSEMBLY…1864

ASSEMBLY…1866

WORK EQUIPMENT…1868

REMOVAL…1868

INSTALLATION…1868

BLADE…1868

REMOVAL…1868

INSTALLATION…1868

ARM AND BUCKET…1870

REMOVAL…1870

INSTALLATION…1870

BUCKET …1870

REMOVAL…1870

INSTALLATION…1870

ARM…1872

REMOVAL…1872

INSTALLATION…1872

BOOM …1874

REMOVAL…1874

INSTALLATION…1874

SECOND BOOM…1876

REMOVAL…1876

INSTALLATION…1876

THIRD BOOM…1876

REMOVAL…1876

INSTALLATION…1876

SECONG AND THIRD BOOM(WITH ARM CYLINDER ASSEMBLY)…1878

REMOVAL…1878

INSTALLATION…1878

FLOOR FRAME…1878

REMOVAL…1878

INSTALLATION…1878

40 MAINTENANCE STANDARD…1880

SWING MACHINERY…1881

SWING CIRCLE…1882

TRACK FRAME…1883

IDLER…1885

TRACK ROLLER…1887

TRACK SHOE…1889

SPROCKET…1890

HYDRAULIC PUMP…1891

6-SPOOL CONTROL VALVE…1892

3-SPOOL CONTROL VALVE…1894

CENTER SWIVEL JOINT…1895

HYDRAULIC CYLINDER…1896

WORK EQUIPMENT…1897

Komatsu Hydraulic Excavator PC50UU Repair Service Manuals