Complete Operation & Maintenance Manuals for Komatsu Mobile Crusher GALEO BR380JG, with all the service information to maintain & operate your crusher.

SEAM059001T – Mobile Crusher GALEO BR380JG-1 Operation & Maintenance Manual (SN1001&up).pdf

TEN00006-03 – Mobile Crusher GALEO BR380JG-1 Operation & Maintenance Manual (SN1201&up).pdf

TEN00168-03 – Mobile Crusher GALEO BR380JG-1E0 Operation & Maintenance Manual (SN2001&up).pdf

TEN00358-01 – Mobile Crusher GALEO BR380JG-1E0 Operation & Maintenance Manual (SN2609&up).pdf

TEN00476-01 – Mobile Crusher GALEO BR380JG-1E0 Operation & Maintenance Manual (SN2621&up).pdf

Total Pages: 1,857 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

FOREWORD

BEFORE READING THIS MANUAL

SAFETY INFORMATION

INTRODUCTION

INTRODUCTION

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

NECESSARY INFORMATION

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

EPA REGULATIONS, ENGINE NUMBER PLATE

POSITION OF SERVICE METER

TABLE OF ENTER SERIAL NO. AND DISTRIBUTOR

SAFETY

SAFETY

SAFETY LABELS

POSITIONS OF SAFETY PICTOGRAMS

SAFETY LABELS

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

PRECAUTIONS BEFORE STARTING OPERATION

PREPARATIONS FOR SAFE OPERATION

FIRE PREVENTION

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

DO NOT GET CAUGHT IN WORK EQUIPMENT

UNAUTHORIZED MODIFICATION

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

PRECAUTIONS FOR OPERATION

PRECAUTIONS FOR JOBSITE

STARTING ENGINE

OPERATION

CRUSHING OPERATION

TRANSPORTATION

TOWING

MAGNETIC SEPARATOR

PRECAUTIONS FOR MAINTENANCE

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

PRECAUTIONS FOR INSPECTION AND MAINTENANCE

OPERATION

GENERAL VIEW

GENERAL VIEW OF MACHINE

GENERAL VIEW OF CONTROLS AND GAUGES

EXPLANATION OF COMPONENTS

MACHINE MONITOR

SWITCHES

CONTROL LEVERS

OPTION-RELATED SWITCHES

CAP, COVER WITH LOCK

REVOLVING WARNING LAMP

ELECTRIC POWER TAKEOFF

FUSIBLE LINK

CONTROLLERS

FUSE

TOOL BOX

OPERATION

CHECK BEFORE STARTING ENGINE

STARTING ENGINE

OPERATIONS AND CHECKS AFTER STARTING ENGINE

STOPPING ENGINE

CHECK AFTER STOPPING ENGINE

MACHINE OPERATION

STEERING MACHINE

OPERATION OF WORK EQUIPMENT

CHECK AND CONFIRMATION OF JAW CRUSHER AFTER WORK

CHECK AFTER FINISHING WORK

LOCKING

RUN-IN OPERATION OF JAW CRUSHER

PRECAUTIONS WHEN OPERATING JAW CRUSHER

EFFICIENT USE OF JAW CRUSHER

SCOPE OF WORKS USING MOBILE CRUSHER

PROHIBITIONS FOR OPERATION

PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS

TRANSPORTATION

TRANSPORTATION PROCEDURE

LOADING, UNLOADING WORK

LIFTING MACHINE

COLD WEATHER OPERATION

PRECAUTIONS FOR LOW TEMPERATURE

AFTER COMPLETION OF WORK

AFTER COLD WEATHER

LONG-TERM STORAGE

BEFORE STORAGE

DURING STORAGE

AFTER STORAGE

STARTING MACHINE AFTER LONG-TERM STORAGE

TROUBLESHOOTING

AFTER RUNNING OUT OF FUEL

PHENOMENA THAT ARE NOT FAILURES

METHOD OF TOWING MACHINE

IF BATTERY IS DISCHARGED

OTHER TROUBLE

MAINTENANCE

GUIDE TO MAINTENANCE

OUTLINE OF SERVICE

HANDLING AND PERFORMANCE OF OIL CLINIC FOR OIL, FUEL, COOLANT

RELATING TO ELECTRIC SYSTEM

OUTLINE OF HYDRAULIC EQUIPMENT

AIR-BLEEDING FROM HYDRAULIC CIRCUIT

WEAR PARTS

WEAR PARTS LIST

JAW CRUSHER RELATED PARTS

PRIMARY CONVEYOR RELATED PARTS

RECOMMENDED FUEL, COOLANT AND LUBRICANTS

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN

KOMATSU GENUINE OIL

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

TORQUE LIST

TOOLS TO USE CHECK AND MAINTENANCE CRUSHER

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

SAFETY CRITICAL PARTS

MAINTENANCE SCHEDULE CHART

MAINTENANCE SCHEDULE CHART

SERVICE PROCEDURE

INITIAL 250 HOURS SERVICE (FIRST MAINTENANCE FOR NEW MACHINE ONLY)

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)

WHEN REQUIRED

CHECK BEFORE STARTING

EVERY 10 HOURS SERVICE

EVERY 100 HOURS SERVICE

EVERY 250 HOURS SERVICE

EVERY 500 HOURS SERVICE

EVERY 1000 HOURS SERVICE

EVERY 2000 HOURS SERVICE

EVERY 4000 HOURS SERVICE

EVERY 5000 HOURS SERVICE

EVERY 8000 HOURS SERVICE

SPECIFICATIONS

SPECIFICATIONS

ATTACHMENTS, OPTIONS

GENERAL PRECAUTIONS

PRECAUTIONS RELATED TO SAFETY

ATTACHMENTS, OPTIONS

ATTACHMENTS, OPTIONS CHART

METHOD FOR CONNECTING HYDRAULIC HOSES FOR OPTIONS

RADIO CONTROL UNIT

ON USE OF RADIO CONTROL UNIT

DIRECTIONS FOR USE

RADIO CONTROL OPERATION

MUCK DISCHARGE CONVEYOR

PROCEDURE FOR RAISING (BENDING) MUCK DISCHARGE CONVEYOR

PROCEDURE FOR LOWERING (EXTEND) MUCK DISCHARGE CONVEYOR

GREASING MUCK DISCHARGE CONVEYOR

CHECK AND ADJUSTMENT OF MUCK DISCHARGE CONVEYOR

FAILURES AND CORRECTIVE ACTIONS

WEARING PARTS

SPECIFICATIONS

M-TYPE CHUTE

METHOD OF OPERATION

GRIZZLY BAR OPENING

HANDLING MACHINES EQUIPPED WITH KOMTRAX

BASIC PRECAUTIONS

MACHINES THAT CAN INSTALL ATTACHMENTS

NAMES OF CONTROL PANEL SWITCHES

HYDRAULIC POWER TAKEOFF PORT

ATTACHMENT PORT

PROCEDURE FOR CONNECTING OPTIONS

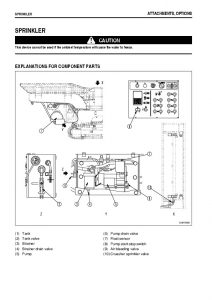

SPRINKLER

EXPLANATIONS FOR COMPONENT PARTS

HOW TO USE SPRINKLER

INSPECTION AND MAINTENANCE

ADDITIONAL SPRINKLER NOZZLE

INDEX

SEAM059001T – Mobile Crusher GALEO BR380JG-1 Operation & Maintenance Manual (SN1001&up)…2

COVER…2

FOREWORD…3

FOREWORD…4

SAFETY INFORMATION…7

INTRODUCTION…9

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE…9

NECESSARY INFORMATION…10

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…10

ENGINE SERIAL NO. PLATE AND POSITION…10

POSITION OF SERVICE METER…11

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…11

CONTENTS…12

SAFETY…16

SAFETY…17

SAFETY LABELS…20

POSITIONS OF SAFETY PICTOGRAMS…21

SAFETY LABELS…22

GENERAL PRECAUTIONS…31

SAFETY RULES…31

IF ABNORMALITIES ARE FOUND…31

CLOTHING AND PERSONAL PROTECTIVE ITEMS…31

FIRE EXTINGUISHER AND FIRST AID KIT…31

SAFETY FEATURES…31

KEEP MACHINE CLEAN…32

ON OPERATOR'S PLATFORM…32

ALWAYS APPLY LOCK WHEN LEAVING UPPER OPERATION DECK…32

HANDRAILS AND STEPS…33

MOUNTING AND DISMOUNTING…33

NO PEOPLE ON ATTACHMENTS…33

CRUSHING OR CUTTING PREVENTION…33

PREVENTION OF BURNS…34

FIRE PREVENTION…34

ACTION IF FIRE OCCURS…35

PRECAUTIONS FOR ATTACHMENTS…35

UNAUTHORIZED MODIFICATION…35

SAFETY AT WORKSITE…35

WORKING ON LOOSE GROUND…36

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES…36

ENSURE GOOD VISIBILITY…36

VENTILATION FOR ENCLOSED AREAS…37

CHECKING SIGNALMAN'S SIGNALS AND SIGNS…37

BE CAREFUL ABOUT ASBESTOS DUST…37

PRECAUTIONS FOR OPERATION…38

STARTING ENGINE…38

CHECKS BEFORE STARTING ENGINE…38

PRECAUTIONS WHEN STARTING…38

PRECAUTIONS IN COLD AREAS…39

OPERATION…40

CHECKS BEFORE OPERATION…40

PRECAUTIONS WHEN CHANGING DIRECTION…40

PRECAUTIONS WHEN TRAVELING…40

TRAVELING ON SLOPES…41

OPERATIONS ON SLOPES…41

PRECAUTIONS WHILE IN OPERATION…41

OPERATE CAREFULLY ON SNOW…41

PARKING MACHINE…42

CRUSHING OPERATION…43

CHECKS AROUND MACHINE…43

TURN MODE SELECTOR SWITCH TO WORK POSITION…43

ENSURE SAFETY WHILE OPERATING IN TANDEM WITH HYDRAULIC EXCAVATOR…44

CHECKS OF CRUSHER BEFORE STARTING OPERATION…44

PRECAUTIONS FOR CRUSHING WORK…44

EMERGENCY STOP TO WARD OFF DANGERS WHILE IN CRUSHING WORK…45

REMOVE FOREIGN MATERIAL FROM INSIDE CRUSHER…45

MAGNETIC SEPARATOR…46

HYDRAULIC MAGNETIC SEPARATOR (HANGING TYPE)…46

TRANSPORTATION…47

LOADING AND UNLOADING…47

SHIPPING…47

BATTERY…48

BATTERY HAZARD PREVENTION…48

STARTING WITH BOOSTER CABLE…49

TOWING…50

WHEN TOWING…50

PRECAUTIONS FOR MAINTENANCE…51

WARNING TAG…51

KEEP WORK PLACE CLEAN AND TIDY…51

APPOINT LEADER WHEN WORKING WITH OTHERS…51

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE…51

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING…52

PRECAUTIONS FOR CONVEYOR MAINTENANCE…52

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE OF FEEDER, CRUSHER…53

PROPER TOOLS…53

PERSONNEL…53

PRECAUTIONS WHEN MOUNTING, DISMANTLING AND STORING ATTACHMENTS…53

PRECAUTIONS FOR WORK UNDER MACHINE…53

NOISE…54

PRECAUTIONS WHEN USING HAMMER…54

REPAIR WELDING…54

REMOVING BATTERY TERMINAL…54

PRECAUTIONS WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION…54

DO NOT DISASSEMBLE RECOIL SPRING…55

PRECAUTIONS WITH HIGH-PRESSURE OIL…55

HANDLING HIGH-PRESSURE HOSES…55

WASTE MATERIAL…55

COMPRESSED AIR…56

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…56

OPERATION…57

GENERAL VIEW…58

GENERAL VIEW OF MACHINE…58

GENERAL VIEW OF CONTROLS AND GAUGES…59

EXPLANATION OF COMPONENTS…63

MACHINE MONITOR…63

SWITCHES…87

CONTROL LEVERS…96

OPTION-RELATED SWITCHES…97

CAP, COVER WITH LOCK…99

REVOLVING WARNING LAMP…101

ELECTRIC POWER TAKEOFF…102

FUSIBLE LINK…104

CONTROLLERS…104

FUSE…104

TOOL BOX…105

OPERATION…106

CHECK BEFORE STARTING ENGINE…106

STARTING ENGINE…124

OPERATIONS AND CHECKS AFTER STARTING ENGINE…128

STOPPING ENGINE…133

CHECK AFTER STOPPING ENGINE…133

MACHINE OPERATION…134

STEERING MACHINE…140

OPERATION OF WORK EQUIPMENT…142

CHECK AND CONFIRMATION OF JAW CRUSHER AFTER WORK…151

CHECK AFTER FINISHING WORK…151

LOCKING…152

RUN-IN OPERATION OF JAW CRUSHER…153

PRECAUTIONS WHEN OPERATING JAW CRUSHER…155

SCOPE OF WORKS USING MOBILE CRUSHER…163

PROHIBITIONS FOR OPERATION…171

PRECAUTIONS WHEN TRAVELING UP OR DOWNHILLS…173

TRANSPORTATION…174

TRANSPORTATION PROCEDURE…174

LOADING, UNLOADING WORK…174

LIFTING MACHINE…180

COLD WEATHER OPERATION…181

PRECAUTIONS FOR LOW TEMPERATURE…181

AFTER COMPLETION OF WORK…183

AFTER COLD WEATHER…184

LONG-TERM STORAGE…185

BEFORE STORAGE…185

DURING STORAGE…185

AFTER STORAGE…185

STARTING MACHINE AFTER LONG-TERM STORAGE…185

TROUBLESHOOTING…186

AFTER RUNNING OUT OF FUEL…186

PHENOMENA THAT ARE NOT FAILURES…186

METHOD OF TOWING MACHINE…186

IF BATTERY IS DISCHARGED…187

OTHER TROUBLE…190

MAINTENANCE…199

GUIDES TO MAINTENANCE…200

OUTLINE OF SERVICE…202

HANDLING AND PERFORMANCE OF OIL CLINIC FOR OIL, FUEL, COOLANT…202

RELATING TO ELECTRIC SYSTEM…205

OUTLINE OF HYDRAULIC EQUIPMENT…205

AIR-BLEEDING FROM HYDRAULIC CIRCUIT…206

WEAR PARTS…207

WEAR PARTS LIST…207

JAW CRUSHER RELATED PARTS…208

PRIMARY CONVEYOR RELATED PARTS…210

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE…211

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…215

CRUSHER ACCESSORY TOOLS…215

TORQUE LIST…217

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…218

SAFETY CRITICAL PARTS…218

MAINTENANCE SCHEDULE CHART…219

MAINTENANCE SCHEDULE CHART…219

SERVICE PROCEDURE…221

INITIAL 250 HOURS SERVICE (FIRST MAINTENANCE FOR NEW MACHINE ONLY)…221

INITIAL 1000 HOURS SERVICE (FIRST MAINTENANCE FOR NEW MACHINE ONLY)…221

WHEN REQUIRED…222

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT…222

CLEAN INSIDE OF COOLING SYSTEM…227

CHECK AND TIGHTEN TRACK SHOE BOLT…229

CHECK AND ADJUST TRACK TENSION…230

INSPECTION OF ELECTRIC HEATER…232

CHECK AND ADJUSTMENT OF JAW CRUSHER…233

CHECK AND ADJUSTMENT OF PRIMARY CONVEYOR…254

INSPECTION AND MAINTENANCE OF MAGNETIC SEPARATOR…259

METHOD FOR RELEASING INTERNAL PRESSURE IN HYDRAULIC CIRCUIT…261

CHECK BEFORE STARTING…263

EVERY 100 HOURS SERVICE…264

GREASING CRUSHER BEARING SEAT…264

GREASING PRIMARY CONVEYOR…265

EVERY 250 HOURS SERVICE…266

CHECK LEVEL OF BATTERY ELECTROLYTE…266

CHECK AND ADJUSTMENT OF JAW CRUSHER V-BELT…268

CHECK OF OIL LEVEL IN CRUSHER MOTOR BEARING CASE AND ADDING OIL…268

EVERY 500 HOURS SERVICE…269

REPLACE FUEL FILTER CARTRIDGE…269

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL…270

CLEAN, INSPECT RADIATOR FINS, OIL COOLER FINS, AFTERCOOLER FINS…271

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE…272

REPLACE HYDRAULIC TANK BREATHER ELEMENT…273

GREASE CRUSHER LINK…273

EVERY 1000 HOURS SERVICE…274

CHANGE OF OIL IN CRUSHER MOTOR BEARING CASE…274

CHANGE OF OIL IN GRIZZLY FEEDER VIBRATOR CASE…274

CHANGE OIL IN DAMPER CASE…275

CHECK ALL TIGHTENING PARTS OF TURBOCHARGER…275

CHECK PLAY OF TURBOCHARGER ROTOR…275

CHECK AND REPLACE OF FAN BELT TENSION…275

REPLACE HYDRAULIC FILTER ELEMENT…276

EVERY 2000 HOURS SERVICE…277

CHANGE OIL IN FINAL DRIVE CASE…277

CLEAN HYDRAULIC TANK STRAINER…278

CLEAN, CHECK TURBOCHARGER…278

CHECK ALTERNATOR, STARTING MOTOR…278

CHECK ENGINE VALVE CLEARANCE, ADJUST…278

CHECK VIBRATION DAMPER…278

EVERY 4000 HOURS SERVICE…279

CHECK WATER PUMP…279

EVERY 5000 HOURS SERVICE…280

CHANGE OIL IN HYDRAULIC TANK AND CLEAN STRAINER…280

SPECIFICATIONS…281

SPECIFICATIONS…282

ATTACHMENTS, OPTIONS…284

GENERAL PRECAUTIONS…285

PRECAUTIONS RELATED TO SAFETY…285

ATTACHMENTS, OPTIONS…286

ATTACHMENTS, OPTIONS CHART…286

METHOD FOR CONNECTING HYDRAULIC HOSES FOR OPTIONS…286

RADIO CONTROL UNIT…287

ON USE OF RADIO CONTROL UNIT…287

DIRECTIONS FOR USE…290

REMOTE CONTROL OPERATION…294

MUCK DISCHARGE CONVEYOR…303

PROCEDURE FOR RAISING (BENDING) MUCK DISCHARGE CONVEYOR…303

PROCEDURE FOR LOWERING MUCK DISCHARGE CONVEYOR…305

GREASING MUCK DISCHARGE CONVEYOR…306

CHECK AND ADJUSTMENT OF MUCK DISCHARGE CONVEYOR…307

FAILURES AND CORRECTIVE ACTIONS…309

WEARING PARTS…311

SPECIFICATIONS…312

M-TYPE CHUTE…313

METHOD OF OPERATION…313

BELT CONVEYOR PROTECTIVE PLATE…314

GRIZZLY BAR OPENING…316

MACHINES THAT CAN INSTALL ATTACHMENTS…317

NAMES OF CONTROL PANEL SWITCHES…317

HYDRAULIC POWER TAKEOFF PORT…317

PROCEDURE FOR CONNECTING OPTIONS…318

HYDRAULIC VIBRATORY SIEVE…319

SPECIFICATION…319

GENERAL VIEW…319

CAUTIONS TO BE NOTED FOR SAFETY…320

CONNECTING METHOD TO MACHINE BODY…320

PRECAUTIONS DURING OPERATION…320

HYDRAULIC SECONDARY CONVEYOR…321

SPECIFICATIONS…321

GENERAL VIEW…321

INCLINED LEG CONNECTING METHOD…323

LIFTING METHOD…324

CONNECTING METHOD TO MACHINE BODY…324

PRECAUTIONS ON OPERATION…324

INSPECTION, MAINTENANCE AND ADJUSTMENT…325

TROUBLES AND CORRECTIVE ACTIONS…327

CONSUMABLE PARTS OF HYDRAULIC SECONDARY CONVEYOR…329

INDEX…331

TEN00006-03 – Mobile Crusher GALEO BR380JG-1 Operation & Maintenance Manual (SN1201&up)…335

COVER…335

FOREWORD…336

FOREWORD…337

SAFETY INFORMATION…340

INTRODUCTION…342

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE…342

BREAKING IN THE NEW MACHINE…342

NECESSARY INFORMATION…343

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…343

ENGINE SERIAL NO. PLATE AND POSITION…343

POSITION OF SERVICE METER…344

TABLE OF ENTER SERIAL NO. AND DISTRIBUTOR…344

CONTENTS…345

SAFETY…349

SAFETY…350

SAFETY LABELS…353

POSITIONS OF SAFETY PICTOGRAMS…354

SAFETY LABELS…355

GENERAL PRECAUTIONS…363

SAFETY RULES…363

IF ABNORMALITIES ARE FOUND…363

CLOTHING AND PERSONAL PROTECTIVE ITEMS…363

FIRE EXTINGUISHER AND FIRST AID KIT…363

SAFETY FEATURES…363

KEEP MACHINE CLEAN…364

ON OPERATOR'S PLATFORM…364

ALWAYS APPLY LOCK WHEN LEAVING UPPER OPERATOR'S PLATFORM…364

HANDRAILS AND STEPS…365

PRECAUTIONS WHEN WORKING IN HIGH PLACES…365

MOUNTING AND DISMOUNTING…365

NO PEOPLE ON ATTACHMENTS…365

CRUSHING OR CUTTING PREVENTION…365

PREVENTION OF BURNS…366

FIRE PREVENTION…366

ACTION IF FIRE OCCURS…367

PRECAUTIONS FOR ATTACHMENTS…367

UNAUTHORIZED MODIFICATION…367

SAFETY AT WORKSITE…367

WORKING ON LOOSE GROUND…368

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES…368

ENSURE GOOD VISIBILITY…368

VENTILATION FOR ENCLOSED AREAS…369

CHECKING SIGNALMAN'S SIGNALS AND SIGNS…369

BE CAREFUL ABOUT ASBESTOS DUST…369

MAGNETIC SEPARATOR…370

PRECAUTIONS FOR OPERATION…371

STARTING ENGINE…371

CHECKS BEFORE STARTING ENGINE…371

PRECAUTIONS WHEN STARTING…371

PRECAUTIONS IN COLD AREAS…371

OPERATION…373

CHECK BEFORE OPERATION…373

PRECAUTIONS WHEN CHANGING DIRECTION…373

PRECAUTIONS WHEN TRAVELING…373

TRAVELING ON SLOPES…374

OPERATIONS ON SLOPES…374

PRECAUTIONS WHILE IN OPERATION…374

OPERATE CAREFULLY ON SNOW…374

PARKING MACHINE…375

CRUSHING OPERATION…376

CHECKS AROUND MACHINE…376

TURN MODE SELECTOR SWITCH TO WORK POSITION…376

ENSURE SAFETY WHILE OPERATING IN TANDEM WITH HYDRAULIC EXCAVATOR…377

CHECKS OF CRUSHER BEFORE STARTING OPERATION…377

PRECAUTIONS FOR CRUSHING WORK…377

EMERGENCY STOP TO WARD OFF DANGERS WHILE IN CRUSHING WORK…378

REMOVE FOREIGN MATERIAL FROM INSIDE CRUSHER…378

TRANSPORTATION…379

LOADING AND UNLOADING…379

SHIPPING…379

BATTERY…380

BATTERY HAZARD PREVENTION…380

STARTING WITH BOOSTER CABLE…381

TOWING…382

WHEN TOWING…382

PRECAUTIONS FOR MAINTENANCE…383

WARNING TAG…383

KEEP WORK PLACE CLEAN AND TIDY…383

APPOINT LEADER WHEN WORKING WITH OTHERS…383

STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE…383

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING…384

PRECAUTIONS FOR CONVEYOR MAINTENANCE…384

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE OF FEEDER, CRUSHER…385

PROPER TOOLS…385

PERSONNEL…385

PRECAUTIONS WHEN MOUNTING, DISMANTLING AND STORING ATTACHMENTS…385

PRECAUTIONS FOR WORK UNDER MACHINE…385

NOISE…386

PRECAUTIONS WHEN USING HAMMER…386

REPAIR WELDING…386

REMOVING BATTERY TERMINAL…386

PRECAUTIONS WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION…386

DO NOT DISASSEMBLE RECOIL SPRING…387

PRECAUTIONS WITH HIGH-PRESSURE OIL…388

HANDLING HIGH-PRESSURE HOSES…388

WASTE MATERIAL…388

COMPRESSED AIR…388

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…389

OPERATION…390

GENERAL VIEW…391

GENERAL VIEW OF MACHINE…391

GENERAL VIEW OF CONTROLS AND GAUGES…392

EXPLANATION OF COMPONENTS…396

MACHINE MONITOR…396

SWITCHES…421

CONTROL LEVERS…430

OPTION-RELATED SWITCHES…431

CAP, COVER WITH LOCK…433

REVOLVING WARNING LAMP…435

ELECTRIC POWER TAKEOFF…436

FUSIBLE LINK…438

CONTROLLERS…438

FUSE…438

TOOL BOX…439

OPERATION…440

CHECK BEFORE STARTING ENGINE…440

STARTING ENGINE…459

OPERATIONS AND CHECKS AFTER STARTING ENGINE…463

STOPPING ENGINE…468

CHECK AFTER STOPPING ENGINE…468

MACHINE OPERATION…469

STEERING MACHINE…475

OPERATION OF WORK EQUIPMENT…477

CHECK AND CONFIRMATION OF JAW CRUSHER AFTER WORK…486

CHECK AFTER FINISHING WORK…486

LOCKING…487

RUN-IN OPERATION OF JAW CRUSHER…488

PRECAUTIONS WHEN OPERATING JAW CRUSHER…490

EFFICIENT USE OF JAW CRUSHER…494

SCOPE OF WORKS USING MOBILE CRUSHER…500

PROHIBITIONS FOR OPERATION…508

PRECAUTIONS WHEN TRAVELING UP OR DOWNHILLS…510

TRANSPORTATION…511

TRANSPORTATION PROCEDURE…511

LOADING, UNLOADING WORK…511

LIFTING MACHINE…517

COLD WEATHER OPERATION…518

PRECAUTIONS FOR LOW TEMPERATURE…518

AFTER COMPLETION OF WORK…520

AFTER COLD WEATHER…520

LONG-TERM STORAGE…521

BEFORE STORAGE…521

DURING STORAGE…521

AFTER STORAGE…521

STARTING MACHINE AFTER LONG-TERM STORAGE…521

TROUBLESHOOTING…522

AFTER RUNNING OUT OF FUEL…522

PHENOMENA THAT ARE NOT FAILURES…522

METHOD OF TOWING MACHINE…523

IF BATTERY IS DISCHARGED…524

OTHER TROUBLE…527

MAINTENANCE…536

GUIDE TO MAINTENANCE…537

OUTLINE OF SERVICE…539

HANDLING AND PERFORMANCE OF OIL CLINIC FOR OIL, FUEL, COOLANT…539

RELATING TO ELECTRIC SYSTEM…542

OUTLINE OF HYDRAULIC EQUIPMENT…542

AIR-BLEEDING FROM HYDRAULIC CIRCUIT…543

WEAR PARTS…544

WEAR PARTS LIST…544

JAW CRUSHER RELATED PARTS…545

PRIMARY CONVEYOR RELATED PARTS…547

RECOMMENDED FUEL, COOLANT AND LUBRICANTS…548

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN…550

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…551

CRUSHER ACCESSORY TOOLS…551

TORQUE LIST…553

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…554

SAFETY CRITICAL PARTS…554

MAINTENANCE SCHEDULE CHART…555

MAINTENANCE SCHEDULE CHART…555

SERVICE PROCEDURE…557

INITIAL 250 HOURS SERVICE (FIRST MAINTENANCE FOR NEW MACHINE ONLY)…557

INITIAL 1000 HOURS SERVICE (FIRST MAINTENANCE FOR NEW MACHINE ONLY)…557

WHEN REQUIRED…558

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT…558

CLEAN INSIDE OF COOLING SYSTEM…563

CHECK AND TIGHTEN TRACK SHOE BOLT…566

CHECK AND ADJUST TRACK TENSION…567

INSPECTION OF ELECTRIC HEATER…569

CHECK AND ADJUSTMENT OF JAW CRUSHER…570

CHECK AND ADJUSTMENT OF PRIMARY CONVEYOR…592

INSPECTION AND MAINTENANCE OF MAGNETIC SEPARATOR…596

METHOD FOR RELEASING INTERNAL PRESSURE IN HYDRAULIC CIRCUIT…599

CHECK BEFORE STARTING…601

EVERY 10 HOURS SERVICE…602

GREASING CRUSHER BEARING SEAT…602

GREASING CRUSHER LINK…602

EVERY 100 HOURS SERVICE…603

GREASING CRUSHER LOCK CYLINDER SECURING POINT…603

GREASING PRIMARY CONVEYOR…604

EVERY 250 HOURS SERVICE…605

CHECK LEVEL OF BATTERY ELECTROLYTE…605

CHECK AND ADJUSTMENT OF JAW CRUSHER V-BELT…608

CHECK OF OIL LEVEL IN CRUSHER MOTOR BEARING CASE AND ADDING OIL…608

EVERY 500 HOURS SERVICE…609

REPLACE FUEL FILTER CARTRIDGE…609

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL…610

CLEAN, INSPECT RADIATOR FINS, OIL COOLER FINS, AFTERCOOLER FINS…611

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE…612

REPLACE HYDRAULIC TANK BREATHER ELEMENT…613

EVERY 1000 HOURS SERVICE…614

CHANGE OF OIL IN CRUSHER MOTOR BEARING CASE…614

CHANGE OF OIL IN GRIZZLY FEEDER VIBRATOR CASE…615

CHANGE OIL IN DAMPER CASE…616

CHECK ALL TIGHTENING PARTS OF TURBOCHARGER…616

CHECK PLAY OF TURBOCHARGER ROTOR…616

CHECK AND REPLACE OF FAN BELT TENSION…616

REPLACE HYDRAULIC FILTER ELEMENT…617

EVERY 2000 HOURS SERVICE…618

CHANGE OIL IN FINAL DRIVE CASE…618

CLEAN HYDRAULIC TANK STRAINER…619

CLEAN, CHECK TURBOCHARGER…619

CHECK ALTERNATOR, STARTING MOTOR…619

CHECK ENGINE VALVE CLEARANCE, ADJUST…619

CHECK VIBRATION DAMPER…619

EVERY 4000 HOURS SERVICE…620

CHECK WATER PUMP…620

EVERY 5000 HOURS SERVICE…621

CHANGE OIL IN HYDRAULIC TANK AND CLEAN STRAINER…621

SPECIFICATIONS…622

SPECIFICATIONS…623

ATTACHMENTS, OPTIONS…625

GENERAL PRECAUTIONS…626

PRECAUTIONS RELATED TO SAFETY…626

ATTACHMENTS, OPTIONS…627

ATTACHMENTS, OPTIONS CHART…627

METHOD FOR CONNECTING HYDRAULIC HOSES FOR OPTIONS…627

RADIO CONTROL UNIT…628

ON USE OF RADIO CONTROL UNIT…628

DIRECTIONS FOR USE…631

REMOTE CONTROL OPERATION…635

MUCK DISCHARGE CONVEYOR…643

PROCEDURE FOR RAISING (BENDING) MUCK DISCHARGE CONVEYOR…643

PROCEDURE FOR LOWERING MUCK DISCHARGE CONVEYOR…644

GREASING MUCK DISCHARGE CONVEYOR…647

CHECK AND ADJUSTMENT OF MUCK DISCHARGE CONVEYOR…648

FAILURES AND CORRECTIVE ACTIONS…650

WEARING PARTS…652

SPECIFICATIONS…653

M-TYPE CHUTE…654

METHOD OF OPERATION…654

BELT CONVEYOR PROTECTIVE PLATE…655

GRIZZLY BAR OPENING…657

HANDLING MACHINES EQUIPPED WITH KOMTRAX…658

BASIC PRECAUTIONS…658

MACHINES THAT CAN INSTALL ATTACHMENTS…659

NAMES OF CONTROL PANEL SWITCHES…659

HYDRAULIC POWER TAKEOFF PORT…659

ATTACHMENT PORT…660

PROCEDURE FOR CONNECTING OPTIONS…661

HYDRAULIC VIBRATORY SIEVE…663

SPECIFICATION…663

GENERAL VIEW…663

CAUTIONS TO BE NOTED FOR SAFETY…664

CONNECTING METHOD TO MACHINE BODY…664

PRECAUTIONS DURING OPERATION…664

HYDRAULIC SECONDARY CONVEYOR…665

SPECIFICATIONS…665

GENERAL VIEW…665

INCLINED LEG CONNECTING METHOD…667

LIFTING METHOD…668

CONNECTING METHOD TO MACHINE BODY…668

PRECAUTIONS ON OPERATION…668

INSPECTION, MAINTENANCE AND ADJUSTMENT…669

TROUBLES AND CORRECTIVE ACTIONS…671

CONSUMABLE PARTS OF HYDRAULIC SECONDARY CONVEYOR…673

SPRINKLER…675

EXPLANATIONS FOR COMPONENT PARTS…675

HOW TO USE SPRINKLER…676

INSPECTION AND MAINTENANCE…679

INDEX…681

TEN00168-03 – Mobile Crusher GALEO BR380JG-1E0 Operation & Maintenance Manual (SN2001&up)…685

COVER…685

FOREWORD…686

BEFORE READING THIS MA…687

SAFETY INFORMATION…688

INTRODUCTION…689

INTRODUCTION…689

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE…689

NECESSARY INFORMATION…690

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…690

EPA REGULATIONS, ENGINE NUMBER PLATE…690

POSITION OF SERVICE METER…691

TABLE OF ENTER SERIAL NO. AND DISTRIBUTOR…691

CONTENTS…692

SAFETY…696

SAFETY…697

SAFETY LABELS…700

POSITIONS OF SAFETY PICTOGRAMS…701

SAFETY LABELS…702

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE…712

PRECAUTIONS BEFORE STARTING OPERATION…712

PREPARATIONS FOR SAFE OPERATION…712

FIRE PREVENTION…714

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE…715

DO NOT GET CAUGHT IN WORK EQUIPMENT…717

UNAUTHORIZED MODIFICATION…717

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…717

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING…717

PRECAUTIONS FOR OPERATION…718

PRECAUTIONS FOR JOBSITE…718

STARTING ENGINE…720

OPERATION…723

CRUSHING OPERATION…726

TRANSPORTATION…729

TOWING…730

MAGNETIC SEPARATOR…731

PRECAUTIONS FOR MAINTENANCE…732

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE…732

PRECAUTIONS FOR INSPECTION AND MAINTENANCE…736

OPERATION…742

GENERAL VIEW…743

GENERAL VIEW OF MACHINE…743

GENERAL VIEW OF CONTROLS AND GAUGES…744

EXPLANATION OF COMPONENTS…748

MACHINE MONITOR…748

SWITCHES…775

CONTROL LEVERS…787

OPTION-RELATED SWITCHES…788

CAP, COVER WITH LOCK…789

REVOLVING WARNING LAMP…791

ELECTRIC POWER TAKEOFF…792

FUSIBLE LINK…794

CONTROLLERS…794

FUSE…794

TOOL BOX…795

OPERATION…796

CHECK BEFORE STARTING ENGINE…796

STARTING ENGINE…821

OPERATIONS AND CHECKS AFTER STARTING ENGINE…823

STOPPING ENGINE…829

CHECK AFTER STOPPING ENGINE…829

MACHINE OPERATION…830

STEERING MACHINE…835

OPERATION OF WORK EQUIPMENT…837

CHECK AND CONFIRMATION OF JAW CRUSHER AFTER WORK…845

CHECK AFTER FINISHING WORK…845

LOCKING…846

RUN-IN OPERATION OF JAW CRUSHER…847

PRECAUTIONS WHEN OPERATING JAW CRUSHER…849

EFFICIENT USE OF JAW CRUSHER…853

SCOPE OF WORKS USING MOBILE CRUSHER…860

PROHIBITIONS FOR OPERATION…868

PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS…871

TRANSPORTATION…872

TRANSPORTATION PROCEDURE…872

LOADING, UNLOADING WORK…873

LIFTING MACHINE…880

COLD WEATHER OPERATION…881

PRECAUTIONS FOR LOW TEMPERATURE…881

AFTER COMPLETION OF WORK…883

AFTER COLD WEATHER…883

LONG-TERM STORAGE…884

BEFORE STORAGE…884

DURING STORAGE…884

AFTER STORAGE…884

STARTING MACHINE AFTER LONG-TERM STORAGE…884

TROUBLESHOOTING…885

AFTER RUNNING OUT OF FUEL…885

PHENOMENA THAT ARE NOT FAILURES…885

METHOD OF TOWING MACHINE…886

IF BATTERY IS DISCHARGED…887

OTHER TROUBLE…891

MAINTENANCE…900

GUIDE TO MAINTENANCE…901

OUTLINE OF SERVICE…903

HANDLING AND PERFORMANCE OF OIL CLINIC FOR OIL, FUEL, COOLANT…903

RELATING TO ELECTRIC SYSTEM…907

OUTLINE OF HYDRAULIC EQUIPMENT…907

AIR-BLEEDING FROM HYDRAULIC CIRCUIT…908

WEAR PARTS…910

WEAR PARTS LIST…910

JAW CRUSHER RELATED PARTS…911

PRIMARY CONVEYOR RELATED PARTS…913

RECOMMENDED FUEL, COOLANT AND LUBRICANTS…914

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…916

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…917

TORQUE LIST…917

TOOLS TO USE CHECK AND MAINTENANCE CRUSHER…918

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…920

SAFETY CRITICAL PARTS…920

MAINTENANCE SCHEDULE CHART…921

MAINTENANCE SCHEDULE CHART…921

SERVICE PROCEDURE…923

INITIAL 250 HOURS SERVICE (FIRST MAINTENANCE FOR NEW MACHINE ONLY)…923

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)…923

WHEN REQUIRED…924

CHECK BEFORE STARTING…986

EVERY 10 HOURS SERVICE…987

EVERY 100 HOURS SERVICE…988

EVERY 250 HOURS SERVICE…989

EVERY 500 HOURS SERVICE…993

EVERY 1000 HOURS SERVICE…1001

EVERY 2000 HOURS SERVICE…1008

EVERY 4000 HOURS SERVICE…1010

EVERY 5000 HOURS SERVICE…1012

EVERY 8000 HOURS SERVICE…1013

SPECIFICATIONS…1014

SPECIFICATIONS…1015

ATTACHMENTS, OPTIONS…1018

GENERAL PRECAUTIONS…1019

PRECAUTIONS RELATED TO SAFETY…1019

ATTACHMENTS, OPTIONS…1020

ATTACHMENTS, OPTIONS CHART…1020

METHOD FOR CONNECTING HYDRAULIC HOSES FOR OPTIONS…1020

RADIO CONTROL UNIT…1021

ON USE OF RADIO CONTROL UNIT…1021

DIRECTIONS FOR USE…1024

RADIO CONTROL OPERATION…1030

MUCK DISCHARGE CONVEYOR…1043

PROCEDURE FOR RAISING (BENDING) MUCK DISCHARGE CONVEYOR…1043

PROCEDURE FOR LOWERING (EXTEND) MUCK DISCHARGE CONVEYOR…1045

GREASING MUCK DISCHARGE CONVEYOR…1048

CHECK AND ADJUSTMENT OF MUCK DISCHARGE CONVEYOR…1049

FAILURES AND CORRECTIVE ACTIONS…1051

WEARING PARTS…1053

SPECIFICATIONS…1054

M-TYPE CHUTE…1055

METHOD OF OPERATION…1055

GRIZZLY BAR OPENING…1056

HANDLING MACHINES EQUIPPED WITH KOMTRAX…1057

BASIC PRECAUTIONS…1057

MACHINES THAT CAN INSTALL ATTACHMENTS…1058

NAMES OF CONTROL PANEL SWITCHES…1058

HYDRAULIC POWER TAKEOFF PORT…1059

ATTACHMENT PORT…1060

PROCEDURE FOR CONNECTING OPTIONS…1062

SPRINKLER…1063

EXPLANATIONS FOR COMPONENT PARTS…1063

HOW TO USE SPRINKLER…1064

INSPECTION AND MAINTENANCE…1067

ADDITIONAL SPRINKLER NOZZLE…1068

INDEX…1072

TEN00358-01 – Mobile Crusher GALEO BR380JG-1E0 Operation & Maintenance Manual (SN2609&up)…1076

COVER…1076

FOREWORD…1077

BEFORE READING THIS MANUAL…1078

SAFETY INFORMATION…1079

INTRODUCTION…1080

INTRODUCTION…1080

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE…1080

NECESSARY INFORMATION…1081

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…1081

EPA REGULATIONS, ENGINE NUMBER PLATE…1081

POSITION OF SERVICE METER…1082

TABLE OF ENTER SERIAL NO. AND DISTRIBUTOR…1082

CONTENTS…1083

SAFETY…1087

SAFETY…1088

SAFETY LABELS…1091

POSITIONS OF SAFETY PICTOGRAMS…1092

SAFETY LABELS…1093

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE…1103

PRECAUTIONS BEFORE STARTING OPERATION…1103

PREPARATIONS FOR SAFE OPERATION…1103

FIRE PREVENTION…1105

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE…1106

DO NOT GET CAUGHT IN WORK EQUIPMENT…1108

UNAUTHORIZED MODIFICATION…1108

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…1108

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING…1108

PRECAUTIONS FOR OPERATION…1109

PRECAUTIONS FOR JOBSITE…1109

STARTING ENGINE…1111

OPERATION…1114

CRUSHING OPERATION…1117

TRANSPORTATION…1120

TOWING…1121

MAGNETIC SEPARATOR…1122

PRECAUTIONS FOR MAINTENANCE…1123

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE…1123

PRECAUTIONS FOR INSPECTION AND MAINTENANCE…1127

OPERATION…1133

GENERAL VIEW…1134

GENERAL VIEW OF MACHINE…1134

GENERAL VIEW OF CONTROLS AND GAUGES…1135

EXPLANATION OF COMPONENTS…1139

MACHINE MONITOR…1139

SWITCHES…1166

CONTROL LEVERS…1178

OPTION-RELATED SWITCHES…1179

CAP, COVER WITH LOCK…1180

REVOLVING WARNING LAMP…1182

ELECTRIC POWER TAKEOFF…1183

FUSIBLE LINK…1185

CONTROLLERS…1185

FUSE…1185

TOOL BOX…1186

OPERATION…1187

CHECK BEFORE STARTING ENGINE…1187

STARTING ENGINE…1212

OPERATIONS AND CHECKS AFTER STARTING ENGINE…1214

STOPPING ENGINE…1220

CHECK AFTER STOPPING ENGINE…1220

MACHINE OPERATION…1221

STEERING MACHINE…1226

OPERATION OF WORK EQUIPMENT…1228

CHECK AND CONFIRMATION OF JAW CRUSHER AFTER WORK…1236

CHECK AFTER FINISHING WORK…1236

LOCKING…1237

RUN-IN OPERATION OF JAW CRUSHER…1238

PRECAUTIONS WHEN OPERATING JAW CRUSHER…1240

EFFICIENT USE OF JAW CRUSHER…1244

SCOPE OF WORKS USING MOBILE CRUSHER…1251

PROHIBITIONS FOR OPERATION…1259

PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS…1262

TRANSPORTATION…1263

TRANSPORTATION PROCEDURE…1263

LOADING, UNLOADING WORK…1264

LIFTING MACHINE…1271

COLD WEATHER OPERATION…1272

PRECAUTIONS FOR LOW TEMPERATURE…1272

AFTER COMPLETION OF WORK…1274

AFTER COLD WEATHER…1274

LONG-TERM STORAGE…1275

BEFORE STORAGE…1275

DURING STORAGE…1275

AFTER STORAGE…1275

STARTING MACHINE AFTER LONG-TERM STORAGE…1275

TROUBLESHOOTING…1276

AFTER RUNNING OUT OF FUEL…1276

PHENOMENA THAT ARE NOT FAILURES…1276

METHOD OF TOWING MACHINE…1277

IF BATTERY IS DISCHARGED…1278

OTHER TROUBLE…1282

MAINTENANCE…1291

GUIDE TO MAINTENANCE…1292

OUTLINE OF SERVICE…1294

HANDLING AND PERFORMANCE OF OIL CLINIC FOR OIL, FUEL, COOLANT…1294

RELATING TO ELECTRIC SYSTEM…1298

OUTLINE OF HYDRAULIC EQUIPMENT…1298

AIR-BLEEDING FROM HYDRAULIC CIRCUIT…1299

WEAR PARTS…1301

WEAR PARTS LIST…1301

JAW CRUSHER RELATED PARTS…1302

PRIMARY CONVEYOR RELATED PARTS…1304

RECOMMENDED FUEL, COOLANT AND LUBRICANTS…1305

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…1307

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…1308

TORQUE LIST…1308

TOOLS TO USE CHECK AND MAINTENANCE CRUSHER…1309

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…1311

SAFETY CRITICAL PARTS…1311

MAINTENANCE SCHEDULE CHART…1312

MAINTENANCE SCHEDULE CHART…1312

SERVICE PROCEDURE…1314

INITIAL 250 HOURS SERVICE (FIRST MAINTENANCE FOR NEW MACHINE ONLY)…1314

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)…1314

WHEN REQUIRED…1315

CHECK BEFORE STARTING…1377

EVERY 10 HOURS SERVICE…1378

EVERY 100 HOURS SERVICE…1379

EVERY 250 HOURS SERVICE…1380

EVERY 500 HOURS SERVICE…1384

EVERY 1000 HOURS SERVICE…1392

EVERY 2000 HOURS SERVICE…1398

EVERY 4000 HOURS SERVICE…1400

EVERY 5000 HOURS SERVICE…1402

EVERY 8000 HOURS SERVICE…1403

SPECIFICATIONS…1405

SPECIFICATIONS…1406

ATTACHMENTS, OPTIONS…1409

GENERAL PRECAUTIONS…1410

PRECAUTIONS RELATED TO SAFETY…1410

ATTACHMENTS, OPTIONS…1411

ATTACHMENTS, OPTIONS CHART…1411

METHOD FOR CONNECTING HYDRAULIC HOSES FOR OPTIONS…1411

RADIO CONTROL UNIT…1412

ON USE OF RADIO CONTROL UNIT…1412

DIRECTIONS FOR USE…1415

RADIO CONTROL OPERATION…1421

MUCK DISCHARGE CONVEYOR…1434

PROCEDURE FOR RAISING (BENDING) MUCK DISCHARGE CONVEYOR…1434

PROCEDURE FOR LOWERING (EXTEND) MUCK DISCHARGE CONVEYOR…1436

GREASING MUCK DISCHARGE CONVEYOR…1439

CHECK AND ADJUSTMENT OF MUCK DISCHARGE CONVEYOR…1440

FAILURES AND CORRECTIVE ACTIONS…1442

WEARING PARTS…1444

SPECIFICATIONS…1445

M-TYPE CHUTE…1446

METHOD OF OPERATION…1446

GRIZZLY BAR OPENING…1447

HANDLING MACHINES EQUIPPED WITH KOMTRAX…1448

BASIC PRECAUTIONS…1448

MACHINES THAT CAN INSTALL ATTACHMENTS…1449

NAMES OF CONTROL PANEL SWITCHES…1449

HYDRAULIC POWER TAKEOFF PORT…1450

ATTACHMENT PORT…1451

PROCEDURE FOR CONNECTING OPTIONS…1453

SPRINKLER…1454

EXPLANATIONS FOR COMPONENT PARTS…1454

HOW TO USE SPRINKLER…1455

INSPECTION AND MAINTENANCE…1458

ADDITIONAL SPRINKLER NOZZLE…1459

INDEX…1463

TEN00476-01 – Mobile Crusher GALEO BR380JG-1E0 Operation & Maintenance Manual (SN2621&up)…1467

COVER…1467

FOREWORD…1468

BEFORE READING THIS MANUAL…1469

SAFETY INFORMATION…1470

INTRODUCTION…1471

INTRODUCTION…1471

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE…1471

NECESSARY INFORMATION…1472

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…1472

EPA REGULATIONS, ENGINE NUMBER PLATE…1472

POSITION OF SERVICE METER…1473

TABLE OF ENTER SERIAL NO. AND DISTRIBUTOR…1473

CONTENTS…1474

SAFETY…1478

SAFETY…1479

SAFETY LABELS…1482

POSITIONS OF SAFETY PICTOGRAMS…1483

SAFETY LABELS…1484

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE…1494

PRECAUTIONS BEFORE STARTING OPERATION…1494

PREPARATIONS FOR SAFE OPERATION…1494

FIRE PREVENTION…1496

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE…1497

DO NOT GET CAUGHT IN WORK EQUIPMENT…1499

UNAUTHORIZED MODIFICATION…1499

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…1499

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING…1499

PRECAUTIONS FOR OPERATION…1500

PRECAUTIONS FOR JOBSITE…1500

STARTING ENGINE…1502

OPERATION…1505

CRUSHING OPERATION…1508

TRANSPORTATION…1511

TOWING…1512

MAGNETIC SEPARATOR…1513

PRECAUTIONS FOR MAINTENANCE…1514

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE…1514

PRECAUTIONS FOR INSPECTION AND MAINTENANCE…1518

OPERATION…1524

GENERAL VIEW…1525

GENERAL VIEW OF MACHINE…1525

GENERAL VIEW OF CONTROLS AND GAUGES…1526

EXPLANATION OF COMPONENTS…1530

MACHINE MONITOR…1530

SWITCHES…1557

CONTROL LEVERS…1569

OPTION-RELATED SWITCHES…1570

CAP, COVER WITH LOCK…1571

REVOLVING WARNING LAMP…1573

ELECTRIC POWER TAKEOFF…1574

FUSIBLE LINK…1576

CONTROLLERS…1576

FUSE…1576

TOOL BOX…1577

OPERATION…1578

CHECK BEFORE STARTING ENGINE…1578

STARTING ENGINE…1603

OPERATIONS AND CHECKS AFTER STARTING ENGINE…1605

STOPPING ENGINE…1611

CHECK AFTER STOPPING ENGINE…1611

MACHINE OPERATION…1612

STEERING MACHINE…1617

OPERATION OF WORK EQUIPMENT…1619

CHECK AND CONFIRMATION OF JAW CRUSHER AFTER WORK…1627

CHECK AFTER FINISHING WORK…1627

LOCKING…1628

RUN-IN OPERATION OF JAW CRUSHER…1629

PRECAUTIONS WHEN OPERATING JAW CRUSHER…1631

EFFICIENT USE OF JAW CRUSHER…1635

SCOPE OF WORKS USING MOBILE CRUSHER…1642

PROHIBITIONS FOR OPERATION…1650

PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS…1653

TRANSPORTATION…1654

TRANSPORTATION PROCEDURE…1654

LOADING, UNLOADING WORK…1655

LIFTING MACHINE…1662

COLD WEATHER OPERATION…1663

PRECAUTIONS FOR LOW TEMPERATURE…1663

AFTER COMPLETION OF WORK…1665

AFTER COLD WEATHER…1665

LONG-TERM STORAGE…1666

BEFORE STORAGE…1666

DURING STORAGE…1666

AFTER STORAGE…1666

STARTING MACHINE AFTER LONG-TERM STORAGE…1666

TROUBLESHOOTING…1667

AFTER RUNNING OUT OF FUEL…1667

PHENOMENA THAT ARE NOT FAILURES…1667

METHOD OF TOWING MACHINE…1668

IF BATTERY IS DISCHARGED…1669

OTHER TROUBLE…1673

MAINTENANCE…1682

GUIDE TO MAINTENANCE…1683

OUTLINE OF SERVICE…1685

HANDLING AND PERFORMANCE OF OIL CLINIC FOR OIL, FUEL, COOLANT…1685

RELATING TO ELECTRIC SYSTEM…1689

OUTLINE OF HYDRAULIC EQUIPMENT…1689

AIR-BLEEDING FROM HYDRAULIC CIRCUIT…1690

WEAR PARTS…1692

WEAR PARTS LIST…1692

JAW CRUSHER RELATED PARTS…1693

PRIMARY CONVEYOR RELATED PARTS…1695

RECOMMENDED FUEL, COOLANT AND LUBRICANTS…1696

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…1698

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS…1699

TORQUE LIST…1699

TOOLS TO USE CHECK AND MAINTENANCE CRUSHER…1700

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…1702

SAFETY CRITICAL PARTS…1702

MAINTENANCE SCHEDULE CHART…1703

MAINTENANCE SCHEDULE CHART…1703

SERVICE PROCEDURE…1705

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)…1705

INITIAL 500 HOURS SERVICE (ONLY AFTER THE FIRST 500 HOURS)…1705

WHEN REQUIRED…1706

CHECK BEFORE STARTING…1768

EVERY 10 HOURS SERVICE…1769

EVERY 100 HOURS SERVICE…1770

EVERY 250 HOURS SERVICE…1771

EVERY 500 HOURS SERVICE…1775

EVERY 1000 HOURS SERVICE…1783

EVERY 2000 HOURS SERVICE…1789

EVERY 4000 HOURS SERVICE…1791

EVERY 5000 HOURS SERVICE…1793

EVERY 8000 HOURS SERVICE…1794

SPECIFICCATIONS…1796

SPECIFICATIONS…1797

ATTACHMENTS, OPTIONS…1800

GENERAL PRECAUTIONS…1801

PRECAUTIONS RELATED TO SAFETY…1801

ATTACHMENTS, OPTIONS…1802

ATTACHMENTS, OPTIONS CHART…1802

METHOD FOR CONNECTING HYDRAULIC HOSES FOR OPTIONS…1802

RADIO CONTROL UNIT…1803

ON USE OF RADIO CONTROL UNIT…1803

DIRECTIONS FOR USE…1806

RADIO CONTROL OPERATION…1812

MUCK DISCHARGE CONVEYOR…1825

PROCEDURE FOR RAISING (BENDING) MUCK DISCHARGE CONVEYOR…1825

PROCEDURE FOR LOWERING (EXTEND) MUCK DISCHARGE CONVEYOR…1827

GREASING MUCK DISCHARGE CONVEYOR…1830

CHECK AND ADJUSTMENT OF MUCK DISCHARGE CONVEYOR…1831

FAILURES AND CORRECTIVE ACTIONS…1833

WEARING PARTS…1835

SPECIFICATIONS…1836

M-TYPE CHUTE…1837

METHOD OF OPERATION…1837

GRIZZLY BAR OPENING…1838

HANDLING MACHINES EQUIPPED WITH KOMTRAX…1839

BASIC PRECAUTIONS…1839

MACHINES THAT CAN INSTALL ATTACHMENTS…1840

NAMES OF CONTROL PANEL SWITCHES…1840

HYDRAULIC POWER TAKEOFF PORT…1841

ATTACHMENT PORT…1842

PROCEDURE FOR CONNECTING OPTIONS…1844

SPRINKLER…1845

EXPLANATIONS FOR COMPONENT PARTS…1845

HOW TO USE SPRINKLER…1846

INSPECTION AND MAINTENANCE…1849

ADDITIONAL SPRINKLER NOZZLE…1850

INDEX…1854

Komatsu Mobile Crusher GALEO BR380JG Operation & Maintenance Manuals