Complete service repair manual with Electrical Wiring Diagrams for Komatsu Motor Graders GD611A-1, GD611R-1, GD613A-1, GD615A-1, GD621A-1, GD622A-1, GD623A-1, GD661A-1, GD625A-1, GD625A-1A, GD625A-1B, GD625A-1C, GD663A-1, GDO663A-2, GD672A-1, GD621R-1, GD623R-1, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Motor Grader GD610 & GD620 & GD660 & GD670 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBMG6150109 – Motor Grader GD610 & GD620 & GD660 & GD670 Shop Manual.pdf

SEAMG6150101 – Motor Grader GD625A-1 Operation & Maintenance Manual.pdf

PRODUCT DETAILS:

Total Pages: 664 + 130 pages

File Format: PDF

Language: English

GD621A, 611A, 661A, 621R, 623R, 611R, 613R-1 mount the S6D105-1 engine;

GD622A, 623A, 625A, 672A, 613A, 663A, 625A4-1C, 625A-1A mount the 6D125-1 engine;

GD615A-1 mount the $6D110-1 engine.

For details of the engines, see the 105 Series Shop Manual, 110 Series Shop Manual and 6D125 Series Shop Manual.

MAIN SECTIONS

SEAMG6150101 – Motor Grader GD625A-1 Operation & Maintenance Manual..2

COVER..2

FOREWORD..3

BREAKING IN YOUR NEW MACHINE..4

CONTENTS..5

SAFETY HINTS..6

GENERAL LOCATIONS AND SPECIFICATIONS..13

INSTRUMENTS AND CONTROLS..14

OPERATING THE AIR CONDITIONER..37

CHECK BEFORE STARTING..38

OPERATING YOUR MACHINE..43

COLD WEATHER OPERATION..51

OPERATING OF WORK EQUIPMENT..56

REVERSING AND REPLACEMENT OF CUTTING EDGE AND END BIT..67

CHANGING TIRES..69

DRIVING ALONG ROAD..71

HANDLING OF BATTERY..72

TRANSPORTATION..75

PERIODIC MAINTENANCE..76

PRECAUTIONS FOR MAINTENANCE..77

MAINTENANCE TABLE..80

OIL FILLER AND LEVEL GAUGE POSITIONS..84

EVERY 50 HOURS SERVICE..85

INITIAL 250 HOURS SERVICE..86

EVERY 250 HOURS SERVICE..86

EVERY 500 HOURS SERVICE..95

EVERY 1000 HOURS SERVICE..101

EVERY 2000 HOURS SERVICE..108

EVERY 4000 HOURS SERVICE..111

WHEN REQUIRED..112

ADJUSTMENT..118

TROUBLE SHOOTING GUIDE..120

STORAGE..124

SERVICE METER..126

MACHINE AND ENGINE SERIAL NUMBERS..127

FUEL,COOLANT AND LUBRICANTS..128

SEBMG6150109 – Motor Grader GD610 & GD620 & GD660 & GD670 Shop Manual..132

COVER..132

CONTENTS..133

10 ENGINE..159

12 TESTING AND ADJUSTING..160

TABLE OF JUDGEMENT STANDARD VALUE..161

TESTING AND ADJUSTING TOOL LIST..166

ADJUSTING VALVE CLEARANCE..167

MEASURING COMPRESSION PRESSURE..169

TESTING AND ADJUSTING FUEL INJECTION TIMING..170

BLEEDING AIR FROM FUEL SYSTEM..172

ENGINE SPEED CONTROL..173

MEASURING EXHAUST GAS COLOR..176

TESTING AND ADJUSTING FAN BELT TENSION..178

MEASURING ENGINE OIL PRESSURE AND TEMPERATURE..179

13 DISASSEMBLY AND ASSEMBLY..180

RADIATOR..181

REMOVAL..181

INSTALLATION..181

FUEL TANK(Incl.HYDRAULIC TANK)ASSEMBLY..185

REMOVAL..185

INSTALLATION..187

20 POWER TRAIN..191

21 STRUCTURE AND FUNCTION..192

GENERAL..193

POWER TRAIN..194

HYDROSHIFT TRANSMISSION PIPING..196

HYDROSHIFT TRANSMISSION CONTROL..197

POWER TRAIN HYDRAULIC CIRCUIT SCHEMATICS..198

POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM..199

JOINT..200

PTO(POWER TAKE OFF)..201

HYDROSHIFT TRANSMISSION AND TRANSFER..202

HYDROSHIFT TRANSMISSION PUMP..208

TRANSMISSION CONTROL VALVE..210

FINAL DRIVE..218

DIFFERENTIAL LOCK PIPING..225

TANDEM DRIVE..227

22 TESTING AND ADJUSTING..229

TABLE OF JUDGEMENT STANDARD VALUE..230

TOOL LIST FOR TESTING AND ADJUSTING..232

INCHING PEDAL TRAVEL AND OPERATING FORCE..233

CHECKING OIL PRESSURE..236

MACHINE TYPE AND INCHING PRESSURE..237

TRANSMISSION CONTROL LEVER TRAVEL AND OPERATING FORCE..238

CHECKING DIFFERENTIAL LOCKING DEVICE OIL PRESSURE..239

23 DISASSEMBLY AND ASSEMBLY..240

TRANSMISSION PUMP..241

REMOVAL..241

INSTALLATION..241

ENGINE(Incl.TRANSMISSION)ASSEMBLY..243

REMOVAL..243

INSTALLATION..247

PTO..267

DISASSEMBLY..267

ASSEMBLY..271

HYDROSHIFT TRANSMISSION..277

DISASSEMBLY..277

ASSEMBLY..293

TRANSFER ASSEMBLY..313

DISASSEMBLY..313

ASSEMBLY..317

TANDEM AND FINAL DRIVE..323

REMOVAL..323

INSTALLATION..323

TANDEM,FINAL DRIVE ASSEMBLY..325

REMOVAL..325

INSTALLATION..325

FINAL DRIVE..329

DISASSEMBLY..329

ASSEMBLY..333

TANDEM,FINAL DRIVE ASSEMBLY..339

DISASSEMBLY..339

ASSEMBLY..343

SIDE CASE ASSEMBLY..351

DISASSEMBLY..351

ASSEMBLY..351

BEVEL GEAR ASSEMBLY..353

DISASSEMBLY..353

ASSEMBLY..353

PINION ASSEMBLY..363

DISASSEMBLY..363

ASSEMBLY..363

24 MAINTENANCE STANDARD..365

PTO,HYDROSHIFT TRANSMISSION AND TRANSFER..366

HYDROSHIFT TRANSMISSION CONTROL VALVE..368

TRANSMISSION PUMP..374

FINAL DRIVE..376

TANDEM DRIVE..378

40 STEERING SYSTEM..379

41 STRUCTURE AND FUNCTION..380

STEERING PIPING..381

STEERING CIRCUIT DIAGRAM..382

STEERING CONTROL VALVE..383

FRONT AXLE..388

STEERING CYLINDER..394

WHEEL..395

42 TESTING AND ADJUSTING..399

TABLE OF JUDGEMENT STANDARD..400

TOOL LIST FOR TESTING AND ADJUSTING..402

CHECKING STEERING WHEEL..403

CHECKING TIRE RUNOUT..404

CHECKING TIRE INFLATION PRESSURE..404

CHECKING TOE-IN..405

43 DISASSEMBLY AND ASSEMBLY..406

FRONT AXLE ASSEMBLY..407

REMOVAL..407

INSTALLATION..407

FRONT AXLE ASSEMBLY..409

DISASSEMBLY..409

ASSEMBLY..415

STEEREMBLY VALVE..421

DISASSEMBLY..421

ASSEMBLY..425

DOUBLE RELIEF VALVE..429

DISASSEMBLY..429

ASSEMBLY..429

44 MAINTENANCE STANDARD..431

FRONT AXLE..432

STEERING CYLINDER..438

50 BRAKE SYSTEM..439

51 STRUCTURE AND FUNCTION..440

BRAKE PIPING..441

BRAKE CIRCUIT DIAGRAM..442

BOOST MASTER..443

AIR BRAKE PIPING..446

AIR BRAKE CIRCUIT SCHEMATICS..448

AIR BRAKE CIRCUIT DIAGRAM..449

BRAKE VALVE..452

AIR COMPRESSOR..456

AIR GOVERNOR..457

CHECK VALVE..458

AIR TANK..459

SAFETY VALVE..459

AUTOMATIC DRAIN VALVE(IF EQUIPPED)..460

AIR DRIER(IF EQUIPPED)..462

WHEEL BRAKE..464

PARKING BRAKE..467

52 TESTING AND ADJUSTING..468

TABLE OF JUDGEMENT STANDARD VALUE..469

TOOL LIST FOR TESTING AND ADJUSTING..469

CHECKING BRAKE PEDAL..470

AIR BLEEDING FROM BRAKE CIRCUIT..472

CHECKING PARKING BRAKE LEVER..473

CHECKING WEAR OF BRAKE DISC..474

53 DISASSEMBLY AND ASSEMBLY..475

BOOST MASTER..476

DISASSEMBLY ..476

ASSEMBLY..478

WHEEL BRAKE..480

REMOVAL..480

INSTALLATION..480

DISASSEMBLY..482

ASSEMBLY..482

WHEEL BRAKE..484

REMOVAL..484

INSTALLATION..484

DISASSEMBLY..488

ASSEMBLY..492

54 MAINTENANCE STANDARD..504

WHEEL BRAKE..505

PARKING BRAKE..507

BOOST MASTER..508

60 HYDRAULIC SYSTEM..509

61 STRUCTURE AND FUNCTION..510

HYDRAULIC PIPING..511

HYDUAULIC CONTROL..521

BLADE ACCUMULATOR SYSTEM(IF EQUIPPED)..523

HYDRAULIC CIRCUIT DIAGRAM..525

OIL COOLING FLOW..529

HYDRAULIC PUMP..530

CIRCLE ROTATION MOTOR..532

CONTROL VALVE..538

FLOW DIVIDER..544

PILOT CHECK VALVE..545

FLOW CONTROL VALVE..549

HYDRAULIC CYLINDER..550

62 TESTING AND ADJUSTING..553

TROUBLESHOOTING(CIRCLE ROTATION MOTOR)..554

63 DISASSEMBLY AND ASSEMBLY..555

HYDRAULIC PUMP(Incl.STEERING PUMP)..556

REMOVAL..556

INSTALLATION..556

BLADE LIFT CYLINDER..558

REMOVAL..558

INSTALLATION..558

DRAWBAR SHIFT CYLINDER..560

REMOVAL..560

INSTALLATION..560

BLADE SIDE SHAFT CYLINDER..562

REMOVAL..562

INSTALLATION..562

ARTICULATE CYLINDER..564

REMOVAL..564

INSTALLATION..564

SCARIFIER CYLINDER..566

REMOVAL..566

INSTALLATION..566

POWER TILT CYLINDER..568

REMOVAL..568

INSTALLATION..568

REAR MOUNT RIPPER CYLINDER..568

REMOVAL..568

INSTALLATION..568

HYDRAULIC CYLINDER..570

DISASSEMBLY..570

ASSEMBLY..574

CIRCLE ROTATION MOTOR..582

DISASSEMBLY..582

ASSEMBLY..588

64 MAINTENANCE STANDARD..602

HYDRAULIC PUMP..603

CONTROL VALVE..605

HYDRAULIC CYLINDER..609

70 WORK EQUIPMENT..613

71 STRUCTURE AND FUNCTION..614

DRAWBAR AND LIFTER..615

BLADE..619

CIRCLE ROTATION GEAR..623

FRAME..625

SCARIFIER(IF EQUIPPED)..626

REAR MOUNTING RIPPER(IF EQUIPPED)..627

72 TESTING AND ADJUSTING..628

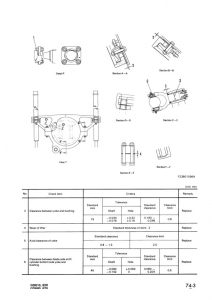

TABLE OF JUDGEMENT STANDARD..629

TOOL LIST FOR TESTING AND ADJUSTING..632

CHECKING CONTROL LEVER..633

CHECKING HYDRAULIC OIL TEMPERATURE..634

CHECKING HYDRAULIC OIL PRESSURE..634

HYDRAULIC DRIFT..636

CHARGING BLADE ACCUMULATOR WITH GAS..637

ADJUSTMENT OF CIRCLE GUIDE..638

73 DISASSEMBLY AND ASSEMBLY..639

BLADE ASSEMBLY..640

REMOVAL..640

INSTALLATION..640

CIRCLE ROTATION GEAR..642

REMOVAL..642

INSTALLATION..642

DISASSEMBLY..644

ASSEMBLY..646

REAR MOUNT RIPPER ASSEMBLY..648

REMOVAL..648

INSTALLATION..648

CIRCLE ROTATION GEAR ASSEMBLY..648

REMOVAL..648

INSTALLATION..648

DISASSEMBLY..650

ASSEMBLY..656

74 MAINTENANCE STANDARD..662

DRAWBAR AND LIFTER..663

BLADE..665

CIRCLE ROTATION GEAR..666

SCARIFIER(IF EQUIPPED)..668

REAR MOUNT RIPPER(IF EQUIPPED)..669

80 ELECTRIC AND ELECTRONIC SYSTEM..672

81 STRUCTURE AND FUNCTION..673

ELECTRICAL CIRCUIT DIAGRAM..674

CIRCUIT DIAGRAM OF CAB..679

ELECTRONIC VEHICLE MONITORING SYSTEM(EVMS)..681

ADJUSTING SPEEDOMETER MODULE(IF EQUIPPED)..689

82 TESTING AND ADJUSTING..690

TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE..691

CIRCUIT DIAGRAM..694

CONNECTOR POSITION FOR TROUBLESHOOTING..696

POSITION OF CONNECTOR(D TYPE)..702

POSITION OF CONNECTOR(P,Q TYPE)..708

CONNECTOR TERMINAL NUMBERS..718

PROCEDURE FOR TROUBLESHOOTING..723

CHECKS BEFORE TROUBLESHOOTING..724

METHOD OF USING TROUBLESHOOTING CHART..725

TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM(M1 TO M-18)(D TYPE)..727

M-1 WHEN STARTING SWITCH IS TURNED ON,MONITOR PANEL DISPLAY DOES NOT APPEAR…728

a) NONE OF MONITOR PANEL WORKS..728

b) PART OF MONITOR PANEL DOES NOT WORK..728

M-2 WHEN STARTING SWITCH IS TURNED ON,MONITOR PANEL DISPLAY DOES NOT GO OUT..728

M-3 WHEN STARTING SWITCH IS TURNED ON,(DO NOT START ENGINE),CHECK BEFORE STARTING ITEMS FLASH OR PREHEATING ITEM LIGHTS UP…729

a) COOLANT LEVEL..729

b) ENGINE OIL LEVEL..729

c) PREHEATER..730

M-4 WHEN STARTING SWITCH IS TURNED ON,(ENGINE STARTED),CHECK BEFORE STARTING ITEMS FLASH…731

a) ALTERNATOR SYSTEM..731

b) ENGINE OIL PRESSURE CIRCUIT..731

M-5 WHEN STARTING SWITCH IS TURNED ON,(DO NOT START ENGINE),CAUTION ITEMS FLASH..732

M-6 WHEN STARTING SWITCH IS ON(ENGINE STARTED),CAUTION ITEMS FLASH..733

a) ENGINE OIL PRESSURE..733

b) COOLANT LEVEL..733

c) COOLANT TEMPERATURE..734

d) BATTERY CHARGE..734

e) FINAL OIL TEMPERATURE..735

f) AIR PRESSURE..735

g) PARKING BRAKE..736

M-7 FUEL TANK IS NOT FULL BUT DISPLAY SHOWS FULL TANK..737

M-8 NO DISPLAY IS GIVEN FOR FUEL LEVEL..737

M-9 ENGINE COOLANT TEMPERATURE IS HIGH,BUT LOWEST LEVEL DISPLAYED..738

M-10 ENGINE COOLANT TEMPERATURE GAUGE GIVES NO DISPLAY..738

M-11 TURN SIGNAL LAMPS,HIGH BEAM LIGHT UP ABNORMALLY,OR DO NOT LIGHT UP..739

a) PILOT DISPLAY OF TURN SIGNAL LAMP(RIGHT)LIGHTS UP..739

b) PILOT DISPLAY OF TURN SIGNAL LAMP(LEFT)LIGHTS UP..739

c) PILOT DISPLAY OF TURN SIGNAL LAMP(RIGHT)DOES NOT LIGHT UP..739

d) PILOT DISPLAY OF TURN SIGNAL LAMP(LEFT)DOES NOT LIGHT UP..740

e) HIGHT BEAM PILOT LAMP DOES NOT LIGHT UP..740

f) HIGH BEAM PILOT LAMP DOES NOT GO OUT..740

M-12 SPEEDOMETER DISPLAY DOES NOT WORK NORMALLY..741

M-13 WHEN ENGINE IN STARTED,SERVICE METER DOES NOT MOVE,WHEN ENGINE IN STOPPED,SERVICE METER MOVES..742

a) SERVICE METER DOES NOT MOVE..742

b) SERVICE METER DOES NOT STOP MOVING..742

M-14 MONITOR PANEL LAMPS DO NOT LIGHT UP..743

a) NO LAMPS ON PANEL LIGHT UP..743

b) SOME LAMPS ON PANEL DO NOT LIGHT UP..743

M-15 CENTRAL WARNING LAMP DOES NOT GO OUT..744

a) MONITOR DISPLAYS NO ABNORMALITY,BUT CENTRAL WARNING LAMP LIGHTS UP INTERMITTENTLY..744

b) CENTRAL WARNING LAMP LIGHTS UP CONTINUOUSLY..744

M-16 CENTRAL WARNING BUZZER DOES NOT STOP..745

a) MONITOR DISPLAYS NO ABNORMALITY,BUT CENTRAL WARNING BUZZER SOUNDS INTERMITTENTLY..745

b) CENTRAL WARNING BUZZER SOUNDS CONTINUOUSLY..745

M-17 EMERGENCY ITEM OR NON-EMERGENCY ITEMS IS FLASHING,BUT WARNING LAMP DOES NOT FLASH..746

M-18 EMERGENCY ITEM IS FLASHING,BUT ALARM BUZZER DOES NOT SOUND..747

TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM(M1 TO M-22)(P,Q TYPE)..755

M-1 MONITOR PANEL PILOT LAMPS DO NOT LIGHT UP FOT 3 SECONDS WHEN STARTING SWITCH IS TURNED ON..756

a) NO LAMPS ON MONITOR PANEL(MONITOR MODULE)LIGHT UP..756

b) NO LAMPS ON MONITOR PANEL(SPEEDOMETER MODULE)LIGHT UP..756

c) SOME LAMPS ON MONITOR PANEL DO NOT LIGHT UP..756

M-2 WHEN STARTING SWITCH IS TURNED ON,ALL MONITOR PANEL LAMPS LIGHT UP BUT DO NOT GO OUT..756

M-3 WHEN STARTING SWITCH IS TURNED ON(WITH ENGINE STOPPED),CHECK ITEMS FLASH..758

a) RADIATOR WATER LEVEL FLASHES..758

b) ENGINE OIL LEVEL FLASHES..759

M-4 PREHEATING IS NOT BEING CARRIED OUT,BUT PREHEATING DISPLAY FLASHES..760

M-5 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED,CHECK ITEMS FLASH..761

a) ALTERNATOR SYSTEM..761

b) ENGINE OIL PRESSURE SYSTEM..762

M-6 WHEN STARTING SWITCH IS TURNED ON WITH ENGINE STOPPED CAUTION ITEMS FLASH..764

M-7 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED,CAUTION ITEMS FLASH..768

a) ENGINE OIL PRESSURE FLASHES..768

b) RADIATOR WATER LEVEL FLASHES..770

c) ENGINE WATER TEMPERATURE FLASHES..770

d) CHARGE FLASHES..771

e) FINAL DRIVE OIL TEMPERATURE FLASHES..772

f) AIR PRESSURE FLASHES..773

g) PARKING BRAKE FLASHES..774

M-8 FOR ONE SECOND AFTER STARTING SWITCH IS TURNED ON(ENGINE STOPPED),ALARM BUZZER DOES NOT SOUND.CAUTION ITEM LAMPS ARE FLASHING BUT ALARM BUZZER DOES NOT SOUND..775

M-9 THERE IS NO ABNORMALITY ON MONITOR DISPLAY,BUT ALARM BUZZER SOUNDS..775

M-10 FOR TWO SECONDS AFTER STARTING SWITCH IS TURNED ON(ENGINE STOPPED),WARNING LAMP DOES NOT LIGHT UP.CAUTION ITEM LAMPS ARE FLASHING BUT WARNING LAMP DOES NOT LIGHT UP…776

M-11 THERE IS NO ABNORMALITY ON MONITOR DISPLAY,BUT WARNING LAMP LIGHTS UP..776

M-12 MONITOR PANEL LIGHTING DOES NOT LIGHT UP..778

a) NO PANEL LIGHTING LIGHTS UP..778

b) PART OF PANEL LIGHTING DOES NOT LIGHT UP..778

M-13 SERVICE METER DOES NOT MOVE WHEN ENGINE IS STARTED;OR SERVICE METER MOVES WHEN ENGINE IS STOPPED.(FOR MACHINES WITH SPEEDOMETER)..779

a) SERVICE METER DOES NOT MOVE WHEN ENGINE IS STARTED..779

b) SERVICE METER MOVES WHEN ENGINE IS STOPPED..779

M-14 ENGINE WATER TEMPERATURE GAUGE SHOWS ABNORMALLY LOW TEMPERATURE..781

M-15 ENGINE WATER TEMPERATURE GAUGE SHOWS NO DISPLAY..781

M-16 FUEL GAUGE ALWAYS SHOWS FULL..782

M-17 NO DISPLAY IS GIVEN FOR FUEL LEVEL GAUGE..782

M-18 HIGH BEAM DOES NOT LIGHT UP..784

M-19 HIGH BEAM STAYS LIGHTED UP..784

M-20 TURN SIGNAL INDICATOR DOES NOT LIGHT UP..786

M-21 TURN SIGNAL INDICATOR STAYS LIGHTED UP..787

M-22 SPEED DISPLAY STAYS AT "0" AND DOES NOT MOVE..789

90 OTHERS..791

AIR CONDITIONER..792

Komatsu Motor Graders GD611A, GD611R, GD613A, GD615A, GD621A, GD622A, GD623A, GD661A, GD625A, GD663A, GD672A, GD621R, GD623R Repair Service Manuals