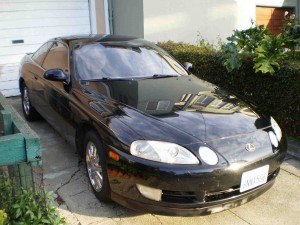

1992-2001 Lexus SC300, SC400 Workshop Repair & Service Manual (4,087 Pages, Searchable, Printable, Bookmarked, iPad-ready PDF)

Complete digital workshop service and repair manual written for the 1992-2001 Lexus SC300, SC400; Production model years: 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001. All styles covered (all models, and engines). It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices.

This QUALITY manual is 100% COMPLETE and INTACT, no MISSING/CORRUPT pages/sections to freak you out! Buy from responsible seller and get INSTANT DOWNLOAD now without wasting your hard-owned money on uncertainty or surprise; this manual is exactly as described.

PRODUCT DETAILS:

Total Pages: more than 4,087 pages

File Format: PDF (Windows & Mac & Linux)

Language: English

Delivery: instant download link displayed on checkout page & emailed to you after payment

Protection: DRM-free; without any restriction

Printable: Yes

This COMPLETE official full workshop service repair manual includes:

* Detailed sub-steps expand on repair procedure information

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Numbered instructions guide you through every repair procedure step by step.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

* Numbered table of contents easy to use so that you can find the information you need fast.

* This manual also makes it easy to diagnose and repair problems with your machines electrical system.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* COMPLETE, Absolutely No Missing Pages!

* Official Service INFORMATION You Can Count On!

* Customer Satisfaction GUARANTEED!

EXCERPT (1992-2001 Lexus SC300, SC400 Service/Repair Manual):

The 1 UZ–FE engine has 8–cylinders in a V–arrangement at a bank angle of 90°. From the front of the RH bank cylinders are numbered 2 – 4 – 6 – 8, and from the front of the LH bank cylinders are 1 – 3 – 5 – 7. The crankshaft is supported by 5 bearings inside the crankcase. These bearings are made of a copper and lead alloy. The crankshaft is integrated with 8 weights for balance. Oil holes are placed in the center of the crankshaft to supply oil to the connecting rods, bearing, pistons and other components. The ignition order is 1 – 8 – 4 – 3 – 6 – 5 – 7 – 2. The cylinder head is made of alminum alloy, with a cross flow type intake and exhaust layout and with pent–roof type combustion chambers. The spark plugs are located in the center of the combustion chambers. At the front and rear of the intake manifold, a water passage has been provided which connects the RH and LH cylinder heads. Exhaust and intake valves are equipped with irregular pitch springs made of special valve spring carbon steel which are capable of functioning at all engine speeds. The RH and LH intake camshaft are driven by a timing belt, and a gear on the intake camshaft engages with a gear on the exhaust camshaft to drive it. The cam journal is supported at 5 (intake) or 4 (exhaust) places between the valve lifters of each cylinder and on the front end of the cylinder head. Lubrication of the cam journals and gears is accomplished by oil being supplied through the oiler port in the center of the camshaft. Adjustment of the valve clearance is done by means of an outer shim type system, in which valve adjusting shims are located above the valve lifters. This permits replacement of the shims without removal of the camshafts. Pistons are made of high temperature–resistant aluminum alloy, and a depression is built into the piston head to prevent interference with the valves. Piston pins are the full–floating type, with the pins fastened to neither the piston boss nor the connecting rods. Instead, snap rings are fitted on both ends of the pins, preventing the pins from falling out.

The No.1 compression ring is made of steel and the No.2 compression ring is made of cast iron. The oil ring is made of a combination of steel and stainless steel. The outer diameter of each piston ring is slightly larger than the diameter of the piston and the flexibility of the rings allows them to hug the cylinder walls when they are mounted on the piston. Compression rings No.1 and No.2 work to prevent gas leakage from the cylinder and the oil ring works to scrape oil off the cylinder walls to prevent it from entering the combustion chambers. The cylinder block is made of aluminium alloy with a bank of 90°. Cast iron cylinders are installed inside the cylinder block. It has 8 cylinders which are approximately twice the length of the piston stroke.