Complete digital official shop manual contains service, maintenance, and troubleshooting information for the 1963-1995 Alfa Romeo 164, Alfetta, Alfetta GTV 6, AR 1750, AR 2000, Guilia GT, Giulietta 54-64, Milano, 75, Spider, Spider Duetto. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your vehicle like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail.

MAKE: Alfa Romeo

MODEL: ’91-’95 164, ’75-’79 Alfetta, ’81-’86 Alfetta GTV 6, ’69-’71 AR 1750, ’72-’74 AR 2000, ’63-’68 Guilia GT, Giulietta 54-64, ’86-’93 Milano/75, ’75-’81 Spider, ’82-’89 Spider, ’91-’94 Spider, Spider Duetto

YEAR: 1963, 1964, 1965, 1966, 1967, 1968, 1969, 1970, 1971, 1972, 1973, 1974, 1975, 1976, 1977, 1978, 1979, 1980, 1981, 1982, 1983, 1984, 1985, 1986, 1987, 1988, 1989, 1990, 1991, 1992, 1993, 1994, 1995

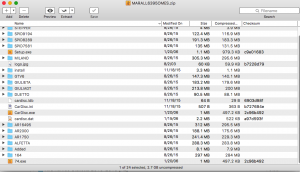

SIZE: 2.7 GB

EXCERPT:

ALFA ROMEO

3.0L V6

MANUFACTURER’S SUGGESTED SCHEDULED MAINTENANCE

The manufacturer recommends the belt be replaced every 50,000 miles.

REMOVAL & INSTALLATION

TIMING BELT

Removal

1. Disconnect negative battery cable. Raise and support vehicle. Remove right front wheel. Remove right front inner fenders. Disconnect throttle opening switch electrical connector. Remove throttle body cover.

2. Remove water pump, air conditioning, and power steering drive belts. Remove hydraulic belt tensioner.

Disconnect crankshaft position sensor connector, and remove sensor. Disconnect constant idle speed actuator electrical connector. Disconnect oil vapor separator hoses.

3. Disconnect accelerator cable. On models equipped with automatic transmission, disconnect kickdown cable. On S models, disconnect engine throttle sensor electrical connector. On all models, disconnect fuel vapor and cruise control hoses.

4. Disconnect fuel pressure regulator and power brake unit vacuum hoses. Disconnect ground strap from air intake box. Remove air intake box attaching screws and clamps, and remove air intake box.

5. Disconnect spark plug wires for cylinders No. 1, 2 and 3. Remove intake ducts and gaskets. Remove right valve cover and gasket. Disconnect spark plug wires for cylinders No. 4, 5 and 6. Remove left side valve cover and gasket.

6. Partially drain cooling system. Disconnect coolant hose from thermostat unit. Disconnect return hose from water pump. Disconnect coolant temperature switch and sensor electrical connectors. If equipped, disconnect oil cooling tubes from heat exchanger.

7. Remove timing belt covers. Remove spark plugs Rotate crankshaft so No. 1 cylinder is at TDC of compression stroke. Flywheel and transmission housing timing marks should align. See Fig. 1. Camshaft sprocket timing marks should align with bearing cap marks. See Fig. 2.

8. Lift belt tensioner arm from timing belt. Insert Holding Tool (1.820.053.00) or equivalent into hole on arm to lock in position. Loosen hydraulic belt tensioner retaining nuts. Push tensioner downward to limit of travel, and tighten upper retaining nut. Remove timing belt.

Fig. 1: Identifying Flywheel Timing Marks

Fig. 2: Identifying Camshaft Timing Marks

Installation

1. Position Adapter (1.825.007.000), or equivalent, and a dial indicator into No. 1 cylinder spark plug hole. See Fig. 2. Ensure camshaft and crankshaft timing marks align.

2. Install timing belt over crankshaft sprocket, left camshaft sprocket, right camshaft sprocket, and oil pump sprocket hydraulic belt tensioner pulley. See Fig. 3. Maintain tension on timing belt during installation.

…