Pages from SEBM023412 – 170-3 Series (QSK23) Diesel Engines Shop Manual

Complete workshop & service manual with electrical wiring diagrams for Komatsu 170 Series Engines (SA12V170-1, SA12V170E-2, S6D170-1, SA6D170-A-1, SA6D170-B-1, SA6D170E-3, SAA6D170E-3, SAA6D170E2-3, SAA6D170E-P910, SAA6D170E-P970). It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

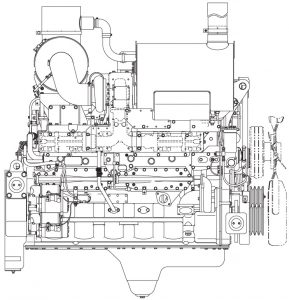

This Komatsu 170 Series Engines (SA12V170-1, SA12V170E-2, S6D170-1, SA6D170-A-1, SA6D170-B-1, SA6D170E-3, SAA6D170E-3, SAA6D170E2-3, SAA6D170E-P910, SAA6D170E-P970) service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

SEBD6161A16 – 6D170-1 Series Diesel Engine Shop Manual.pdf

SEBD61700104 – 8V170-1 Series Diesel Engine Shop Manual.pdf

SEBD61800104 – 12V170-1 Series Diesel Engine Shop Manual.pdf

SEBE61800105 – 12V170-1 Series Engine Shop Manual.pdf

SEBES6161000 – 6D170-1 Series Diesel Engine Shop Manual.pdf

SEBM008107 – 6D170-2 Series Diesel Engine Shop Manual.pdf

SEBM023407 – 170-3 Series Diesel Engine Shop Manual.pdf

SEBM023412 – 170-3 Series (QSK23) Diesel Engine Shop Manual.pdf

SEBM036601 – 12V170-2 Series Engine Shop Manual.pdf

SEN00190-13 – 170E-5 Series Engine Shop Manual.pdf

EXCERPT:

CONTENTSGENERAL ………………… 01-1

11 STRUCTURE AND FUNCTION………………… 11-1

12 TESTING AND ADJUSTING……………… 12-1

13 DISASSEMBLY AND ASSEMBLY………… 13-1

14 MAINTENANCE STANDARD ………… 14-1

15 REPAIR AND REPLACEMENT OF PARTS ………. 15-1

…

ADJUSTING INJECTOR SET LOAD

1. Remove the cover of the flywheel housing, then install barring device G1.

2. Remove the cylinder head cover.

3. Using barring device G1, rotate the crankshaft in the normal direction to set No. 1 cylinder at compression top dead center, and align pointer b with the [1.6TOP] line a on the crankshaft pulley.

★ Watch the movement of the rocker arm and check that the No. 1 cylinder is at the compression stroke. (If the rocker arms for both the intake and exhaust sides move only the amount of the valve clearance, the cylinder is at the compression stroke.)

★ The cylinder where at compression top is different from the cylinder where the injector is being adjusted, so check the table below when carrying out the operation.

★ Cylinder at compression top and cylinder for adjustment of injector:

…