Komatsu PC03-05-07-09-10-12-15-18-20-25-27-30-35-40-45-50-55 Hydraulic Excavator

Complete workshop & service manual with electrical wiring diagrams for Komatsu Hydraulic Excavator PC03-2, PC05-6, PC07-1, PC09-1, PC10-6, PC10-7, PC12R-8, PC15MR-1, PC15-2, PC15-3, PC15R-8, PC18MR-2, PC18MR-3, PC20-3, PC20MRX-1, PC20MR-2, PC20-6, PC20-7, PC20R-8, PC25-1, PC25R-8, PC27MRX-1, PC27MR-2, PC27MR-3, PC27R-8, PC30MRX-1, PC30MR-2, PC30-3, PC30MR-3, PC30-6, PC30-7, PC30R-8, PC35MRX-1, PC35MR-2, PC35MR-3, PC35R-8, PC40MRX-1, PC40MR-2, PC40-6, PC40-7, PC40R-8, PC45-1, PC45MRX-1, PC45MR-3, PC45R-8, PC50UU-1, PC50MR-2, PC50UU-2, PC55MR-3. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Komatsu Hydraulic Excavator PC03-2, PC05-6, PC07-1, PC09-1, PC10-6, PC10-7, PC12R-8, PC15MR-1, PC15-2, PC15-3, PC15R-8, PC18MR-2, PC18MR-3, PC20-3, PC20MRX-1, PC20MR-2, PC20-6, PC20-7, PC20R-8, PC25-1, PC25R-8, PC27MRX-1, PC27MR-2, PC27MR-3, PC27R-8, PC30MRX-1, PC30MR-2, PC30-3, PC30MR-3, PC30-6, PC30-7, PC30R-8, PC35MRX-1, PC35MR-2, PC35MR-3, PC35R-8, PC40MRX-1, PC40MR-2, PC40-6, PC40-7, PC40R-8, PC45-1, PC45MRX-1, PC45MR-3, PC45R-8, PC50UU-1, PC50MR-2, PC50UU-2, PC55MR-3 service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

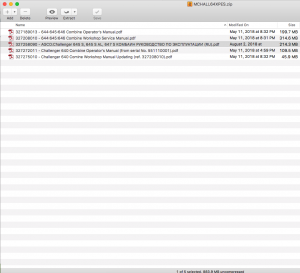

FILELIST (1.57 GB PDF):

EEPB000800 – Hydraulic Excavator PC05-6F Parts Book.pdf

SEAM020MB600 – Hydraulic Excavator PC05-6, PC10-6, PC15-2 Operation & Maintenance Manual.pdf

SEAM020P0700 – Hydraulic Excavator PC20-7 Operation & Maintenance Manual.pdf

SEAM020U0100 – Hydraulic Excavator PC50UU-1 Operation & Maintenance Manual.pdf

SEAM020U0101 – Hydraulic Excavator PC50UU-1 Operation & Maintenance Manual.pdf

SEAM005500 – Hydraulic Excavator PC50UU-2 Operation & Maintenance Manual.pdf

SEAM005503T – Hydraulic Excavator PC50UU-2 Operation & Maintenance Manual.pdf

SEAM006600 – Hydraulic Excavator PC25-1, PC30-7, PC40-7, PC45-1 Operation & Maintenance Manual.pdf

SEAM009502T – Hydraulic Excavator PC40-7 Operation & Maintenance Manual.pdf

SEAM015102T – Hydraulic Excavator PC12R-8, PC15R-8 Operation & Maintenance Manual.pdf

SEAM015203T – Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8 Operation & Maintenance Manual.pdf

SEAM015301 – Hydraulic Excavator PC30R-8, PC35R-8, PC40R-8, PC45R-8 Operation & Maintenance Manual.pdf

SEAM015304T – Hydraulic Excavator PC35R-8, PC45R-8 Operation & Maintenance Manual.pdf

SEAM034800 – Hydraulic Excavator PC28UU-2 Operation & Maintenance Manual.pdf

SEAM035202T – Hydraulic Excavator PC20MRx-1Operation & Maintenance Manual.pdf

SEAM035203 – Hydraulic Excavator PC20MRx-1 Operation & Maintenance Manual.pdf

SEAM035305T – Hydraulic Excavator PC27MR-x1, PC30MR-x1, PC35MR-x1 Operation & Maintenance Manual.pdf

SEAM040601 – Hydraulic Excavator PC03-2 Operation & Maintenance Manual.pdf

SEAM043000 – Hydraulic Excavator PC40MRx-1, PC45MRx-1 Operation & Maintenance Manual.pdf

SEAM043006T – Hydraulic Excavator PC40MRx-1, PC45MRx-1 Operation & Maintenance Manual.pdf

SEAM044501T – Hydraulic Excavator GALEO PC09-1 Operation & Maintenance Manual.pdf

SEAM044502 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual.pdf

SEAM044900T – Hydraulic Excavator PC15MRX-1 Operation & Maintenance Manual.pdf

SEAM055301T – Hydraulic Excavator GALEO PC40MR-2, PC50MR-2 Operation & Maintenance Manual.pdf

SEAM060100T – Hydraulic Excavator GALEO PC35MR-2 Operation & Maintenance Manual.pdf

SEBM020M0604 – Hydraulic Excavator PC05-6, PC07-1, PC10-6, PC15-2 Shop Manual.pdf

SEBM020P0703 – Hydraulic Excavator PC10-7, PC15-3, PC20-7 Shop Manual.pdf

SEBM020R0604 – Hydraulic Excavator PC20-6, PC30-6, PC40-6 Shop Manual.pdf

SEBM020S0707 – Hydraulic Excavator PC25-1, PC30-7, PC40-7, PC45-1 Shop Manual.pdf

SEBM020U0104 – Hydraulic Excavator PC50UU-1 Shop Manual.pdf

SEBM0225C01 – Hydraulic Excavator PC20-3, PC30-3 Shop Manual.pdf

SEBM000906 – Hydraulic Excavator PC50UU-2 Shop Manual.pdf

SEBM010801 – Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8 Shop Manual.pdf

SEBM012603 – Hydraulic Excavator PC30R-8, PC35R-8, PC40R-8, PC45R-8 Shop Manual.pdf

SEBM012604 – Hydraulic Excavator PC30R-8, PC35R-8, PC40R-8, PC45R-8 Shop Manual.pdf

SEBM013103 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual.pdf

SEBM016602 – Hydraulic Excavator PC20MRX-1 Shop Manual.pdf

SEBM016808 – Hydraulic PC27MRX-1, PC30MRX-1, PC35MRX-1, PC40MRX-1, PC45MRX-1 Shop Manual.pdf

SEBM019002 – Hydraulic Excavator PC15MR-1 Shop Manual.pdf

SEBM025000 – Hydraulic Excavator PC03-2 Shop Manual.pdf

SEBM026105 – Hydraulic Excavator PC09-1 Shop Manual.pdf

SEBM032411 – Hydraulic Excavator PC27MR-2, PC30MR-2, PC35MR-2, PC40MR-2, PC50MR-2 Shop Manual.pdf

SEBM037001 – Hydraulic Excavator PC20MR-2 Shop Manual.pdf

SEBM038404 – Hydraulic Excavator PC18MR-2 Shop Manual.pdf

SEN04063-07 – Hydraulic Excavator PC27MR-3, PC30MR-3, PC35MR-3 Shop Manual.pdf

SEN04306-04 – Hydraulic Excavator PC18MR-3 Shop Manual.pdf

SEN04597-06 – Hydraulic Excavator PC45MR-3, PC55MR-3 Shop Manual.pdf

TEN00052-01 – Hydraulic Excavator GALEO PC18MR-2 Operation & Maintenance Manual.pdf

TEN00054-03 – Hydraulic Excavator GALEO PC40MR-2, PC50MR-2 Operation & Maintenance Manual.pdf

TEN00062-04 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual.pdf

TEN00099-01 – Hydraulic Excavator PC27MR-2, PC35MR-2 Operation & Maintenance Manual.pdf

TEN00101-02 – Hydraulic Excavator GALEO PC20MR-2 Operation & Maintenance Manual.pdf

TEN00115-00 – Hydraulic Excavator GALEO PC27ME-2, PC35MR-2 Operation & Maintenance Manual.pdf

TEN00115-01 – Hydraulic Excavator GALEO PC27MR-2, PC35MR-2 Operation & Maintenance Manual.pdf

TEN00193-00 – Hydraulic Excavator GALEO PC40MR-2, PC50MR-2 Operation & Maintenance Manual.pdf

TEN00194-00 – Hydraulic Excavator GALEO PC27MR-2, PC35MR-2 Operation & Maintenance Manual.pdf

TEN00284-03 – Hydraulic Excavator GALEO PC27MR-3, PC35MR-3 Operation & Maintenance Manual.pdf

TEN00292-03 – Hydraulic Excavator PC18MR-3 Operation & Maintenance Manual.pdf

TEN00306-03 – Hydraulic Excavator PC45MR-3, PC55MR-3 Operation & Maintenance Manual.pdf

TEN00378-03 – Hydraulic Excavator PC27MR-3, PC35MR-3 Operation & Maintenance Manual.pdf

TEN00390-03 – Hydraulic Excavator PC45MR-3, PC55MR-3 Operation & Maintenance Manual.pdf

TEN00507-01 – Hydraulic Excavator PC27MR-3, PC35MR-3 Operation & Maintenance Manual.pdf

TEN00508-01 – Hydraulic Excavator PC45MR-3, PC55MR-3 Operation & Maintenance Manual.pdf

TEN00514-01 – Hydraulic Excavator PC18MR-3 Operation & Maintenance Manual.pdf

TEN00549-00 – Hydraulic Excavator PC18MR-3 Operation & Maintenance Manual.pdf

TEN00552-01 – Hydraulic Excavator PC27MR-3, PC35MR-3 Operation & Maintenance Manual.pdf

TEN00555-00 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual.pdf

WEAM000101 – Hydraulic Excavator PC20R-8, PC27R-8 Operation & Maintenance Manual.pdf

WEAM002702 – Hydraulic Excavator PC12R-8, PC12R-8 HS, PC15R-8, PC15R-8 HS Operation & Maintenance Manual.pdf

WEAM003000 – Hydraulic Excavator PC15R-8 Operation & Maintenance Manual.pdf

WEAM003001 – Hydraulic Excavator PC15R-8 Deluxe Operation & Maintenance Manual.pdf

WEAM003100 – Hydraulic Excavator PC27R-8 Operation & Maintenance Manual.pdf

WEAM003102 – Hydraulic Excavator PC27R-8 Deluxe Operation & Maintenance Manual.pdf

WEAM003200 – Hydraulic Excavator PC35R-8, PC45R-8 Operation & Maintenance Manual.pdf

WEAM003202 – Hydraulic Excavator PC35R-8, PC45R-8 Deluxe Operation & Maintenance Manual.pdf

WEAM006600 – Hydraulic Excavator PC30MR-2, PC35MR-2 Operation & Maintenance Manual.pdf

WEAM007000 – Hydraulic Excavator GALEO PC20MR-2 Operation & Maintenance Manual.pdf

WEAM007700 – Hydraulic Excavator GALEO PC14R-2 Operation & Maintenance Manual.pdf

WEAM007800 – Hydraulic Excavator GALEO PC16R-2 Operation & Maintenance Manual.pdf

WEBM000100 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual.pdf

WEBM000101 – Hydraulic Excavator PC12R-8, PC15R-8 Shop Manual.pdf

WEBM000200 – Hydraulic Excavator PC20R-8, PC27R-8 Shop Manual.pdf

WEBM000201 – Hydraulic Excavator PC20R-8, PC27R-8 Shop Manual.pdf

WEBM002800 – Hydraulic Excavator PC15R-8 Shop Manual.pdf

WEBM002900 – Hydraulic Excavator PC27R-8 Shop Manual.pdf

WEBM003000 – Hydraulic Excavator PC35R-8, PC45R-8 Shop Manual.pdf

WEBM003800 – Hydraulic Excavator PC27R-8 Deluxe Shop Manual.pdf

WEBM003900 – Hydraulic Excavator PC35R-8, PC45R-8 Deluxe Shop Manual.pdf

EXCERPT:

ADJUSTMENT OF VALVE CLEARANCE

• Adjust the clearance between valve and rockers to the following values:

With engine cold – Suction valves 0.20 – Exhaust valve 0.20

1 – Remove the valve cover.

2 – Rotate the drive shaft in the normal direction of rotation, until the No. 1 cylinder is in the top dead centre in a compression stroke corresponding to the alignment between the reference mark on the casing (1) and the mark (2) on the pulley.

* If the cylinder is in a compression stroke, the valves do not move when the drive shaft is rotated slightly. If the valves do move, rotate the drive shaft by one turn and realign the reference marks (1) and (2).

3 – Loosen the lock nut (3) and unscrew the adjustment screw (6) by approximately 1 turn.

* Check that the valve cap (5) is lying flat on the valve stem and that there is no lopsided wear.

1 – If the valve caps (5) are damaged, replace them with new ones.

2 – Make sure that the valve caps fit perfectly and are lying flat on the valve stem.”

4 – Insert the feeler gauge A1 between the rocker (4) and the valve cap (5).

Rotate the adjusting screw (6) until it rubs against the feeler gauge A1.

Secure this position with the nut (3).

Lock nut: 25.5±2.5 Nm

* After locking the nut (3), check the valve clearance again.

5 – After adjusting the No. 1 cylinder, rotate the drive shaft 240° each time and adjust the valve clearance of the other cylinders according to the ignition sequence.

* Ignition sequence: 1 – 3 – 2.

• Assembly of the valve cover

1 – Check the condition of the gasket (7) of the valve cover (8), and the 0-rings (9). Thoroughly clean the contact surface on the cylinder heads.

2 – Replace the valve cover (8) and mount the 0-rings

(9) and the lock nuts (10).

Lock nuts for cover: 25±3 Nm

����…

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD – OPERATION FOR EACH FUNCTION AND VALVE

L.H., R.H. TRAVEL JUNCTION CIRCUIT PC27MR, 30MR-2

1. When traveling in a straight line

FUNCTION

ï To compensate for any difference in the oil flow in the left and right travel circuits when traveling in a straight line, the junction circuit opens when the left and right travel spools are operated.

ï In this way, the flow of oil to the left and right travel motors is almost the same when traveling in a straight line, so there is no travel deviation.

ï When steering the machine, the difference in the load pressure returns the reducing valve of the travel valve on the inside of the turn and the opening of the notch in the travel junction valve spool becomes smaller, so the machine can be steered.

OPERATION

ï When left and right travel spools (1) are operated, the pump discharge flows from pump circuit PP and circuits PA to actuator circuits B.

ï When traveling in a straight line, to make actuator circuits PA equal, left and right reducing valves (2) are pushed to the right by the same amount, and notch a and the travel junction circuit are opened.

ï In this way, the left and right travel actuator circuits are interconnected by the travel junction circuit, so if any difference occurs in the flow of oil to the left and right travel motors, the compensation is carried out to prevent any deviation in travel.

2. Steering when traveling

OPERATION

• When traveling in a straight line, if left travel spool (L. H. 1) is returned to the neutral position and the steering is operated, a difference (R. H. B > L. H. B) is generated in the load pressure of left and right travel actuator circuits PA, and LS pressure PLS becomes the same pressure as R.

H. B.

• As a result, flow control valve (3) on the left travel side is pushed to the left by LS circuit PLS.

Because of this, the opening of the left notch a is made smaller, so it becomes possible to operate the steering when traveling.

• Damper b is provided in the circuit to damper any excessive characteristics in the opening or closing of the travel junction circuit if the spool is operated suddenly.

…