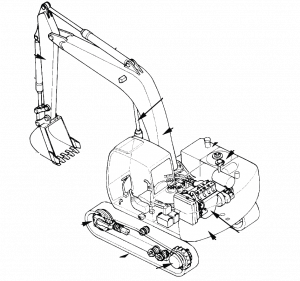

Complete workshop & service manual with electrical wiring diagrams for Hitachi Excavator EX80-5. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Hitachi Excavator EX80-5 service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

FILELIST:

EM1C1NA21 – Hitachi Excavator EX80-5 Operator’s Manual.pdf

TO152ENA – Hitachi Excavator EX80-5 Technical Manual (Operational Principle).pdf

TT152ENA – Hitachi Excavator EX80-5 Technical Manual (Troubleshooting).pdf

TT152ENACIR – Hitachi Excavator EX80-5 Circuit Diagrams.pdf

W152ENA – Hitachi Excavator EX80-5 Workshop Manual.pdf

T152ENA00CIR (attach to TT152E-NA) – Hitachi Excavator EX80-5 Electrical Diagram & Harness

W152ENA00 – Hitachi Excavator EX80-5 Workshop Manual

1 General Information.pdf

2 Upperstructure.pdf

3 Undercarriage.pdf

4 Front Attachment.pdf

5 Engine and Accessory.pdf

Index.pdf

EXCERPT:

SECTION 4

FRONT ATTACHMENT

—CONTENTS—

Group 1 Front Attachment

Remove and Install

Front Attachment ……..W4-1-1

Maintenance Standard……W4-1-8

Standard Dimensions for Arm and Bucket

Connection …….W4-1-11

Group 2 Cylinder

Remove and Install Cylinder …..W4-2-1

Disassemble Cylinder …..W4-2-11

Assemble Cylinder ……W4-2-26

Maintenance Standard……..W4-2-32

…

Remove Bucket Cylinder

CAUTION: Prevent personal injury. Metal

debris may fly off when a hammer is used to remove pins.

1. Lay wooden blocks under the arm tip and in the clearance between arm (2) top surface and bucket cylinder (1).

IMPORTANT: Before removing pin (6), secure links with wires to prevent links from falling.

2. Remove ring (5) and stopper pin (3) from the link to remove pin (6). Remove thrust plates (4) from the mating faces between the links and the bucket

cylinder rod.

3. Bind cylinder rod (7) with wire so that cylinder rod (7) is not extended.

…