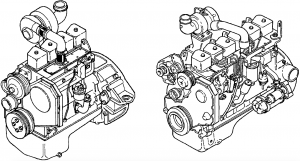

Pages from CEBM614SH0 – KDC 614 Series Engine (1991 Series) Shop Manual

Complete workshop & service manual with electrical wiring diagrams for Komatsu KDC 410 & KDC 610 & KDC 614 Series Engine. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Komatsu KDC 410 & KDC 610 & KDC 614 Series Engine service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

FILELIST:

CEBM610SH0 – KDC 410 & KDC 610 Series Engine (1991 Series) Shop Manual.pdf

CEBM610TR0 – KDC 410 & KDC 610 Series Engine (1991 Series) Troubleshooting & Repair Manual.pdf

CEBM614SH0 – KDC 614 Series Engine (1991 Series) Shop Manual.pdf

CEBM614TR1 – KDC 614 Series Engine (1991 Series) Troubleshooting & Repair Manual.pdf

EXCERPT:

TABLE OF CONTENTS

Introduction . . . 1

Engine Identification . . . . E

Engine Disassembly and Assembly – Group 00 . . . . . . . 0

Cylinder Block – Group 01 . . . . 1

Cylinder Head – Group 02 . . . . 2

Rocker Levers – Group 03 . . . . 3

Cam Followers – Group 04 . . . . 4

Fuel System – Group 05 . . . . 5

Injectors and Fuel Lines – Group 06 . . . . . 6

Lubricating Oil System – Group 07 . . . . . . 7

Cooling System – Group 08 . . . . . . . . . 8

Drive Units – Group 09 . . . . . 9

Air Intake System – Group 10 . . . . . . . . 10

Exhaust System – Group 11 . . . . . . . . . 11

Air Equipment – Group 12 . . . 12

Electrical Equipment – Group 13 . . . . . . 13

Engine Testing – Group 14 . . . 14

Instruments and Controls – Group 15 . . . . . 15

Mounting Adaptations – Group 16 . . . . . 16

Specifications and Torque Values – Group 18 . . . . . . . . . 18

Service Literature . . . . . . L

Index . . . ..X

…

Viscous Vibration Damper – Cleaning

Warning: When using a steam cleaner, wear protective clothing and safety glasses or a face shield. Hot steam will cause serious personal injury.

Clean the vibration damper with a solvent cleaner or steam clean. Dry with compressed air.

Viscous Vibration Damper – Inspection

Check the mounting web for cracks. Check the housing for dents or raised surfaces. Replace the vibration damper if any of these defects are identified.

…