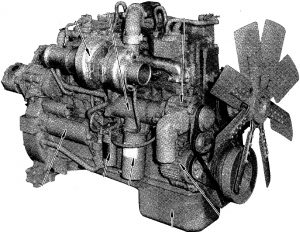

Complete workshop & service manual with electrical wiring diagrams for Komatsu TNV, N-855, EG Series Diesel Engines. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Komatsu TNV, N-855, EG Series Diesel Engines service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

WEBMTNV000 – TNV Series Diesel Engine (3D82AE_3D84E_3D88E_4D88E_4D98E_4D106_S4D84E_S4D98E_S4D106) Shop Manual.pdf

SEBM06500A02 – EG Series Engine Generators Shop Manual.pdf

SEBE6710A03 – Komatsu-N-855 Series Diesel Engine Shop Manual.pdf

SEBDCOMP009 – Komatsu Component of Engine Shop Manual.pdf

EXCERPT:

TABLE OF CONTENTS

01 GENERAL …… 01-1

02 STRUCTURE AND FUNCTION ……. 02-1

03 CHECK … 03-1

04 TROUBLESHOOTING .. 04-1

05 ASSEMBLY … 05-1

…

PERIODIC INSPECTION

As even a healthy man receives periodic examinations to maintain his health and to discover a disease in an early stage, so an engine generator requires periodic inspections to maintain its performance and to discover a trouble in an early stage. While the periodic inspection timings are specified in this manual and the instruction manual, it is important to conduct periodic inspections regardless of the inspection and servicing timings if it was recognized as necessary in view of the operating conditions of the machine or its activity rate, the daily inspection, etc.

Described in this chapter are the cautions when inspecting the generator and the handling of the engine cooling water, fuel, and oil. Table 3.1 shows the inspection and servicing list for your reference.

1. AC GENERATOR

The generator, which is prone to be damaged by moisture, oil, dust, etc., must always be kept dry and clean. To clean the generator, a dry cloth should be used instead of a cloth dampened with water or oil. When using compressed air, use dry air, and clean the machine interior beforehand. (We recommend to use an electric vacuum cleaner.)

During the daily inspection check abnormal noise generation from the generator, odor, abnormal vibration, etc. by using a screwdriver or a rod. Also check by using a torque wrench at least once every six months that the engine coupling, which is an important part, is tightened to the specified torque.

…