INSTANT DOWNLOAD (add to cart)

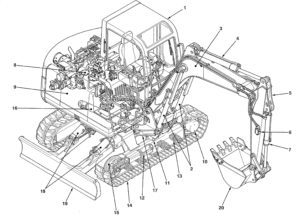

Complete workshop & service manual with electrical wiring diagrams for Takeuchi Compact Excavator TB070, TB070W. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Takeuchi Compact Excavator TB070, TB070W service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

950+ pages, bookmarked, Searchable, Printable, high quality PDF

Takeuchi Compact Excavator TB070W Workshop Manual; 488 pages; Serial Number TB070W: 17n00004~.

Takeuchi Compact Excavator TB070 Workshop Manual; 456 pages; Serial Number TB070: 1703004~.

EXCERPT:

CONTROL VALVE – HYDRAULIC UNITS

Slew Flow Control Function

This function switches the quantity of hydraulic oil flowing to the slew motor to change the slewing speed between normal and slow. It also keeps the flow to the motor steady even when the supply pressure changes during slow speed slewing.

1. Normal speed mode

When there is no pilot pressure at port FC, spool (1), push rod (2) and piston (3) are positioned at the left side by spring (4). In addition, pre-choke pressure Pl is led to the left side of spool (1) through pilot hole (5) and post-choke pressure P2 is led to the right side of spool (1) through pilot hole (6). At this time, all the oil supplied from port P3 flows to the slew motor.

2. Slow speed mode

When the pilot pressure reaches port FC, piston (3) moves to the right side, push rod (2) and spool (1) also move, and the difference between pre-choke pressure Pl and post-choke pressure P2 at spool (1) works to maintain a constant pressure (PC). Part of the hydraulic oil supplied from port P3 passes through the control orifice (7) and flows to the slew motor, and the remaining oil flows to tank port T2. The pressure at port P3 (PS) at this time increases, and when the flow increases, the difference in pressure between Pl and P2 increases, so spool (1) moves to the right side, the control orifice (7) is choked, the pressure difference [Pl – P2] is kept at PC, and the flow to the slew motor does not increase.

Inversely, when the pressure (PS) at port P3 decreases, the difference in pressure between Pl and P2 decreases, so spool (1) is moved to the left side by spring (4) until the pressure difference reaches PC and orifice (7) opens, so the flow to the slew motor does not decrease.

In this way, only a specific quantity of the oil supplied flows to the slew motor even when the supply pressure changes, the remaining being release to tank port T2.

This makes it possible to slew in the slow speed mode with a slow flow.

…