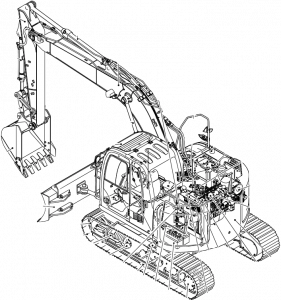

Complete workshop & service manual with electrical wiring diagrams for New Holland/Kobelco E265B, E265BLC, E305B. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

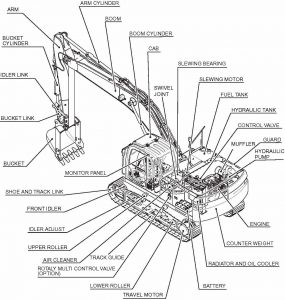

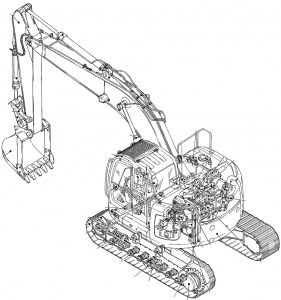

This New Holland/Kobelco E265B, E265BLC, E305B Hydraulic Excavator service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

FILELIST:

604.13.673 – New Holland_Kobelco E265B, E305B Tier 3 Hydraulic Excavator Worksop Manual.pdf

87495895A – E265B Crawler Excavators Service Repair Manual.pdf

87731199 – E265B, E265BLC Hydraulic Excavators Shop Manual.pdf

87731200 – E265B, E265BLC (HS Engine) Hydraulic Excavators Shop Manual.pdf

87731201 – E265B, E265BLC Hydraulic Excavators Shop Manual.pdf

87731202 – E265B, E265BLC (HS Engine) Hydraulic Excavators Shop Manual.pdf

87746510A – New Holland Kobelco E265B, E305B Hydraulic Excavator Worksop Manual.pdf

87746510A – New Holland_Kobelco E265B, E305B Hydraulic Excavator Worksop Manual.pdf

Section 3 Undercarriage E265-E305 Tier 3 Shop Manual.pdf

EXCERPT:

AIR CONDITIONER SYSTEM

DISASSEMBLY AND ASSEMBLY OF UNIT

1. Removing inner air filter

Slide the inner air filter (1) leftward and remove it from the unit (2).

2. Removing selector box

Remove 6 plus screws (3), remove connector (4) connected to the mode actuator (5) on mode selector box (6), and separate the mode selector box from the unit (2).

3. Removing main harness

Pull out 3 harness clamps (7) from the unit (2), and disconnect all connected connectors and remove harness (8) on the body from the unit (2).

4. Removing upper unit case

1) Remove air MIX rod (9) and air MIX rod sub (10) from air MIX lever (11).

2) Remove 12 plus screws (12) which are used to install the upper and lower unit casings (2a).

Pull out the upper unit casing (2b) upward giving attention to the thermistor harness so as not to be caught by the casing.

5. Replacing blower controller

1) Remove 2 plus screws (14) and remove the blower controller (15) from the upper unit casing (2b).

2) Install new blower controller by the reverse procedure of removal.

* Do not disassemble the blower controller.

6. Removing heater core

…