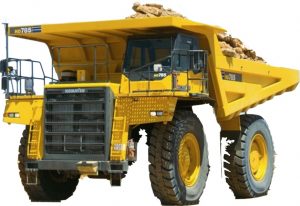

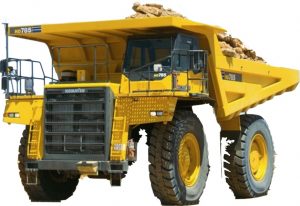

Komatsu HD325-405-465-605-785-985

Complete workshop & service manual with electrical wiring diagrams for Komatsu Dump Truck HD325-5, HD325-6, HD325-7, HD325-7R, HD405-6, HD405-7, HD405-7R, HD465-2, HD465-3, HD465-5, HD465-7, HD465-7E0, HD605-5, HD605-7, HD605-7E0, HD785-3, HD785-5, HD785-5LC, HD785-7, HD985-3, HD985-5. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

These Komatsu Dump Truck HD325-5, HD325-6, HD325-7, HD325-7R, HD405-6, HD405-7, HD405-7R, HD465-2, HD465-3, HD465-5, HD465-7, HD465-7E0, HD605-5, HD605-7, HD605-7E0, HD785-3, HD785-5, HD785-5LC, HD785-7, HD985-3, HD985-5 service & repair manuals (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) are divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

FILELIST (2.38 GB PDF):

CEAM006003 – Dump Truck HD785-5LC Operation & Maintenance Manual.pdf

CEAM014100 – Dump Truck HD785-5LC Operation & Maintenance Manual.pdf

CEAM018608 – Dump Truck HD785-7 Operation & Maintenance Manual.pdf

CEAW004806 – Dump Truck HD785-7 Field Assembly Manual.pdf

CEBM006103 – Dump Truck HD785-5LC Shop Manual.pdf

CEBM013801 – Dump Truck HD785-5LC Shop Manual.pdf

CEBM019012 – Dump Truck HD785-7 Shop Manual.pdf

EEAM029201 – Dump Truck HD325-7, HD405-7 Operation & Maintenance Manual.pdf

EPAM025104 – Camião Basculante HD325-7, HD405-7 Manual de Operação e Manutenção (PT).pdf

GEN00010-01 – Dump Truck HD465-7, HD605-7 Field Assembly Instruction.pdf

GEN00020-00 – Dump Truck HD325-6, HD405-6 Field Assembly Manual.pdf

GEN00026-00 – Dump Truck HD465-5, HD605-5 Field Assembly Instruction.pdf

GEN00027-03 – Dump Truck HD785-5 Field Assembly Instruction.pdf

GEN00045-05 – Dump Truck HD325-7, HD405-7 Field Assembly Manual.pdf

GEN00046-04 – Dump Truck HD465-7E0, HD605-7E0 Field Assembly Instruction.pdf

GEN00058-08 – Dump Truck HD785-7 Field Assembly Instruction.pdf

GEN00084-00 – Dump Truck GALEO HD325-7R, HD405-7R Field Assembly Instruction.pdf

GEN00119-01 – Dump Truck HD785-7 Field Assembly Instruction.pdf

SEAM566D01 – Dump Truck HD320-3, HD325-3 Operation & Maintenance Manual.pdf

SEAM0569S300 – Dump Truck HD465-3 Operation & Maintenance Manual.pdf

SEAM0569S301 – Dump Truck HD465-3 Operation & Maintenance Manual.pdf

SEAM0569S303 – Dump Truck HD465-3 Operation & Maintenance Manual.pdf

SEAM000802 – Dump Truck HD325-6 Operation & Maintenance Manual.pdf

SEAM000803 – Dump Truck HD325-6 Operation & Maintenance Manual.pdf

SEAM000805 – Dump Truck HD325-6 Operation & Maintenance Manual.pdf

SEAM000806 – Dump Truck HD325-6 Operation & Maintenance Manual.pdf

SEAM000807 – Dump Truck HD325-6 Operation & Maintenance Manual.pdf

SEAM000808 – Dump Truck HD325-6Operation & Maintenance Manual.pdf

SEAM000817T – Dump Truck HD325-6, HD405-6 Operation & Maintenance Manual.pdf

SEAM000819T – Dump Truck HD325-6, HD405-6 Operation & Maintenance Manual.pdf

SEAM003601 – Dump Truck HD785-3 Operation & Maintenance Manual.pdf

SEAM020406T – Dump Truck HD785-5 Operation & Maintenance Manual.pdf

SEAM05610302 – Dump Truck HD785-3 Operation & Maintenance Manual.pdf

SEAM05660501 – Dump Truck HD325-5 Operation & Maintenance Manual.pdf

SEAM05660505 – Dump Truck HD325-5 Operation & Maintenance Manual.pdf

SEAM05690500 – Dump Truck HD465-5 Operation & Maintenance Manual.pdf

SEAM05690508 – Dump Truck HD465-5, HD605-5 Operation & Maintenance Manual.pdf

SEAM05690513T – Dump Truck HD465-5, HD605-5 Operation & Maintenance Manual.pdf

SEAMW00500 – Dump Truck HD325-6 Operation & Maintenance Manual.pdf

SEBM0569C02 – Mechanical Truck HD465-2 Shop Manual.pdf

SEBM0569S308 – Dump Truck HD465-3 Shop Manual.pdf

SEBM000704 – Dump Truck HD325-6, HD405-6 Shop Manual.pdf

SEBM013917 – Dump Truck HD785-5, HD985-5 Shop Manual.pdf

SEBM015115 – Dump Truck HD325-6, HD405-6 Shop Manual.pdf

SEBM015209 – Dump Truck HD465-5, HD605-5 Shop Manual.pdf

SEBM027616 – Dump Truck HD465-7, HD605-7 Shop Manual.pdf

SEBM05610311 – Dump Truck HD785-3, HD985-3 Shop Manual.pdf

SEBM05660510 – Dump Truck HD325-5 Shop Manual.pdf

SEBM05690507 – Dump Truck HD465-5 Shop Manual.pdf

SEBMW00401 – Dump Truck HD325-6, HD405-6, HD465-5, HD605-5, HD785-5 Shop Manual.pdf

SEN00486-13 – Dump Truck HD325-7, HD405-7 Shop Manual.pdf

SEN00486-14 – Dump Truck HD325-7, HD405-7 Shop Manual.pdf

SEN01081-18 – Dump Truck HD465-7E0, HD605-7E0 Shop Manual.pdf

SEN01274-23 – Dump Truck HD785-7 Shop Manual.pdf

SEN02373-08 – Dump Truck HD325-7R, HD405-7R Shop Manual.pdf

SEN05900-01 – Dump Truck HD785-7 Shop Manual.pdf

TEN00017-05 – Dump Truck GALEO HD465-7, HD605-7 Operation & Maintenance Manual.pdf

TEN00041-05 – Dump Truck HD325-6, HD405-6 Operation & Maintenance Manual.pdf

TEN00042-05 – Dump Truck HD785-5 Operation & Maintenance Manual.pdf

TEN00137-09 – Dump Truck HD325-7, HD405-7 Operation & Maintenance Manual.pdf

TEN00138-08 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual.pdf

TEN00164-08 – Dump Truck HD785-7 Operation & Maintenance Manual.pdf

TEN00271-03 – Dump Truck HD465-7, HD605-7 Operation & Maintenance Manual.pdf

TEN00331-00 – Dump Truck HD325-7, HD405-7 Operation & Maintenance Manual.pdf

TEN00332-00 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual.pdf

TEN00348-02 – Dump Truck HD325-7, HD405-7 Operation & Maintenance Manual.pdf

TEN00370-03 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual.pdf

TEN00371-03 – Dump Truck HD875-7 Operation & Maintenance Manual.pdf

TEN00425-07 – Dump Truck HD325-7, HD405-7 Operation & Maintenance Manual.pdf

TEN00439-07 – Dump Truck HD465-7E0, HD605-7E0 Operation & Maintenance Manual.pdf

TEN00440-08 – Dump Truck HD785-7 Operation & Maintenance Manual.pdf

TEN00598-02 – Dump Truck HD875-7 Operation & Maintenance Manual.pdf

EXCERPT:

Removal and installation of fuel injector assembly

Removal

Stop the machine on a level ground, set the parking brake switch in the “PARK” position, and lock the tires with chocks.

Raise the body and fix it with the lock pin. k Disconnect the cable from the negative (–) terminal of the battery.

Remove the fuel injector assembly. For details, see “Removal and installation of cylinder head assembly”.

Do not drain the coolant.

Note that some parts will be obstacles to removal of the fuel injector assemblies of some cylinders.

It is not necessary to remove the turbocharger assembly when removing the fuel injectors of the No. 1, No. 2, No. 6 and No. 7 cylinders.

Installation

Carry out installation in the reverse order to removal.

Install the fuel injector assembly. For details, see “Removal and installation of cylinder head assembly”.

…