New Holland_Ford 8160, 8260, 8360, 8560

Complete workshop & service manual with electrical wiring diagrams for Ford New Holland 60 Series Tractors (8160, 8260, 8360, 8560). It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Ford New Holland 60 Series Tractors (8160, 8260, 8360, 8560) service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

“40816040.pdf”

Ford New Holland 60 Series Tractors (8160, 8260, 8360, 8560) Service Manual

1,414 pages PDF

Part number 40816040 English

Ford New Holland 60 Series Tractors (8160, 8260, 8360, 8560) Repair Manual

…

— — —

“86588680.pdf”

Ford New Holland 8160 8260 8360 8560 Section 2 – Electrical System Supplement

280 pages

EXCERPT:

SECTION 1 – ENGINES (Engine)

DIESEL ENGINE-DESCRIPTION AND OPERATION

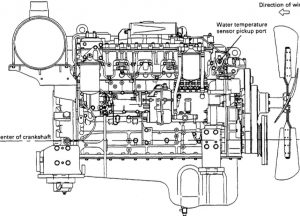

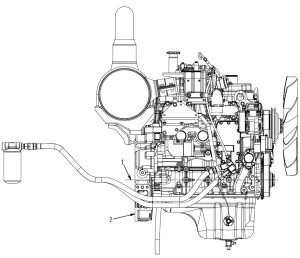

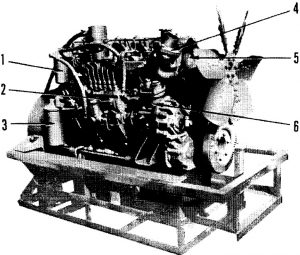

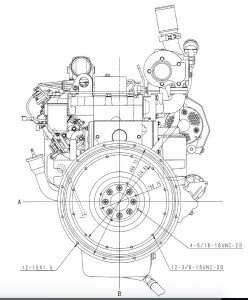

The engines are 6 cylinder and available in naturally aspirated and turbocharged forms.

All engines feature cross flow cylinder heads, with the inlet and exhaust manifolds on opposite sides of the cylinder head. The fuel and air combustion process, takes place in the specially designed bowl in the crown of the pistons.

CYLINDER HEAD ASSEMBLY

The cylinder head incorporates valves and springs, with the valve rocker arm shaft assembly bolted to the cylinder block through the cylinder head. Cylinder head retaining bolts are evenly spaced with a six point pattern around each cylinder, this ensures an even clamping load across the cylinder head area.

The intake and exhaust manifolds are bolted to the head, the intake manifold is mounted on the right hand side of the engine, with the diesel injectors mounted outside the rocker cover. The exhaust manifold is mounted on the left hand side of the engine. Water outlet connections and thermostat being attached to the front of the cylinder block directly behind the radiator.

…