Pages from SEBE6120A05 – 155-4 Series Diesel Engine Shop Manual

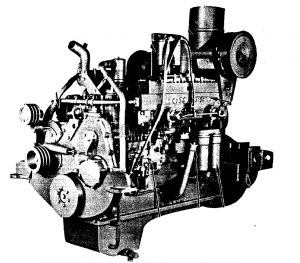

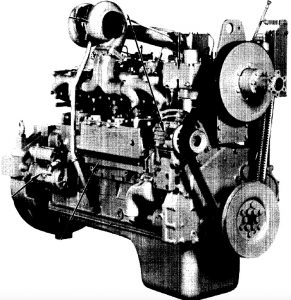

Complete workshop & service manual with electrical wiring diagrams for Komatsu 155-4 Series Diesel Engine. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Komatsu 155-4 Series Diesel Engine service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

SEBE6120A04 – 155-4 Series Engine Shop Manual.pdf

SEBE6120A05 – 155-4 Series Diesel Engine Shop Manual.pdf

EXCERPT:

TABLE OF CONTENTS

01 GENERAL .. 1-1

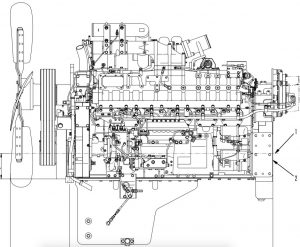

11 STRUCTURE AND FUNCTION GENERAL STRUCTURE . . . . . . . .. . . . . 11-004

INTAKE AND EXHAUST SYSTEM . . . . . . 11-102

ENGINE … 11-201

LUBRICATION SYSTEM . . . . . . . 11-302

FUEL SYSTEM . . . . . . . . 11-401

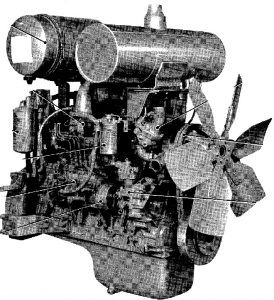

COOLING SYSTEM . . . . . . . . 11-502

ACCESSORY . . . . . . 11-602

12 TESTING AND ADJUSTING

FUEL SYSTEM . . . . . . . . 12-402

PERFORMANCE TEST …. 12-701

TESTING AND ADJUSTING TOOL LIST .. 12-901

TESTING AND ADJUSTING, TROUBLESHOOTING CRITERIA …. 12-902

13 DISASSEMBLY AND ASSEMBLY

OVERALL DISASSEMBLY . . . . . . 13-004

OVERALL ASSEMBLY . . . . . 1 3-1 02

DISASSEMBLY AND ASSEMBLY OF ASSEMBLY PART . . . . . 13-202

14 MAINTENANCE STANDARD

INTAKE AND EXHAUST SYSTEM .. 14-004

ENGINE . . . . . . . 14-008

LUBRICATION SYSTEM . . . . . . . 14-030

COOLING SYSTEM . . . . . . . . 14-036

ACCESSORY . . . . . . 14-03 7

15 REPAIR AND REPLACEMENT … 15-001

…

FUEL SYSTEM – STRUCTURE AND FUNCTION

The block assembly in place can be angularly repositioned, relative to the pump housing, by turning the flange sleeve. Turning the block affects the injection timing. Thus, the relationship between the plunger and the inlet port is determined by the angular and vertical positions of the block assembly in the housing.

The pressure-feed lubrication mentioned previously refers to the tappets. Pressurized lubricating oil is led into the pump housing from the engine lubricating system. An oil orifice opens out into the bore in which the tappet reciprocates in sliding contact. The oil is forced through the orifice into this sliding clearance around the tappet. The camshaft and the moving parts in the governor are lubricated with this oil. A return line is provided to return the oil back to the engine lubricating system.

…