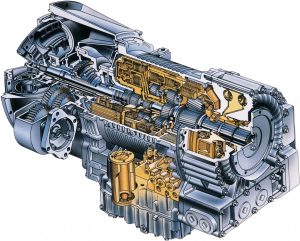

SAMPLE – Allison Transmission 1000/2000/3000/4000 Product Families Factory Service & Shop Manual

Complete workshop & service manual with bonus troubleshooting manuals for Allison Transmission 1000/2000/3000/4000 Product Families. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Allison Transmission 1000/2000/3000/4000 Product Families service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

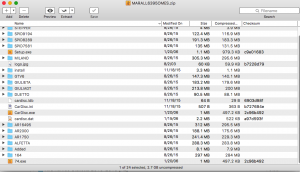

FILELIST:

“GN4008EN.pdf”

Allison Transmission Allison 4th Generation Controls (1000 Product Family, 2000 Product Family) In-Chassis Maintenance; 2007 JANUARY; GN4008EN

“JA3664EN.pdf”

Allison Transmission VOCATIONAL MODELS In-Chassis Maintenance; 2004 APRIL 01; JA3664EN

1000 EVS, 1000 HS, 1000 MH, 1000 PTS, 1000 RDS, 1000 SP, B 210, 2100 EVS, 2100 HS, 2100 MH, 2100 PTS, 2100 RDS, 2100 SP, B 220, 2200 EVS, 2200 HS, 2200 MH, 2200 PTS, 2200 RDS, 2200 SP, 2500 EVS, 2500 HS, 2500 MH, 2500 PTS, 2500 RDS, 2500 SP

1000 Series, 2000 Series, 2000 MH Series, 2400 Series

“MT4015EN.pdf”

Allison 4th Generation Controls – 3000 Product Family (Except 3700 SP), 4000 Product Family Mechanic’s Tips; 2005 FEBRUARY, Rev. 1 2005 SEPTEMBER; MT4015EN

“OM3349EN.pdf”

Motorhome Series 3000/4000 Operator’s Manual; 2005/09

Allison Transmission VOCATIONAL MODELS Motorhome Series (MH) Transmissions

3000 and 4000 Product Families

WTEC III Controls and Allison 4th Generation Controls

3000 MH, 4000 MH

“OM4118EN.pdf”

Allison Transmission 1000 & 2000 Product Families International Models Operator’s Manual; 2005/09

Includes Allison 4th Generation Controls

1000, 1000 MH, 1000 SP, 2100, 2100 MH, 2100 SP, 2200, 2200 MH, 2200 SP 2500, 2500 MH, 2500 SP

“SM2148EN.pdf”

3000 Product Family WTEC II & III Controls Service Manual (Rev 2016/01)

Allison Transmission VOCATIONAL MODELS

3000 EVS, 3000 HS, 3000 MH, 3000 PTS, 3000 RDS, 3000 SP, 3000 TRV, MD 3060, MD 3060P, MD 3060R, MD 3060PR, MD 3066, MD 3066P, MD 3066R, MD 3066PR, MD 3070PT, 3200 SP, 3200 TRV, 3500 EVS, 3500 HS, 3500 MH, 3500 PTS, 3500 RDS, 3500 SP, MD 3560, MD 3560P, MD 3560R, MD 3560PR, 3700 SP, B 300, B 300P, B 300R, B 300PR, B 400, B 400P, B 400R, B 400PR, T 250, T 255, T 260, T 265, T 270, T 280, T 310, T 325, T 350, T 375

“SM2457EN.pdf”

4000 Product Family On-Highway Transmissions WTEC II & III Controls Service Manual (Rev 2007/03)

Allison Transmission WTEC II AND WTEC III CONTROLS VOCATIONAL MODELS

4000 EVS, 4000 HS, 4000 MH, 4000 RDS, 4000 SP, 4000 TRV, HD 4060, HD 4060P, HD 4060R, HD 4060PR, HD 4070, HD 4070P, HD 4070R, HD 4070PR, HD 4076, 4500 EVS, 4500 HS, 4500 SP, 4500 TRV, HD 4560, HD 4560P, HD 4560R, HD 4560PR, 4700 EVS, 4700 RDS, 4700 SP, 4800 EVS, 4800 SP, B 500, B 500P, B 500R, B 500PR, T 425, T 450

“SM3191EN.pdf”

1000 and 2000 Product Families Pre-4th Gen Controls Service Manual (Rev 2004/12)

Allison Transmission VOCATIONAL MODELS SERVICE MANUAL; 2004 DECEMBER

1000 EVS, 1000 HS, 1000 MH, 1000 PTS, 1000 RDS, 1000 SP, 2100 EVS, 2100 HS, 2100 MH, 2100 PTS, 2100 RDS, 2100 SP, 2200 EVS, 2200 HS, 2200 MH, 2200 PTS, 2200 RDS, 2200 SP, 2500 EVS, 2500 HS, 2500 MH, 2500 PTS, 2500 RDS, 2500 SP, B 210, B 220

“SM4006EN.pdf”

1000 and 2000 Product Families Allison 4th Generation Controls Service Manual

Allison Transmission VOCATIONAL MODELS SERVICE MANUAL; 2005 MAY, Rev. 1 2005 SEPTEMBER

1000 EVS, 1000 HS, 1000 MH, 1000 PTS, 1000 RDS, 1000 SP, 2100 EVS, 2100 HS, 2100 MH, 2100 PTS, 2100 RDS, 2100 SP, 2200 EVS, 2200 HS, 2200 MH, 2200 PTS, 2200 RDS, 2200 SP, 2500 EVS, 2500 HS, 2500 MH, 2500 PTS, 2500 RDS, 2500 SP, 2300 HS, 2300 RDS, B 210, B 220

“SM4013EN.pdf”

3000 Product Family Service Manual

ALLISON 4TH GENERATION CONTROLS VOCATIONAL MODELS SERVICE MANUAL; 2005 OCTOBER

3000 EVS, 3000 HS, 3000 MH, 3000 PTS, 3000 RDS, 3000 TRV, 3200 SP, 3200 TRV, 3500 EVS, 3500 RDS, 3500 SP, 3700 SP, B 300, B 400, T 250, T 255, T 260, T 265, T 270, T 280, T 310, T 325, T 350

“SM4014EN.pdf”

4000 Product Family Service Manual

ALLISON 4TH GENERATION CONTROLS VOCATIONAL MODELS SERVICE MANUAL; 2005 OCTOBER

4000 EVS, 4000 HS, 4000 MH, 4000 RDS, 4000 SP, 4000 TRV, 4500 EVS, 4500 HS, 4500 RDS, 4500 SP, 4700 EVS, 4700 RDS, 4700 SP, 4800 EVS, 4800 SP, B 500, T 425, T 450, T 525

“TS2470EN.pdf”

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

1998 MAY; REV. 1 1999 OCTOBER; REV. 2 2004 JULY; REV. 3 2005 DECEMBER

MD/HD/B SERIES TRANSMISSIONS

WTEC II Controls

(Pre-TransID and TID 1)

MD 3060/MD 3066/MD 3560(P)(R)

MD 3070PT

HD 4060/HD 4560(P)(R)

B 300/B 400/ B 500(P)(R)

“TS2712EN.pdf”

ALLISON TRANSMISSION ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

This document covers the following on- and off-highway transmission models:

MT(B) 648; CLBT 5962 and 6062

HT(B) 741, 746 and 748; DP 8963

HT(B) 755CR and 755DR; CL(B)T 9681

V 731, V 731RH, VR 731, and VR 731RH; CLT 755 and CL(B)T 755

“TS2973EN.pdf”

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

2005 OCTOBER

REV. 1 OCTOBER 2006

VOCATIONAL MODELS

3000 VOCATIONAL MODELS

3000 HS 3500 RDS B 300(P)(R)

3000 RDS 3500 EVS B 400(P)(R)

3000 EVS T 200

3000 MH T 300

3000 PTS

3000 TRV

3200 SP 3500 SP 3700 SP

3200 TRV

MD 3060 MD 3560 MD 3070PT

MD 3066

4000 VOCATIONAL MODELS

4000 EVS 4500 EVS 4700 EVS 4800 EVS B 500

4000 HS 4500 HS 4700 RDS

4000 MH 4500 RDS

4000 RDS 4500 SP

4000 TRV 4500 TRV

HD 4060 HD 4560 HD 4070 HD 4076 B 500P

HD 4060P HD 4560P HD 4070P B 500R

HD 4060R HD 4560R HD 4070R B 500PR

HD 4060PR HD 4560PR HD 4070PR T 425 T 450

“TS3192EN.pdf”

ALLISON 1000/2000/2400 PRODUCT FAMILIES ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

2003 APRIL

REV. 1 2004 MAY

“TS3353EN.pdf”

5000, 6000, 8000, 9000 Series Transmissions

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC2) TROUBLESHOOTING MANUAL

2005 DECEMBER

M 5610A M 5610AR

S 5610H S 5610MR S 5610M

M 6610A M 6610AR

S 6610H S 6610HR S6610M S 6610MR

M 8610A M 8610AR

S 8610H S 8610HR S 8610M S 8610MR

M 9610A M 9610AR

S 9610A S 9610AR S 9610M S 9610MR

S 9805M S 9805MR

S 9810A S 9810AR S 9810H S 9810HR

S 9810M S 9810MR

“TS3977EN.pdf”

2008 FEBRUARY

REV. 2 2008 SEPTEMBER

ALLISON 4th GENERATION CONTROLS

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL

“TS3977FR.pdf”

GROUPES DE PRODUITS 1000 ET 2000 MANUEL DE DÉPANNAGE — COMMANDES ALLISON 4ème GÉNÉRATION

JANVIER 2006

“TS3989FR.pdf”

FÉVRIER 2005

GROUPES DE PRODUITS 3000 ET 4000 MANUEL DE DÉPANNAGE—COMMANDES ALLISON 4ème GÉNÉRATION

MODÈLES SPÉCIALISÉS Manuel de dépannage FÉVRIER 2005

MODÈLES 3000 SPÉCIALISÉS

3000 HS 3500 RDS B 300(P)(R)

3000 RDS 3500 EVS B 400(P)(R)

3000 EVS T 200

3000 MH T 300

3000 PTS

3000 TRV

3200 SP 3500 SP 3700 SP 3200 TRV

MODÈLES 4000 SPÉCIALISÉS

4000 EVS 4500 EVS 4700 EVS 4800 EVS B 500

4000 HS 4500 HS 4700 RDS B 500P

4000 MH 4500 RDS B 500R

4000 RDS 4500 SP B 500PR

4000 TRV 4500 TRV T 425 T 450

“CD2456EN“

4000 Product Family Series Transmissions Parts Catalog CD

EXCERPT:

MODULE REBUILD

b. Ground Sleeve Inspection

NOTE:

• The ground sleeve bushing and bearing are re- placed with the ground sleeve installed in the front support.

— Replace the needle bearing if the bearing is damaged.

— Replace the bushing if the bushing is damaged or the ID specification is not met.

• The only time the ground sleeve is pressed from the front support is to replace the ground sleeve.

— The new ground sleeve comes with a pre-installed bushing.

— Replace the ground sleeve if the ground sleeve splines or seal-ring bore specification is not met.

• The bearing must be removed to replace the ground sleeve. If the ground sleeve and the bear- ing both need replacing, replace the ground sleeve first.

• Replace the ground sleeve if it does not meet specifications.

1. Inspect the splines of ground sleeve (1) for damage and wear. No visible wear is allowed.

2. Measure the ID of ground sleeve (2) at the turbine shaft sealring bore (Dimension A). Maximum ID is 45.450 mm (1.7894 inch).

3. Measure the ID of ground sleeve bushing (1) (Dimension B). Maximum ID is 33.820 mm (1.3315 inch).

…