Complete digital official shop manual contains service, maintenance, and troubleshooting information for the ATSG Transmissions. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your vehicle like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for ATSG Transmissions is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

ATSG Transmissions Manuals

@Seminar Information@

7706 pages, 311 MB PDF, 1988-2011

*** *** *** *** *** *** *** *** *** ***

@Technical Service Bulletin@

214 MB PDF, 1986-2012

*** *** *** *** *** *** *** *** *** ***

@Service Manual@

18,636 pages, 987 MB PDF

“3-SPEED.pdf” 87 pages

SUBARU 3 SPEED

This booklet contains general description and the procedures necessary to repair, overhaul, or service the three speed Subaru automatic transaxle. Although this transaxle comes in 2 wheel drive and 4 wheel drive the transfer case is not covered. The 3 speed transaxle have both lock-up and non-lock-up converters. The lock-up version is found in most 1986-UP models.

— — — — — — — — —

“4 HP 18 SUPPLEMENT.pdf” 48 pages

SAAB 9000 SUPPLEMENT

The Saab 4-HP-18 is a four speed automatic transmission designed for front wheel drive transversely mounted engine vehicles. A fluid coupling (torque converter) is used to transmit power from the engine into the transmission via the turbine shaft. Built into the torque converter is a damper plate that connects the 3/4 clutch drum shaft mechanically to the crank shaft so as to drive the 3/4 clutch drum at crankshaft speed . The damper plate is also used to prevent a 2-3 and 3-4 shift shock. The converter also drives a positive displacement pump to provide the transmission with fluid pressure. The 4-HP-18 uses a Ravigneaux planetary gear train consisting of sun gears, planet gears, I planet carrier and 1 ring gear. The different ratios are obtained through this gear train by the driving and holding of specific elements in this gear set. This

driving and holding of specific elements in the gear set is accomplished by the use of 5 different clutch packs, 1 band and 2 one-way holding devices.

The purpose of this supplemental manual is to show the engineering differences of the Saab 9000 version of the 4-HP-18 transmission. For tear down and reassembly, use the ATSG Eagle Premier, Dodge Monaco Tectran Manual on the 4-HP-18.

— — — — — — — — —

“4-SPEED.pdf” 96 pages

SUBARU 4 SPEED 1990-1997

This booklet contains general description and the procedures necessary to repair, overhaul, or service the 1990-97 Subaru 4 speed electronic automatic overdrive transmission. The Subaru 4 speed is a fully automatic front or All wheel drive transmission. This unit is based on the Nissan RE4R01A platform. The shift pattern is controlled electronically with a Transmission Control Module. The TCM will vary shift points, as it is constantly interpreting numerous electronic signals from various operational sensors located on the vehicle. The TCM also controls the apply and release of the Transfer Clutch which on All wheel Drive models controls the rear drive shaft output for 4 wheel drive.

— — — — — — — — —

“4F20E.pdf” 120 pages

FORD 4F20E

The 4F20E electronically controlled automatic transaxle features a combination of electronic and mechanical systems to control forward gear shifting torque converter lock-up for quietness and economy and self diagnosis capability for simplifying trouble shooting procedures. The electronic system controls the transaxle shifting in forward speeds and controls torque converter lock-up by means of solenoid actuated valves. These shift solenoid valves, when activated apply the friction elements (clutches and bands) to control shifting in the planetary gear. The shift timing and lock-up events are regulated by the TCM in programmed logic and in response to input sensors and switches to produce optimum performance.

— — — — — — — — —

“4F27E.pdf” 112 pages

Ford Motor Company in a joint venture with Mazda in Japan have developed a new design transaxle designed specifically for use in the Ford Focus, with the designation 4F27E, and Mazda designation is FN4A-EL. The new 4F27E transaxle is produced by Ford Motor Company in Sterling Heights, Michigan.

This is a four speed, Front Wheel Drive, with fully electronic controls for the upshifts and downshifts, with 4th gear being overdrive. The individual gear ratios are achieved through two planetary gear sets connected one behind the other. The components of the planetary gear sets are driven or locked by means of four multiple plate clutches, one brake band and a one-way roller clutch. To minimize fuel consumption, the torque converter clutch is applied by the PCM in 3rd and 4th gears, depending on throttle position and vehicle speed. This unit is designed to use Mercon® V automatic transmission fluid.

The manual selector lever gives the driver a choice of “P”, “R”, “N”, “D”, “2”, “1”, and all ranges are explained in detail in this manual. It is also possible to operate an O/D cancel switch, located on the selector lever, to prevent the transaxle from shifting into 4th gear or to shift down to 3rd gear.

— — — — — — — — —

“4HP18-22-24.pdf” 160 pages

BMW, AUDI, PORSCHE Technicians Guide INDEX

ZF 4HP-18FLE AND ZF 4HP-18 FLA DIAGNOSTIC INFORMATION

ZF 4HP-22/24 SERIES DIAGNOSTIC INFORMATION

MODEL “E-7” VALVE BODY WITH 5 SOLENOIDS

MODEL “E-9” VALVE BODY WITH 4 SOLENOIDS

ZF 5HP-18 DIAGNOSTIC INFORMATION

ZF 5HP-19FL DIAGNOSTIC INFORMATION

ZF 5HP-24 DIAGNOSTIC INFORMATION

ZF 5HP-30 DIAGNOSTIC INFORMATION

— — — — — — — — —

“4L30-E.pdf” 120 pages

THM 4L30-E

This booklet contains the general description and the procedures necessary to repair, overhaul, or service the Hydra-matic 4L30-E transmission that is currently found in the Opel Omega, Opel Senator, BMW, and the Isuzu Trooper/Rodeo. This transmission is a completely electronic controlled, 4 speed, rear wheel drive unit.

Gear ratios are as follows:

Opel/BMW

1st Gear 2.40

2nd Gear

3rd Gear

4th Gear

Reverse

Trooper/Rodeo

2.86

1.48 1.62

1.00 1.00

0.72 0.72

2.00 2.00

— — — — — — — — —

“4L60-E UPDATE HANDBOOK.pdf” 120 pages

THM 4L60-E/4L65-E

Since the introduction of the THM 4L60-E transmission in model year 1993, there have been many major engineering design changes to improve durability and reliability. These changes have affected nearly every part used in the THM 4L60-E. This “Update Handbook” will explain each change, the parts affected by the change, and any parts interchangeability concerns created by the change.

Beginning at the start of production for model year 2001, General Motors introduced a new transmission designated THM 4L65-E with many engineering changes. Currently this unit is found in all 2001 Cadillac Escalade and any vehicle with 6.0L engine or larger, that was previously equipped with the THM 4L60-E transmission. We will also cover the changes in the THM 4L65-E transmission in this booklet.

— — — — — — — — —

“4L60-E.pdf” 112 pages

THM 4L60-E

This booklet contains general description and the procedures necessary to repair, overhaul, or service the new THM 4L60-E electronic automatic overdrive transmission. The 4L60-E is a fully automatic rear wheel drive transmission. This unit is basically a THM 700-R4 with electronic controls added to the valve body. The shift pattern is controlled electronically with 2 shift solenoids that receive a ground signal from the Powertrain

Control Module (PCM). The PCM will vary shift points, as it is constantly interpreting numerous electronic signals from various operational sensors located on the vehicle.

The PCM also controls the apply and release of the Torque Converter Clutch (TCC). This transmission also received another PWM solenoid in 1995 to control TCC apply feel. Line pressure and shift feel are controlled electronically with a Pressure Control Solenoid (PCS), located on the valve body and dependent on TPS and VSS signals.

— — — — — — — — —

“4L60E-80E CODE BOOK.pdf” 185 pages

4L60E/65E/70E- 4L80E/85E DIAGNOSTIC CODE BOOK

The GM 4L60E/65E/70E-4L80E/85E Diagnostic Code Book is designed to provide the technician with a step by step diagnostic approach to each and every transmission code available from 1991 to the 2007 model year.

— — — — — — — — —

“4L80-E.pdf” 120 pages

THM 4L80-E

This booklet contains general description and the procedures necessary to repair, overhaul, or service the THM 4L80-E electronic overdrive automatic transmission. The THM 4L80-E is a fully automatic rear wheel drive transmission. It provides Park, Reverse, Neutral, and four forward speeds with 4th gear being overdrive.

The shift pattern is controlled electronically with two solenoids that receive a ground signal from the Powertrain Control Module (PCM). The PCM will vary shift points and shift feel, as it is constantly interpreting numerous electronic signals from various operational sensors located on the vehicle. The PCM also controls the Torque Converter Clutch (TCC) apply speed, apply feel, and the release electronically with a solenoid.

Line pressure and shift feel are also controlled electronically with a Pressure Control Solenoid (PCS) located on the valve body. This function is also controlled by the PCM and the numerous electronic signals from the sensors.

— — — — — — — — —

“4R44E-4R55E.pdf” 120 pages

FORD 4R44E/4R55E

The Ford 4R44E/4R55E is a fully electronic controlled, four speed, rear wheel drive transmission. At first glance it resembles the familiar A4LD transmission. The shift timing, shift feel, line pressure and TCC are all computer controlled in the 4R44E/4R55E transmissions. There are three compound planetary gearsets, three bands, three multi-disc clutch packs and two one-way freewheel assemblies.

— — — — — — — — —

“4R100.pdf” 120 pages

The Ford 4R100 transmission is an updated version of the E4OD and was first introduced in the 1999 model year, and is currently found in the F250, F350, F450 and F550 Super Duty trucks, E150, E250, E350, E450 vans and the Expedition/Navigator/Excursion vehicles equipped with the 5.4L, 6.8L, and 7.3L engines. Some of the 4R100 units are equipped with a Power-Take-Off (PTO) window on the left hand side of the transmission case.

The revisions in the 4R100 have created many new engineering changes that have affected many of the internal and external parts that will affect the servicing, repairing and overhaul of these units.

— — — — — — — — —

“4R100UPDATE HANDBOOK.pdf” 107 pages

FORD 4R100 “UPDATE HANDBOOK”

Since the introduction of the 4R100 transmission in model year 1998, there have been many engineering changes to improve Pleaseability, Reliability and Durability concerns. These changes have affected most every part used in this transmission. This “Update Handbook” will explain each change, the reason for the change, and any parts interchangeability concerns created by the change, along with any part numbers needed to update your transmission.

— — — — — — — — —

“4T40-E.pdf” 128 pages

THM 4T40-E

This booklet contains general description and the procedures necessary to repair, service, or overhaul the THM 4T40-E electronic overdrive automatic transaxle. This unit was first introduced in the 1995 Chevrolet Cavalier and Pontiac Sunfire vehicles, and will eventually replace the THM 125C (3T40).

The THM 4T40-E is a fully automatic front wheel drive transaxle. It provides park, reverse, neutral, and 4 forward speeds including overdrive. The shift pattern is controlled electronically with 2 shift solenoids that receive a ground signal from the Powertrain Control Module (PCM). The PCM will vary shift points, as it is constantly interpreting numerous electronic signals from various operational sensore located on the vehicle. The PCM also controls apply and release of the Torque Converter Clutch. Line pressure and shift feel are also controlled electronically with a Pressure Control Solenoid (PCS) located on the valve body and is dependant on TPS and VSS signals.

— — — — — — — — —

“4T60-E.pdf” 120 pages

THM 4T60-E

This booklet contains the procedures necessary to overhaul, repair or service the THM 4T60-E transaxle. The THM 4T60-E is a fully automatic front wheel drive transaxle that provides park, reverse, neutral and four forward speeds, with 4th gear being overdrive.

— — — — — — — — —

“4T65-E UPDATE HANDBOOK.pdf” 118 pages

THM 4T65-E UPDATE HANDBOOK

Since the introduction of the THM 4T65-E transmission in model year 1997, there have been many major engineering design changes to improve durability and reliability. These changes have affected many of the parts used in the THM 4T65-E. This “Update Handbook” will cover preliminary information and will also explain each change, the parts affected by the change, and any parts interchangeability concerns created by the change.

This manual is a companion manual to the 4T65-E Blue assembly and disassembly manual and is most helpful during a rebuild.

— — — — — — — — —

“4T65-E.pdf” 120 pages

THM 4T65-E

This booklet contains general description and overhaul procedures necessary to repair, overhaul or service the THM 4T65-E electronic overdrive automatic transaxle. This transaxle was introduced in the 1997 model year in several different models using the 3.8L supercharged engine and some models with the 3.8L and 3.4L engines. The THM 4T65-E is very similar to the 4T60-E and some of the parts are common with this unit. We wish to thank General Motors Corp. for the information and illustrations that have made this booklet possible.

— — — — — — — — —

“4T80-E.pdf” 112 pages

G.M. 4T80-E, THM 4T80-E

This booklet contains the general description, diagnosis charts, and the procedures necessary to overhaul, repair or service the General Motors THM 4T80-E four speed automatic overdrive transaxle. This information will assist you in training your technicians to provide your customers with the best possible transmission service that is available.

— — — — — — — — —

“5L40E-4L40E.pdf” 128 pages

HYDRA-MATIC 4/5L40-E

Beginning at the start of production for some 1999 models, BMW has introduced a new 5 speed automatic transmission that is designed and manufactured by General Motors Powertrain division in Strasbourg, France and is illustrated in Figure 1. This new transmission is designated as follows:

GM Designation – 5L40-E BMW Designation – A5S 360R

Model year 1999 applications are as follows:

Model year 2003 applications are as follows:

3 Series BMW, with 2.5L Gasoline Engine, Used in USA and Japan.

3 Series BMW, with 2.8L Gasoline Engine, Used in USA and Japan.

5 Series BMW, with 3.0L Diesel Engine, Used Worldwide.

Cadillac CTS model, Gasoline Engine, Used Worldwide

— — — — — — — — —

“5L40E.pdf” 128 pages

— — — — — — — — —

“5R55E.pdf” 120 pages

FORD 5R55E

The 5R55E transmission produced by Ford Motor Company, was introduced in the 1997 model year, and is the first 5 speed automatic found in domestic vehicles. It is currently found in the 1997 Aerostar Van, 1997-2001 Ranger Trucks, both 2WD and 4WD, and 1997-2001 Explorer vehicles, equipped with the 4.0L engine. This unit is very similar to the 4R44E, but has different computer strategy that energizes the overdrive band in first gear, to create the added gear ratio. Refer to the application chart found on Page 7 for the new computer strategy. Many of the parts between the 4R44E and 5R55E units may look the same, but are not all interchangeable. Be very careful when selecting replacement parts, if it becomes necessary.

— — — — — — — — —

“5R55N.pdf” 120 pages

FORD 5R55N

This booklet contains general description and overhaul procedures necessary to repair, overhaul or service the new Ford Motor Co 5R55N transmission. The Ford 5R55N transmission was first introduced in the 2000 model year, and is currently found in the Lincoln “LS” and Jaguar X200. We wish to thank Ford Motor Company for the information and illustrations that have made this booklet possible.

The 5R55N transmission has 5 forward speeds, reverse and is fully electronic controlled. Internally, it looks similar to the previous 5R55E unit, but very few minor components are actually the same. Following are the internal components used in the new 5R55N transmission.

3 Planetary Compound Gear Sets: Overdrive, Forward and Rear.

3 Brake Bands: Overdrive, Intermediate and Low/Reverse.

4 Multi-Plate Clutch Packs: Coast, Forward, Direct and Intermediate.

3 One-Way Clutches: Overdrive, Intermediate and Low.

Electronic Controlled Shifts, Torque Converter Clutch and Pressure.

— — — — — — — — —

“5R55W-5R55S.pdf” 120 pages

FORD 5R55S, FORD 5R55W

The Ford 5R55S and 5R55W transmissions are both very similar in design to the Ford 5R55N transmission and use electronic shift controls. The 5R55S/W are both “Syncrounous” units, as they do not use the intermediate clutch and intermediate sprag that the 5R55N incorporates. The Ford 5R55S and 5R55W transmissions were

introduced in 2002, found in the Ford Explorer and Mercury Mountaineer vehicles, and are available in both 2WD and 4WD configurations. For model year 2003 they are also in the Lincoln LS, Lincoln Aviator and Ford Thunderbird. They are designed for operation in longitudinal powertrains for rear wheel drive vehicles.

— — — — — — — — —

“5R110W.pdf” 120 pages

FORD 5R110W (“TorqShift”)

The new Ford 5R110W, referred to by Ford Motor Company as the “TorqShift” transmission, is a redesign of the 4R100 transmission with some previous strategy applied. This unit was introduced in model year 2003 in the F Series Trucks and the Excursion vehicles that are equipped with the new 6.0L diesel engine. The

“TorqShift” (5R110W) is a 5 speed, rear wheel drive unit that actually has six forward speeds available, depending on hot or cold mode operation. The gear ratio for 1st gear was lowered from 2.71 to 3.09. For 2nd gear the overdrive clutch is applied to provide a ratio of 2.20. 3rd gear provides a ratio of 1.54, which is the same ratio as the previous second gear. All sound familiar? When in cold mode operation, below -15°C (5°F), determined by the TFT sensor, the overdrive clutch is engaged in 3rd gear to provide a ratio of 1.09 for 4th gear, and the transmission will shift directly into 6th gear (overdrive), which is a ratio of 0.71. In cold mode the transmission shifts 1st gear, 2nd gear, 3rd gear, 4th gear, 6th gear. When in hot mode the transmission will shift 1st gear, 2nd gear, 3rd gear, 5th gear (ratio 1.00), 6th gear. Either way it is still a five speed unit with six forward

gear ratios available, depending on cold mode or hot mode of operation.

— — — — — — — — —

“6HP26_TG.pdf” 73 pages

THE ZF6HP26 TRANSMISSION

BMW PRELIMINARY INFORMATION

The ZF Company has produced several 6 speed transmissions which are being used in car lines such as Jaguar, BMW, Volkswagen and Audi. Currently they have the 6HP19, the 6HP19FL and FLA, the 6HP26 and 6HP26A61, the 6HP32 and 32A. Although there are similarities among these units, they also have very significant differences. As a result, this short presentation will only be in regard to the 6HP26.

ZF6HP26 transmission within itself has several versions so as to accommodate the different car manufacturers and various engines they are fitted with, but the basic design and function of the transmission are the same.

— — — — — — — — —

“6L80.pdf” 108 pages

6L80 (6 Speed)

The new Hydra-matic 6L80 (6 Speed) is a fully automatic, six speed, rear wheel drive, electronic controlled transmission that features clutch to clutch shifting. It was first introduced in the 2006 Corvette with the 6.0L engine, Cadillac STSV/XLRV with the 4.4L engine, and is scheduled for Pick-ups in 2007, as shown in Figure 1. It consists primarily of a four element torque converter, two planetary gear sets, five clutch packs, one sprag and a hydraulic pressurization and control system. Two planetary gear sets provide the six forward gear ratios and reverse. Changing gear ratios is fully automatic and is accomplished through the use of a Transmission Control Module (TCM), that is located within the transmission. The TCM receives and monitors various electronic sensor inputs, and uses this information to shift the transmission at the optimum time. The TCM commands shift solenoids and variable bleed Clutch Pressure Control (CPC) solenoids within the transmission to control shift timing. The TCM controls shift feel through the CPC solenoids. The TCM also controls the apply and release of the torque converter clutch which allows the engine to deliver the maximum fuel efficiency without sacrificing vehicle performance. This manual contains procedures necessary to diagnose, overhaul and/or repair the new 6L80 (6 Speed) transmission from General Motors.

— — — — — — — — —

“09D.pdf” 136 pages

TOUAREG, AUDI Q7,

PORSCHE CAYENNE

TR60SN “09D” Transmission

The Japanese company AISIN Co., LTD is the manufacturer and developer of the Rear Wheel Drive TR60SN transmission, which is a 6 speed, fully automatic and electronic controlled transmission. Volkswagen engineers were also involved, in conjunction with Aisin, in the development process for their vehicles and Volkswagen gave it the “09D” designation.

The TR60SN, 09D transmission is used in a wide variety of applications and engine sizes. As a result, the number of friction plates, and planetary gears (3 or 4 pinion), will vary depending on torque load requirements of the specific vehicle. The TR60SN transmission uses a gear ratio sensitive system, requiring the correct transmission interchange. The TR60-SN is currently used in the Porsche Cayenne, Volkswagen Touareg, and Audi Q7 vehicles.

The 09D transmission uses a Lepelletier arrangement, using a simple planetary coupled with a Ravigneaux type, dual planetary. This is the same type of gear set that was used in the FMX. This arrangement makes six forward speeds and reverse possible, with only five clutch packs and one freewheel.

This manual contains the procedures necessary to diagnose, rebuild and/or repair the TR60SN “09D” transmission and is intended for automotive technicians that are familiar with the operation of automatic transmissions.

— — — — — — — — —

“09G.pdf” 124 pages

AUDI, JETTA, PASSAT,

09G/09M Transaxle

The Japanese company AISIN Co., LTD is the manufacturer and developer of the Front Wheel Drive TF60SN transaxle, which is a 6 speed, fully automatic and electronic controlled transaxle. Volkswagen engineers were also involved, in conjunction with Aisin, in the development process for their vehicles and they gave it the 09G/09M designation. BMW gave it the designation 6F21WA for their Mini-Cooper.

The 09G/09M transaxle is used in a wide variety of applications and engine sizes. As a result, the number of friction plates, planetary ratios, intermediate ratios and final drive ratios will vary depending on torque load requirements of the specific vehicle. The TF60SN transaxle uses a gear ratio sensitive system, requiring the correct transaxle interchange. The TF60-SN is used in the BMW Mini Cooper, Volkswagen and Audi vehicles. This transaxle is referred to as the TF60-SN, 09G, 09M, 6F21WA and in some overseas vehicles as 09K. As a result there are a variety of different case and part configurations. Some of these units have the heat exchanger attached to the transmission while others use a remote heat exchanger. This alters the case, case cover and the valve body and if incorrect parts are used, severe planetary failure will occur. This manual covers these differences so that this mistake will not happen to you.

The 09G/09M transaxle uses a Lepelletier arrangement, using a simple planetary coupled with a Ravigneaux planetary. This arrangement makes six forward speeds and reverse possible, with only five clutch packs and one freewheel.

This manual contains the procedures necessary to diagnose, rebuild and/or repair the 09G/09M transaxle and is intended for automotive technicians that are familiar with the operation of automatic transmissions.

— — — — — — — — —

“30-80LE.pdf” 120 pages

ISUZU AW30-80LE

The AW30-80LE is a rear wheel drive, four speed, electronically controlled, fully automatic transmission.

Internal components consist of a lock-up torque converter, oil pump, 5 multi-disc clutch packs, 1 brake band and three planetary gear sets. The valve body includes electronic solenoids for shift control that are controlled by a Transmission Control Unit (TCU). Shift control is determined by vehicle speed and throttle position sensor signals, that are constantly monitored by the TCU. Throttle cable is used for line pressure control.

— — — — — — — — —

“41_42 Series Automatic Transmission Repair (8169901121).pdf” 60 pages

This course provides hands on experience in the disassembly and assembly of the hydraulic and mechanical control systems of the 41TE/AE, 42LE & 42RLE transaxles. The goal of this course is to provide the technician with information and the tools to disassemble, reassemble and properly set-up the differentials of these transaxles. The 41TE/AE & 42LE transaxles are found on the following DaimlerChrysler vehicles:

Caravan/Voyager 41AE-AWD, 41TE-FWD

Cirrus/Stratus 41TE

Sebring Convertible 41TE

Neon 41TE

PT Cruiser 41TE

Intrepid/Concorde/300M 42LE

Wrangler 42RLE

This course contains six modules of training information:

Module 1 Disassembly of the 41/42 Series Electronic Automatic Transmissions

Module 2 Assembly of the 42LE Differential

Module 3 Assembly of the 41TE Differential

Module 4 Assembly of the Transmission’s Centerline

Module 5 Disassembly and Assembly of the Input Clutch Assembly

Module 6 Disassembly and Assembly of the Valve Body

— — — — — — — — —

“41TE CODE BOOK SPANISH.pdf” 96 pages

— — — — — — — — —

“41TE_42LE Operation and Diagnosis (8169901039).pdf” 42 pages

— — — — — — — — —

“41TE_AE & 42LE Transaxle Electronics (8169997107).pdf” 108 pages

— — — — — — — — —

“41TE-A604-42LE-A606 CODE BOOK.pdf” 96 pages

— — — — — — — — —

“41TE_AE & 42LE Transaxle Repair (8169997099).pdf” 56 pages

— — — — — — — — —

“42LE_A606.pdf” 103 pages

CHRYSLER 42LE (A-606)

The 42LE four speed transaxle has many similarities to the A-604. Both these units are fully computer controlled. The 42LE is mounted in the same fashion as the rear drive transmissions. That is NORTHSOUTH (longitudinally, whereas the A-604 is transverse mounted. Since the front axle of the vehicle passes through the bell housing the pump support shaft and the turbine shaft are longer.

— — — — — — — — —

“42RE ELEC GOVERNOR.pdf” 120 pages

FORD 5R55E

The 5R55E transmission produced by Ford Motor Company, was introduced in the 1997 model year, and is the first 5 speed automatic found in domestic vehicles. It is currently found in the 1997 Aerostar Van, 1997-2001 Ranger Trucks, both 2WD and 4WD, and 1997-2001 Explorer vehicles, equipped with the 4.0L engine. This unit is very similar to the 4R44E, but has different computer strategy that energizes the overdrive band in first gear, to create the added gear ratio. Refer to the application chart found on Page 7 for the new computer strategy. Many of the parts between the 4R44E and 5R55E units may look the same, but are not all interchangeable. Be very careful when selecting replacement parts, if it becomes necessary.

— — — — — — — — —

“42RE_A500SE_full.pdf” 106 pages

— — — — — — — — —

“42RE.pdf” 120 pages

CHRYSLER 42RE

The Chrysler 42RE (A500SE) is a 4 speed automatic transmission. Mechanical and hydraulic components in the 42RE are similar to those found in the 42RH (A500) transmissions. The major difference between them involves the method they use to produce governor pressure for shift control. The 42RE (A500SE) uses electronic components to create governor pressure and the 42RH (A500) uses a mechanical governor to create governor pressure.

First through third gear in the 42RE (A500SE) are provided by the clutches, bands, low roller clutch and planetary gear sets located in the transmission main case. Fourth gear is provided by the overdrive unit, located in the extension housing and contains an overdrive clutch, overdrive direct clutch, overrun roller clutch and overdrive planetary gear set. The 42RE

(A500SE) Overdrive Unit is shorter than the 42RH (A500), resulting from elimination of the mechanical governor, governor support and governor oil tubes.

— — — — — — — — —

“45RFE-545RFE.pdf” 120 pages

CHRYSLER 45RFE

Beginning at the start of production for the 1999 model year Chrysler Corporation has introduced a brand new rear wheel drive transmission for the 99 Jeep Grand Cherokee with the 4.7L engine, and scheduled for the Ram Pick-up for the 2000 model year. This is the first completely new rear wheel drive automatic transmission from Chrysler in more than thirty years. The 45RFE designation tells us that this new unit has 4 forward speeds, a relative torque rating of 5, is for Rear drive vehicles and is Fully Electronic controlled. Refer to Figure 1. The 545RFE was introduced in 2003 in 3.7 and 5.7 engines. There are few differences in the components between the 45RFE and the 545RFE, although the main difference is the addition of a fifth ratio, which is electronically controlled.

— — — — — — — — —

“45RFE.pdf” 112 pages

— — — — — — — — —

“46RE-47RE-48RE.pdf” 144 pages

46RE, 47RE, 48RE

The 46RE, 47RE and 48RE family of transmissions by the Chrysler Group, are fitted behind a wide variety of engine sizes, including diesel, and across various vehicle lines. They are also available in 2WD and 4WD configurations. Beginning at the start of production for model year 2005, Dodge trucks equipped with the 5.9L diesel and 48RE transmission were equipped with an electronically controlled Transmission Throttle Valve Actuator (TTVA). This Actuator has replaced the previous Throttle Valve Cable and all associated linkage. A push-in Transmission Range Sensor was implemented in model year 2002 to replace the screw-in Park/Neutral switch.

— — — — — — — — —

“68RFE.pdf” 112 pages

DODGE RAM 68RFE

Beginning at the start of production for the 2006 model year Chrysler Corporation has introduced a new version of the 5/45RFE transmission and is found in Dodge Ram trucks. The new 68RFE designation tells us that this new unit has 6 forward speeds, a relative torque rating of 8, is for Rear drive vehicles and is Fully Electronic controlled. Refer to Figure 1. The 68RFE transmission is a sophisticated, multi-range, electronically controlled transmission which combines optimized gear ratios for responsive performance, improved efficiency features, and low NVH (Noise, Vibration, Harshness). Other features include driver adaptive shifting and three, 6 pinion, planetary gear sets to provide wide ratio capability with precise ratio steps for optimum drivability. There have been several engineering changes in the geartrain to improve durability and reliability.

— — — — — — — — —

“096-097.pdf” 80 pages

V.W. AUDI PASSAT 095, 096, 097

The 095, 096 and 097 transmission is a fully electronic four speed automatic transaxle and is currently found in the Volkswagen Cabrio, Corrado, Golf, Jetta, Passat, and the Audi 80, 90, 100, and Cabriolet vehicles. This manual provides the information and procedures necessary to repair, overhaul and service this transaxle. Repairs should not be attempted by unqualified or untrained individuals. Standard safety precautions must be used in order to protect the vehicle and the individual doing the roper tools for the application, and the Original Manufacturers tool recommendations.

— — — — — — — — —

“125C UPDATE HANDBOOK.pdf” 86 pages

THM 12SC

Since the introduction of the THM 125 transaxle in model year 1980, there have been many major engineering changes. These changes have affected nearly every part used in the 125 and 125c. This Update Handbook will explain each change, the parts affected by the change, any parts interchangeability problems created by the change. This Update Handbook will cover all of the changes from start of production up through and including model year 1987, along with common problems, and fixes, for the THM 125 transaxle. The THM 125 was produced in model years 1980, 81 and early 1982. The THM 125C transaxle, introduced in early 1982, provided the addition of a converter clutch torque converter. The converter clutch was added to increase fuel economy by eliminating the fluid coupling of the transaxle at road load conditions, replacing it with a direct mechanical connection.”

— — — — — — — — —

“125C.pdf” 96 pages

THM 125C (3T40)

This is booklet contains the general description, diagnosis and overhaul procedures necessary to repair, or service the THM 125C (3T40) transaxle. In addition to this booklet for the assembly and overhaul disassembly procedures, the Green Update Handbook available from ATSG is also necessary to inform you of the many engineering changes that have occured over the years. The THM 125C transaxle represents the addition of a converter clutch to the THM 125 transaxle that was introduced in 1980. The Torque Converter Clutch was added to increase fuel economy by eliminatin luid coupling of the transmission at road load conditions, replacing it with a direct mechanical connection.

— — — — — — — — —

“180C.pdf” 87 pages

THM 180 (TRl-MATIC)

This booklet contains the general description, diagnosis and overhaul procedures necessary to service the THM 180 and 180C (Tri-matic) transmission.

— — — — — — — — —

“200-4R.pdf” 96 pages

THM 200-4R

This booklet contains the general description, diagnosis charts, and the procedures necessary to overhaul, repair or service the General Motors THM 200-4R four speed automatic overdrive transmission. This information will assist you in training your technicians to provide your customers with the best possible transmission service that is available.

— — — — — — — — —

“200C.pdf” 80 pages

GENERAL MOTORS 200C

This contains the general description, diagnosis and overhaul procedures necessary to repair, overhaul or service this transmission.

— — — — — — — — —

“203-205.pdf” 39 pages

NEW PROCESS 203 -205

With more 4 wheel drive vehicles coming into our shops, the need for information on transfer cases has increased. Mike Weinberg of Rockland Standard Gear has gathered information on various types and model transfer cases that are most common. This series of booklets cover the general information, operation, tear down, and assembly of these units. And in most cases a parts breakdown is shown which helps in ordering replacement parts.

— — — — — — — — —

“231-241.pdf” 56 pages

NEW PROCESS 231-241

— — — — — — — — —

“350C.pdf” 82 pages

THM 350C

— — — — — — — — —

“400.pdf” 96 pages

THM 400

This booklet contains general description and overhaul procedures necessary to repair, overhaul or service the THM 400 transmission, and is found in both passenger cars and trucks. The THM 400 transmission was first introduced in 1964 and was used through the 1990 model year with some engineering changes that occurred during that time. We have included the major changes and updates in the appropriate sections of this booklet.

— — — — — — — — —

“404-470.pdf” 96 pages

CHRYSLER A-404/413/415/470

— — — — — — — — —

“404-670.pdf” 104 pages

CHRYSLER A404 thru A670

This booklet contains the general description, diagnosis, and assembly/disassembly procedures necessary to repair, overhaul, or service the A404, A413, A415, A470 and A670 transaxles. We have also included the updates and engineering changes that we are aware of, that have occured over the years.

— — — — — — — — —

“440-T4 UPDATE HANDBOOK VOL 1.pdf” 102 pages

— — — — — — — — —

“440-T4 UPDATE HANDBOOK VOL 2.pdf” 56 pages

— — — — — — — — —

“440-T4.pdf” 104 pages

THM 440-T4 (4T60)

This booklet contains the general description, diagnosis and overhaul procedures necessary to repair, overhaul, or service the THM 440-T4 overdrive automatic transaxle. The THM 440-T4 is a fully automatic front wheel drive transaxle. It provides Park, Reverse, Neutral and four forward speeds, with fourth gear being overdrive. Changing of the four forward gears is fully automatic, in relation to vehicle speed and throttle position. Vehicle Speed Signals (Governor), Throttle Position Signals (T.V. Cable), and Engine Torque Signals (Modulator) are constantly sent to the transaxle valve body to provide the proper gear ratio for maximum efficiency and performance at all throttle openings.

— — — — — — — — —

“700-R4-4L60 82 – 86.pdf” 96 pages

THM 700-R4 (4L60) 1982-1986

The THM 700-R4 transmission is a fully automatic unit consisting of a 3 element torque converter with the addition of a converter clutch.

— — — — — — — — —

“700-R4-4L60 87 – 93.pdf” 119 pages

GENERAL MOTORS 700-R4 1987-1993

This booklet contains general description and procedures necessary to repair, overhaul, or service the 1987-1993 THM 700-R4 transmission and includes all design levels.

— — — — — — — — —

“700-R4-4L60 UPDATE HANDBOOK.pdf” 120 pages

’82-’93 THM 700-R4 (4L60) UPDATE HANDBOOK

The 1987 through 1993 THM 700-R4 transmissions were produced with many engineering design changes. These changes have affected nearly every part used in the 700-R4. This “Update Handbook” will explain each change, the reason for the change, the parts that are affected by the change and any parts interchangeability concerns created by the change. 1993 was the last year the 700-R4 transmission was produced and this manual will cover all changes up through and including the 1993 changes.

— — — — — — — — —

“722-3-4.pdf” 120 pages

MERCEDES 722.3, 722.4

Mercedes first introduced the 722 models in model year 1980. The 722.3 is found in most models and the 722.4 is found in the 190 vehicles. This manual covers the procedures necessary to overhaul and repair both of these units. This manual also covers the differences between the units in the valve body and governor. The basic internal components such as the pump, gear-sets, drums clutches and bands are the same. This manual includes both the original manufacturers information along with some of the engineering changes and updates.

— — — — — — — — —

“722-5.pdf” 104 pages

MERCEDES 722.5

Mercedes introduced the five speed automatic overdrive transmission in the 1989 model year. At a quick glance it looks the same as the four speed 722.3 and 722.4 models. The extension housing is the quickest way to identify the five speed unit, as this is where the overdrive section was added. The 4-5 and the 5-4 shifts are a computer module. This manual covers the testing, disassembly, inspection and reassembly of the Mercedes 722.5 unit.

— — — — — — — — —

“722-6.pdf” 120 pages

MERCEDES, JAGUAR, DAIMLER/CHRYSLER “722.6” “5 Speed”

The Mercedes 722.6 transmission made its first debut here in the United States in 1996. It is used behind 4, 6, 8 and 12 cylinder gasoline engines, as well as their diesel engines. It is their first completely computer controlled transmission and their first to have a transmission with a converter clutch. This electronically controlled 5 speed automatic transmission consists of 3 compound planetary gear sets, 3 multiple disc driving clutches, 3 multiple disc brake clutches and 2 free-wheel clutches, with 5th gear being overdrive. The Electronic Transmission Controller (ETC) controls transmission operation matching engine performance during the shift phase. The driver can choose between 2 driving programs, S for standard driving programs and W for winter driving programs. Winter option provides a second gear start and a higher gear ratio for a reverse movement. Standard mode provides a first gear take off and a lower reverse gear ratio.

— — — — — — — — —

“722-8TG.pdf” 48 pages

The 722.8 is Mercedes Front Wheel Drive Continuous Variable Transmission.

— — — — — — — — —

“722.9.pdf” 28 pages

— — — — — — — — —

“A4LD-UPDATE HANDBOOK.pdf” 110 pages

Since the start of production in 1985, the FORD A4LD transmission has received many major engineering design changes. These design level changes have affected nearly every part used in the A4LD transmission. This “Update Handbook” will explain the purpose of each change, the parts that are affected by the change, and any parts interchangeability problems created by the change.

— — — — — — — — —

“A4LD.pdf” 112 pages

FORD A4LD

This booklet contains the general description, diagnosis, repair and overhaul procedures necessary to service the Ford A4LD overdrive transmission.

— — — — — — — — —

“A40-41-A40D-43DE.pdf” 112 pages

TOYOTA/VOLVO A40 SERIES

TOYOTA/VOLVO A40/A41-A43D/A43DE/AW70/AW71

The A40 Series of transmissions are covered in this manual. In the teardown and assembly section we are using an A43D transmission. We refer to the different valve body configurations where applicable. Although the A40 and A41 do not have the overdrive unit, the assembly is very similar. The A40 series transmissions are found in Toyota and Volvo vehicles. The units have minor differences and use different gaskets and seals. The Volvo unit may be referred to as the BW55, Not to be confused with the A55 (Tercel). We have illustrated the gaskets for the various valve bodies in a separate section in this manual. This section also shows valve body disassembly. There have been many gasket and seal changes on these models. We advise you to check the gaskets f the original unit, and compare them with the replacement gaskets to ensure that correct gaskets are installed.

— — — — — — — — —

“A55.pdf” 85 pages

TOYOTA A-55 TRANSAXLE

The A-55 Transaxle is a front wheel drive fully automatic transmission with both 2 and 4 wheel drive applications. Troubleshooting, teardown-assembly, removal and installation is fully covered.

— — — — — — — — —

“A130.pdf” 89 pages

TOYOTA A-130 TRANSAXLE

— — — — — — — — —

“A140.pdf” 102 pages

TOYOTA A140/A140E

— — — — — — — — —

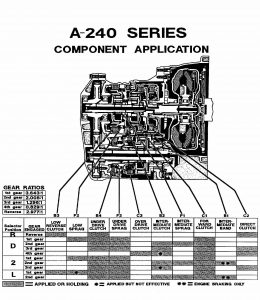

“A240.pdf” 88 pages

TOYOTA A240

— — — — — — — — —

“A340 E-H.pdf” 96 pages

TOYOTA A-340 EH

The Toyota A-340 E and A-340 H automatic overdrive unit was designed for use in trucks. The unit comes with either computer controls (E) or hydraulic controls (H). This unit was introduced in 1985 vehicles. This booklet covers teardown and assembly of both the 340 E and 340 H models.

— — — — — — — — —

“A340-E TRANSFER CASE.pdf” 64 pages

A340H – A55 A WD

In the continuing process to keep the technician updated on the four wheel drive vehicles we now introduce the manual on the A350H transfer case which is found in Toyota and Isuzu models. This series of booklets cover the general information, operation tear down and assembly on these units. And in most cases a parts breakdown is shown which helps in ordering replacements parts. Also included in this manual is a breakdown and assembly of the all wheel drive found in the Tercel with the Asian A-55 automatic transmission.

— — — — — — — — —

“A340E.pdf” 96 pages

TOYOTA A-340 EH

— — — — — — — — —

“A440-F.pdf” 96 pages

TOYOTA A-440F

— — — — — — — — —

“A500-42RH-A518-46RH-A628-47RH.pdf” 90 pages

42RH (A500) – 46RH (A518) – 47RH (A618)

The A500 (42RH) (A999 Family) and A518 (46RH) (A727 Family) are both rear wheel drive transmissions with the overdrive section incorporated in the extension housing, and first made their appearance in 1988. The A500, beginning at start of production, was designed with a new electronic controlled 3-4 shift and electronic controlled converter clutch. The A518 however only received the electronic controlled 3-4 shift and in 1992 received the electronic controlled converter clutch. The A500 and A518 transmissions are found in the Dakota, Pick-up Trucks, Ramchargers, Vans and Ram-50 vehicles. In the Ram-50’s, the transmission is referred to as the R4AC1 for 2WD versions and the V4AC1 for 4WD applications. A larger version of the A518 (46RH), known as the A618 (47RH), which basically has more clutch plates for increased torque carrying behind 5.9L diesel engines and the 8.0L pickup trucks.”

— — — — — — — — —

“A500.pdf” 88 pages

— — — — — — — — —

“A540-E.pdf” 95 pages

TOYOTA A540E

The Toyota A540E is an automatic overdrive transaxle that is found in the V-6 Camry model vehicles. It is an electronic controlled transaxle and very similar to the A140.

— — — — — — — — —

“A604_Part1.pdf” 158 pages

Chrysler A604

Since the introduction of the Chrysler A604 Transaxle in model year 1990, there have been many engineering changes to improve Pleaseability, Driveability, and Durability concerns. These changes have affected many parts used in the A604 transaxle. This “update handbook” will explain each change, and any parts interchangeability problem created by the change, along with any part numbers deemed necessary.

— — — — — — — — —

“A604_Part2.pdf” 88 pages

— — — — — — — — —

“A604_Part3.pdf” 5 pages

— — — — — — — — —

“A604_Part4.pdf” 96 pages

— — — — — — — — —

“A604-41TE HANDBOOK.pdf” 72 pages

— — — — — — — — —

“A604-41TE UPDATE HANDBOOK REVISED.pdf” 120 pages

CHRYSLER A604 (41TE) “UPDATE HANDBOOK”

— — — — — — — — —

“A604-41TE.pdf” 88 pages

— — — — — — — — —

“A606-42LE.pdf” 104 pages

CHRYSLER A-606 (42LE)

— — — — — — — — —

“A670-A413.pdf” 85 pages

A-413 and A-670 TORQUEFLITE AUTOMATIC TRANSAXLES

Chrysler A-670

The A-670 is a three speed automatic transaxle, built by the Chrysler Corporation. This three speed transaxle differs from the A-404 series of transmissions with the addition of the lock-up solenoid, transmission housing, clutch drum, final drive carrier and more. We have put the updated parts together with the previous parts showing the running changes and the interchangeability.

— — — — — — — — —

“A670.pdf” 86 pages

Chrysler A-670

— — — — — — — — —

“A727-A904.pdf” 78 pages

TORQUEFLITE A727, A904

This manual contains the procedures necessary to service, repair and overhaul both the A727 and the A904 transmissions, and some of the differences between these two units. These transmissions have been with us now for over 40 years. The operation of the torque converter clutch is also covered in this booklet.

— — — — — — — — —

“A750E.pdf” 82 pages

— — — — — — — — —

“A761E.pdf” 91 pages

— — — — — — — — —

“A999_A904T.pdf” 88 pages

Chrysler A-999, A-904T Transmission

— — — — — — — — —

“ACURA INTEGRA COMPUTER RO BOOK.pdf” 111 pages

RO ACURA INTEGRA 1990

The Acura transmission is a computer controlled 4 speed front wheel drive transaxle with one reverse speed and a converter clutch.

— — — — — — — — —

“ACURA INTEGRA HYDRAULIC CA BOOK.pdf” 80 pages

CA ACURA INTEGRA 1987

The Acura Integra transaxle is a hydraulic controlled 4 speed front wheel drive unit with 4 forward speeds and one reverse with a converter clutch.

— — — — — — — — —

“Air Check Book.pdf” 112 pages

PASSAGE ID / AIR CHECK

This manual covers passage identification for the purpose of air checking the bands and clutches of many domestic and foreign transmissions and transaxles. Not all passages are easily checked without the assistance of a test plate but the passages are identified for informational purposes.

— — — — — — — — —

“ALLISON.pdf” 120 pages

ALLISON 1000/2000 SERIES

Beginning at the start of production for the 2000 model year, General Motors introduced two new Allison automatic transmissions referred to as the 1000 Series and the 2000 Series, for light duty (8600-19850 GVW) and medium duty (19850-3000 GVW) commercial trucks.

The 1000 and 2000 Series transmissions both have helical cut planetary gear systems to minimize noise concerns and come in two different gear ratio configurations. The 1000 Series uses closer steps to improve the shift quality that we now expect from an automatic transmission. The 2000 Series uses wider steps to accommodate the greater vehicle weights associated with the 2000 Series. The gear ratios for both of the new units are shown in this Manual.

— — — — — — — — —

“AOD.pdf” 96 pages

FORD AOD

The Ford AOD transmission was the first domestic produced Automatic Overdrive Transmission. This book contains the general description of the transmission, adjustment procedures, diagnosis, removal and installation in the vehicle and dis-assembly and assembly of the unit.

— — — — — — — — —

“AODE-4R70W-4R70E 4R75E UPDATE HANDBOOK.pdf” 122 pages

UPDATE HANDBOOK AODE, 4R70W, 4R70E, 4R75E

Since the introduction of the AOD-E transmission in model year 1992, there have been many major engineering design changes to improve durability and reliability. These changes have affected nearly every part used in the AOD-E, including two name changes, 4R70W and 4R75E. This “Update Handbook” will explain each change, the parts affected by the change, and any parts interchangeability concerns created by the change.

— — — — — — — — —

“AODE.pdf” 112 pages

FORD AOD-E

The AOD-E transmission is a four speed, rear wheel drive, automatic overdrive transmission which is completely electronic controlled and includes a torque converter clutch. In its general appearance it resembles the hydraulically controlled AOD transmission. The easiest identification between the two will be the two shafts protruding from the front on the AOD-E unit as opposed to the three shafts on the AOD.

— — — — — — — — —

“AS.pdf” 64 pages

HONDA AS AK

The Honda 4 speed automatic transaxle made its first appearance in the 1983 Honda Accord and Prelude vehicles utilizing the AK model. In 1984 the AS model was introduced and the AK was discontinued. The AS model was the first model with a partial lock up feature. The AS continued through 1985 in all carbureted Accord and Prelude vehicles. The AK and AS model transaxle’s are significantly different then the popular F4 model used in the fuel injected Accord and Prelude vehicles beginning in 1986.

— — — — — — — — —

“ATX.pdf” 96 pages

FORD ATX

— — — — — — — — —

“AX4N.pdf” 120 pages

FORD AX4N

The Ford Motor AX4N automatic transaxle is a four speed unit with total electronic controls and is designed for operation in a transverse powertrain for front wheel drive vehicles. Currently found in Taurus, Sable and Windstar vehicles.

— — — — — — — — —

“AXOD-AXODE-AX4S UPDATE HANDBOOK.pdf” 120 pages

AXOD/AXODE (AX4S) UPDATE HANDBOOK

Since the introduction of the Ford AXOD transaxle in model year 1986, there have been many major engineering design changes that have affected many of the parts used in the AXOD transaxle. This version of the AXOD “Update Handbook” begins with the 1986 model year and will explain each change, the parts affected by the change, and any parts interchange problems created by the change. This booklet is an updated version of the original. This updated version of the AXOD Update Handbook will also cover the changes that occurred in the 1991 model year, when electronic controls were adapted to the AXOD transaxle, making it an AXODE, and now called an AX4S X4S transaxle. We have included the changes on the AX4S transaxle up through and including model year 2002.

— — — — — — — — —

“AXOD.pdf” 111 pages

FORD AXOD

The AXOD is an automatic four speed, front wheel drive transaxle with fourth gear being overdrive. This unit is equipped with a Torque Converter Clutch which is electronically controlled by the EEC-IV computer system. Once all processor conditions are met, the torque converter may apply in either third or fourth speeds. All other automatic shifts are hydraulically controlled.

Ford Motor Company used the AXOD from 1986 thru 1990 in the Ford Taurus and the Mercury Sable, and from 1988 thru 1990 in the Lincoln Continental.

— — — — — — — — —

“AXODE-AX4S.pdf” 120 pages

FORD AXODE/AX4S

This booklet contains the general description, diagnosis charts, and the procedures necessary to overhaul, repair or service the Ford Motor Company AXODE/AX4S four speed automatic overdrive transaxle. This information will assist you in training your technicians to provide your customers with the best possible transmission service that is available.

— — — — — — — — —

“BAXA.pdf” 112 pages

HONDA ACCORD BAXA/MAXA

HONDA PRELUDE M6HA

The USA built BAXA and the Japan built MAXA and the M6HA transaxle is part of a new generation of 3 shaft transaxles. The features that make these units unique are the use of 6 solenoids, 2 pressure switches and NO one-way clutches. This new generation transaxle’s PCM has a unique solenoid strategy to control shift overlap for upshifts and downshifts. The PCM also requires a full complement of sensors to control shift timing and shift feel. All pertinent information for tear-down and as diagnosis, covering 1997 to 2001 models, has been included in this manual.

— — — — — — — — —

“BW65-66.pdf” 80 pages

BORG/WARNER MODEL 65/66

This manual provides information on the teardown assembly and hydraulic operation of the model 65/66 transmissions found in the Jaguar, BMW, and Peugeot models. A section on trouble shooting and diagnosis has also been included.

— — — — — — — — —

“C-5.pdf” 96 pages

FORD C-5

The C-5 transmission was produced from 1982 thru 1987. It is similar to the C-4 with a slight modification to the valve body and the addition of a centrifugal lock-up converter clutch.

When diagnosing this unit, you can use the same trouble shooting methods as the C-4.

— — — — — — — — —

“C-6.pdf” 78 pages

C-6 TRANSMISSION

The C-6 transmission was first introduced in September 1965, for the 1966 model Ford, Mercury and Lincoln car lines.

— — — — — — — — —

“C3-SUPPLEMENT.pdf” 24 pages

Ford C3

— — — — — — — — —

“CD4E-LA4A-EL.pdf” 120 pages

FORD CD4E

The FORD CD4E is a computer controlled, four speed automatic overdrive transaxle and first appeared in the 1994 Probe with the 2.0 Liter engine. This unit is also found in the Ford Contours and the Mercury Mystique. This manual covers the procedures necessary for diagnosis, teardown, repair and overhaul of the CD4E transaxle.

— — — — — — — — —

“CD4E.pdf” 120 pages

— — — — — — — — —

“CHECKBALL BOOK Domestic Volume I.pdf” 120 pages

CHECKBALL BOOK DOMESTIC

This “Checkball Manual” will show you the checkball locations in the case and valve body of transmissions manufactured from 1980 up through 2003. We have covered the updates that have occured in similar model transmissions, where checkball locations may have changed. This manual covers most transmissions manufactured by Chrysler Corporation, Ford Motor Company and General Motors Corporation. We also have included some Import transmissions that are found in Domestic vehicles.

— — — — — — — — —

“CHECKBALL BOOK Domestic Volume II.pdf” 97 pages

— — — — — — — — —

“CHECKBALL BOOK Import Volume I.pdf” 103 pages

— — — — — — — — —

“CHECKBALL BOOK Import Volume II.pdf” 112 pages

— — — — — — — — —

“CHECKBALL BOOK Import Volume III.pdf” 136 pages

— — — — — — — — —

“DOMESTIC COMPUTER CONTROL.pdf” 112 pages

The purpose of this manual is to assist the technician in diagnosing computer controlled transmissions. It will help guide the technician through individual electrical check on solenoids and sensors with the aid of a scanner and a multi-meter. It will cover where and how to retrieve codes using a scanner and a jumper lead where possible with a list of these codes and there explanations.

— — — — — — — — —

“E4OD UPDATE HANDBOOK.pdf” 120 pages

FORD E4OD “UPDATE HANDBOOK”

Since the introduction of the E4OD transmission in model year 1989, there have been many engineering changes to improve Pleaseability, Reliability and Durability concerns.

— — — — — — — — —

“E4OD.pdf” 108 pages

The FORD E4OD automatic transmission is a four speed unit with total electronic shift control and is designed for operation in longitudinal powertrains for rear wheel drive applications. The E4OD is currently found in “F” Series Trucks and “E” Series Vans.

— — — — — — — — —

“E40D.pdf” 108 pages

— — — — — — — — —

“F4-EAT-F4E-III.pdf” 120 pages

— — — — — — — — —

“F4.pdf” 88 pages

Honda F4 4-SPEED

This manual covers only the Honda F4 transaxle installed in fuel injected Preludes from 1985-1987 and all Accords from 1986-1989 sold in the US the transaxle is transverse mounted and has four forward speeds and a converter clutch. The 4th gear is a .700 to 1 ratio.

— — — — — — — — —

“F4A3.pdf” 120 pages

MITSUBISHI F4A3 W4A3

There are two different models of this transaxle. The F4A3 is the two wheel drive model and the W4A3 is the all wheel drive or four wheel drive model, both of which are front wheel drive transaxles. The disassembly and assembly of these units are very similar. We have high lighted the differences in these units in the component rebuild section so that the technician will have the information necessary to service, repair or rebuild both of these units. This manual also contains the information necessary in diagnosing mechanical, hydraulic and electronic concerns on both units.

— — — — — — — — —

“F4A41-F4A42-F4A51.pdf” 120 pages

MITSUBISHI F4A41, F4A42, F4A51

This is a four speed, Front Wheel Drive transaxle, with fully electronic controls for the upshifts and downshifts, with 4th gear being overdrive.

— — — — — — — — —

“F4A51.pdf” 120 pages

MITSUBISHI F4A41, F4A42, F4A51

This is a four speed, Front Wheel Drive transaxle, with fully electronic controls for the upshifts and downshifts, with 4th gear being overdrive.

— — — — — — — — —

“F5A51.pdf” 172 pages

MITSUBISHI F5A5A (F5A51) & HYUNDIA/KIA A5GF1, A5HF1 (F5A51)

— — — — — — — — —

“FORD1350.pdf” 76 pages

WARNER GEAR 1350-1354

— — — — — — — — —

“FORD1354.pdf” 64 pages

WARNER GEAR 1345-1356

— — — — — — — — —

“FREEWHEEL BOOK.pdf” 112 pages

— — — — — — — — —

“G4A-EL.pdf” 116 pages

Mazda G4A-EL

— — — — — — — — —

“G4A-HL.pdf” 112 pages

Mazda G4A-HL

— — — — — — — — —

“GF4EAT-GF4A-EL.pdf” 112 pages

MAZDA GF4A-EL AND FORD GF4EAT

The Ford GF4EAT is currently found in the 1993 Probe equipped with the 2.5L engine. The Mazda version designated GF4A-EL is found in the “626” equipped with 2.0L and 2.5L engines.

— — — — — — — — —

“IMPORT COMPUTER CONTROL VOLUME I.pdf” 104 pages

Import Pass Book Volume 1

— — — — — — — — —

“IMPORT COMPUTER CONTROL VOLUME II.pdf” 103 pages

Import Pass Book Volume 2

— — — — — — — — —

“JEEP AW4.pdf” 115 pages

JEEP AW-4

The AW-4 is a four speed, electronically controlled automatic transmission.

— — — — — — — — —

“JEEP229.pdf”

72 pages

New Process 229-242

— — — — — — — — —

“JF506E HANDBOOK.pdf” 112 pages

UPDATE HANDBOOK JATCO JF506E

FOUND IN: MANUFACTURERS I.D.

Mazda “MPV” beginning in 2002 (3.0L V6)

Mazda “6” beginning in 2003 (3.0L V6)

Land Rover “Freelander” beginning in 2002 (2.5L V6)

Jaguar “X” Type beginning in 2002 (2.5L/3.0L V6)

VW “Jetta” beginning in 2002 (1.8L Gas/1.9L Diesel)

VW “GTI” beginning in 2002 (1.8L Engine)

VW “Golf” beginning in 2004 (1.9L Diesel)

— — — — — — — — —

“JF506E.pdf” 128 pages

JATCO JF506E

The JATCO5 speed automatic transmission is known as the JF506E in the Jaguar X Type and Land Rover’s Freelander. In the Mazda 6 and MPV, it is known as the JA5A-EL and with VW’s Golf, GTI and Jetta it is the 09A. Overseas it is known as the 5F1J or the Durashift -5-Tronic transmission used in the Mondeo vehicle starting in 2002.5 model year. It is based on an earlierAG5 transmission used in the 2000 Galaxy which is a fully automatic and electronically controlled front wheel drive transmission. The JF5 transmission ratios are achieved with 3 planetary gear sets that are held and/or driven by 4 multi-plate drive clutches, 2 multi-plate brake or holding clutches, 1 band and 2 one-way holding devices. The internal components locations and names are identified in Figure1. This manual contains the procedures necessary to diagnose, overhaul and/or repair the Mazda JF506E transaxle, and is intended for automotive technicians that are familiar with the operation of automatic transmissions.

— — — — — — — — —

“JR403E.pdf” 120 pages

ISUZU JR403-E “ELECTROMATIC”

The JR403-E transmission, also known as the “Electromatic” by GM, is currently found in 1988 and up GMC Tiltmaster Trucks, Isuzu Trucks, Nissan Diesel Trucks, Mazda Trucks and Mitsubishi Trucks. This fully electronic controlled transmission is similar in design to the RE4R01A found in Nissan Pathfinders, 240SX and 300SX vehicles, but on a much larger scale. This manual contains information and procedures for assembly/disassembly, diagnosing electrical problems, and was compiled from GMC and ISUZU factory repair

manuals.

The JR403-E transmission is fully electronic controlled, consisting of shift solenoids, a line pressure solenoid, a converter clutch solenoid, a overrun clutch solenoid and a fluid temperature sensor. There is built into the vehicles a self diagnostic procedure to aid in diagnosing electrical concerns and is also included in this manual.

— — — — — — — — —

“JUSTY.pdf” 112 pages

Subaru Justy CVT Transmission

— — — — — — — — —

“K4.pdf” 94 pages

Honda 4 Speed Computer Controlled

This manual covers the HONDA 4 speed transaxle that is computer controlled.

— — — — — — — — —

“KF 100.pdf” 78 pages

SPECTRUM KF-100

The KF-100 Automatic Transaxle found in the new Chevrolet Spectrum is designed for front wheel drive vehicles. It is a compact type transaxle consisting of the transmission and differential in one unit. The transaxle is designed so that the preload on the tapered roller bearings can be adjusted by the use of shims. The final gear in the transaxle is of a helical type design requiring no tooth contact adjustment.

— — — — — — — — —

“KM-171.pdf” 96 pages

MITSUBISHI KM-171

The KM-171 is a 3 speed automatic transaxle front wheel drive with a converter clutch. The shift pattern is hydraulic controlled.

— — — — — — — — —

“KM-175.pdf” 96 pages

MITSUBISHI KM-175

This manual covers the procedures necessary to disassemble, inspect, assemble and repair the KM-175 transaxle found in both the Mitsubishi and Hyundai vehicles. Also included are some of the electrical diagnosis procedures necessary for some of the sensors. This unit is very similar to the KM-176 and KM-177 units. The designation of these units are dependent on the vehicle engine size.

— — — — — — — — —

“KM-177.pdf” 120 pages

MITSUBISHI KM-177

This manual covers the procedures necessary to disassemble, inspect, assemble and repair the KM-177 transaxle found in both the Mitsubishi and Hyundai vehicles. Also included are some of the electrical diagnosis procedures necessary for some of the sensors. We also show some of the differences between the converter clutch models and the open converter models. This unit is very similar to the KM-175 and KM-176 units. The designation of these units are dependent on the vehicle engine size.

— — — — — — — — —

“L3N71B.pdf” 52 pages

Nissan L3N71B

— — — — — — — — —

“L4N71B.pdf” 92 pages

Nissan L4N71B

— — — — — — — — —

“LEGEND 91 COMPUTER MPYA BOOK.pdf” 112 pages

ACURA LEGEND 1991

The 1991 Legend transaxle Is a completely new unit. As you will notice the engine is mounted in a north south direction.

— — — — — — — — —

“LEGEND COMPUTER L5 PL5X BOOK.pdf” 112 pages

L5 – PL5X

ACURA LEGEND 1990

— — — — — — — — —

“LEGEND HYDRAULIC G4 BOOK.pdf” 78 pages

ACURA G4 LEGEND 1987

The Legend transmission is a hydraulic controlled 4 speed front wheel drive transaxle with one reverse speed and a converter clutch. The teardown – assembly and trouble shooting is covered in this manual.

— — — — — — — — —

“M24A.pdf”

HONDA CIVIC 3 SHAFT M24A

This Booklet covers the 3 shaft Honda unit that is found in the Civic models. Although at first glance you will see solenoids on this unit, it is not a computer controlled shifting model. The solenoids are for the converter clutch engagement. This unit is hydraulically controlled.

— — — — — — — — —

“MB1-MJ3.pdf” 93 pages

RENAULT MB1 – MJ3

The MB1 and MJ3 Transmissions are covered in detail along with teardown-assembly and trouble-shooting. The MB1 Transmission is found in the Alliance and Encore, the MJ3 Transmission is found in the Sportwagon and Fuego.

— — — — — — — — —

“MX 17.pdf” 104 pages

SPRINT SUZUKI

The SPRINT SUZUKI 3 SPEED automatic transaxle is electrically controlled, fully automatic transmission, it utilized a regular non lock-up hydraulic torque converter, two planetary gear sets, two multidisc clutch packs in drums, one multidisc clutch in the case and a one way clutch assembly. We have included the latest information on the Geo Metro full electric control for this transmission on the final pages of this manual.

— — — — — — — — —

“N4AEL.pdf” 96 pages

MAZDA N4A-EL

The N4A-EL is a four speed overdrive transmission with shifts and shift timing being controlled by the on board EC-AT control unit. The torque converter is equipped with a lock-up mechanism and is also controlled by the EC-AT control unit. This converter has a stall ratio of 1. 900: 1.

The line pressure used for shift feel is determined by engine vacuum to the modulator, pressure regulator valve, and spring in the transmission. This transmission consists of three planetary gear sets, four clutch packs, two bands and two sprags. It holds 7. 7 US

quarts of Dextron II or M-111 automatic transmission fluid and is currently found in the Mazda 929 and early MPV’s.

— — — — — — — — —

“O1M_Tiptroinc.pdf” 42 pages

TIPTRONIC 01M

Valvebody Mapping (Passage Identification)

Valvebody Breakdown and valve identification Spring Specifications

— — — — — — — — —

“PASS BOOK.pdf” 120 pages

This PASS BOOK is the first in a series of books designed to assist the technician in diagnosing computer controlled transmissions. The word PASS stands for Pressures, Applications, Solenoids and Sensors. The purpose of this book is to be a quick reference guide to Pressure specifications, Application charts, Solenoid and Sensor readings for both Domestic and Import computer controlled transmissions. This book contains the most frequently used data for quick diagnosis and deals specifically with the electronics found on the transmission itself. For diagnosing specific electrical systems throughout the vehicle relating to the transmission operation, the Inport and Domestic PASS BOOKS complete the series of manuals designed to aid the technician in diagnosing computer controlled transmissions.

— — — — — — — — —

“PX4B.pdf” 101 pages

HONDA PX4B

PX4B – 1990 ACCORD

APX4 – 1991/1992 ACCORD

MPWA – 1991/1992 ACCORD ONLY

MP1A – 1992 PRELUDE

This manual covers only the Honda models listed above and sold in the U.S. The 1991/1992 Accord may have a APX4 or MPWA. The APX4 is built in the U.S. and the MPWA is built in Japan. The MPWA transaxle covered in this manual is for the Honda Accord only. The Acura Vigor has a transaxle with the same model designation, but is entirely different. This transaxle is transverse mounted, has four forward speeds with 4th gear being overdrive and is equipped with a converter clutch. The MP1A Transaxle Control Unit (TCU) uses a different strategy to allow the Prelude to apply the converter clutch in the D3 position. There are different gear ratios for different vehicle applications. Extra care should be used when interchanging parts and transaxles. This transaxle is designed to have engine braking in M1 and M2. Externally the PX4B, APX4, MPWA and MP1A, are visually very similar.

— — — — — — — — —

“R4A51-V5A51.pdf” 128 pages

R/V4A51 AND V5A51

R/V4A51 R=2WD, V=4WD

This is a four speed, Rear Wheel Drive transmission, with fully electronic controls for the upshifts and downshifts, with 4th gear being overdrive. The individual gear ratios are achieved through two planetary gear sets connected one behind the other. The components of the planetary gear sets are driven or held by means of five multiple plate clutch packs, and a low sprag. To minimize fuel consumption, the torque converter clutch is applied by the PCM, depending on throttle position and vehicle speed. These units are currently found in Mitsubishi Montero 1999-2002 models, equipped with 3.0L and 3.5L engines.

V5A51 V=4WD

This is a four speed, Rear Wheel Drive transmission, with fully electronic controls for the upshifts and downshifts, with 4th gear being overdrive. The individual gear ratios are achieved through two planetary gear sets connected one behind the other. The components of the planetary gear sets are driven or held by means of five multiple plate clutch packs, and a low sprag.

To minimize fuel consumption, the torque converter clutch is applied by the PCM, depending on throttle position and vehicle speed. These units are currently found in Mitsubishi Montero 1999-2002 models, equipped with 3.0L and 3.5L engines.

— — — — — — — — —

“RE4FO2A.pdf” 95 pages

NISSAN RE4R02A

The Nissan RE4F02A is a fully automatic, electronically controlled transaxle that features a combination of electronic and mechanical systems to control the upshift and downshift of all forward gears and the apply and release of the torque converter clutch.

— — — — — — — — —

“re4fo4a.pdf” 116 pages

NISSAN RE4F04A

— — — — — — — — —

“re4ro1a.pdf” 96 pages

NISSAN/MAZDA RE4R01A

The RE4R01A transmission is currently found in Nissan Pathfinders, 300ZX, 240SX, Mazda MPV’s, B2200 and B2600i vehicles. Also the Infinity J30, M30, and Subaru Legacy vehicles have similar units.

— — — — — — — — —

“RE5FO5A.pdf” 128 pages

INFINITI/NISSAN RE5RO5A

— — — — — — — — —

“rl3fo1a.pdf” 62 pages

NISSAN – RL3F01A

The RL3F01A is a three speed automatic transaxle front wheel drive with a converter clutch.

— — — — — — — — —

“rl4fo2a.pdf” 98 pages

NISSAN RL4F02A

— — — — — — — — —

“rl4fo3a-v.pdf” 112 pages

NISSAN RL4R03A/V

— — — — — — — — —

“rl4ro1a.pdf” 104 pages

NISSAN RL4R01A

— — — — — — — — —

“SATURN.pdf” 120 pages

SATURN TAAT

The Saturn TransAxle Automatic Transmission (TAAT) first appeared in the 1991 Saturn vehicles.

— — — — — — — — —

“TF60SN.pdf” 124 pages

AUDI, JETTA, PASSAT, 09G/09M Transaxle

The Japanese company AISIN Co., LTD is the manufacturer and developer of the Front Wheel Drive TF60SN transaxle, which is a 6 speed, fully automatic and electronic controlled transaxle. Volkswagen engineers were also involved, in conjunction with Aisin, in the development process for their vehicles and they gave it the 09G/09M designation. BMW gave it the designation 6F21WA for their Mini-Cooper. The 09G/09M transaxle is used in a wide variety of applications and engine sizes. As a result, the number of friction plates, planetary ratios, intermediate ratios and final drive ratios will vary depending on torque load requirements of the specific vehicle. The TF60SN transaxle uses a gear ratio sensitive system, requiring the correct transaxle interchange. The TF60-SN is used in the BMW Mini Cooper, Volkswagen and Audi vehicles. This transaxle is referred to as the TF60-SN, 09G, 09M, 6F21WA and in some overseas vehicles as 09K. As a result there are a variety of different case and part configurations. Some of these units have the heat exchanger attached to the transmission while others use a remote heat exchanger. This alters the case, case cover and the valve body and if incorrect parts are used, severe planetary failure will occur. This manual covers these differences so that this mistake will not happen to you. The 09G/09M transaxle uses a Lepelletier arrangement, using a simple planetary coupled with a Ravigneaux planetary. This arrangement makes six forward speeds and reverse possible, with only five clutch packs and one freewheel.”

This manual contains the procedures necessary to diagnose, rebuild and/or repair the 09G/09M tran nd is intended for automotive technicians that are familiar with the operation of automatic transmissions.

— — — — — — — — —

“Torqueflight_A-727_A-904.pdf” 78 pages

Chrysler TORQUEFLIGHT A-727 A-904

— — — — — — — — —

“Torqueflight_A404_A413_A415_A470.pdf” 95 pages

CHRYSLER A-404/413/415/470

— — — — — — — — —

“TR60SN.pdf” 136 pages

TOUAREG, AUDI Q7,

PORSCHE CAYENNE

TR60SN “09D” Transmission

The Japanese company AISIN Co., LTD is the manufacturer and developer of the Rear Wheel Drive TR60SN transmission, which is a 6 speed, fully automatic and electronic controlled transmission. Volkswagen engineers were also involved, in conjunction with Aisin, in the development process for their vehicles and Volkswagen gave it the 09D designation.

The TR60SN, 09D transmission is used in a wide variety of applications and engine sizes. As a result, the number of friction plates, and planetary gears (3 or 4 pinion), will vary depending on torque load requirements of the specific vehicle. The TR60SN transmission uses a gear ratio sensitive system, requiring the correct transmission interchange. The TR60-SN is currently used in the Porsche Cayenne, Volkswagen Touareg, and Audi Q7 vehicles. The 09D transmission uses a Lepelletier arrangement, using a simple planetary coupled with a Ravigneaux type, dual planetary. This is the same type of gear set that was used in the FMX. This arrangement makes six forward speeds and reverse possible, with only five clutch packs and one freewheel. This manual contains the procedures necessary to diagnose, rebuild and/or repair the TR60SN 09D transmission and is intended for automotive technicians that are familiar with the operation of automatic transmissions.

— — — — — — — — —

“U140-240.pdf” 120 pages

TOYOTA/LEXUS U140E/F AND U240E SERIES

Starting at the beginning of production for the 1998 model year for Lexus and 2000 for Toyota, a new transaxle, designated as the, U140/U240 series was introduced into service. This Transaxle’s shift points, and shift feel are electronically controlled by a Powertrain Control Module. This is accomplished by the PCM monitoring engine load and adjusting solenoid duty cycle to match pressure rise and shift feel.

This front wheel drive transaxle has four forward gears, and one reverse gear. The unit is comprised of three connecting clutches, three holding brakes, three planetary gear sets, and two one-way clutches. In addition, there is a clutch located in the torque converter which is applied via the ECM for increased fuel economy. The primary difference between the U140E/F and the U240E is clutch capacity. The U140 series being used primarily in the V6 applications, thus, containing a greater number of friction elements in the individual clutch packs, while the U240 series is utilized primarily in the smaller 4 cylinder engines.

— — — — — — — — —

“VIGOR.pdf” 111 pages

ACURA VIGOR MPWA

ACURA 2.5TL Ml WA

This manual contains tear down and assembly information and some basic electrical diagnostics for the 1992 to 1994 Acura Vigor with the MPWA transaxle and the 1995 and later Acura 2.5 TL with the M1WA transaxle. Although these two transaxles are very similar, it is the intention of this manual to illustrate the subtle differences between them. These two transaxles bare a strong resemblance to the Acura Legend with the MPYA transaxle in as much as they all are inline (north-south) mounted and have removable oil pans. The major difference between the MPYA in the Legend and the MPWA/MlWA is the MPYA utilizes a reverse clutch while the MPWA/M1WA utilize a reverse selector and fork assembly.

These transaxles contain a low hold clutch which provides a manual low gearshift position and have a complete compliment of electronics to control shift timing, TCC control as well as line pressure rise.

@Service Manual 2@

109 MB PDF

GENERAL MOTORS

TH125 Transmissions – TH125 (M34) 3T40, TH125C (MD9)

Saturn TAAT – Saturn Transmission – TAAT – FWD 4 Speed

A210, GM MX17 – 3 Speed FWD

TH180 Transmissions – TH180 (MD3) 3L30, TH180C (MD2)