Pages from 9803-3690 – JCB Compact Loadalls (520-40, 524-50, 527-55) Service Manual

Complete workshop & service manual with electrical wiring diagrams for JCB Loadall (520-40, 520-50, 524-50, 525-50, 525-50S, 520-55 RS, 520-55 AWS, 526-55, 526-55 AWS, 526S AWS, 527-55). It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This JCB Loadall (520-40, 520-50, 524-50, 525-50, 525-50S, 520-55 RS, 520-55 AWS, 526-55, 526-55 AWS, 526S AWS, 527-55) service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

FILELIST:

9803-3610 – JCB Loadall (520-55 RS/AWS, 526-55, 526-55 AWS, 526S AWS) Service Manual.pdf

9803-3620 – JCB Loadall (520-50, 525-50, 525-50S) Service Manual.pdf

9803-3690 – JCB Compact Loadalls (520-40, 524-50, 527-55) Service Manual .pdf

Loadalls 2000_2010 Electrical Wiring Diagrams (BONUS MATERIAL).pdf

EXCERPT:

Service Manual

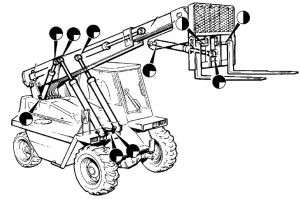

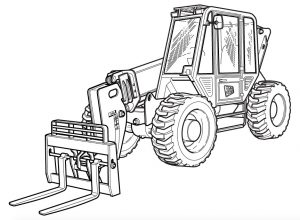

Compact Loadalls

Section 1 – General Information

Section 2 – Care and Safety

Section 3 – Maintenance

Section A – Attachments

Section B – Body and Framework

Section C – Electrics

Section D – Controls

Section E – Hydraulics

Section F – Transmissions

Section G – Brakes

Section H – Steering

Section K – Engine

…

Fire Extinguisher (if fitted)

Checking the Fire Extinguisher

Check the fire extinguisher for damage, security and signs of leaking.

Check that the gauge A indicates that the extinguisher is charged i.e. the needle is in the GREEN segment.

Note: If the needle is in or very near the RED segment at either end of the gauge, the extinguisher must be serviced or replaced.

Make sure the safety pin B is fitted and secure.

The extinguisher should be serviced every 12 months by a suitably qualified person.

…